Patents

Literature

43 results about "Direct chill casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct Chill casting is a method for the fabrication of cylindrical or rectangular solid ingots from non-ferrous metals, especially Aluminum, Copper, Magnesium and their alloys. The original ingots are usually further processed by other methods (rolling, forging, etc.). More than a half of global aluminum production uses the Direct Chill casting process.

Process of producing aluminum alloy sheet exhibiting reduced roping effects

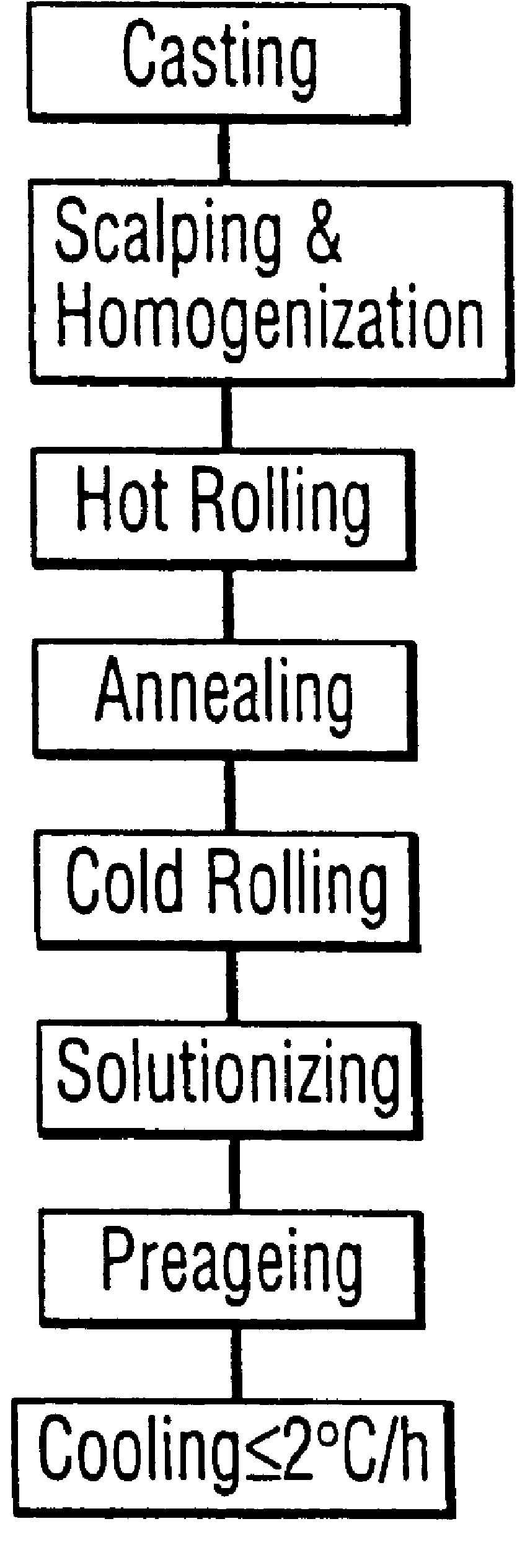

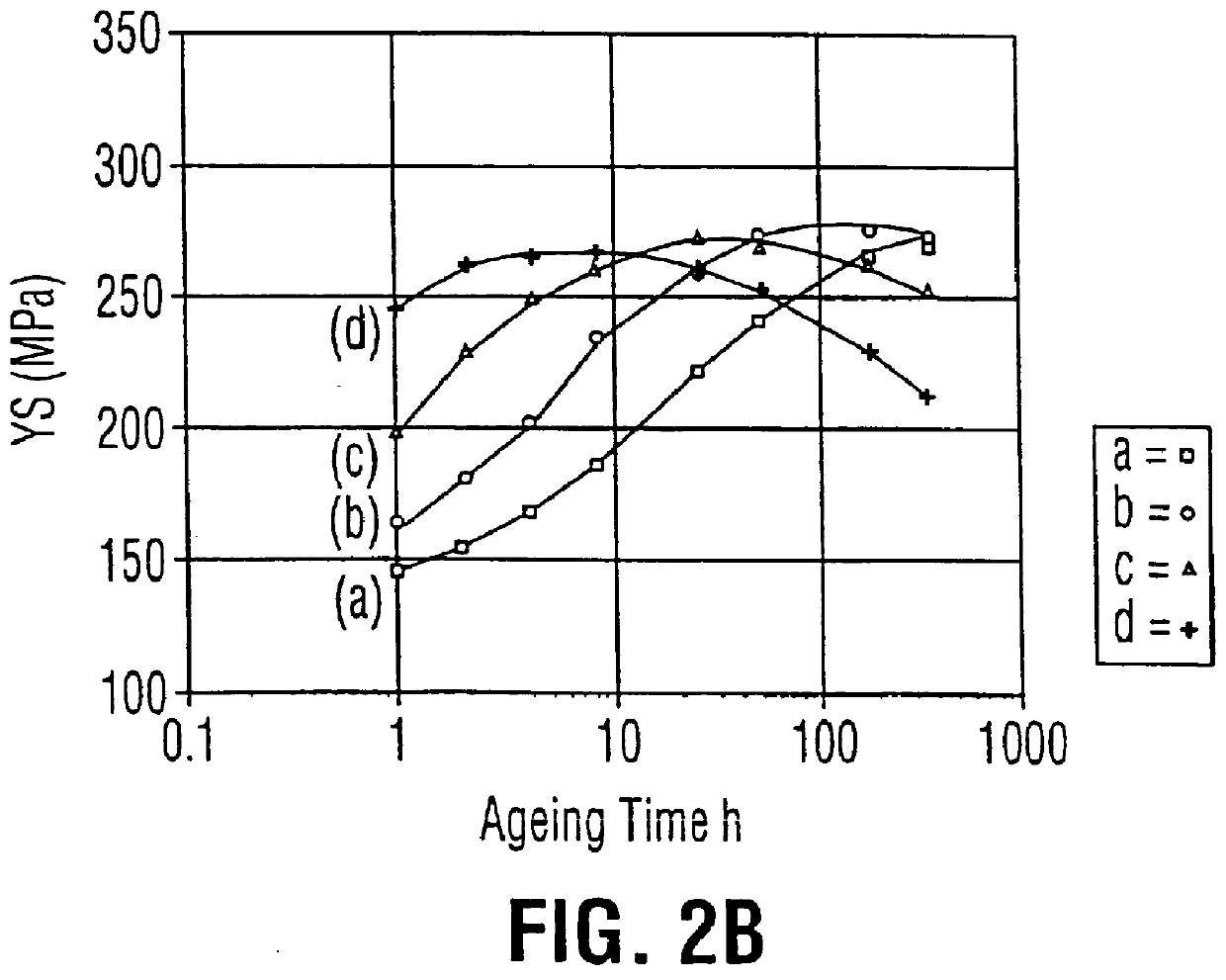

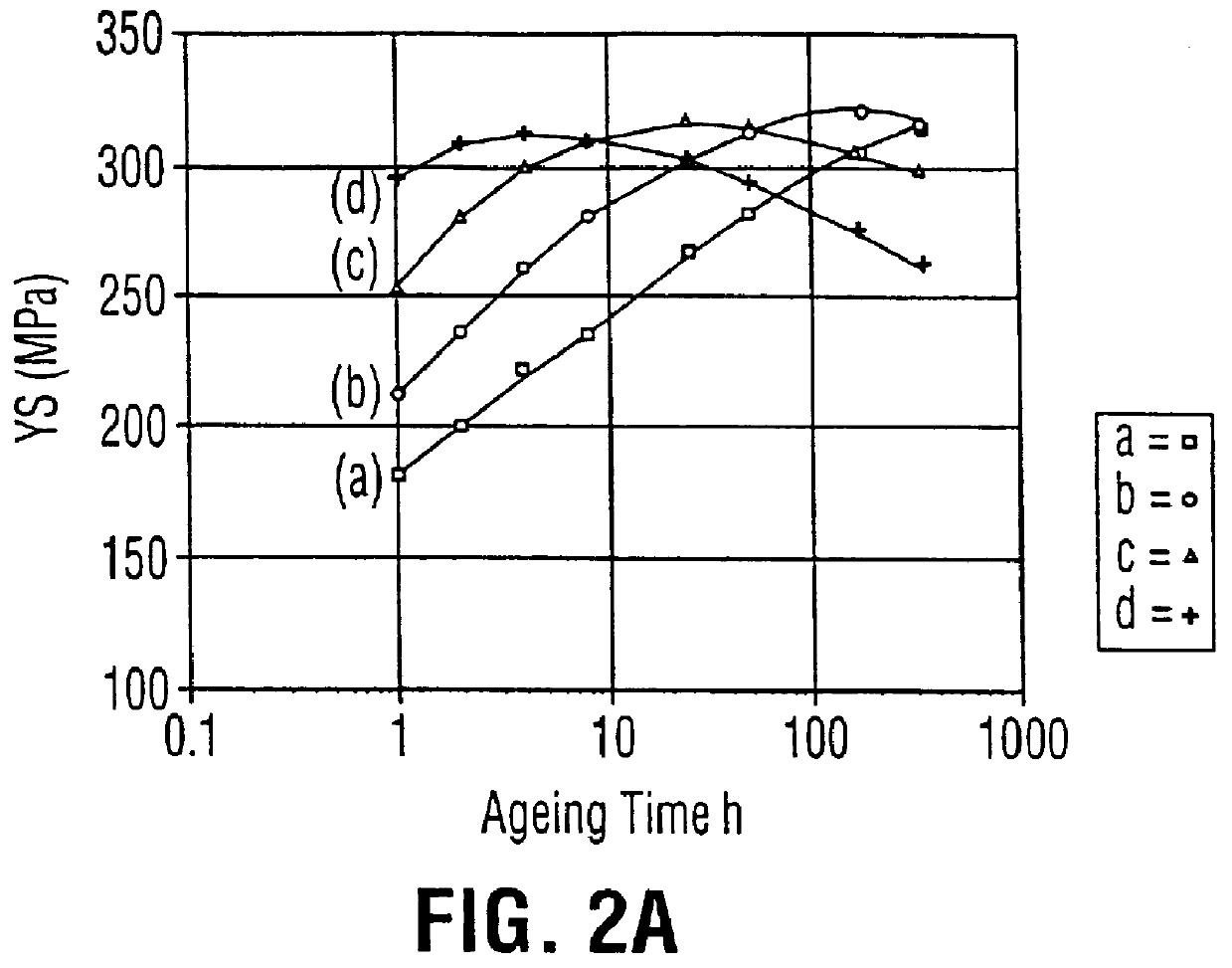

A process of producing an aluminum alloy sheet product suitable for forming into automotive parts and exhibiting reduced roping effects. The process involves producing an aluminum alloy sheet product by direct chill casting an aluminum alloy to form a cast ingot, homogenizing the ingot, hot rolling the ingot to form and intermediate gauge product, cold rolling the intermediate gauge product to form a product of final gauge, and subjecting the final gauge product to a solutionizing treatment by heating the product to a solutionizing temperature, followed by a pre-aging step involving cooling the product to a coiling temperature above 50 DEG C., coiling the cooled product at the coiling temperature, and cooling the coiled final gauge product from the coiling temperature above 50 DEG C. to ambient temperature at a rate less than about 10 DEG C. per hour to improve T8X temper characteristics of the product. Additionally, a batch anneal step is carried out on the intermediate gauge product or at an intermediate stage of the cold rolling to reduce or eliminate roping tendencies of the alloy sheet product. To maintain a high T8X response, the alloy used in the process has the following composition: 0.4 to 1.1% by weight magnesium; 0.3 to 1.4% by weight silicon; 0 to 1.0% by weight copper; 0 to 0.4% by weight iron; 0 to 0.15% by weight manganese; 0 to 0.15% weight naturally-occurring impurities (collective total); and the balance aluminum. The invention also relates to a sheet alloy product exhibiting reduced roping effects produced by the indicated process.

