Multi-axis linkage ultrafast laser processing system

A processing system and ultra-fast laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to perform three-dimensional processing, improve the quality of the processed surface, reduce the size and quantity of chipping, reduce the The effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the present invention clearer and easier to understand, the embodiments of the present invention are described in conjunction with the following figures by way of example only and not limitation:

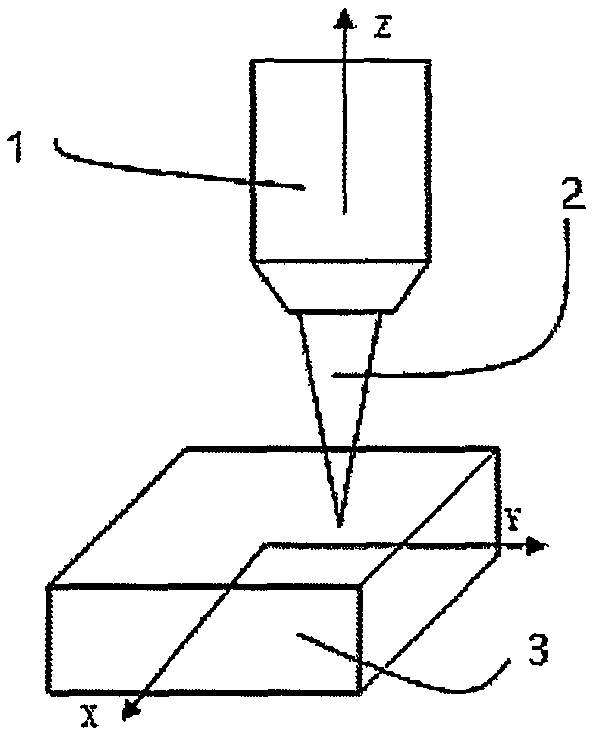

[0035] Figure 1-a It shows a system for two-dimensional plane machining of brittle materials based on a three-axis linkage system in the prior art. The optical module 1 can move vertically along the Z axis, and the workpiece 3 can move linearly on the plane along the X and Y axes.

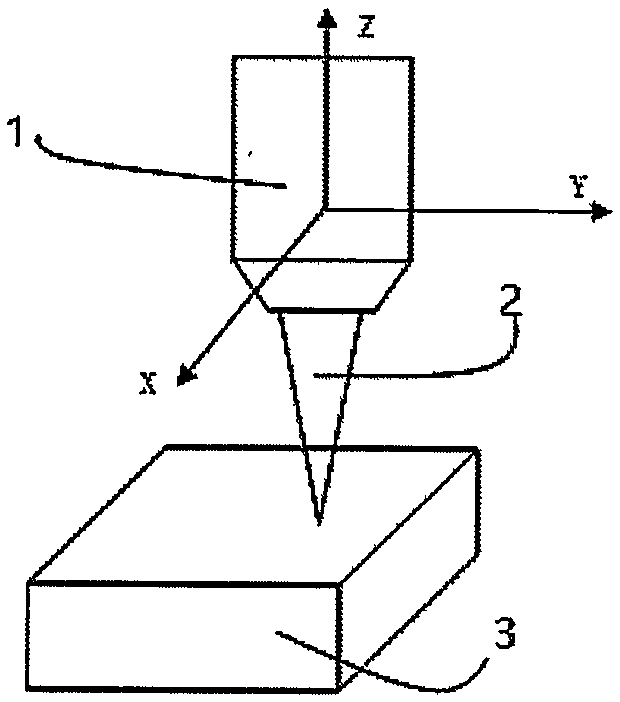

[0036] Figure 1-b It shows another system for two-dimensional plane machining of brittle materials based on a three-axis linkage system in the prior art. The optical module 1 can move linearly along the X, Y and Z axes, while the workpiece 3 is fixed.

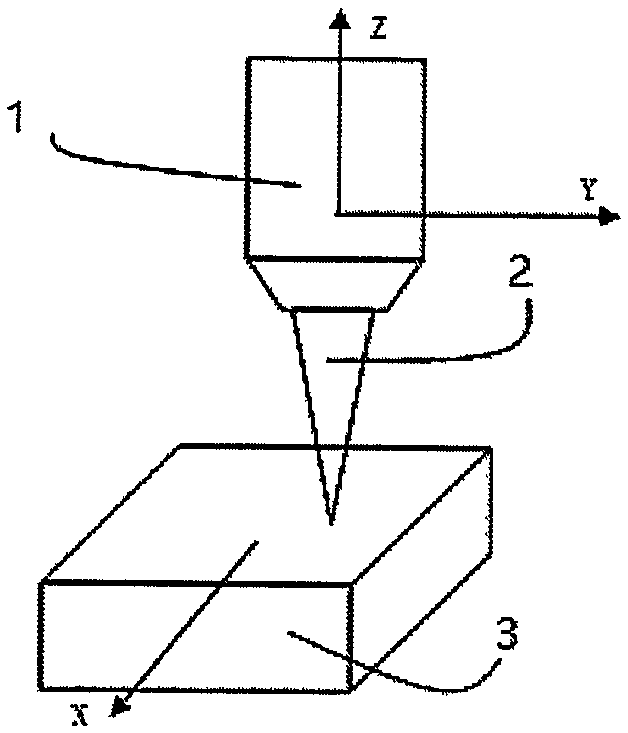

[0037] Figure 1-c It shows another system for two-dimensional plane machining of brittle materials based on a three-axis linkage system in the prior art. The optical module 1 can move linearly along the Z and Y axes, while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com