Coated abrasive grinder of propeller blade

A belt grinder and propeller technology, applied in the direction of belt grinder, grinding machine, grinding/polishing equipment, etc., can solve the problems of poor processing accuracy, low processing efficiency, and difficult to guarantee the quality of the profile, so as to reduce management and production costs , Improve the qualified rate of finished products and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

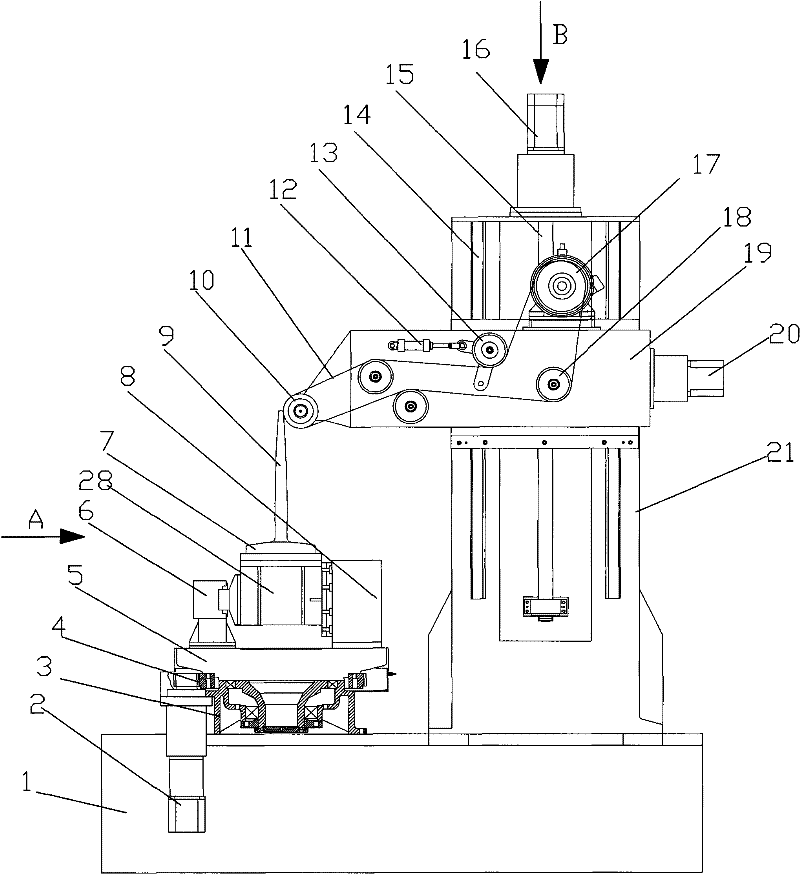

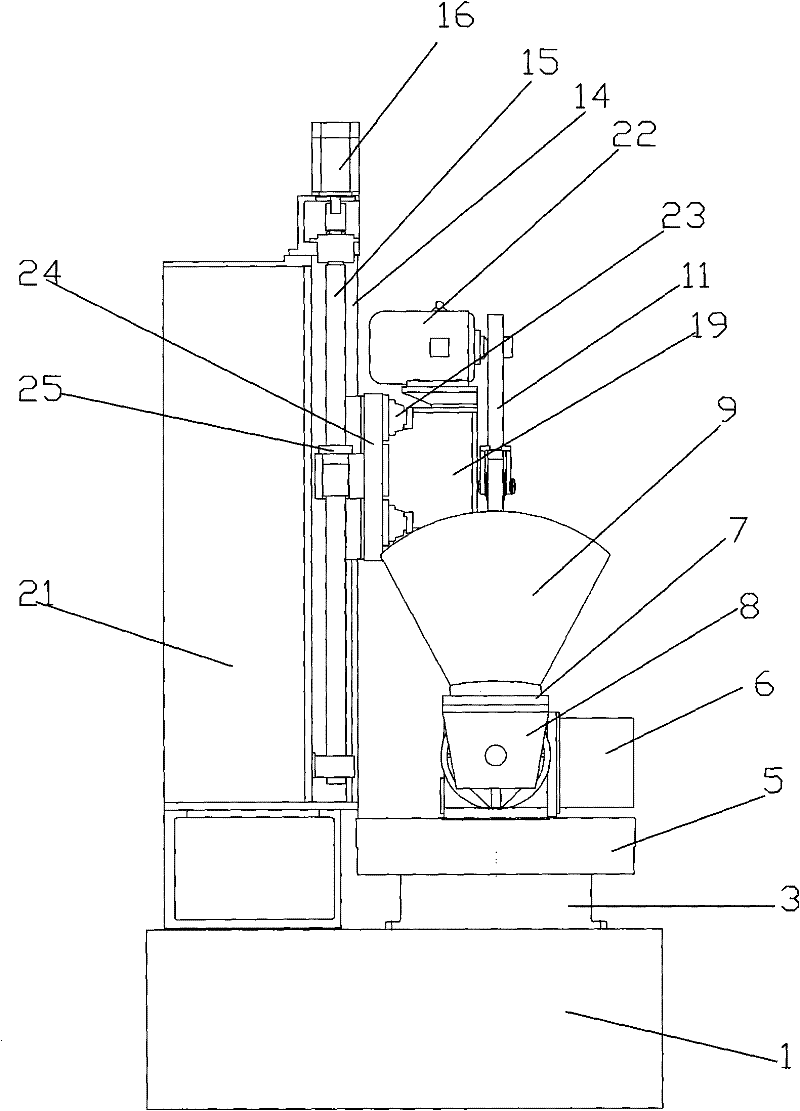

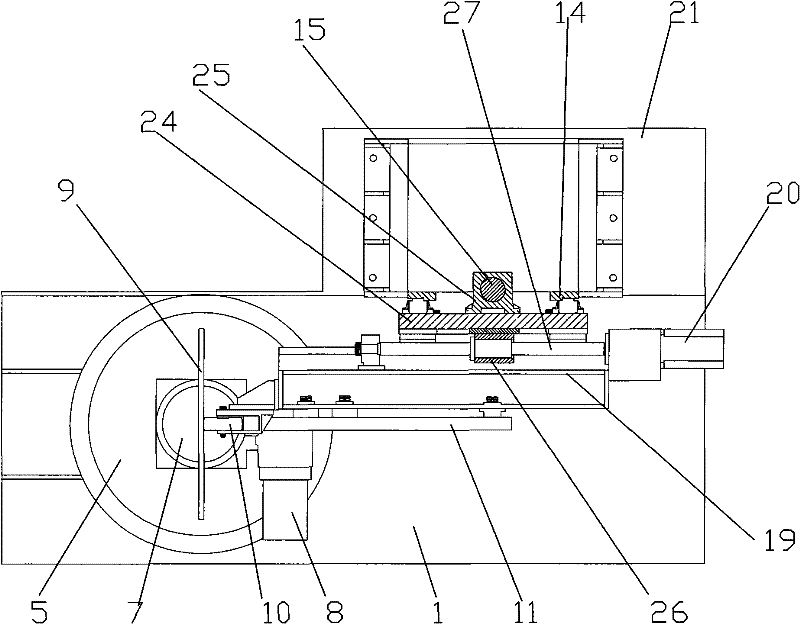

[0024] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 2 View along the B direction, as shown in the figure: the propeller blade abrasive belt grinder of this embodiment includes a bed 1, a grinding head mechanism, a grinding head feeding mechanism, a workpiece orientation adjustment mechanism and an automatic control system;

[0025] Grinding head mechanism comprises abrasive belt 11, driving wheel 17, contact wheel 10, tensioning wheel 13 and grinding head driving motor 22, and described abrasive belt 11 walks around driving wheel 17 and contacting wheel 10 and is tensioned by tensioning wheel 13, The power output shaft of the grinding head drive motor 22 is in transmission cooperation with the drive wheel 17;

[0026] The grinding head feeding mechanism includes an axial feeding mechanism and a radial feeding mechanism relative to the workpiece, and the radial feeding mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com