Owner:NOVELIS INC

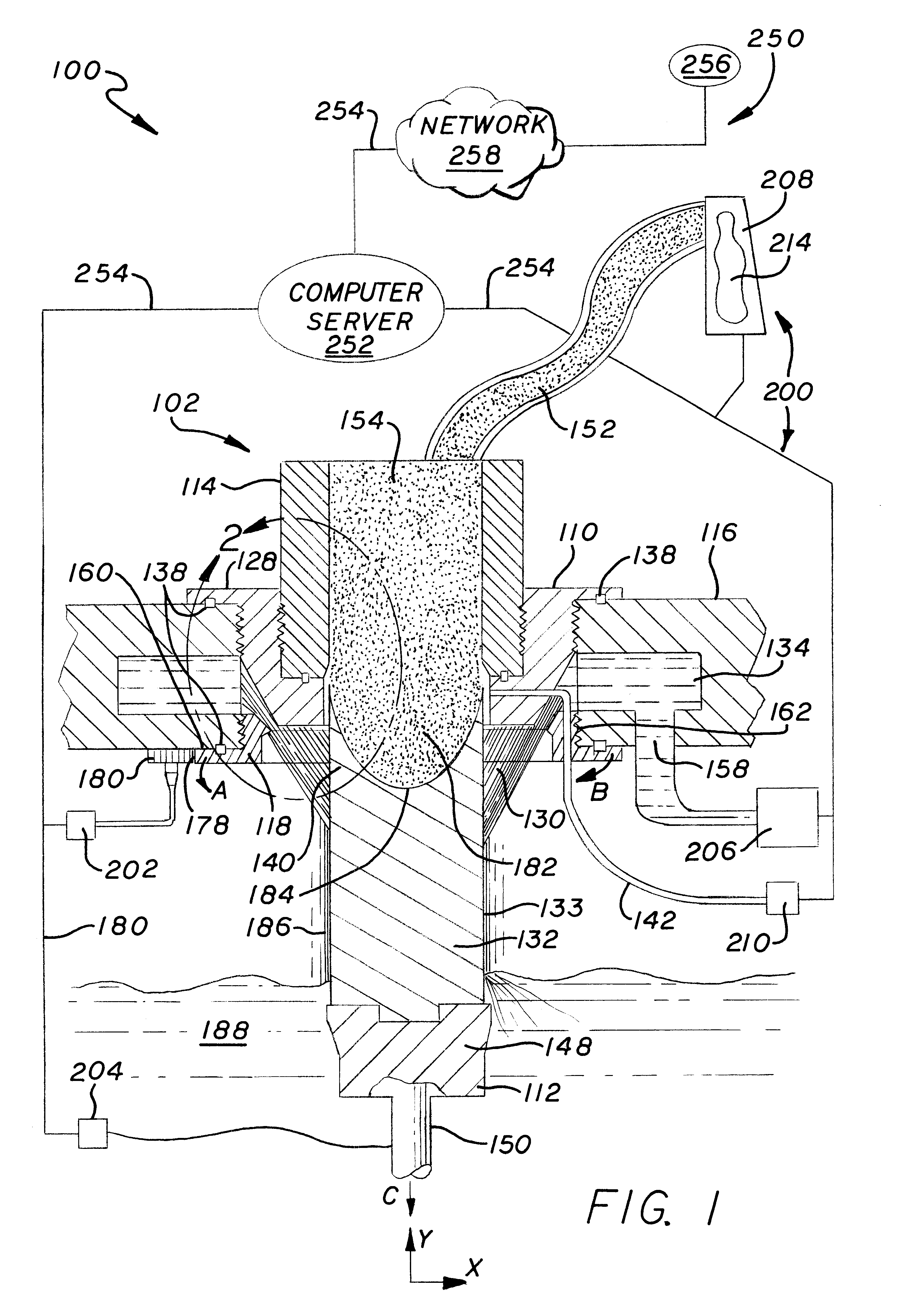

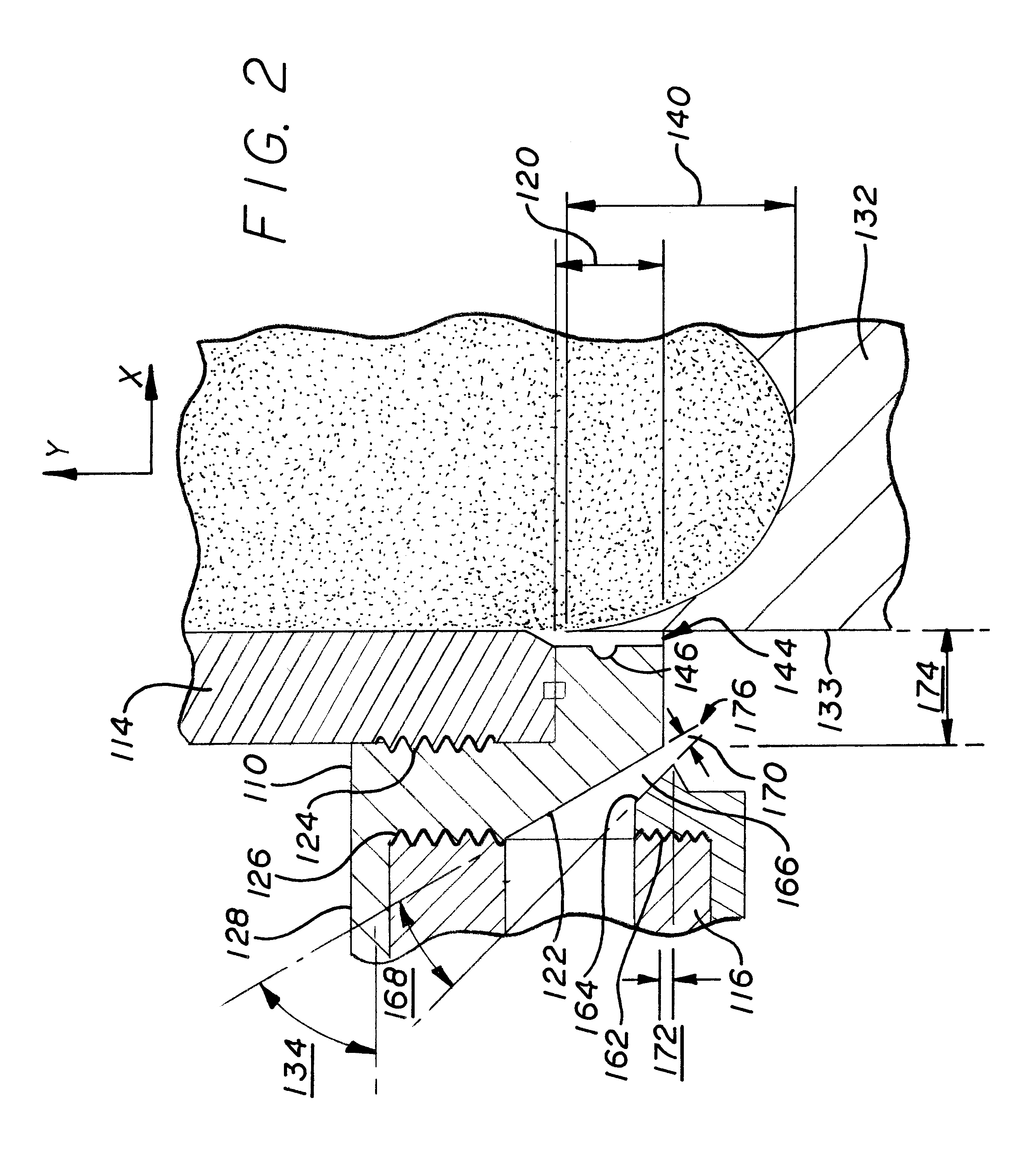

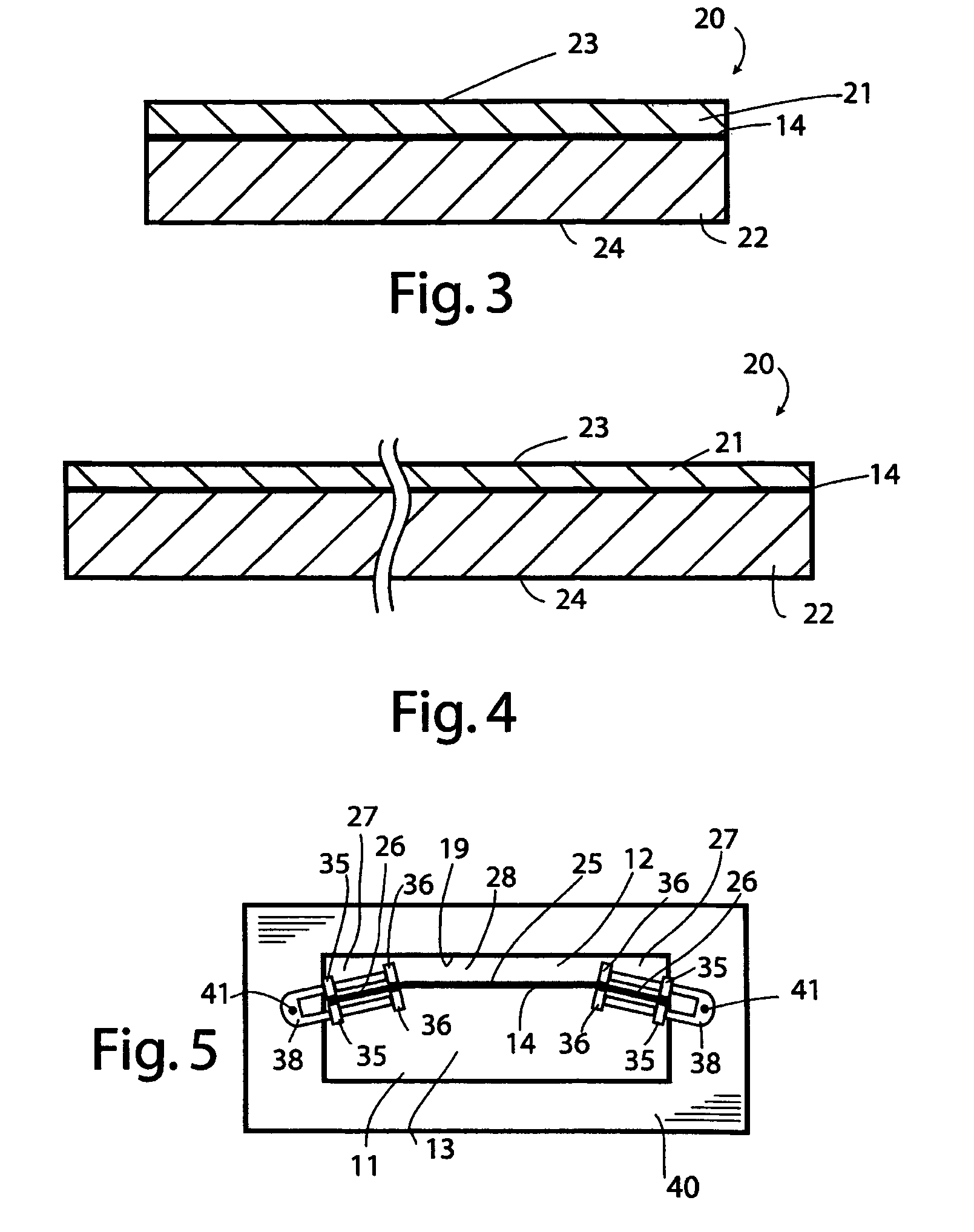

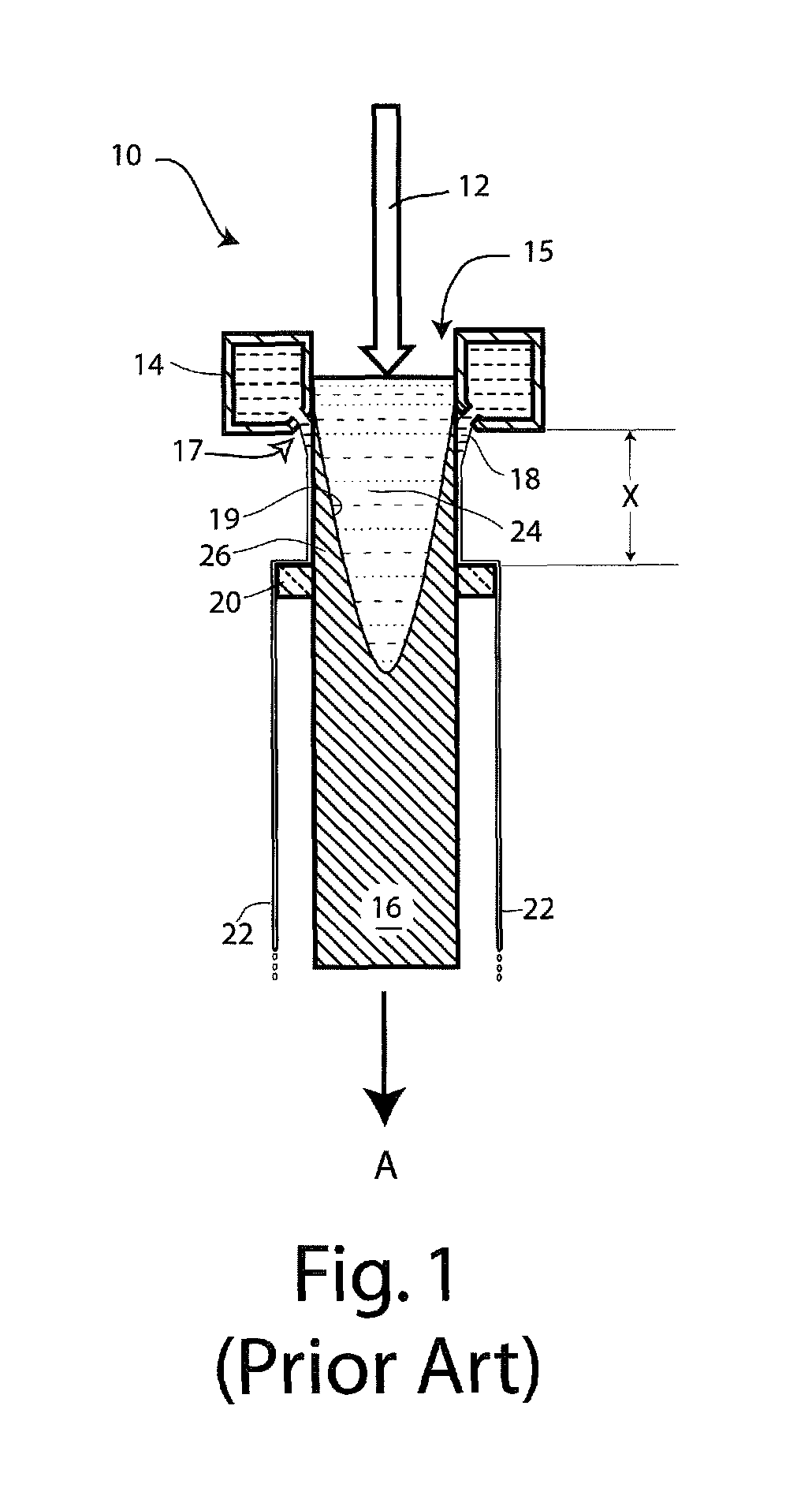

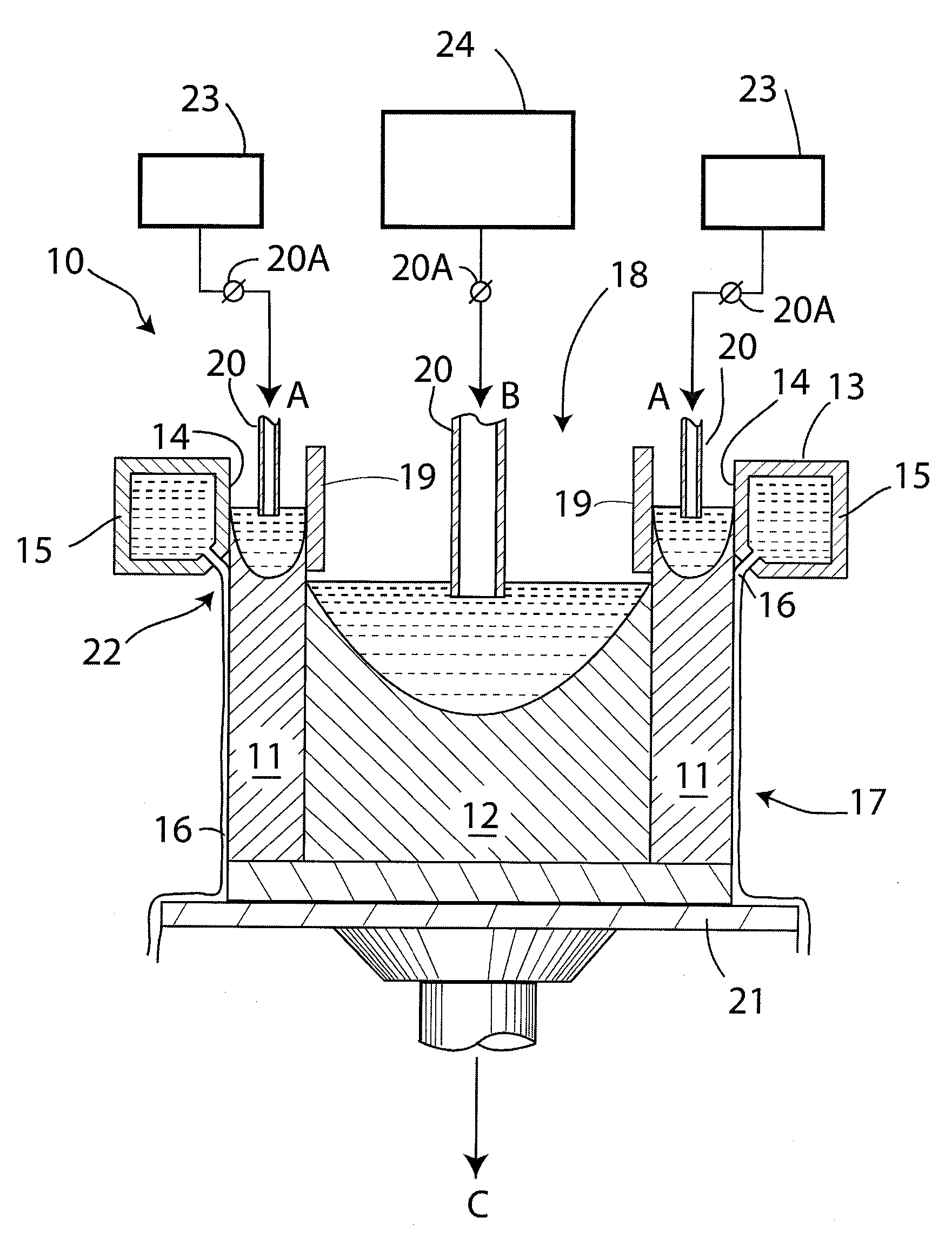

Direct chill casting mold system

An embodiment includes a casting mold. The casting mold may include a mold body having a direction surface and a coolant box coupled to the mold body. The casting mold further may include a coolant ring having a regulation surface where the coolant ring may be coupled to the coolant box so as to bring the regulation surface and the direction surface together to form a nozzle. The casting mold further may include a mold starting head.

