Automatic equal-diameter elbow roundness shaping and cutting all-in-one machine

An all-in-one machine and equal-diameter technology, which is applied in the direction of shearing devices, metal sawing equipment, and other manufacturing equipment/tools, can solve problems such as low degree of automation, prolonging processing time, and easy breakage of pull cords, etc., to achieve Scientific and reasonable structural design, improved processing efficiency, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

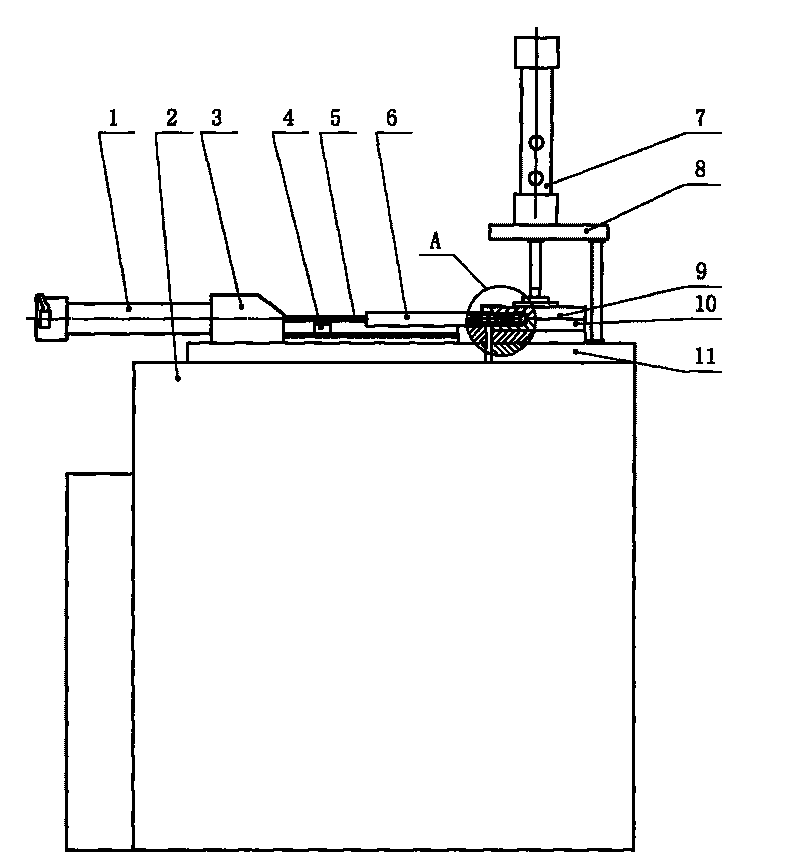

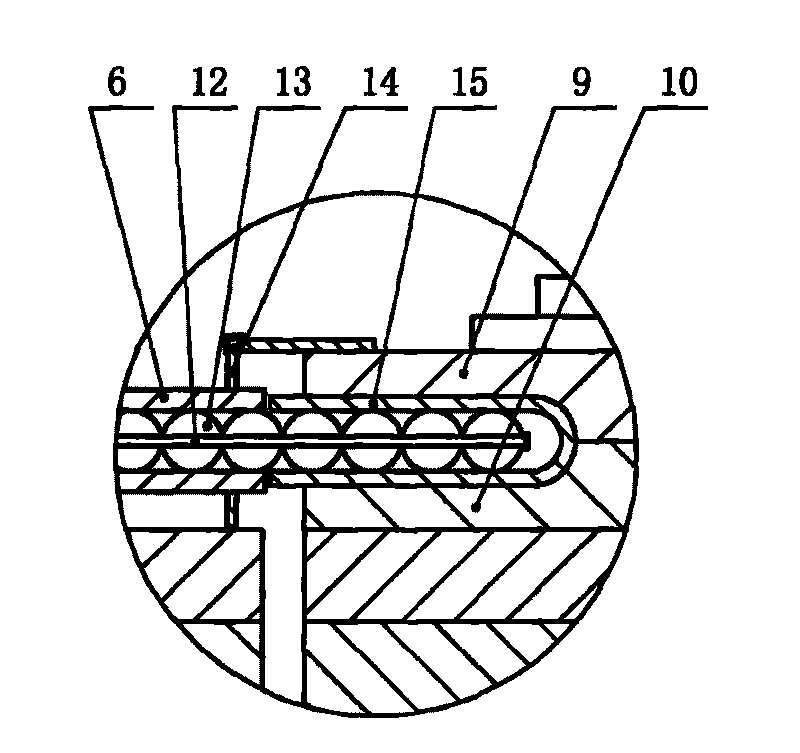

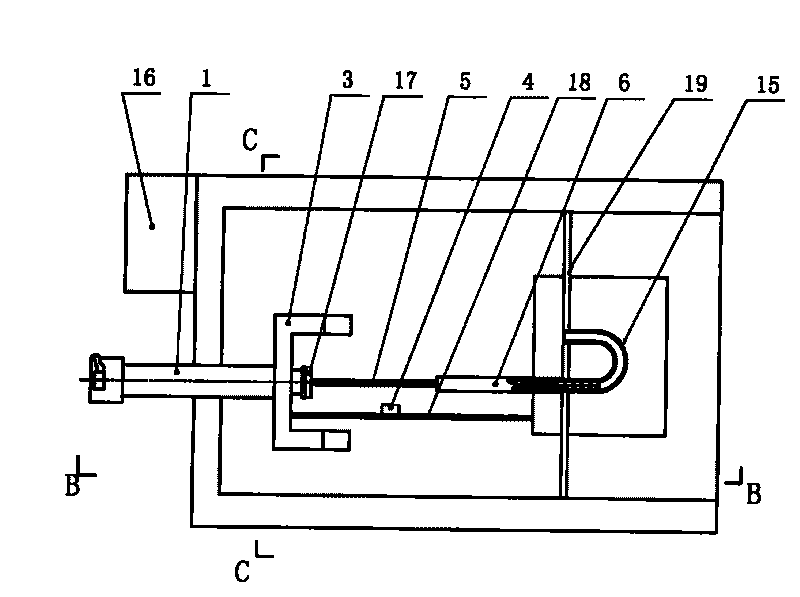

[0022] The automatic equal-diameter elbow roundness shaping and cutting integrated machine is composed of a main body 2, a working table 11, an upper template 9, a lower template 10, and a die cylinder 7. The worktable is fixed on the upper surface of the main frame, and the die cylinder is vertically installed on the workbench through the installation frame 8. The lower template and the upper template, the lower template and the upper template are respectively fixed on the surface of the worktable and the end of the push rod of the die cylinder. The pressing surfaces of the templates are respectively formed with equal-diameter semicircular curved grooves (not marked in the figure) that are fastened to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com