Apparatus and method for horizontal casting and cutting of metal billets

A metal bar and equipment technology, applied in the field of horizontal casting equipment, to achieve the effect of improving the surface quality of the bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

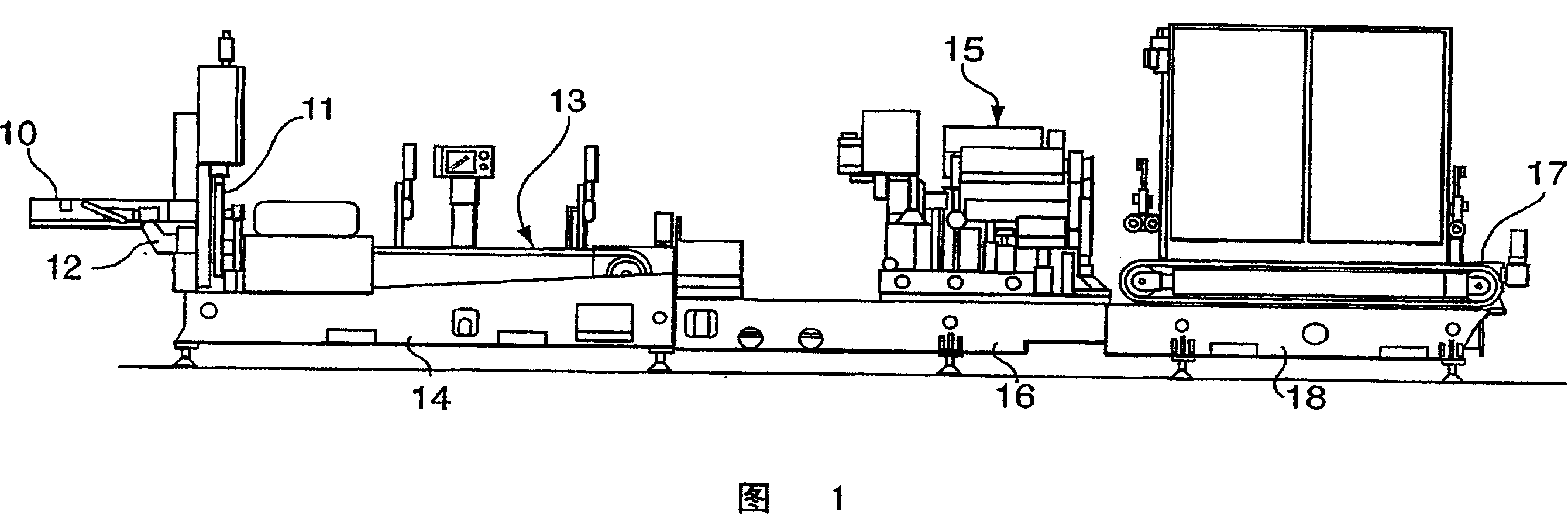

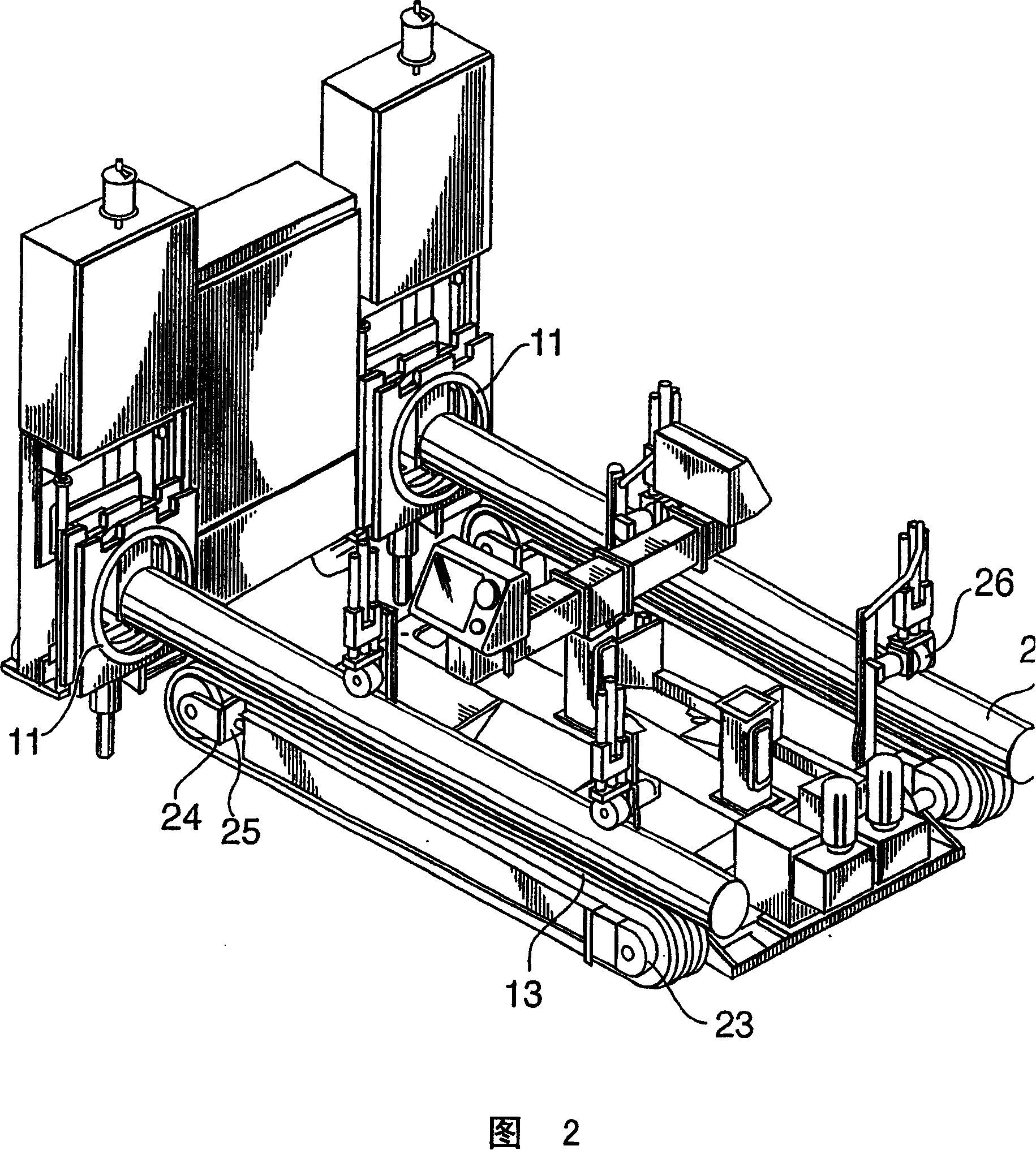

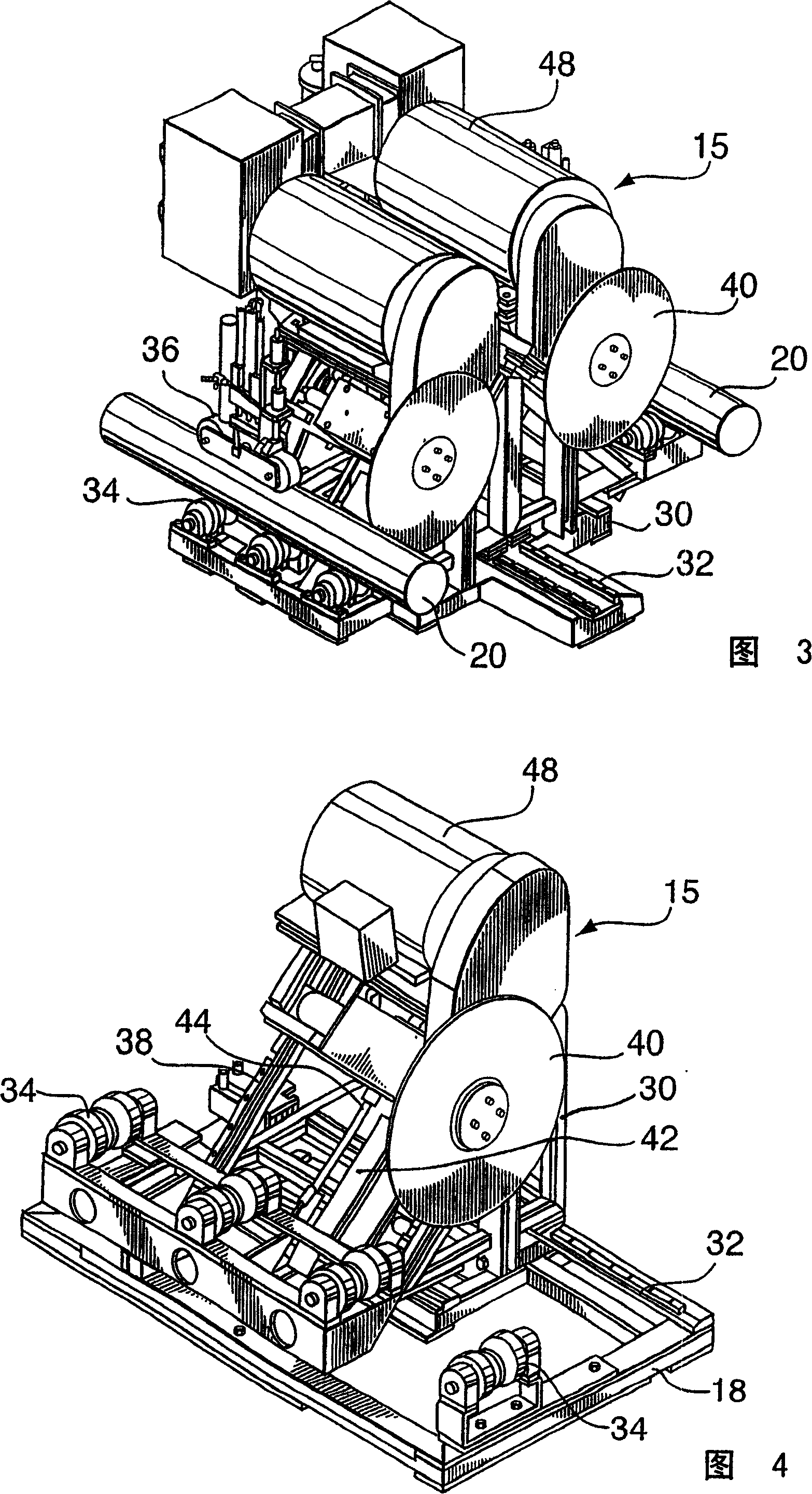

[0034] A preferred embodiment of the invention is generally shown in Figure 1, wherein the casting station comprises a molten metal supply launder 10, a casting mold 11 and a removable metal transfer between the launder and the mould. paragraph 12. The continuous casting operation itself and the molds used for this purpose do not form an essential part of the invention and will therefore not be discussed in detail. Of course, it should be understood that the drawn and continuously cast bars will have solidified sufficiently before the point at which they are subjected to downstream processing that the physical configuration or surface quality characteristics of the cast metal bars are not adversely affected. Suitable casting molds are more fully described in copending application Ser. No. 10 / 735,076 entitled "Horizontal Continuous Casting of Metals," filed December 11, 2003, and assigned to the same assignee as the present invention, The disclosure of that patent application ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com