Owner:TILAK RAVINDRA V

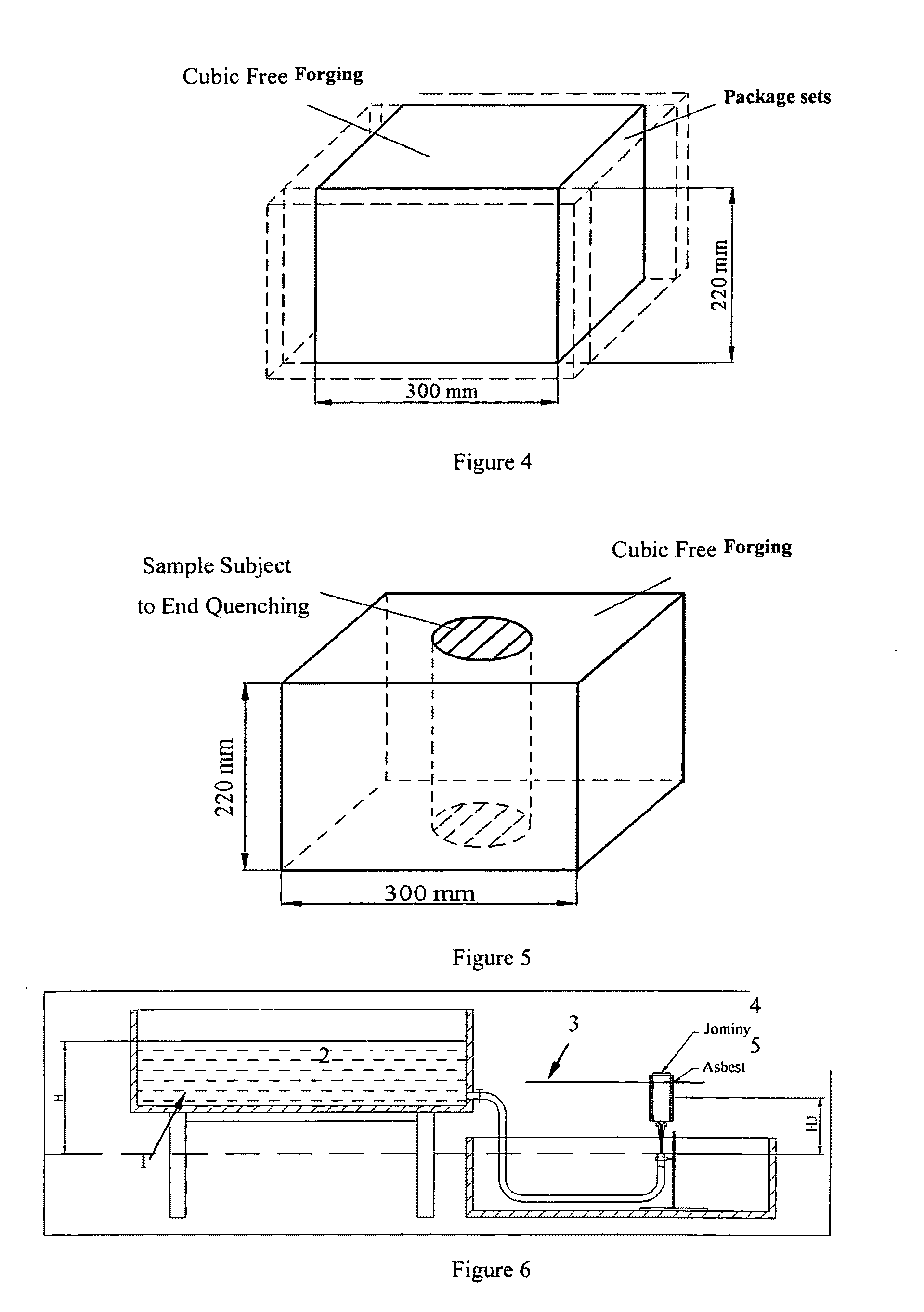

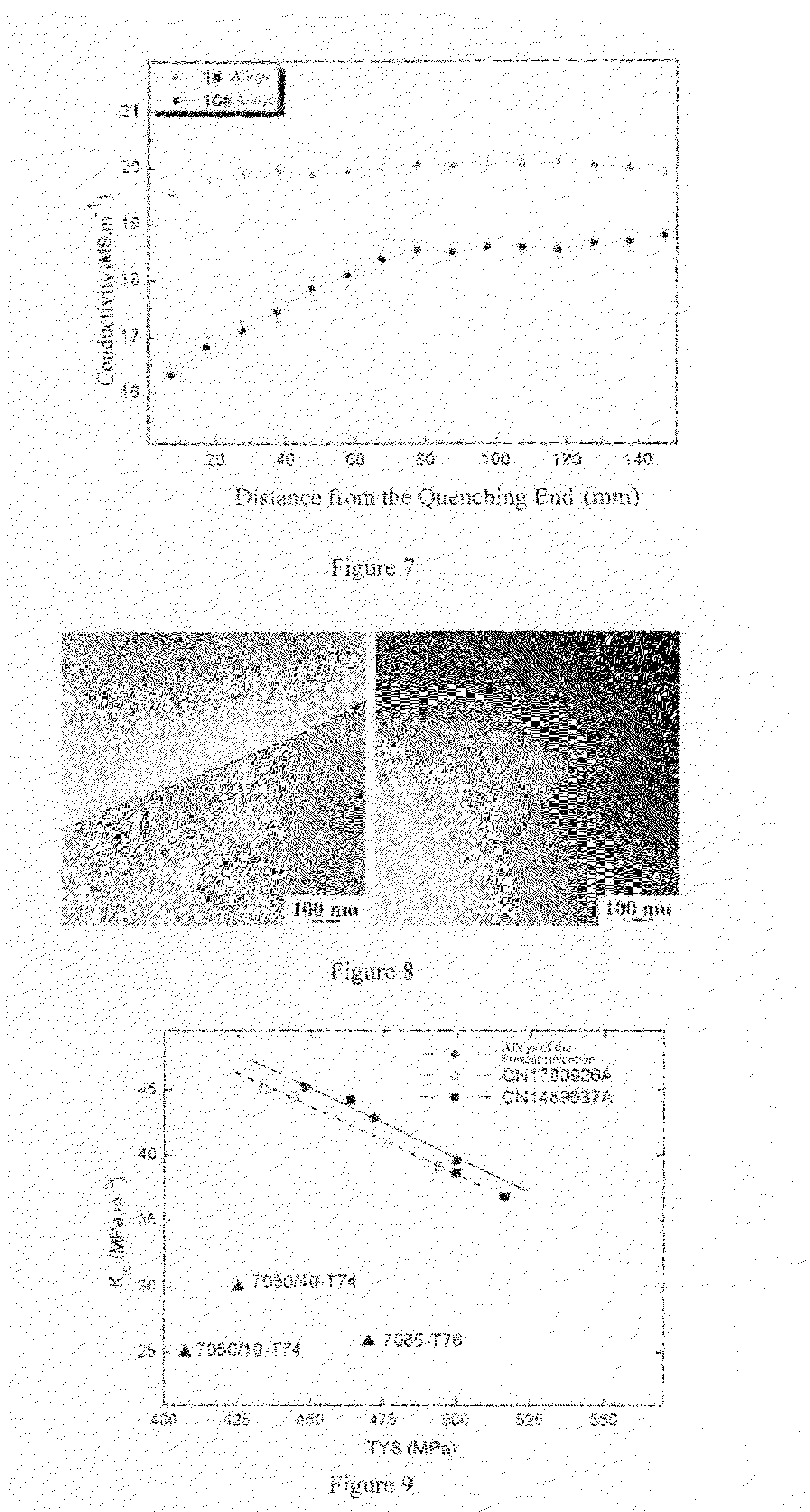

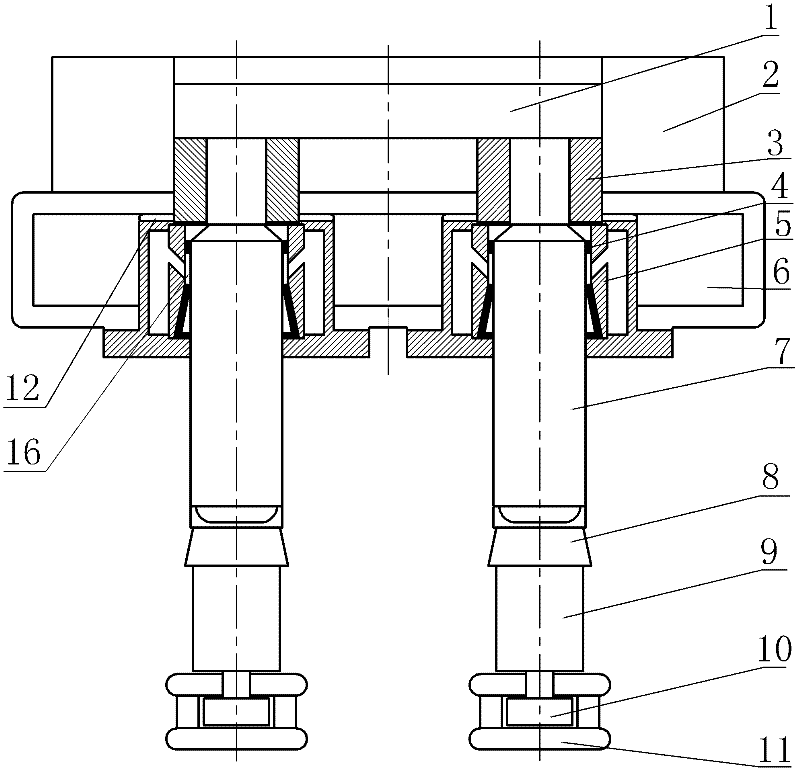

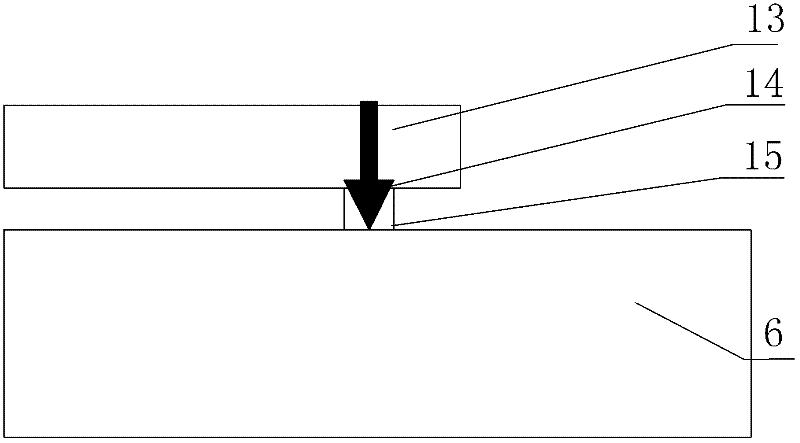

Aluminum alloy products for manufacturing structural components and method of producing the same

ActiveUS20110297278A1Improve performanceLarge thicknessHeat treatment process controlDamage toleranceDirect chill casting

An aluminium alloy product for manufacturing structural components, made from direct chill casting ingots comprises, based on wt %: Zn 7.5˜8.7, Mg 1.1˜2.3, Cu 0.5˜1.9, Zr 0.03˜0.20, the balance being Al, incidental elements and impurities. The levels of Zn, Mg, Cu, and Zr in the aluminum alloy products satisfy the expressions of (a) 10.5≦Zn+Mg+Cu≦11.0; (b) 5.3≦(Zn / Mg)+Cu≦6.0; and (c) (0.24−D / 4800)≦Zr≦(0.24−D / 5000). D is the minimum length of a line section connecting any two points on the periphery of the cross section of the ingot and passing through the geometrical center of the cross section. 250 mm≦D≦1000 mm. The aluminum alloy products have a superior combination of strength and damage tolerance, and exhibit homogeneous and consistent performance on the surface, at various depths under the surface, and in the core of the product. A method of producing the aluminum alloy products is also provided.

Owner:GRIMAT ENG INST CO LTD

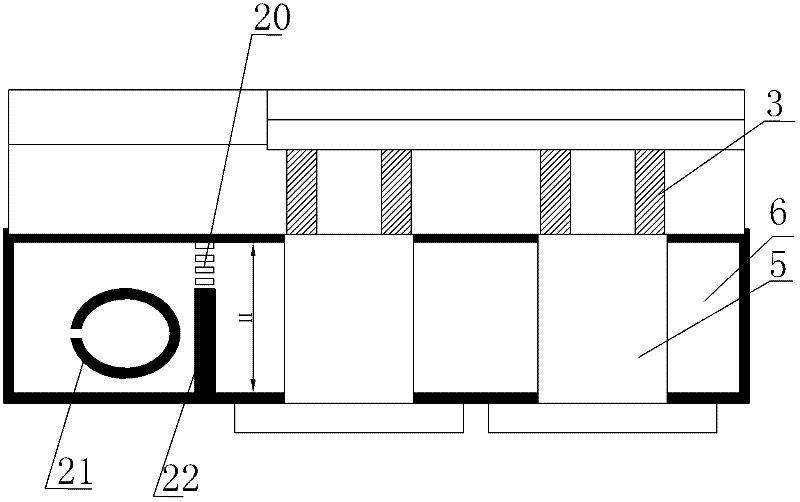

Equipment and method for casting plurality of aluminum alloy ingots with small diameters by using vertical direct chilling casting (DC)

The invention provides equipment and a method for casting a plurality of aluminum alloy ingots with small diameters by using vertical direct chilling casting (DC) and relates to the equipment and the method for casting the aluminum alloy ingots, which aim to solve the problems of low consistency of metal temperatures, low water cooling uniformity and high possibility of ingot suspension or tension fracture and flow running in each crystallizer in the process of casting the aluminum alloy ingots with the small diameters by the conventional technology for casting the plurality of aluminum alloy ingots with the small diameters by using the vertical DC. The method comprises the following steps of: communicating all branch outlets on runners with a plurality of upper end inlets of hot top caps correspondingly one by one; communicating the lower end outlet of each hot top cap with a crystallizer inlet of the crystallizer, wherein the distances between a flow storage slot and the runners of all crystallizers are same; heating a heat preserving sleeve to the temperature of between 100 and 150 DEG C; opening the outlet of a smelting furnace, feeding molten aluminum alloy into all the crystallizers through the runners, and performing water cooling; stopping for 5 to 10 seconds after the liquid level of the molten aluminum alloy in the runners reaches a preset position; and moving an ingot guiding device downwards. The surface of each ingot is smooth, does not have cracks and has small segregation tumors, and each ingot does not have air pores, is not loose and has small grains.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

