A wire electric discharge cutting device and a method for controlling liquid volume between electrodes

An EDM wire and cutting device technology, applied in electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve problems such as affecting processing quality, easy bifurcation of working fluid, and inability to automatically adjust the amount of working fluid between electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

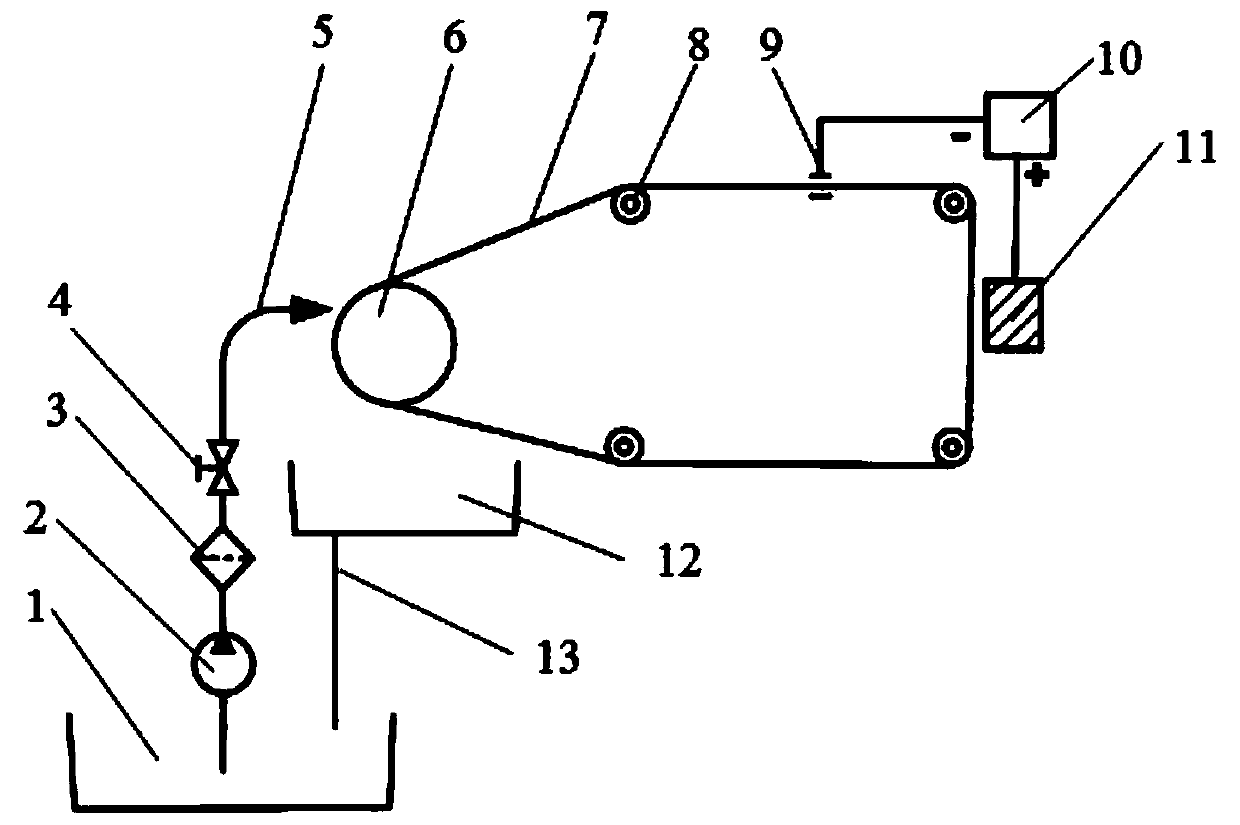

[0021] Such as figure 1 It is a schematic structural diagram of a wire EDM device under an embodiment of the present invention. It is mainly composed of two parts: a liquid supply system and a cutting system. As shown in the figure, the cutting system includes 6 wire barrels and 4 guide wheels at different positions. 8. The wire electrode 7 and the pulse power supply 10 connected to the wire electrode 7, the workpiece 11 is cut at the position shown in the figure, and the position of the workpiece can be adjusted according to the actual situation. The wire electrode is driven by the wire barrel and is driven by the four guide wheels 8 The outside of the workpiece 11 is rotated to cut the workpiece through the wire electrode at the workpiece 11. The rotation speed of the wire electrode can be adjusted by the rotation speed of the wire barrel 6 to control the rotation speed of the wire electrode through the wire barrel 6.

[0022] Such as figure 1 As shown, the left position of th...

Embodiment 2

[0035] Embodiment 2: This embodiment discloses a working medium for electric spark cutting, that is, inter-electrode working fluid, which is used for electric spark cutting in embodiment 1. The working medium is a SiC nanofluid working medium. The nanofluid can form uniform and stable negatively charged micelles, and the repulsive force between the negatively charged micelles prevents their coalescence. Therefore, the working medium can maintain long-term uniformity without external stirring, and it can cut the surface of the workpiece while cutting online. Modification does not require post-processing operations on the workpiece.

[0036] The composition and mass percentage of SiC nanofluid are as follows

[0037] 98 parts of deionized water;

[0038] 0.8 parts of SiC nanoparticles with a particle size of 50nm;

[0039] Dispersion stabilizer 0.6 part of sodium carboxymethyl cellulose;

[0040] Surfactant 1.2 parts of sodium dodecylbenzene sulfonate;

[0041] 0.4 parts of anti-settling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com