Machining method and device of compressor inlet guide blade

A technology of inlet guide vane and processing method, which is applied in the field of mechanical processing and can solve problems such as lack of inlet guide vane processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

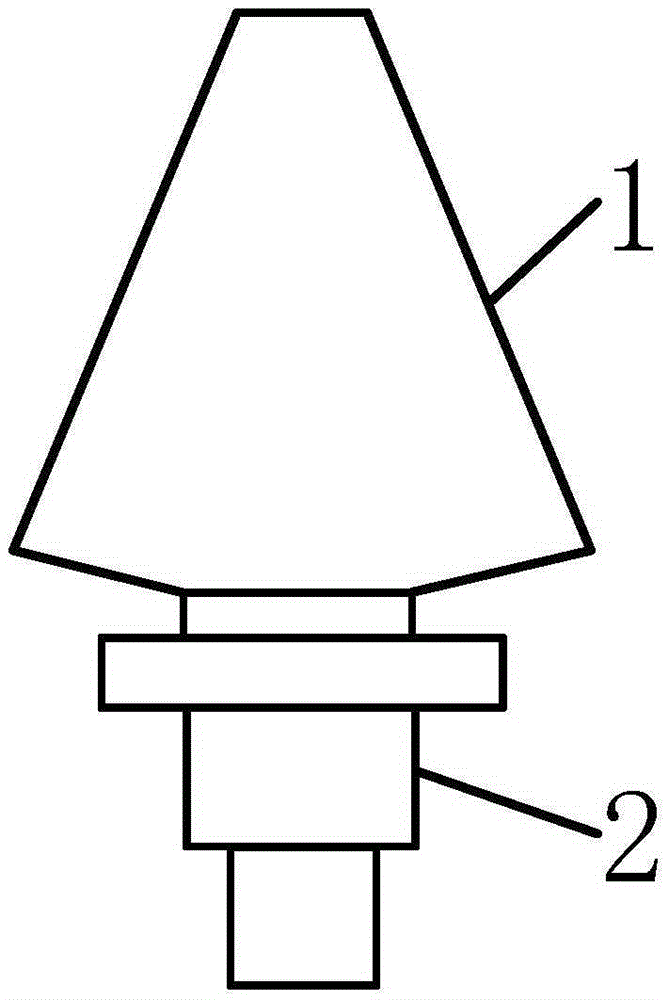

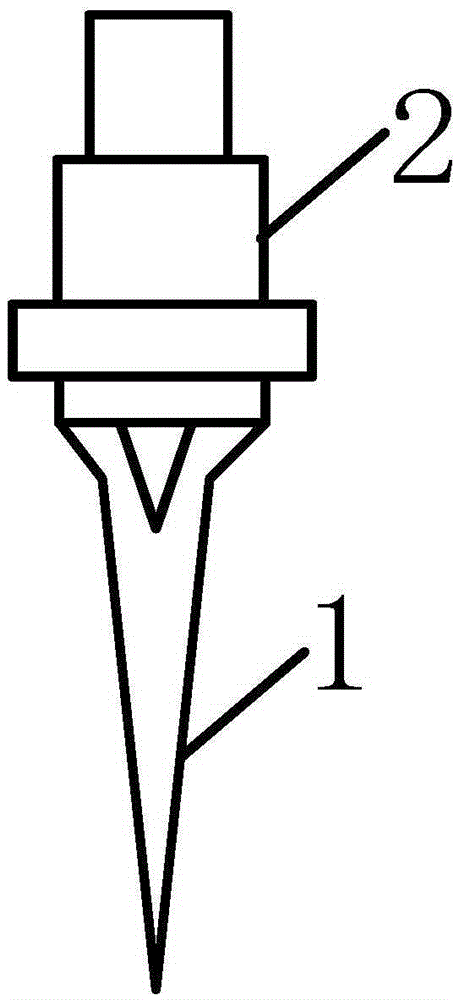

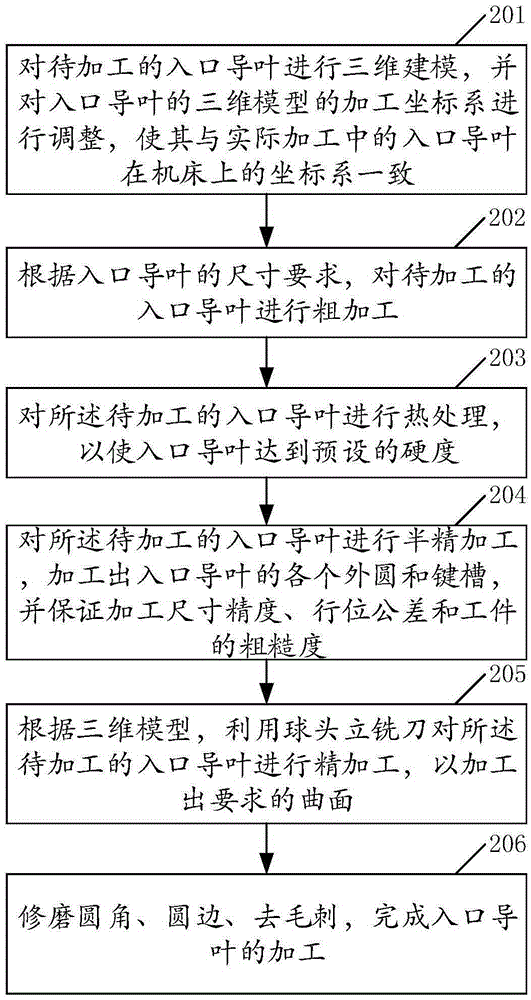

[0025] Such as Figure 1a and 1b As shown, it is a design drawing of the processing of the inlet guide vane provided by the embodiment of the present invention, wherein the inlet guide vane is composed of a blade 1 and a petiole 2 . The following combines how to process such as Figure 1a and 1b The inlet guide vane is shown, and a processing method of compressor inlet guide vane is introduced in detail, such as figure 2 shown, including:

[0026] Step 201, performing three-dimensional modeling of the inlet guide vane to be processed, and adjusting the machining coordinate system of the three-dimensional model of the inlet guide vane so that it is consistent with the coordinate system of the inlet guide vane in actual processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com