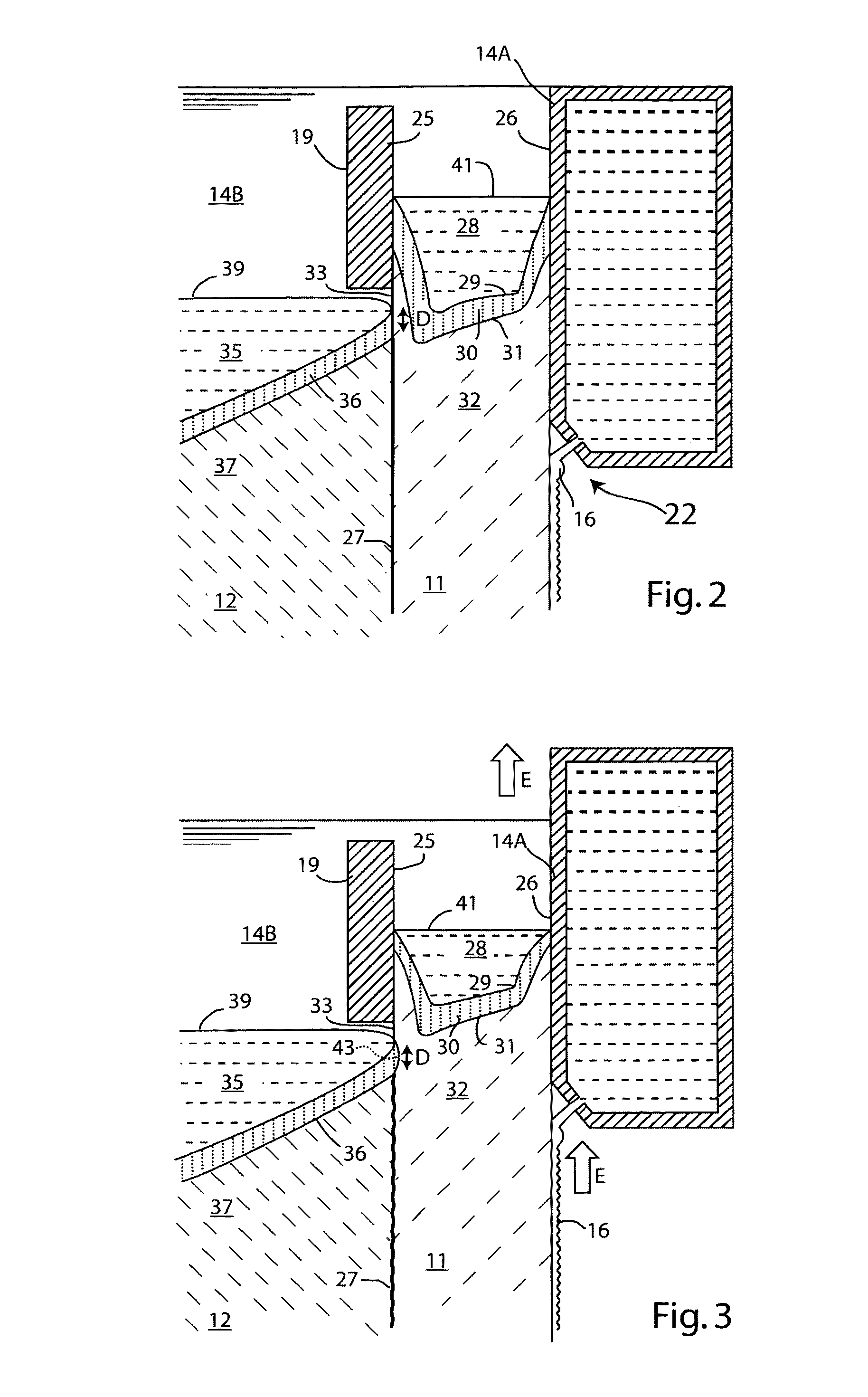

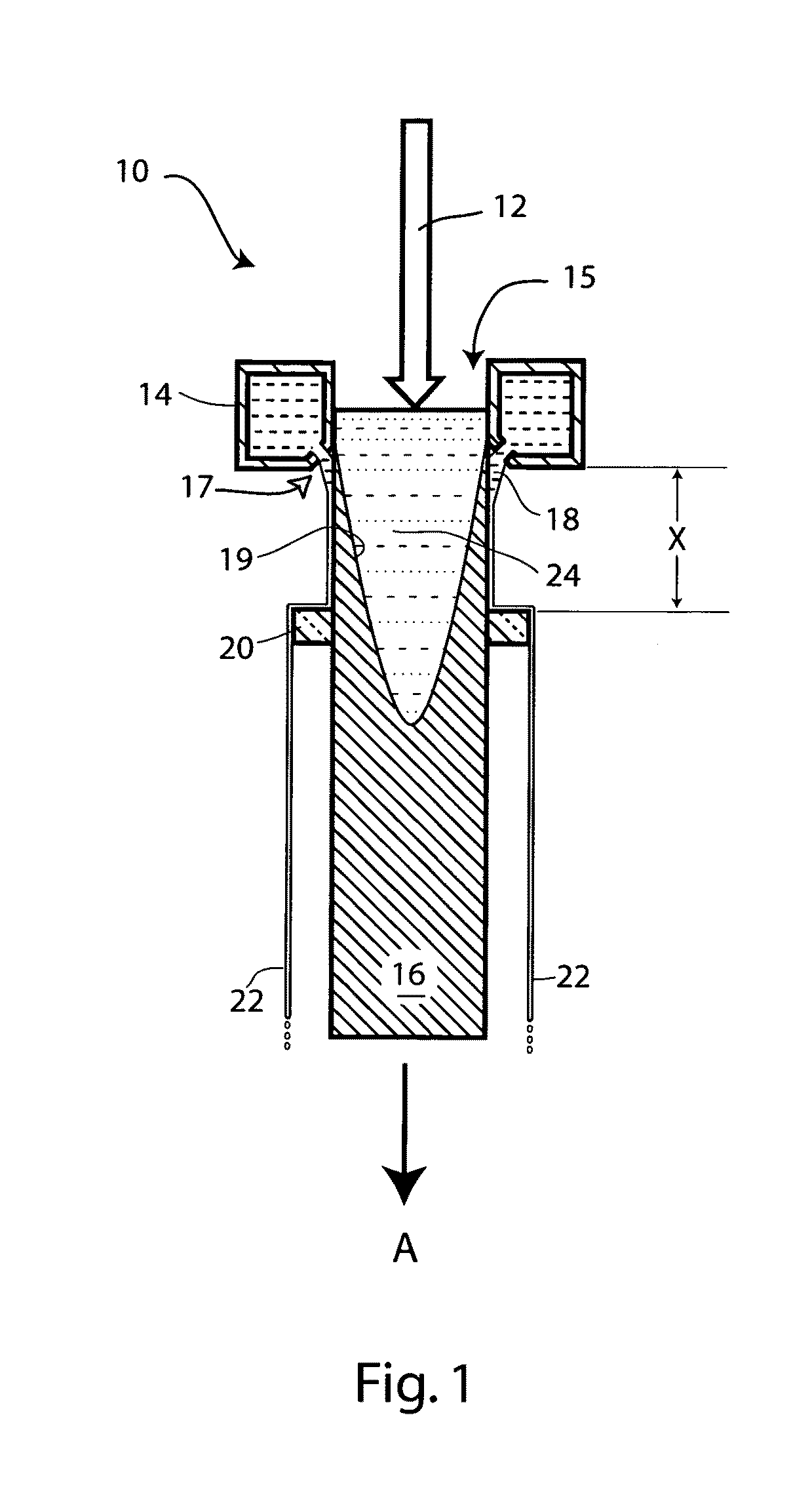

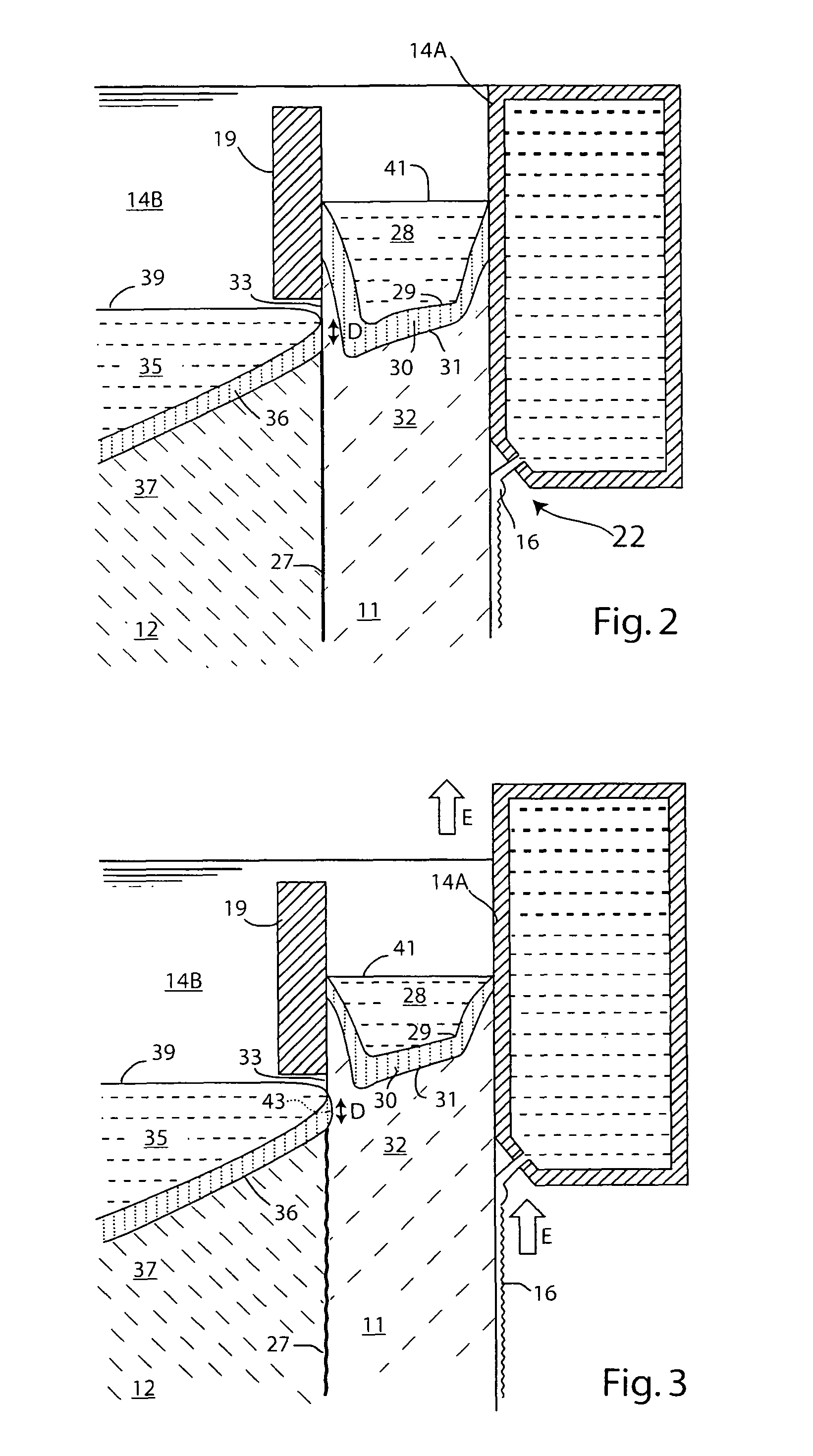

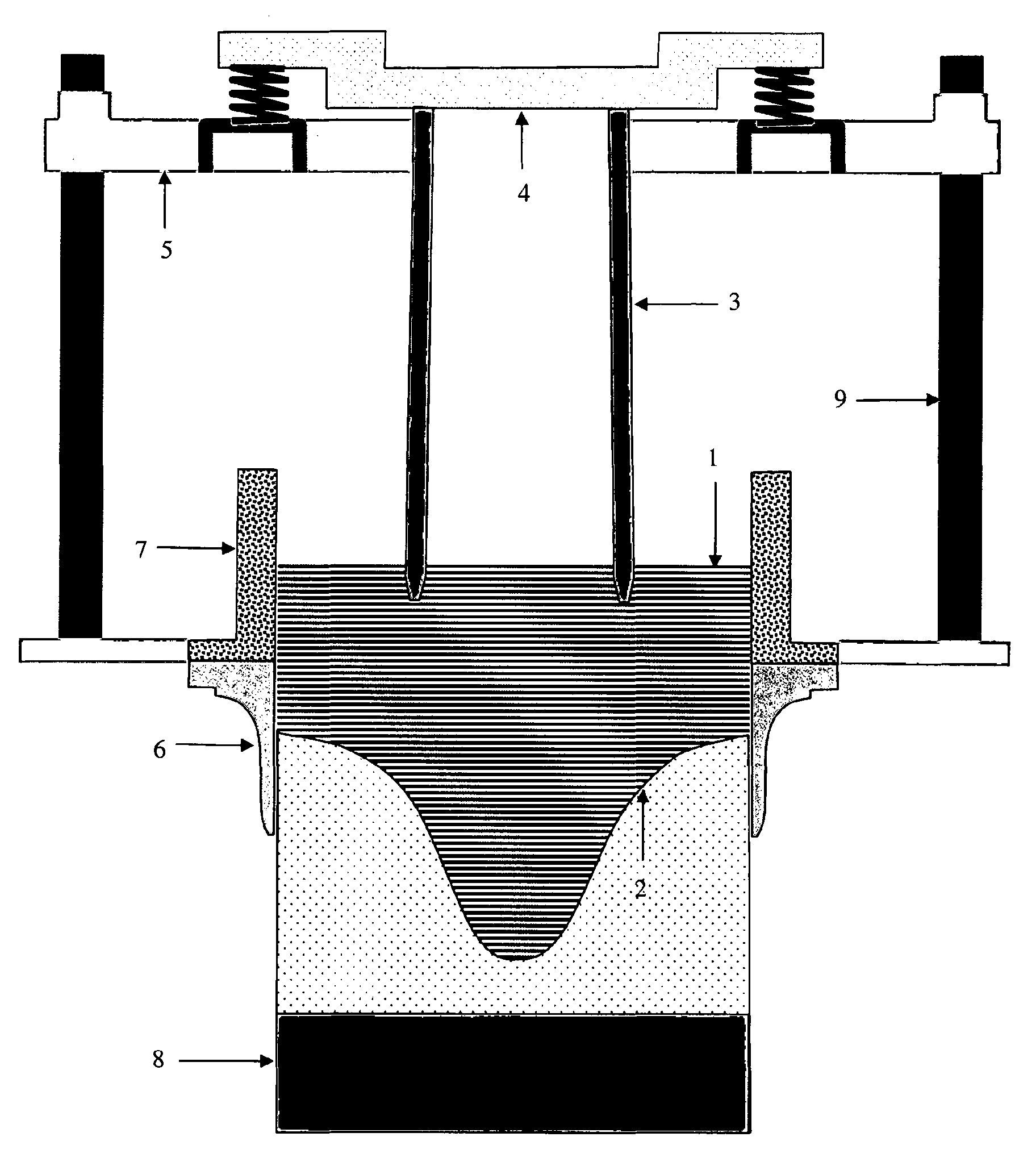

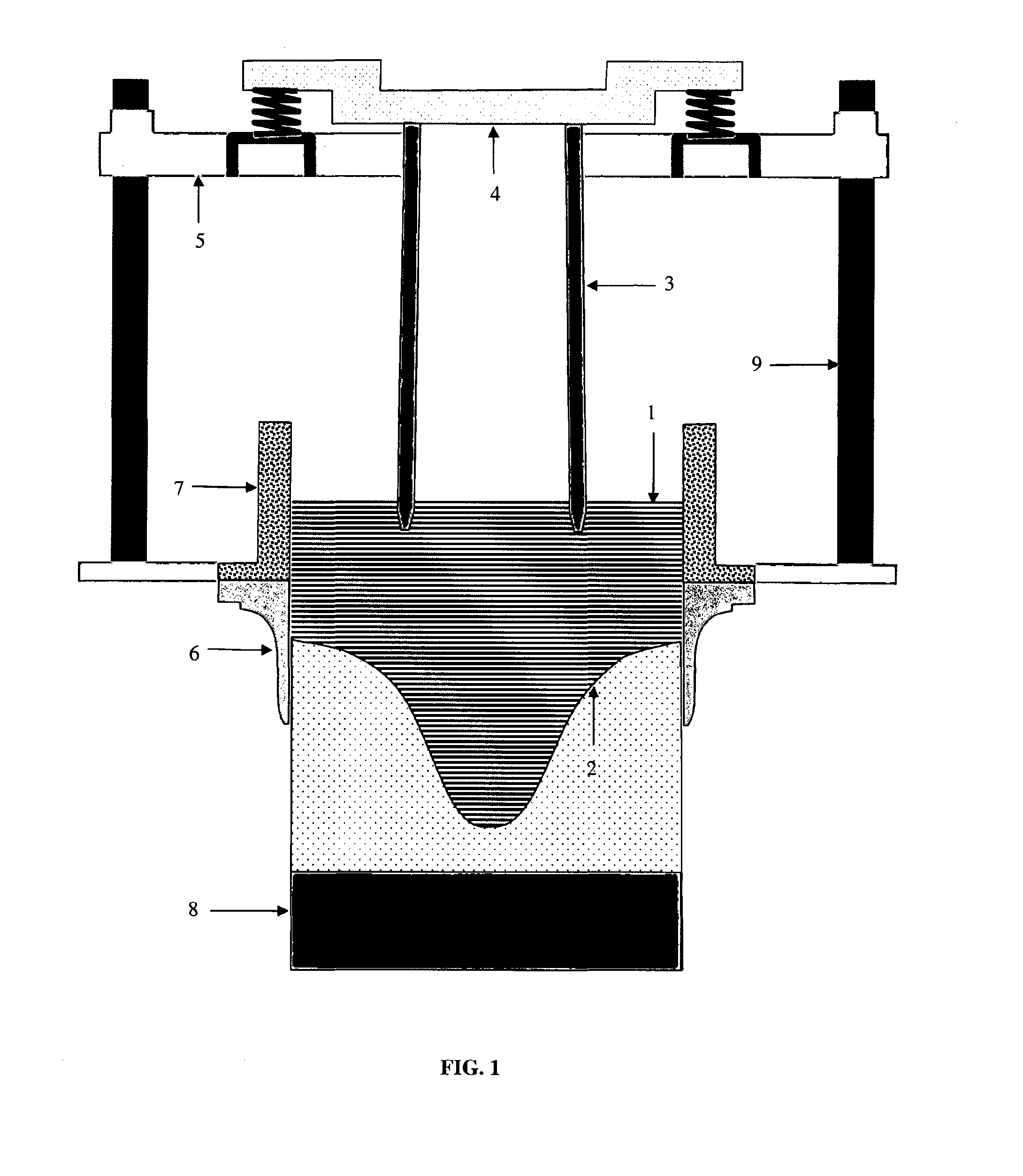

