Full mechanical band saw machine tool

An all-mechanical, band-saw technology, applied in the field of all-mechanical band saw machine tools, can solve the problems of increased workload, complicated operation and trouble, and achieve the effect of saving hydraulic oil and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment;

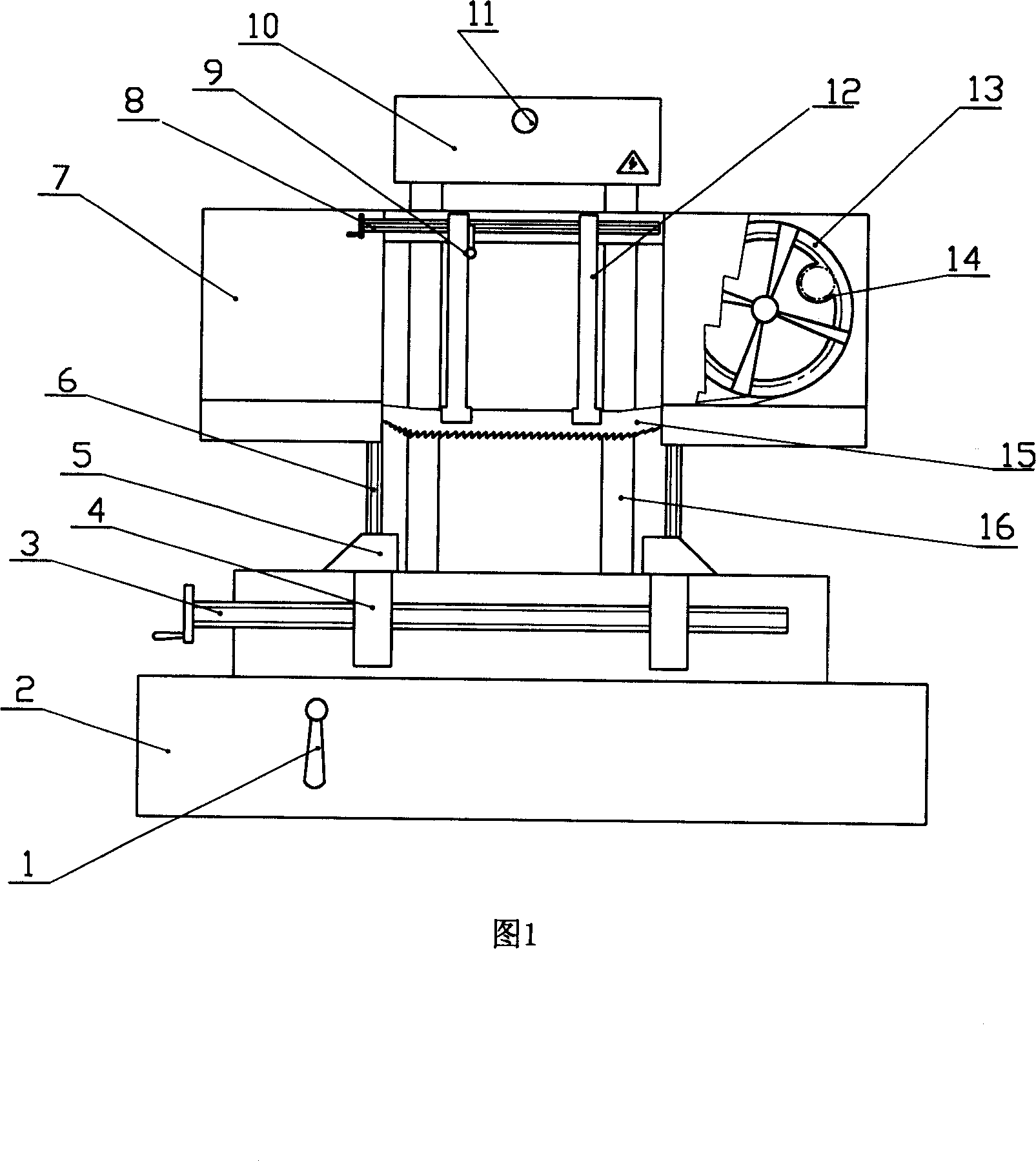

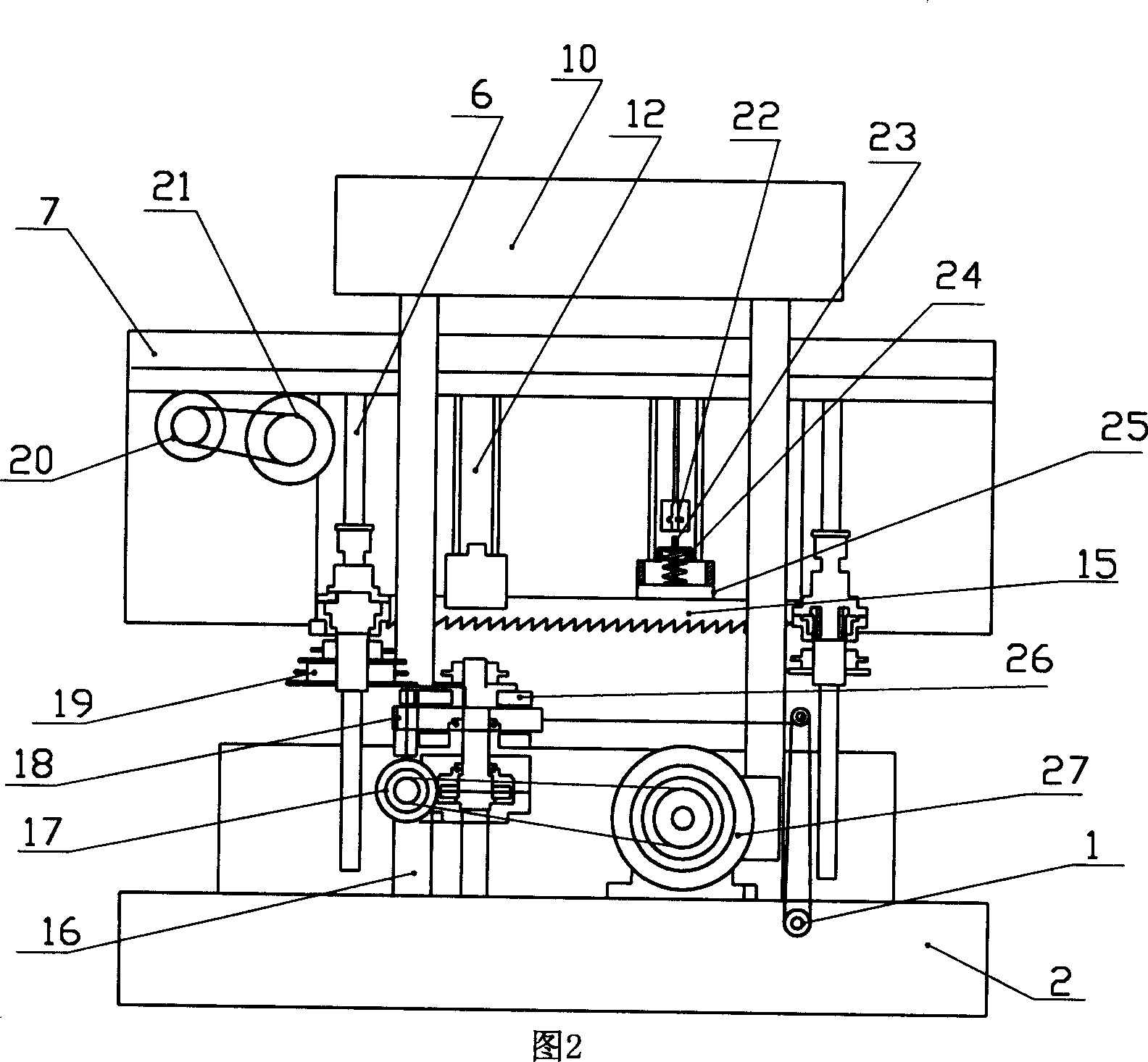

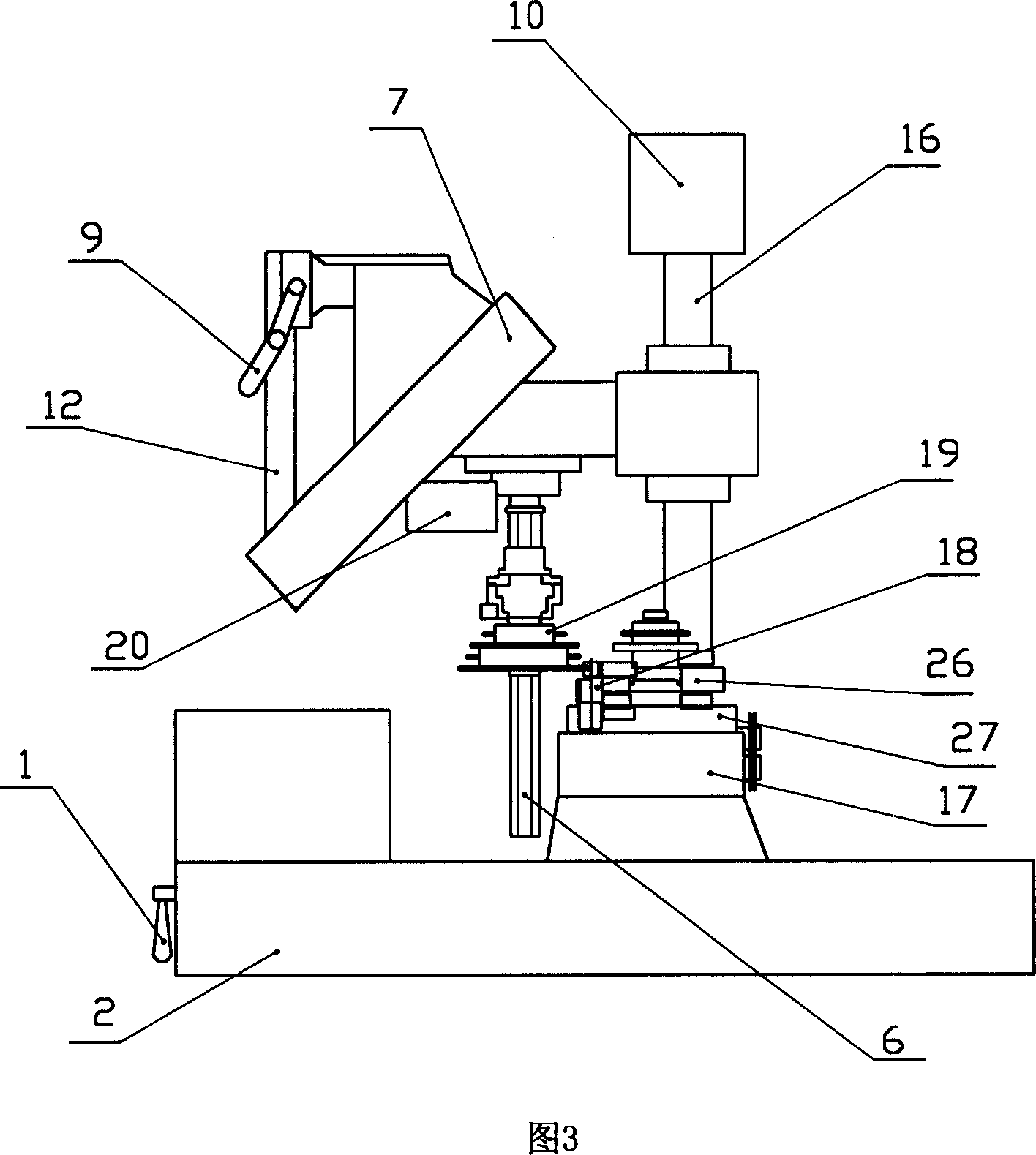

[0015] An all-mechanical band saw machine tool, as shown in Figure 1, which includes: a base 2, a guide column 16 fixed on the base 2, a bow frame 7 moving up and down along the guide column 16, and a drive at both ends of the bow frame 7. Wheel 13, driven wheel and the saw blade 15 connecting the main and driven wheels, the control cabinet 10 is fixedly installed on the guide column 16, the power switch 11 is fixedly installed on the control cabinet 10; the upper stroke switch and the lower stroke are fixedly installed on the guide column 16 Switch; sawing motor 21 is fixedly installed below bow frame 7; worm wheel 20 is fixedly installed below bow frame 7, and sawing motor 21 is connected with worm wheel 20 belts; The worm gear shaft on the worm gear 20 is fixedly connected, and the small driving wheel 14 is meshed with the internal teeth of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com