Tube assembly joint

A node and pipe technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of large assembly and welding workload, large space occupied by on-site assembly of trusses, inconvenient transportation, etc., to ensure welding quality and processing size. Accuracy, beautiful and smooth appearance, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

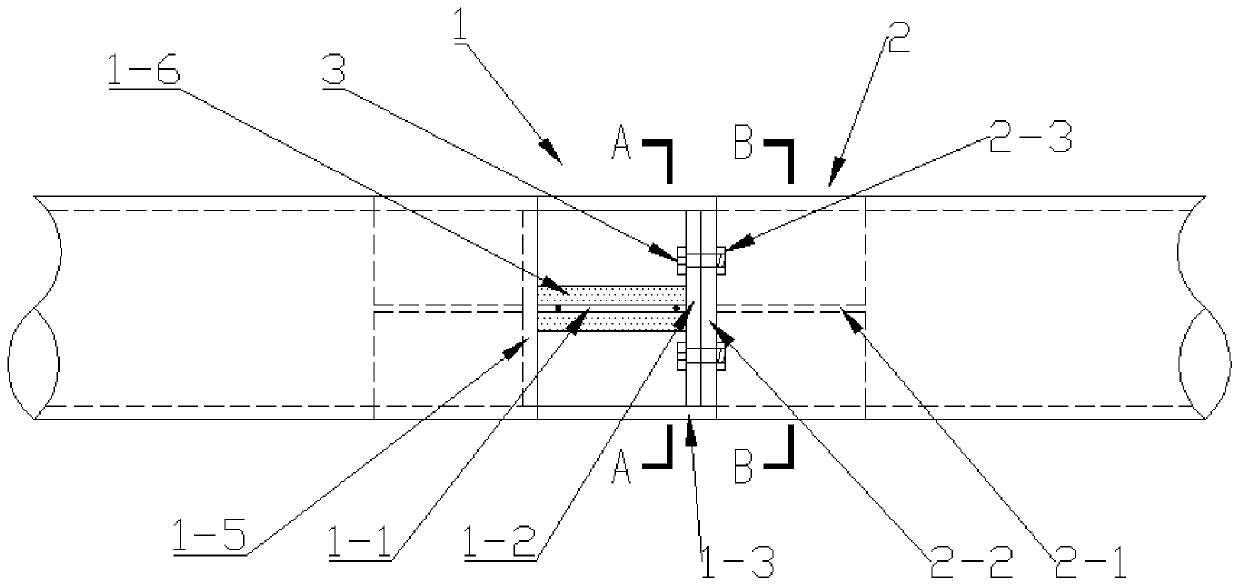

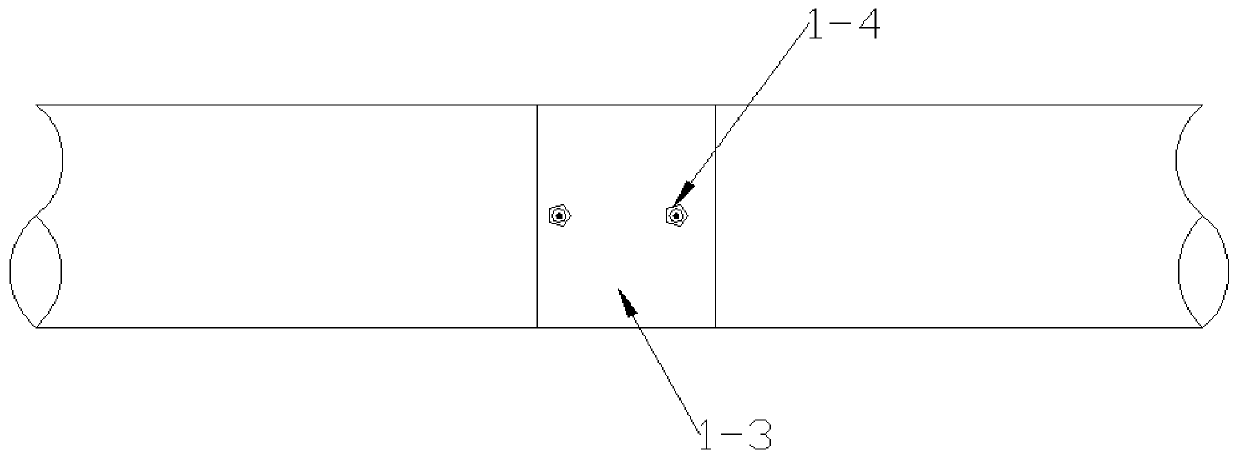

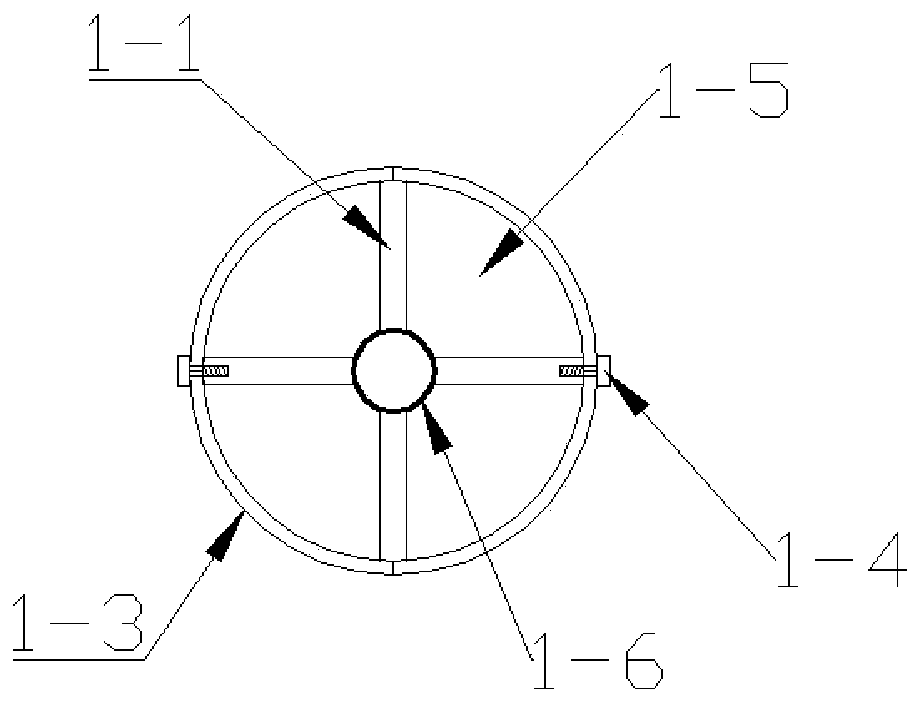

[0017] Such as Figure 1 to Figure 4 A pipe assembly node is shown, which includes: device I1 and device II2 respectively arranged at both ends of the butt steel pipe interface; both ends of the butt steel pipe interface are provided with stiffening grooves;

[0018] The device I1 includes a cross stiffening plate I1-1 and a left connecting flange 1-2. One end of the cross stiffening plate I1-1 is inserted into the stiffening groove of the left butt steel pipe and fixed by welding. The cross stiffening plate The other end of I1-1 protrudes from the left butt steel pipe and connects with the left connecting flange 1-2; the cross stiffening plate I1-1 protrudes from the edge of the left butt steel pipe to provide connection bolt holes, and the cross stiffener A sheath pipe 1-3 is provided on the outer periphery of the part of the plate I1-1 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com