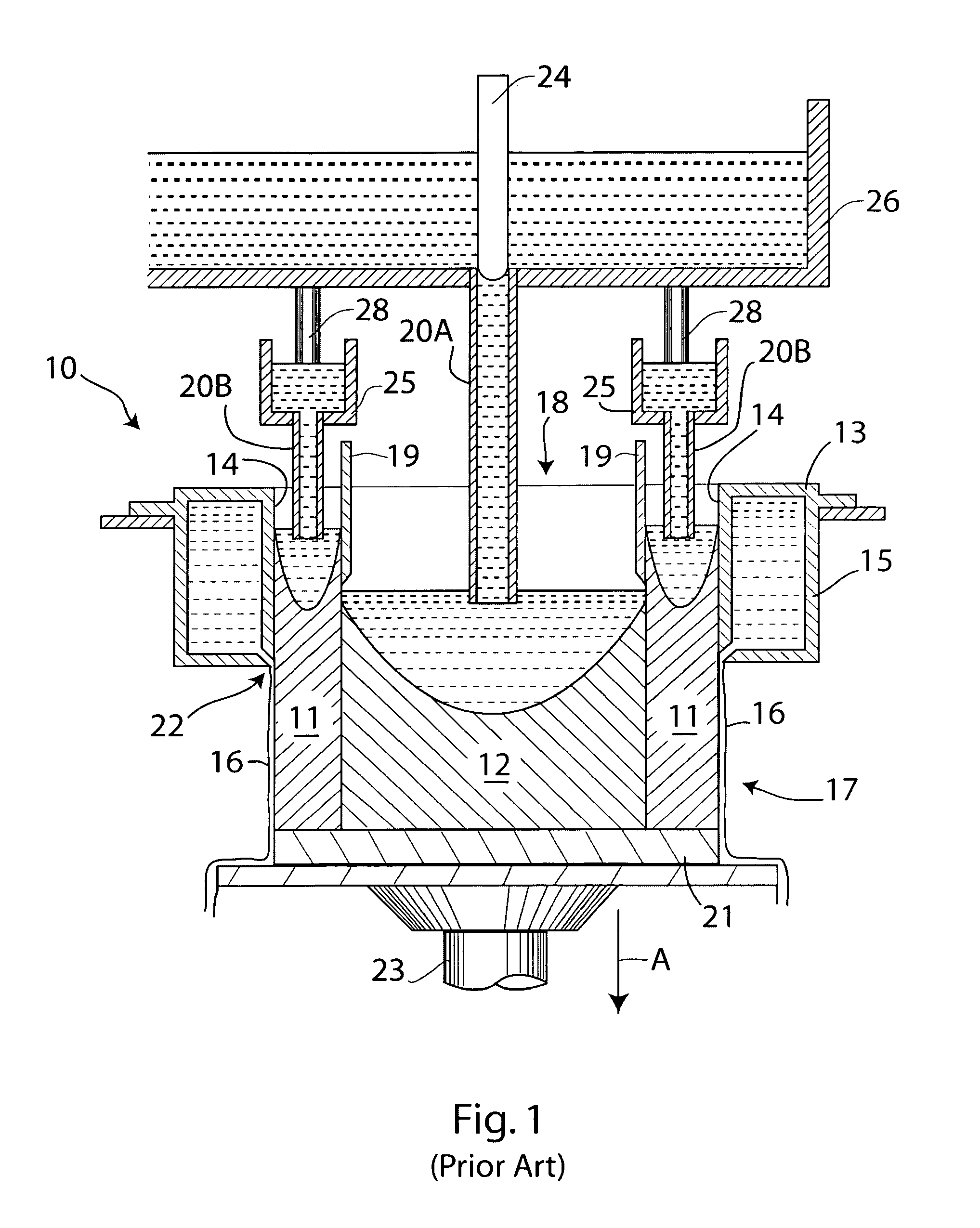

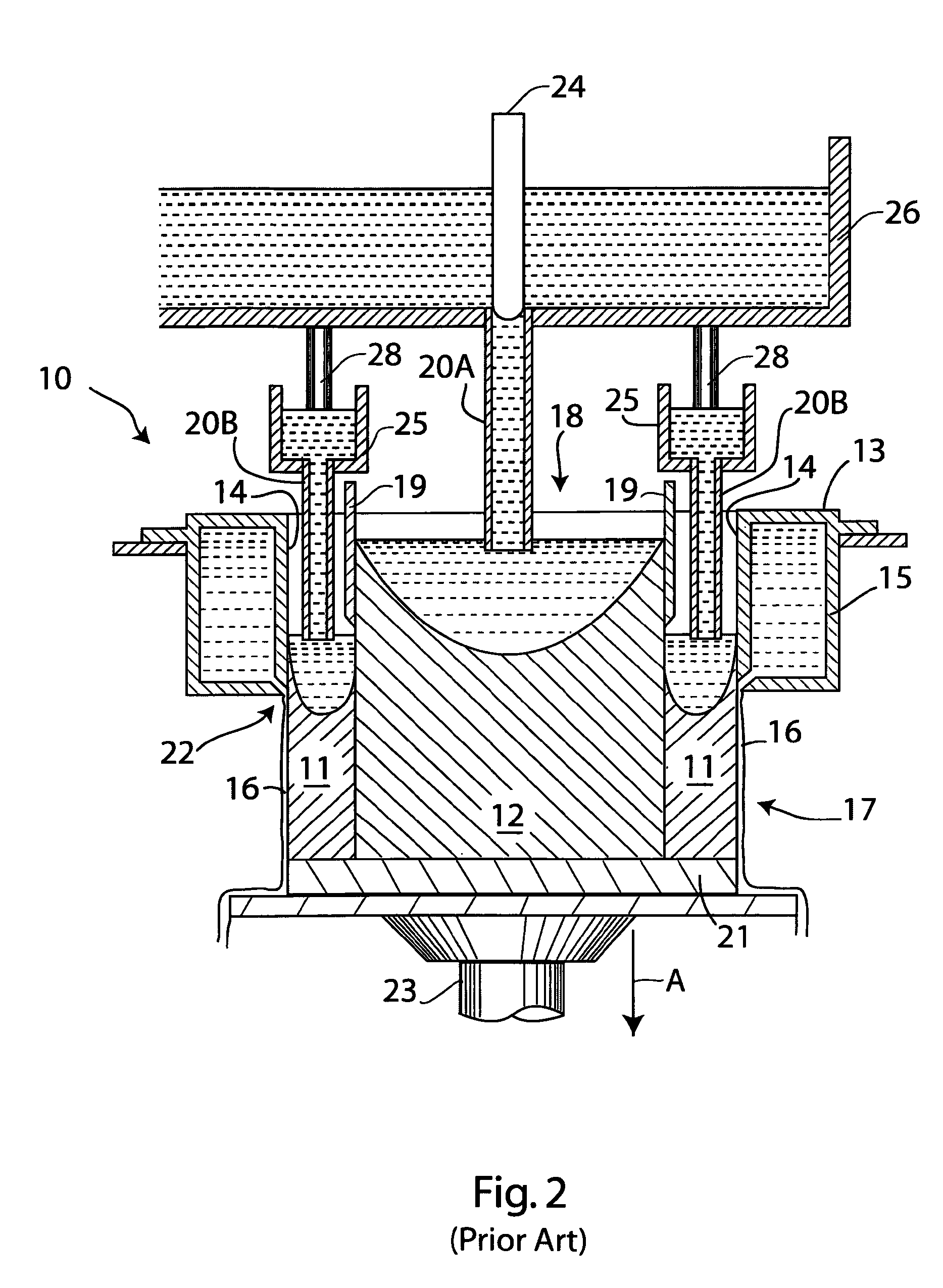

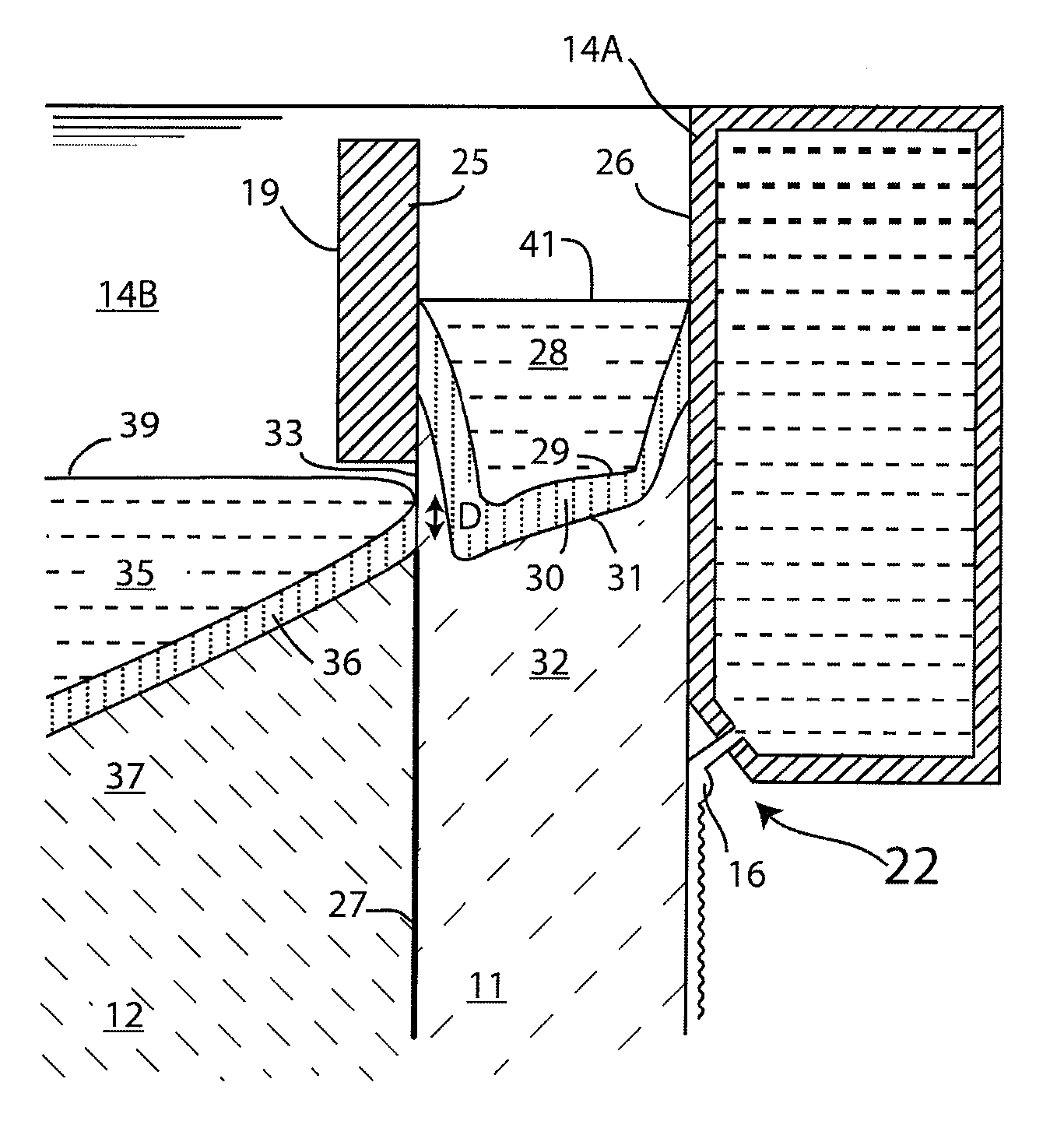

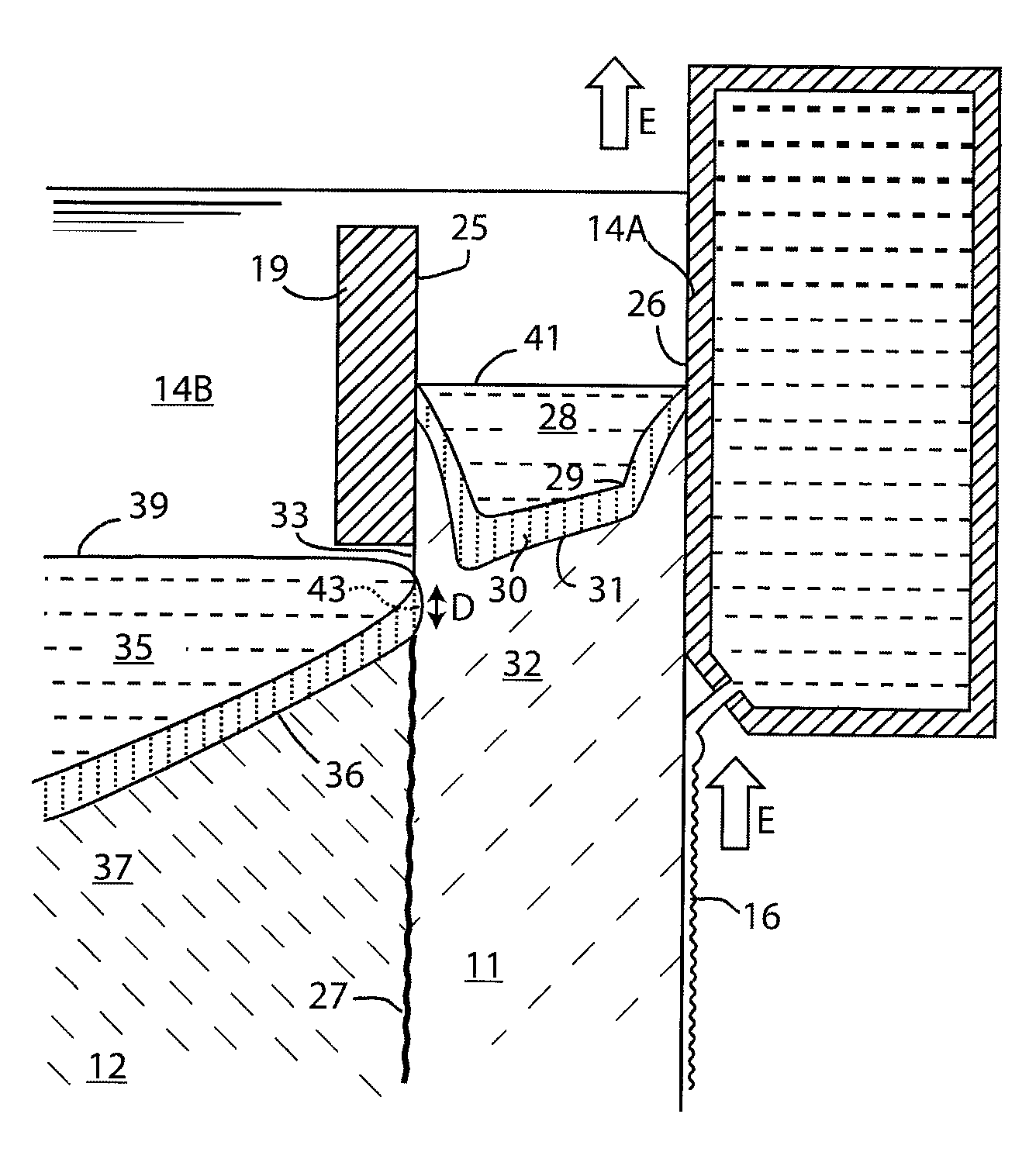

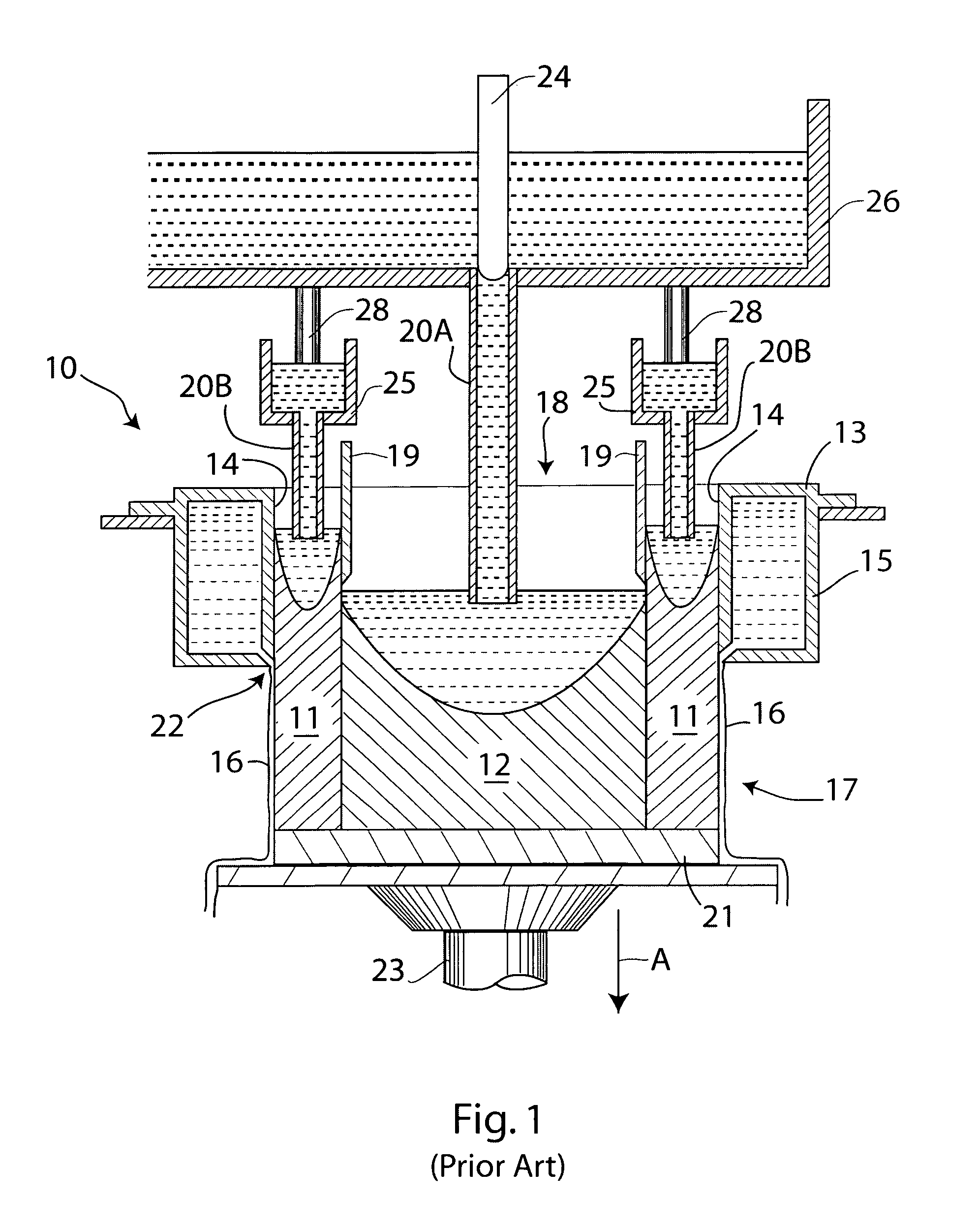

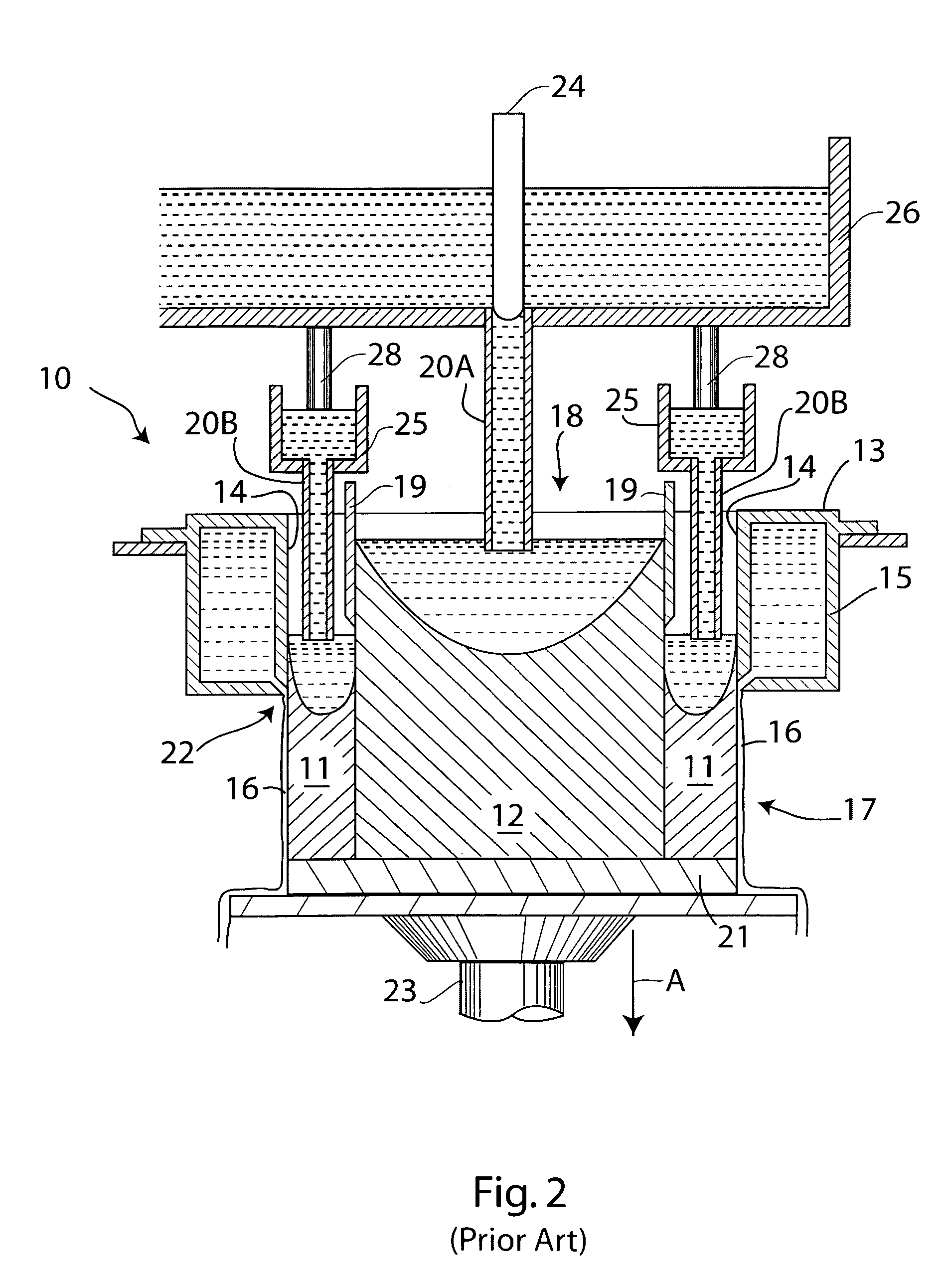

