Machining method and device for bearing standard block

A processing method and leveling technology, applied in the direction of bearing components, shafts and bearings, manufacturing tools, etc., can solve problems such as the processing method of leveling blocks lacking bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

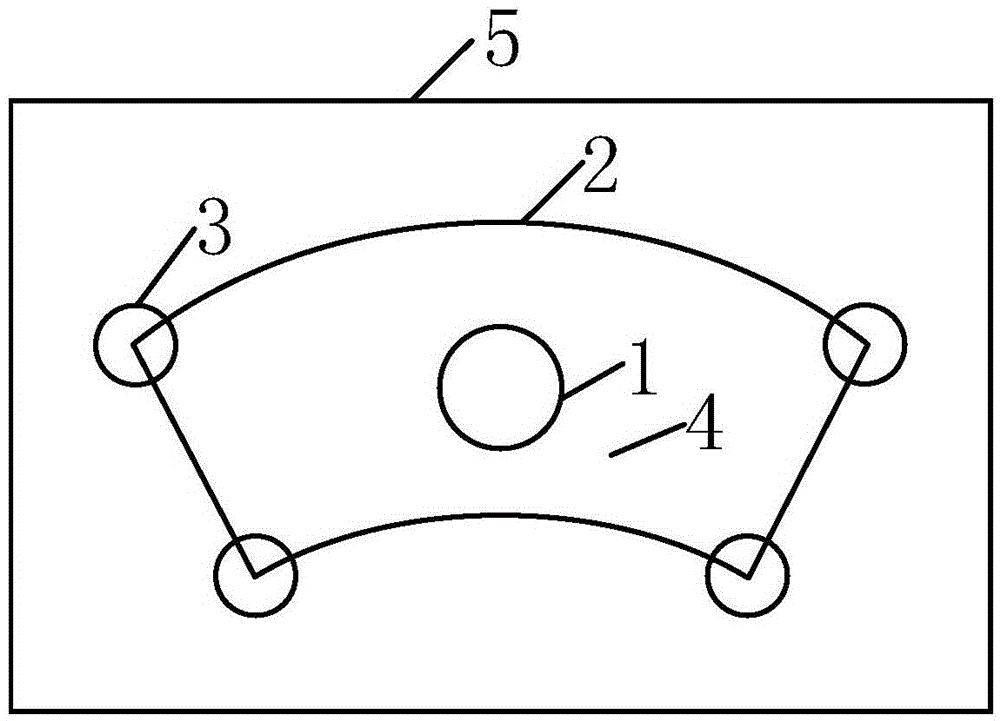

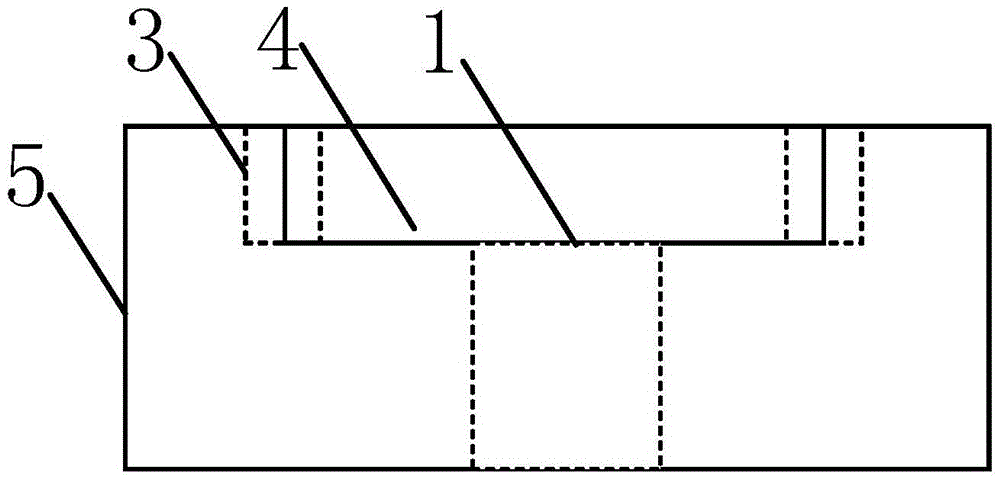

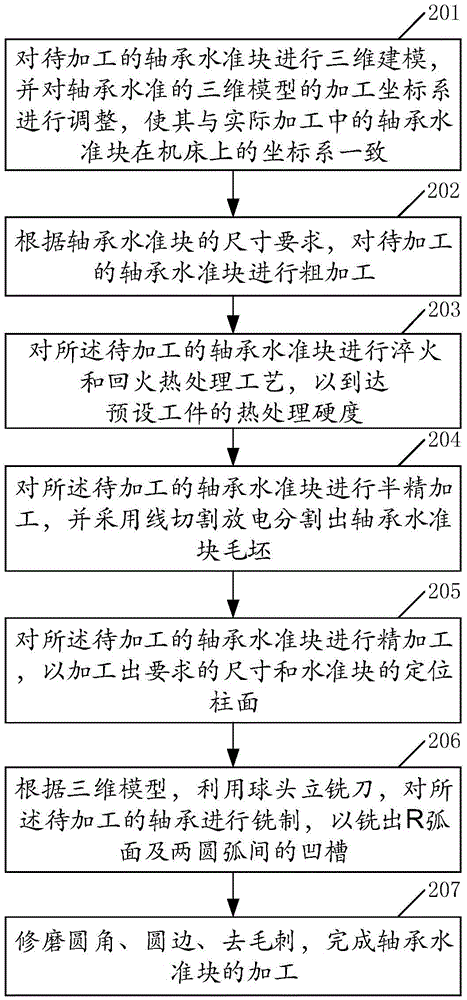

[0027] like Figure 1a and 1b As shown, it is the tooling design drawing of the bearing level block processing provided by the embodiment of the present invention, wherein, between the R arc surfaces 2 is a groove 4, the center of the groove 4 is the first positioning hole 1, and the four corners of the sector are the center is provided with a second positioning hole 3 . The following combination of how to process such as Figure 1a and 1b The bearing level block is shown, and a processing method of the bearing level block is introduced in detail, such as figure 2 shown, including:

[0028] Step 201 , carrying out three-dimensional modeling of the bearing level block to be processed, and adjusting the processing coordinate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com