On-line servo cutting-to-length device for large-diameter PC steel bars

A fixed-length shearing, large-diameter technology, applied in shearing devices, devices for shearing forming blanks, shearing machine control devices, etc., can solve the problems of poor precision, low production efficiency, complex structure, etc. Accuracy, simple structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

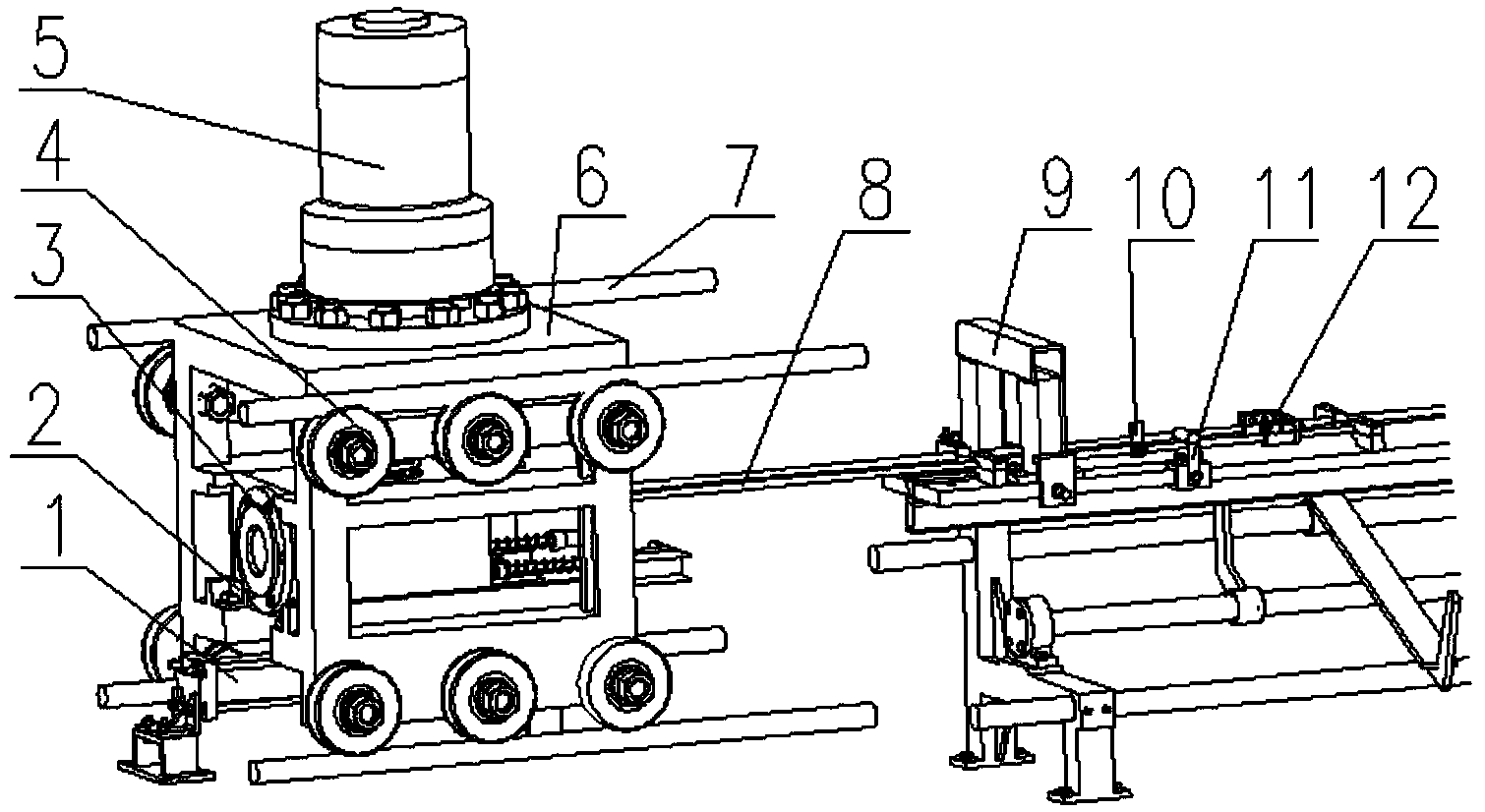

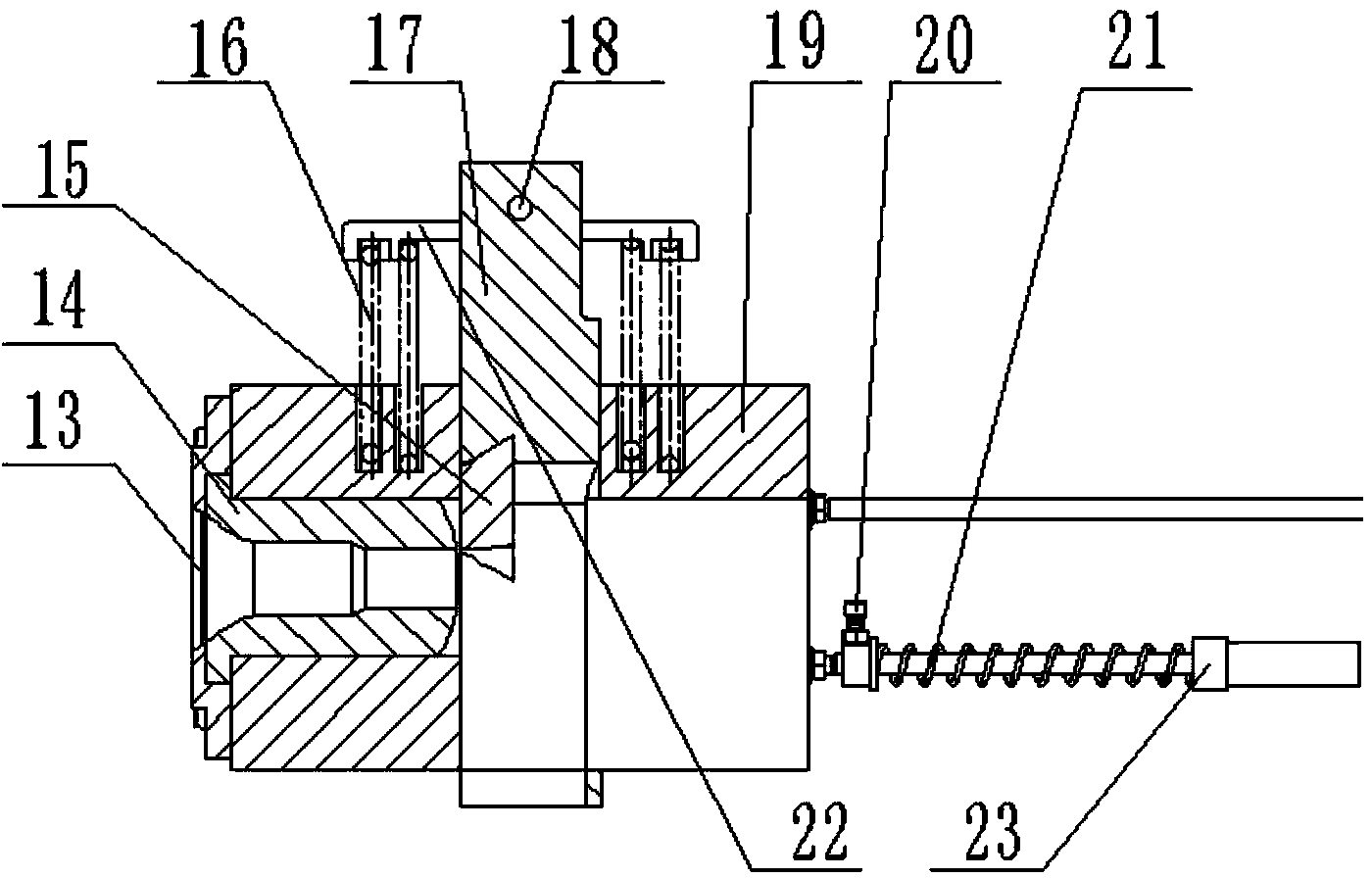

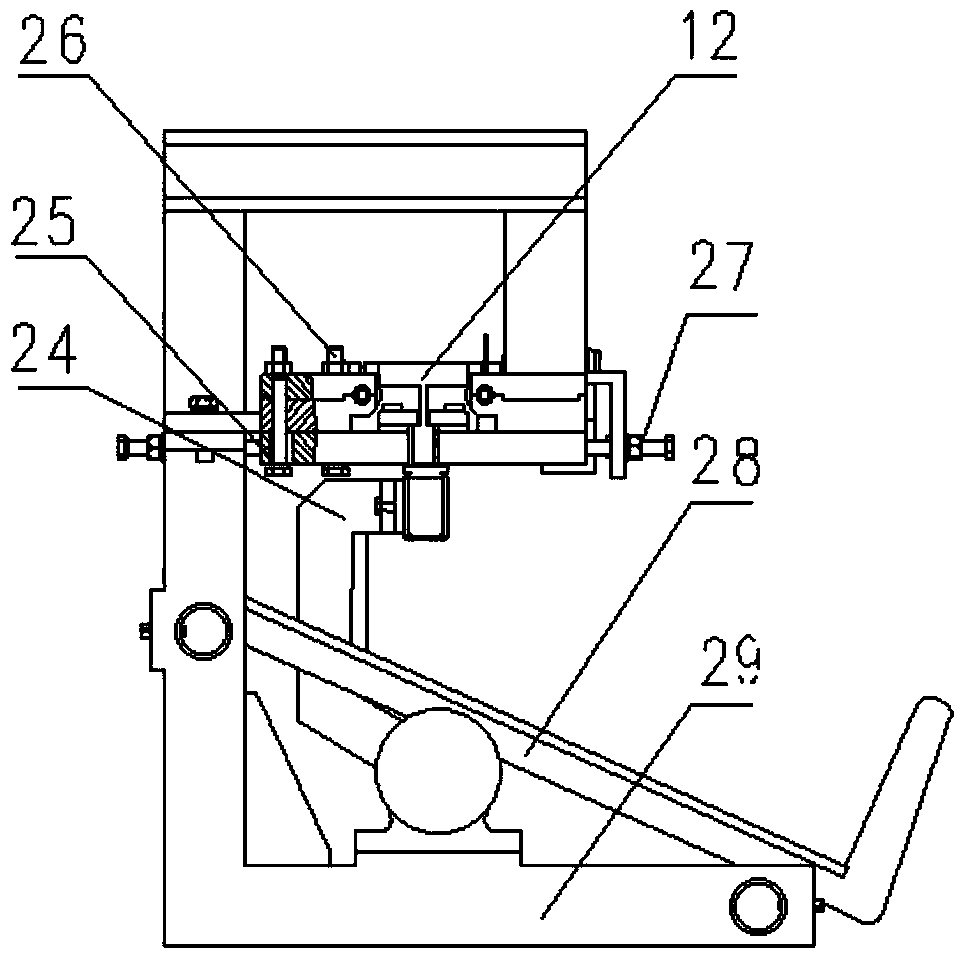

[0016] In the following, a more detailed description will be given to a large-diameter PC steel rod online follow-up shearing device to length in conjunction with the accompanying drawings.

[0017] exist figure 1 In the three-dimensional schematic diagram of the large-diameter PC steel rod online follow-up fixed-length shearing device shown, the frame 6 is a rectangular frame, and two rows of guide wheels 4 are respectively arranged on both sides of the frame, and the upper row of guide wheels is located on the upper column. Below the guide rail 7, the lower row of guide wheels is located above the lower cylindrical guide rail. The two ends of the cylindrical guide rail are fixed on the racks on both sides, and can be threaded or hinged. The bottom of the front end of the vehicle frame (the end opposite to the material receiving mechanism) is connected with the piston rod of the servo cylinder 1, and the cylinder body of the servo cylinder is fixed on the foundation. The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com