Sequential casting of metals having similar freezing ranges

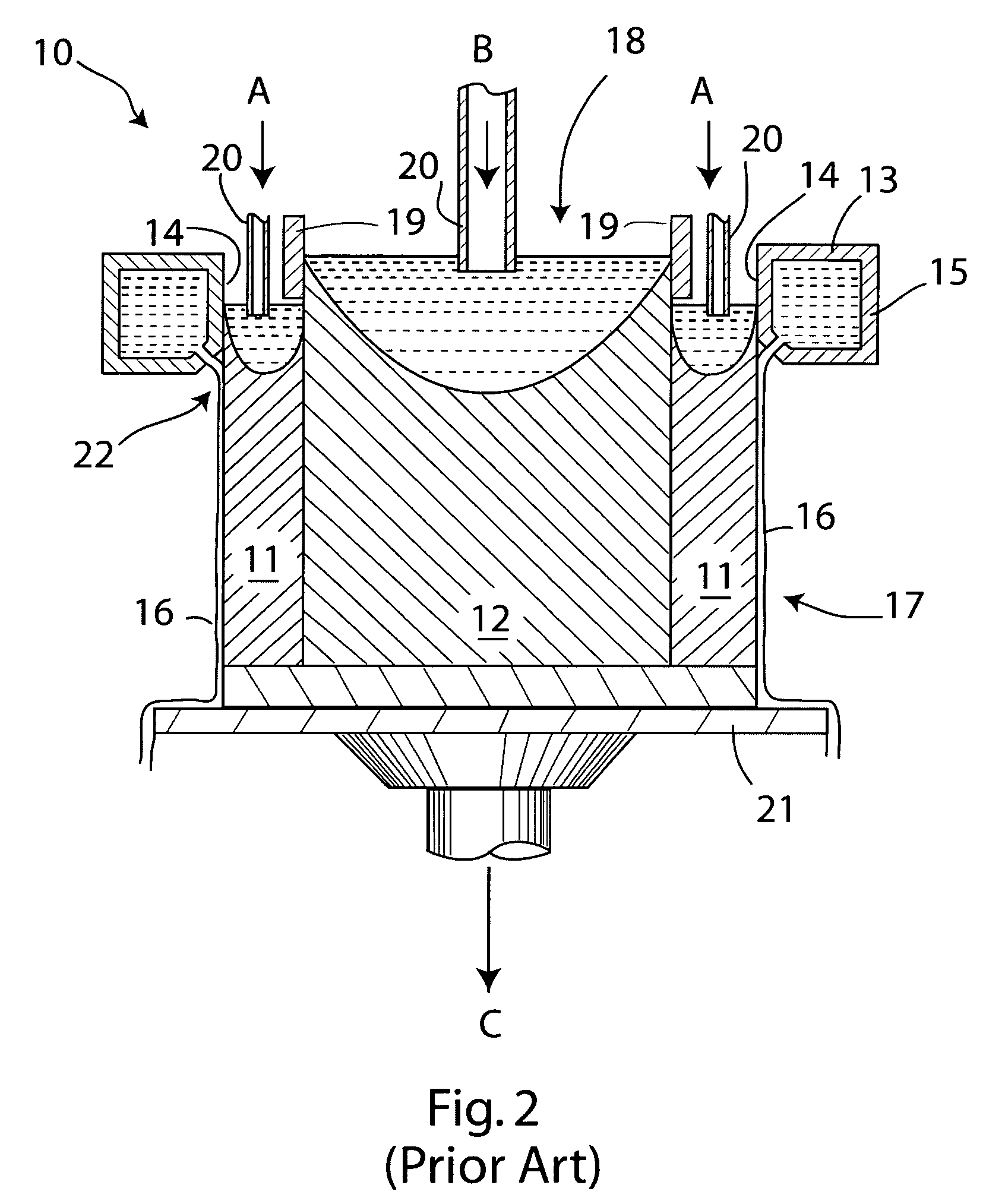

ActiveUS20100025003A1Add equipmentImproved techniqueMelt-holding vesselsIngot casting plantsWater flowDirect chill casting

