Abrasive belt grinding center suitable for full surface grinding and polishing of blisks

A technology of integral blisk and abrasive belt grinding, which is used in abrasive belt grinders, metal processing equipment, grinding workpiece supports, etc. The problems of meshing, narrow passage between blades, and difficult processing of materials can reduce management and production costs, ensure the quality of the profile, and ensure the rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

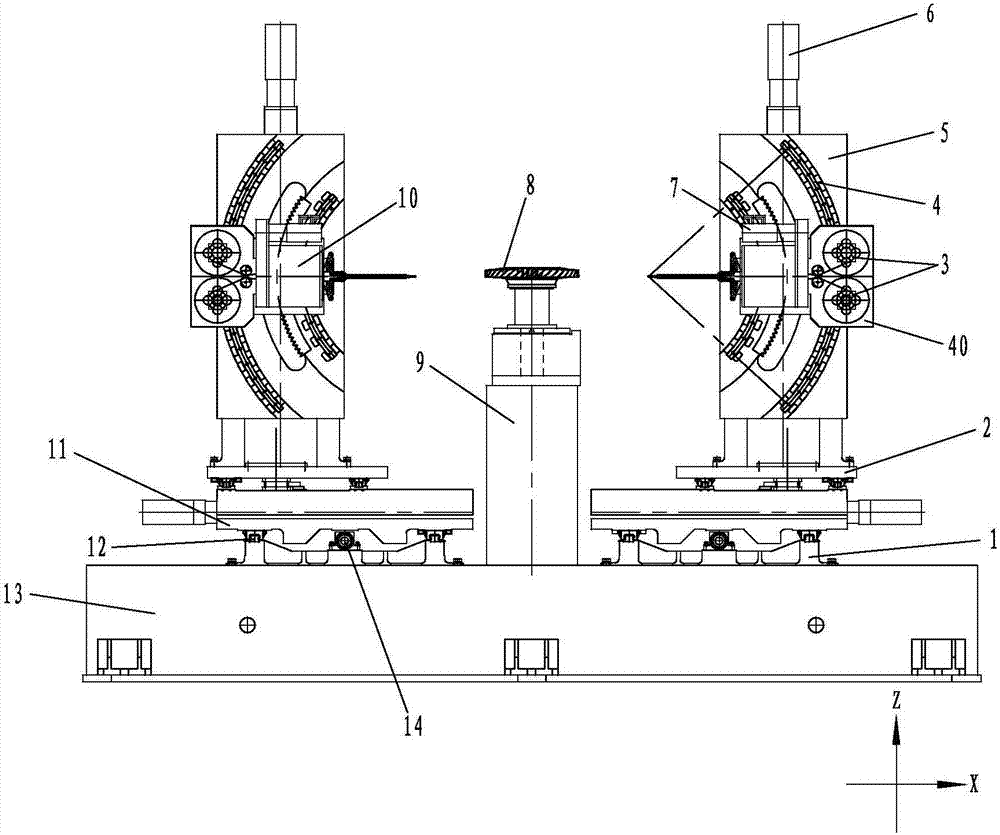

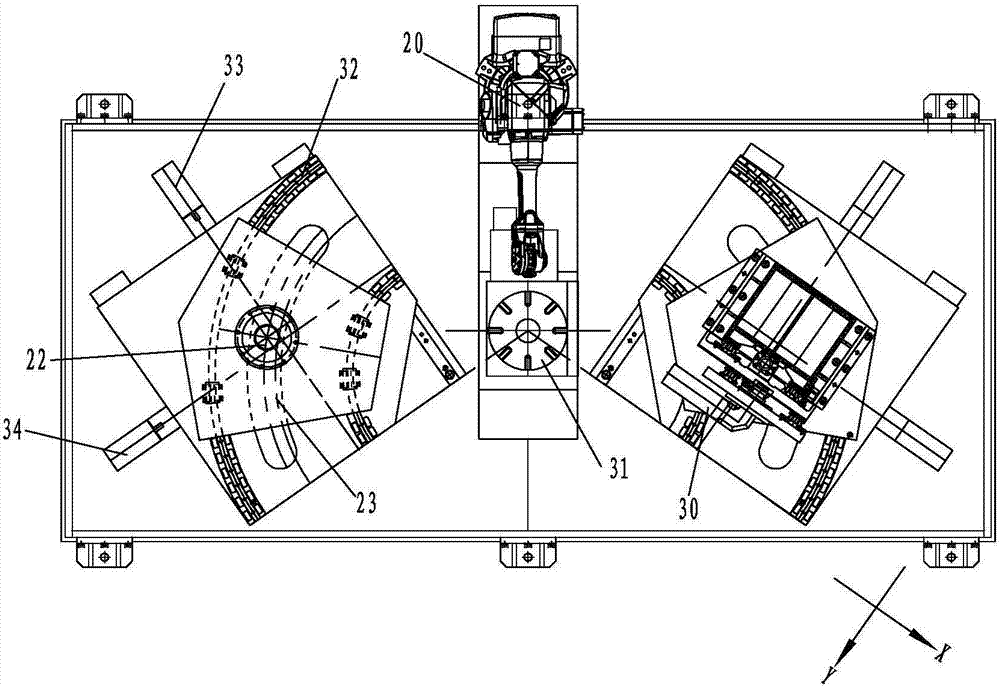

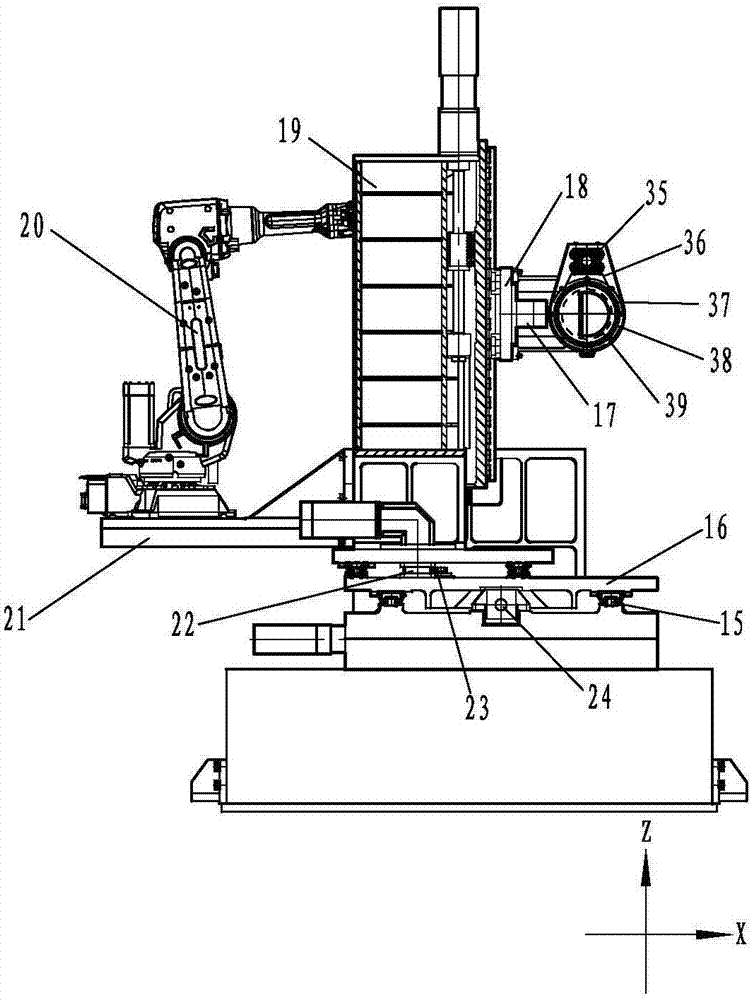

[0039] Such as figure 1 , figure 2 , Figure 4 As shown, the bed 13 is a cuboid structure, and an indexing turntable support 9 is arranged in the middle of the upper surface of the bed 13. The indexing turntable support 9 is perpendicular to the upper surface of the bed 13, and the lower end of the indexing turntable support 9 is in contact with the bed 13. Phase is fixed, and the numerical control indexing turntable 31 is installed on the top of indexing turntable support 9. The numerically controlled indexing turntable 31 is arranged on the symmetry axis of the grinding center, and the fixture is installed through the numerically controlled indexing turntable 31 for clamping the workpiece 8 so that the workpiece 8 can rotate around the Z axis. The structure and working principle of the fixture are prior art, and will not be repeated here.

[0040] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com