Boring-based cantilever shaft machining method for achieving large-size irregular appearances

A processing method and cantilever shaft technology, which are applied in metal processing equipment, components of boring machines/drilling machines, metal processing machinery parts, etc. The effect of surface quality problems and dimensional out-of-tolerance, improvement of machining accuracy, and suppression of workpiece vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

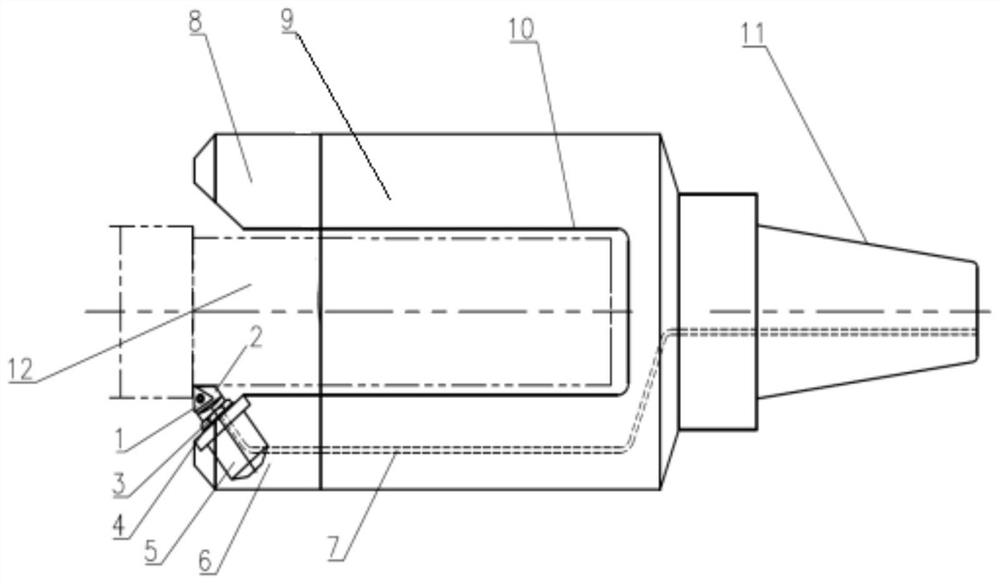

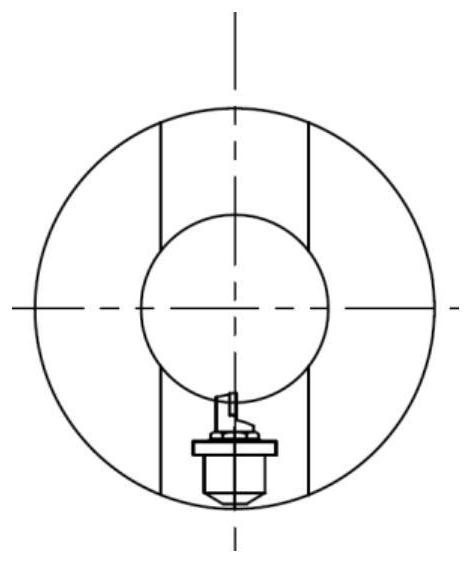

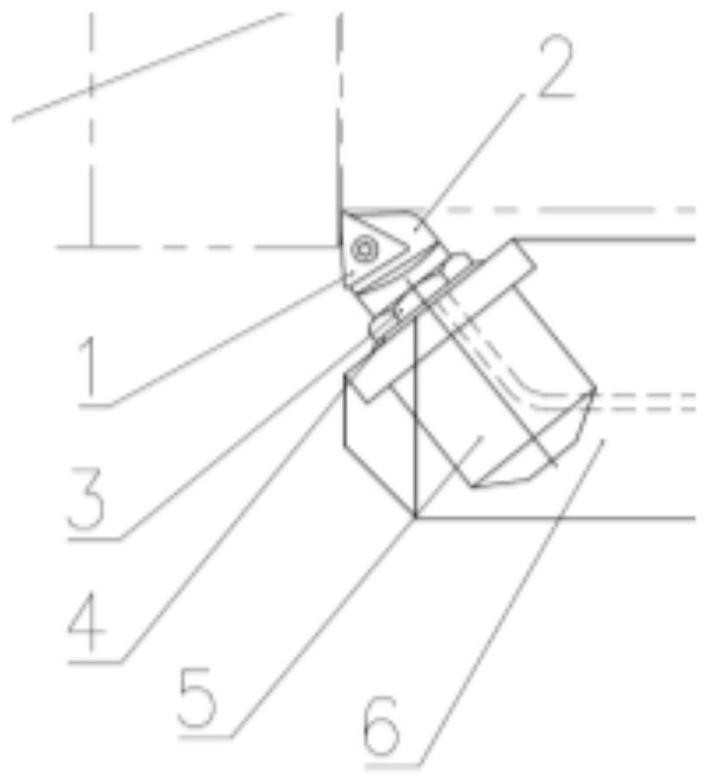

[0016] combine Figure 1-Figure 4 , a kind of cantilever shaft machining method based on machining center boring to realize large size and irregular shape of the present invention, based on the following processing device, including blade 1, blade reinforcement plate 2, diameter fine adjustment nut 3, dial 4, knife Body installation mechanism 5, processing arm 6, coolant channel 7, balance arm 8, rigid reinforcement ring 9, tool handle cone 11;

[0017] The processing device is connected to the main shaft of the machining center through the tool holder cone 11, the machining device is driven to rotate around the axis of the main shaft through the rotational movement of the main shaft of the machining center, and the processing device is driven to perform linear motion through the linear movement of the main shaft; the rigid reinforcing ring 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com