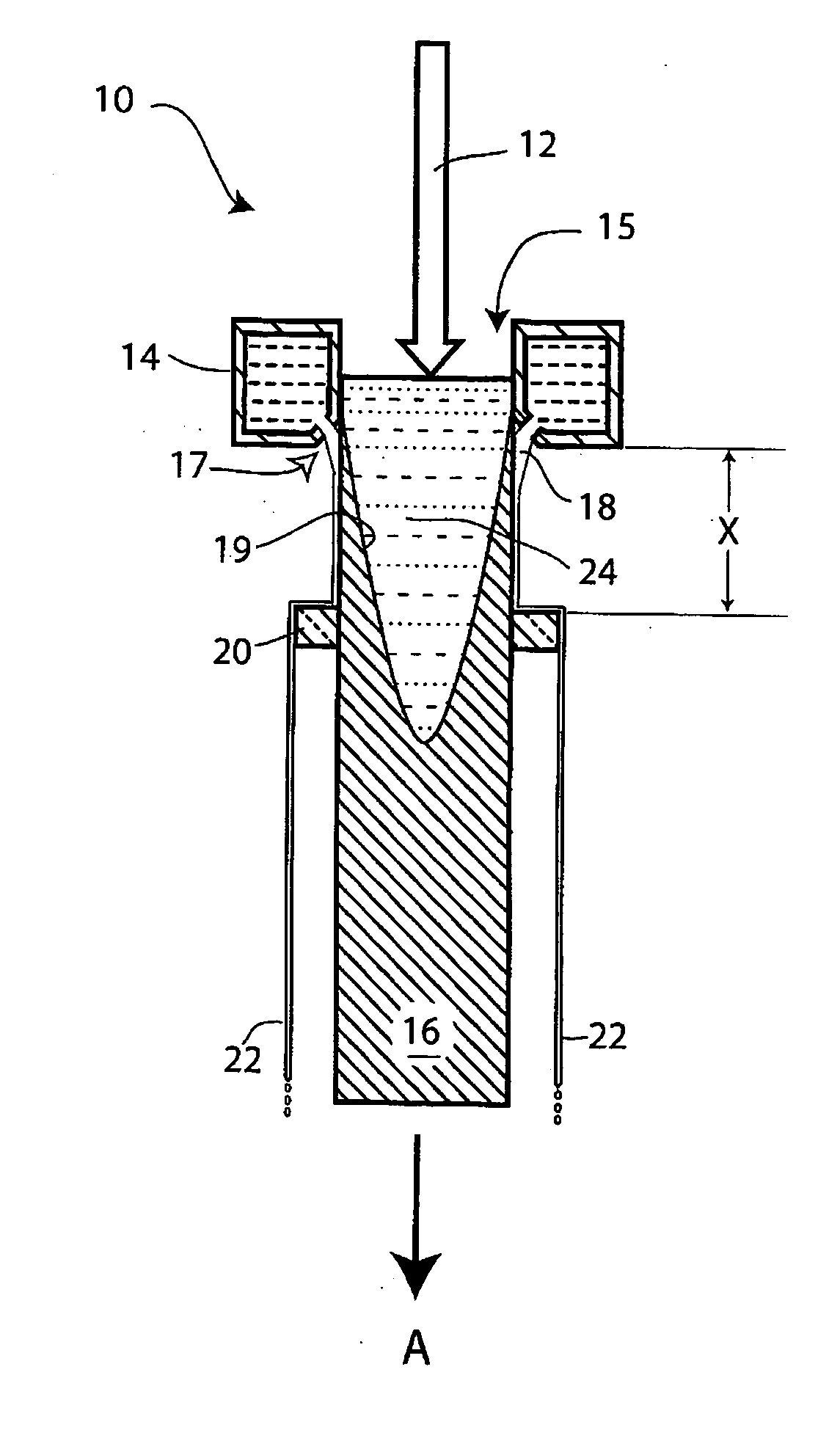

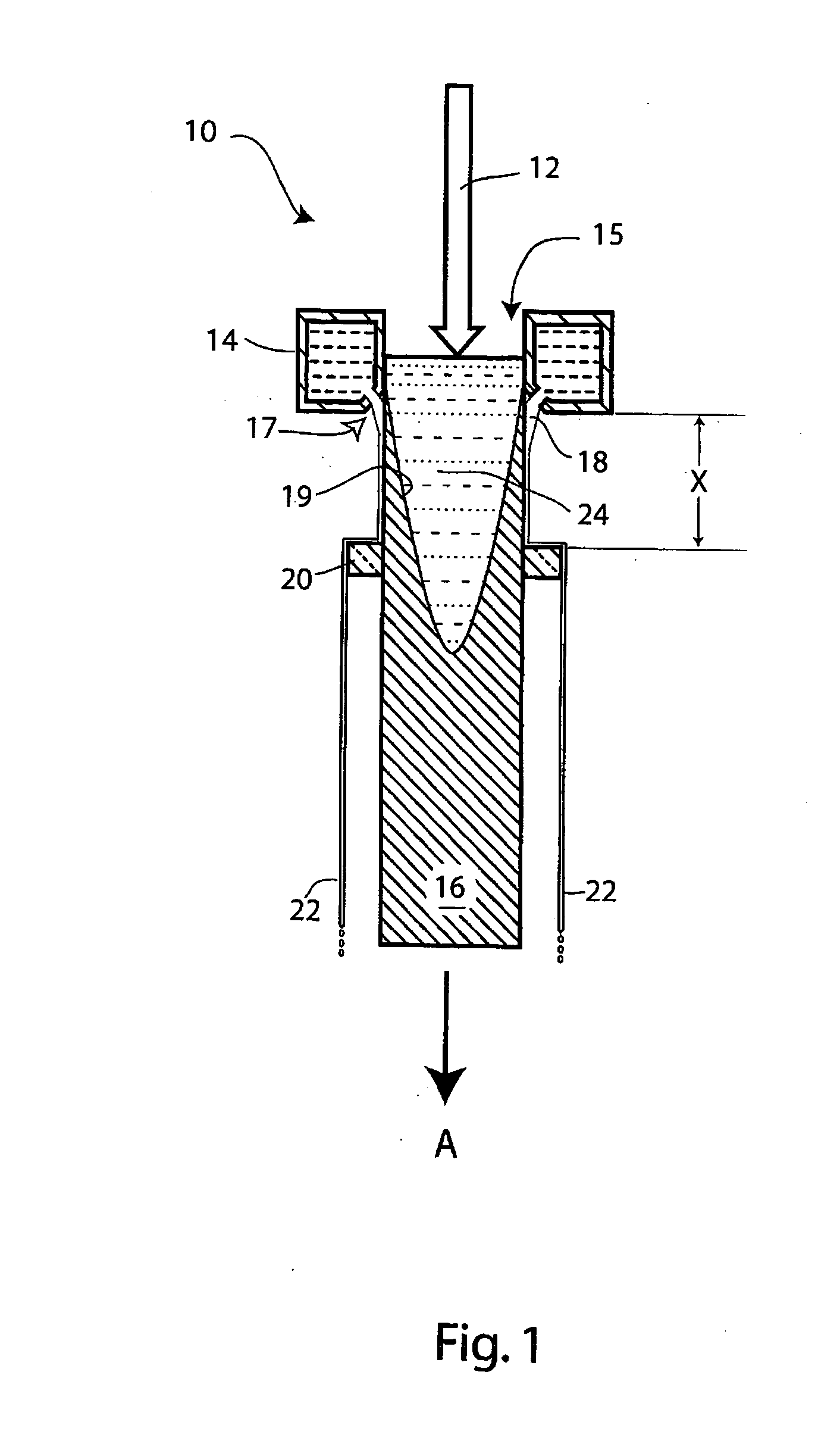

A method and apparatus is disclosed for sequentially direct chill casting a composite ingot made of metals having similar freezing ranges. Poor adhesion between the layers and low reliability of casting are addressed by adjusting the position of secondary cooling (created by applying water streams to the emerging ingot) relative to the upper surfaces of the molten metal pools compared to the conventional positions of first application of the secondary cooling. This can be achieved by moving one or more walls of the mold (when the secondary cooling emanates from the bottom of such walls), or adjusting the height of the molten metal pools within the mold and moving cooled divider walls between the pools. The relative temperatures and conditions of the metals at positions where they meet at the metal interface may therefore be optimized.

Owner:NOVELIS INC

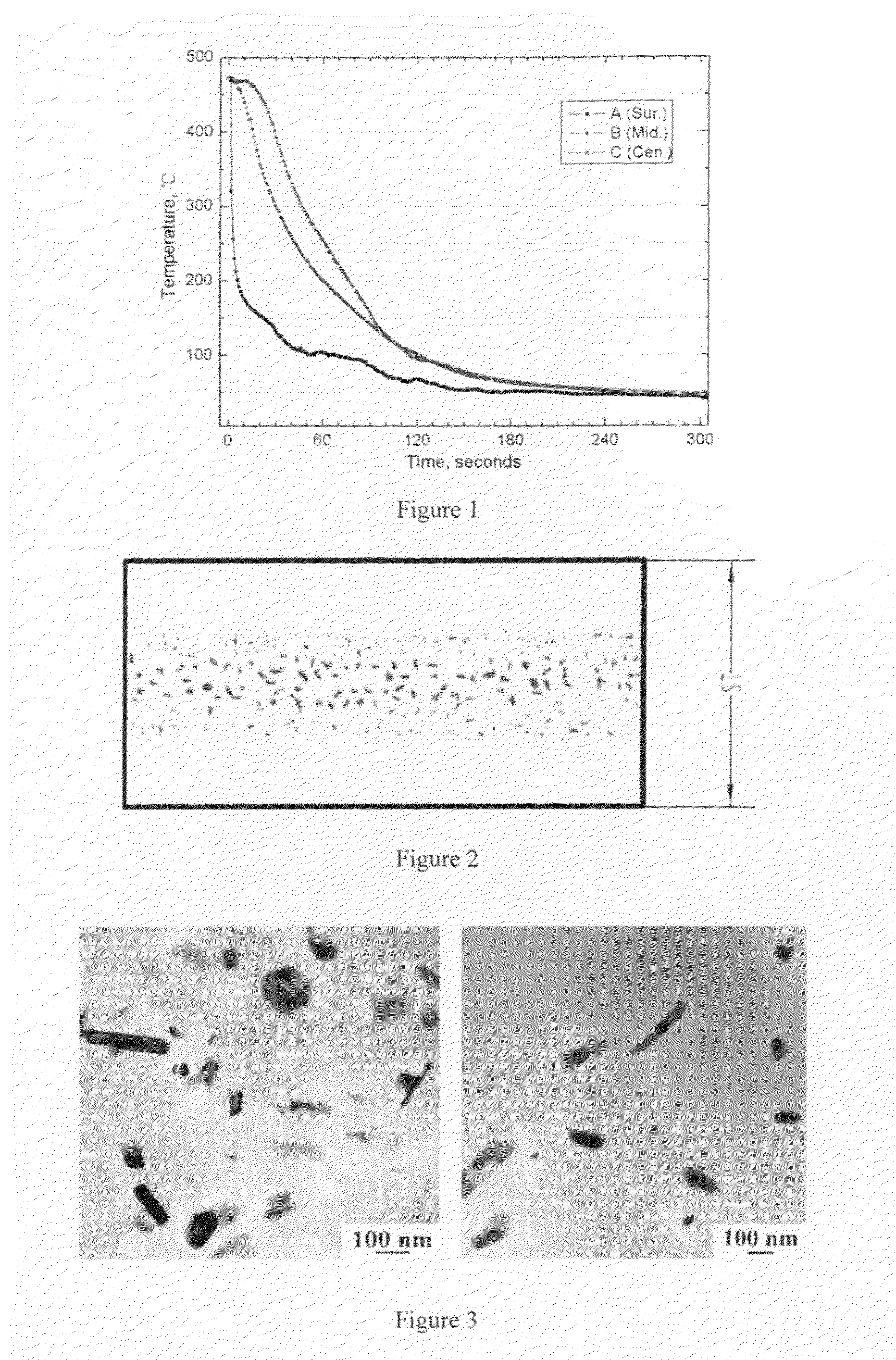

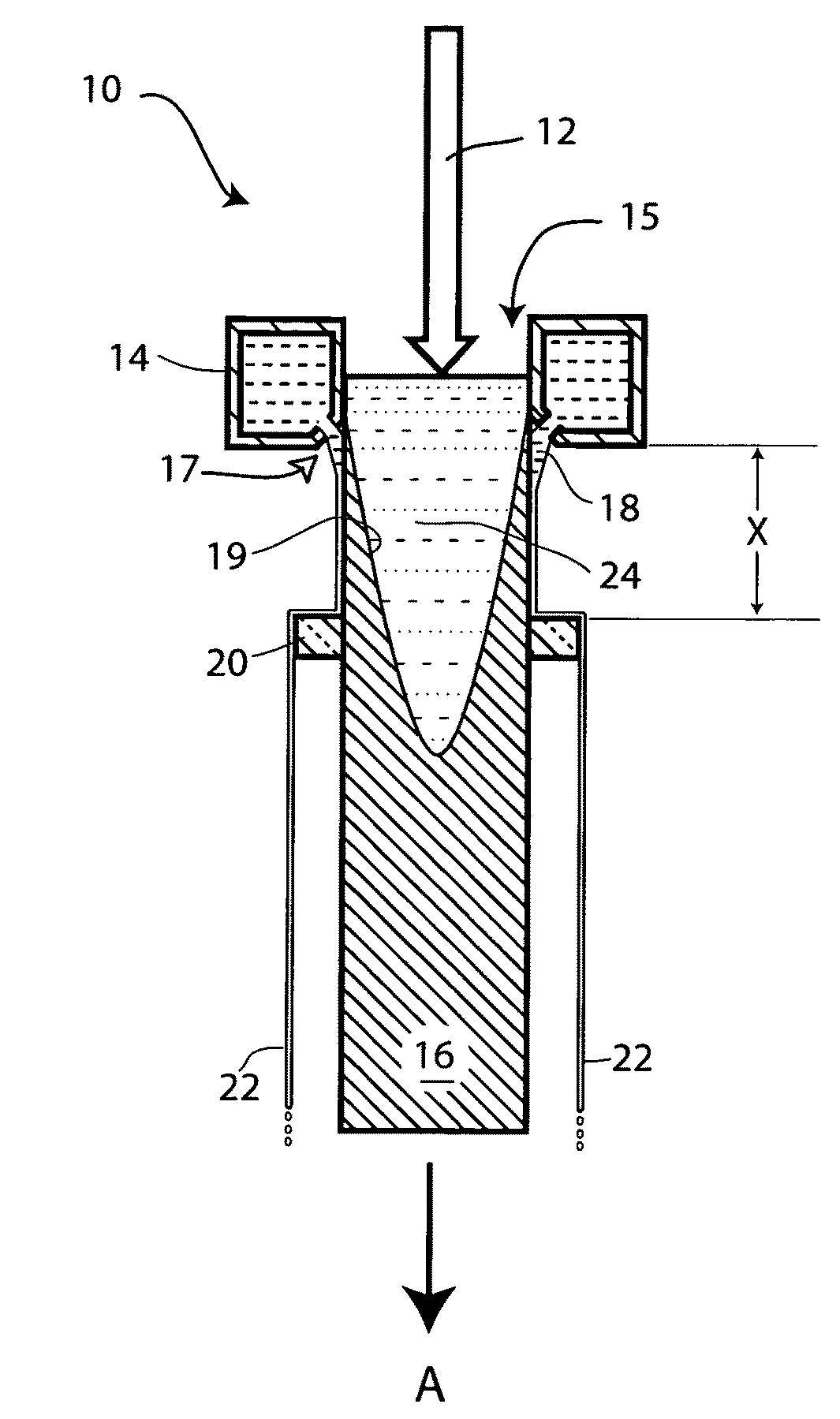

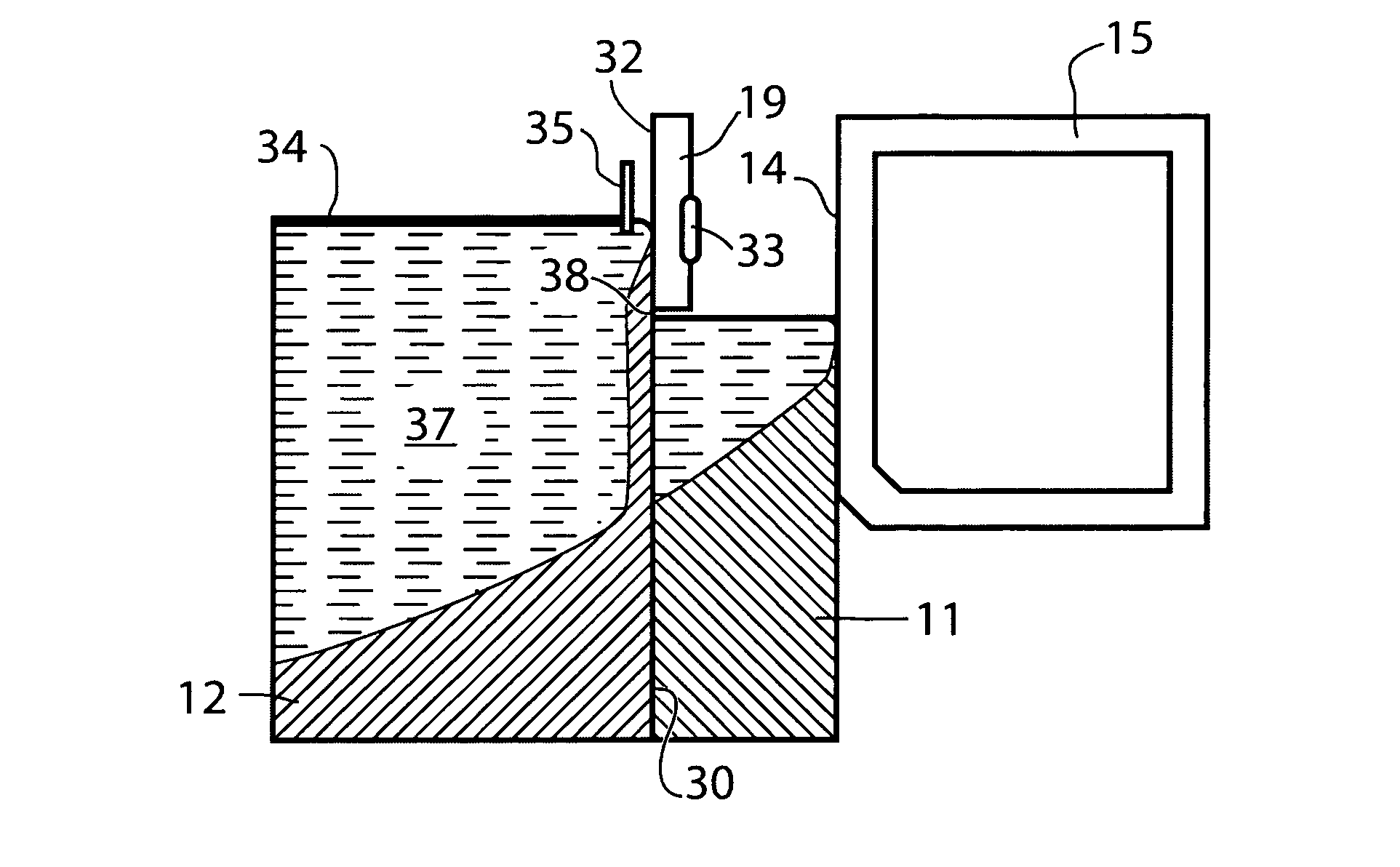

Homogenization and heat-treatment of cast metals

A method of casting a metal ingot with a microstructure that facilitates further working, such as hot and cold rolling. The metal is cast in a direct chill casting mold, or the equivalent, that directs a spray of coolant liquid onto the outer surface of the ingot to achieve rapid cooling. The coolant is removed from the surface at a location where the emerging embryonic ingot is still not completely solid, such that the latent heat of solidification and the sensible heat of the molten core raises the temperature of the adjacent solid shell to a convergence temperature that is above a transition temperature for in-situ homogenization of the metal. A further conventional homogenization step is then not required. The invention also relates to the heat-treatment of such ingots prior to hot working.

Owner:NOVELIS INC

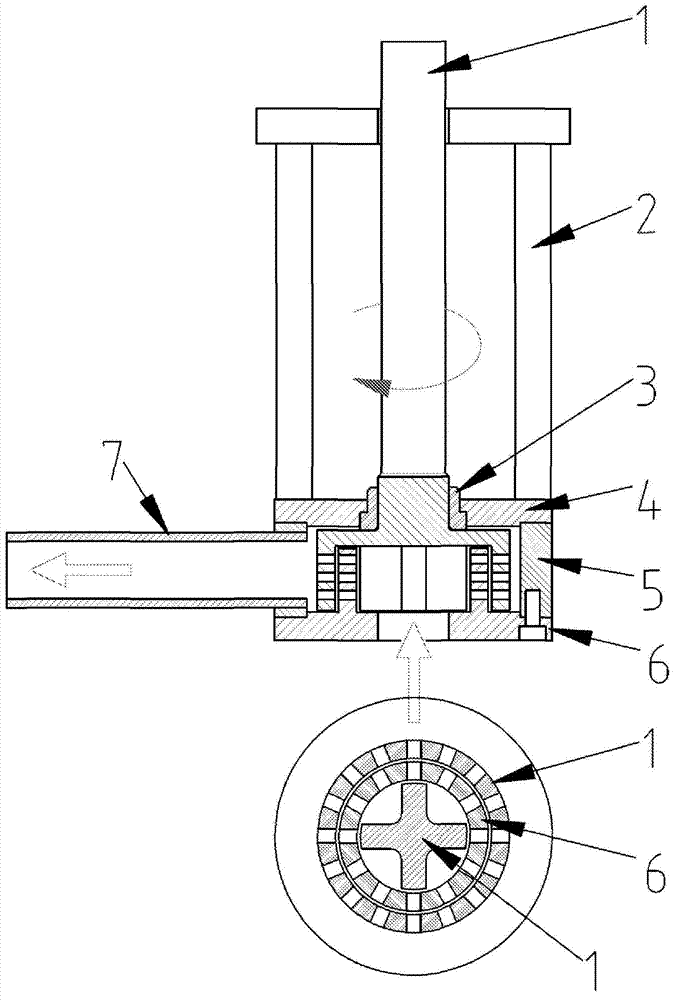

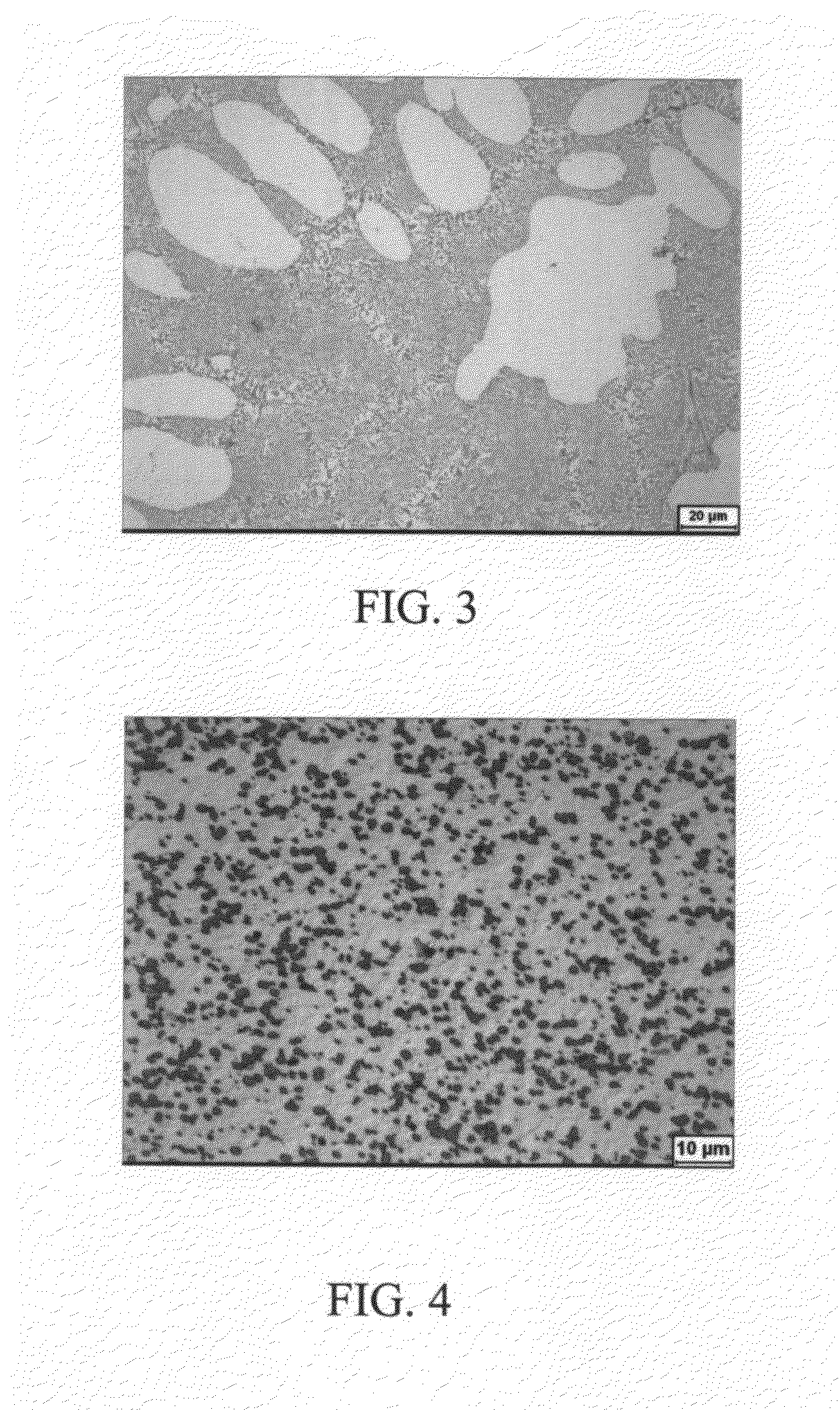

Apparatus and method for liquid metals treatment

ActiveUS20130228045A1Improve efficiencySpeed up chemical reactionsStirring devicesCasting apparatusParticulatesGas phase

This invention relates to an apparatus (high shear device) and method for treating liquid metals by intensive melt shearing. The apparatus comprises a stator and a rotor with a small gap between them to provide intensive melt shearing for dispersing efficiently and distributing uniformly gas, liquid and solid phases in liquid metals without severe turbulence at the melt surface. The device can be extended to a multistage high shear pump by arranging individual rotor / stator assemblies either concentrically (one in another) or vertically. The device and high shear pump can be readily integrated into existing casting processes. The device is suitable for use in casting processes including high pressure die casting, low pressure die casting, gravity die casting, sand casting, investment casting, direct chill casting, twin roll casting, and any other casting process which requires liquid metal as a feedstock. In addition, the device is particularly suitable for providing conditioned liquid metal for both shape casting and continuous (or semi-continuous) casting of metallic materials, preparing high quality semi-solid slurries, solidification processing of particulate reinforced metal matrix composites, mixing immiscible metallic liquids and degassing of liquid metals prior to any casting processes.

Owner:BRUNEL UNIVERSITY

High strength aluminum casting alloy

The present invention discloses a high strength Al—Zn—Mg—Cu (7000 series) alloy that can be cast, the cast alloy having a tensile strength of at least 500 megapascals (MPa) and 4% elongation. The cast alloy composition can include about 5.5-9.0 weight percent (wt. %) of zinc, 2.0-3.5 wt. % of magnesium, 0.1-0.5 wt. % scandium, 0.05-0.20 wt. % zirconium, 0.5-3.0 wt. % copper, 0.10-0.45 wt. % manganese, 0.01-0.35 wt. % iron, 0.01-0.20 wt. % silicon with a balance of aluminum and possible casting impurities. The alloy also has good fluidity comparable to high silicon cast aluminum alloys and components can be manufactured using direct chill casting, sand casting, and / or sand casting under high pressure.

Owner:RAO UES

Homogenization and heat-treatment of cast metals

A method of casting a metal ingot with a microstructure that facilitates further working, such as hot and cold rolling. The metal is cast in a direct chill casting mold, or the equivalent, that directs a spray of coolant liquid onto the outer surface of the ingot to achieve rapid cooling. The coolant is removed from the surface at a location where the emerging embryonic ingot is still not completely solid, such that the latent heat of solidification and the sensible heat of the molten core raises the temperature of the adjacent solid shell to a convergence temperature that is above a transition temperature for in-situ homogenization of the metal. A further conventional homogenization step is then not required. The invention also relates to the heat-treatment of such ingots prior to hot working.

Owner:NOVELIS INC

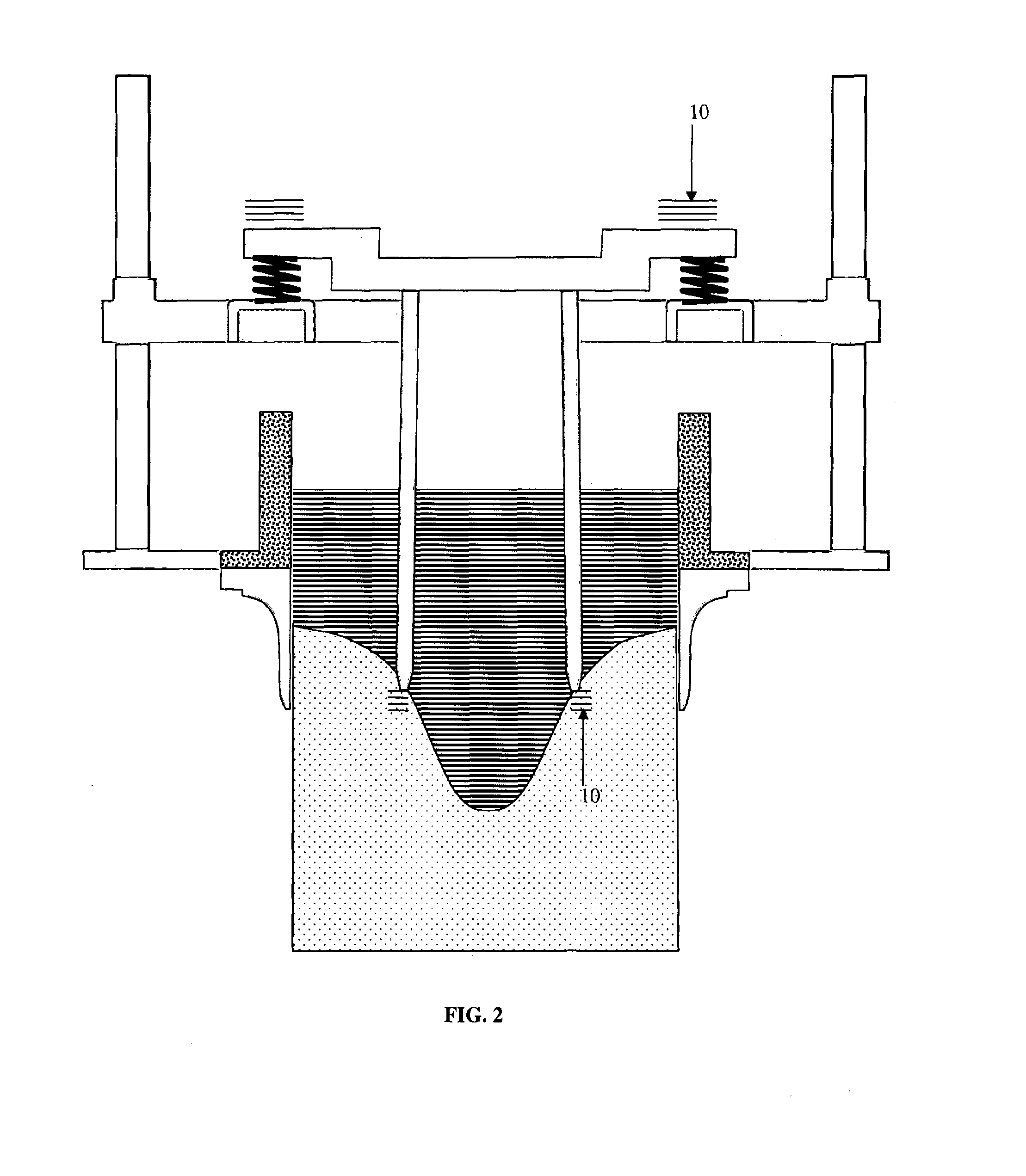

Elimination of shrinkage cavity in cast ingots

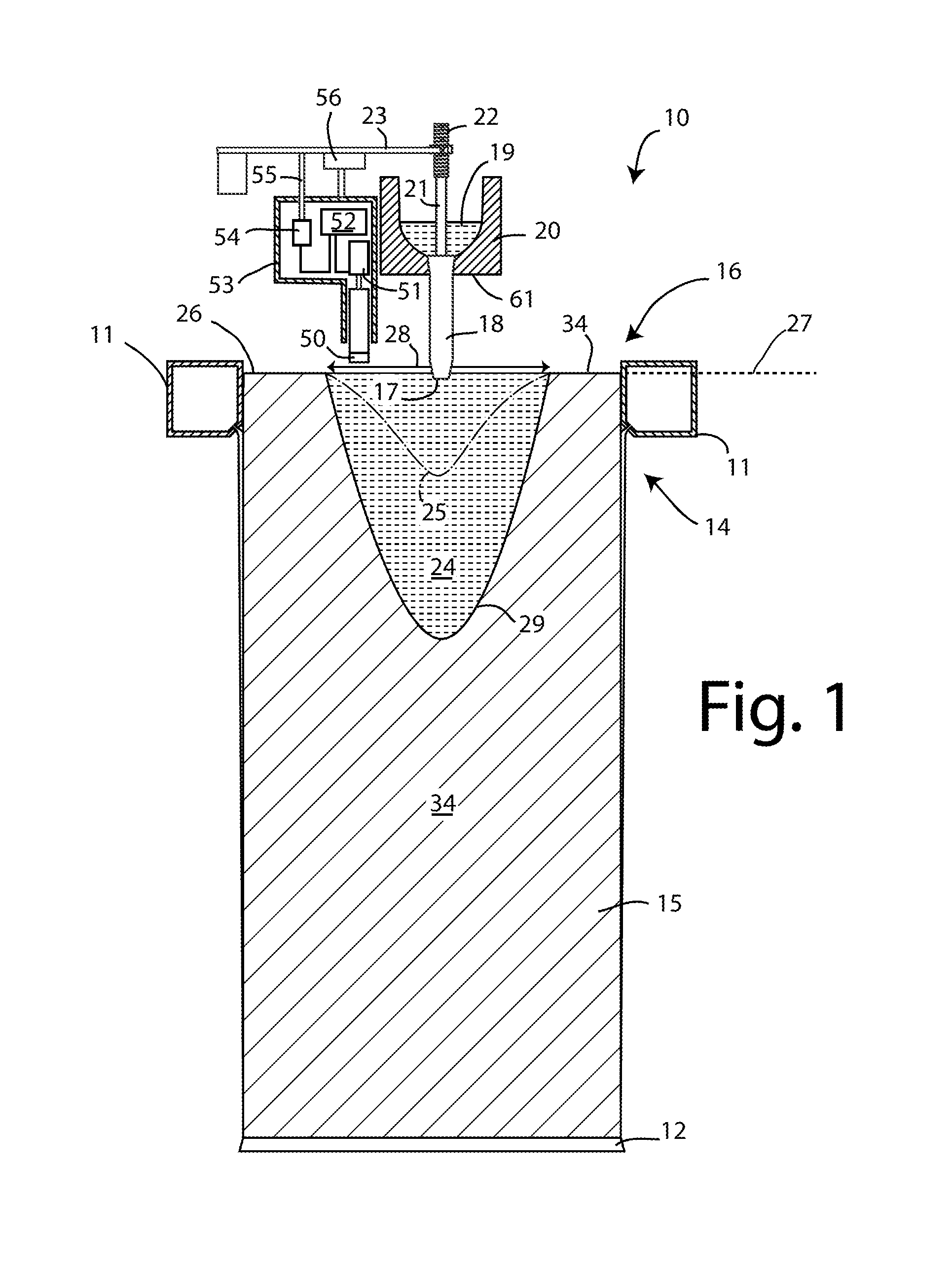

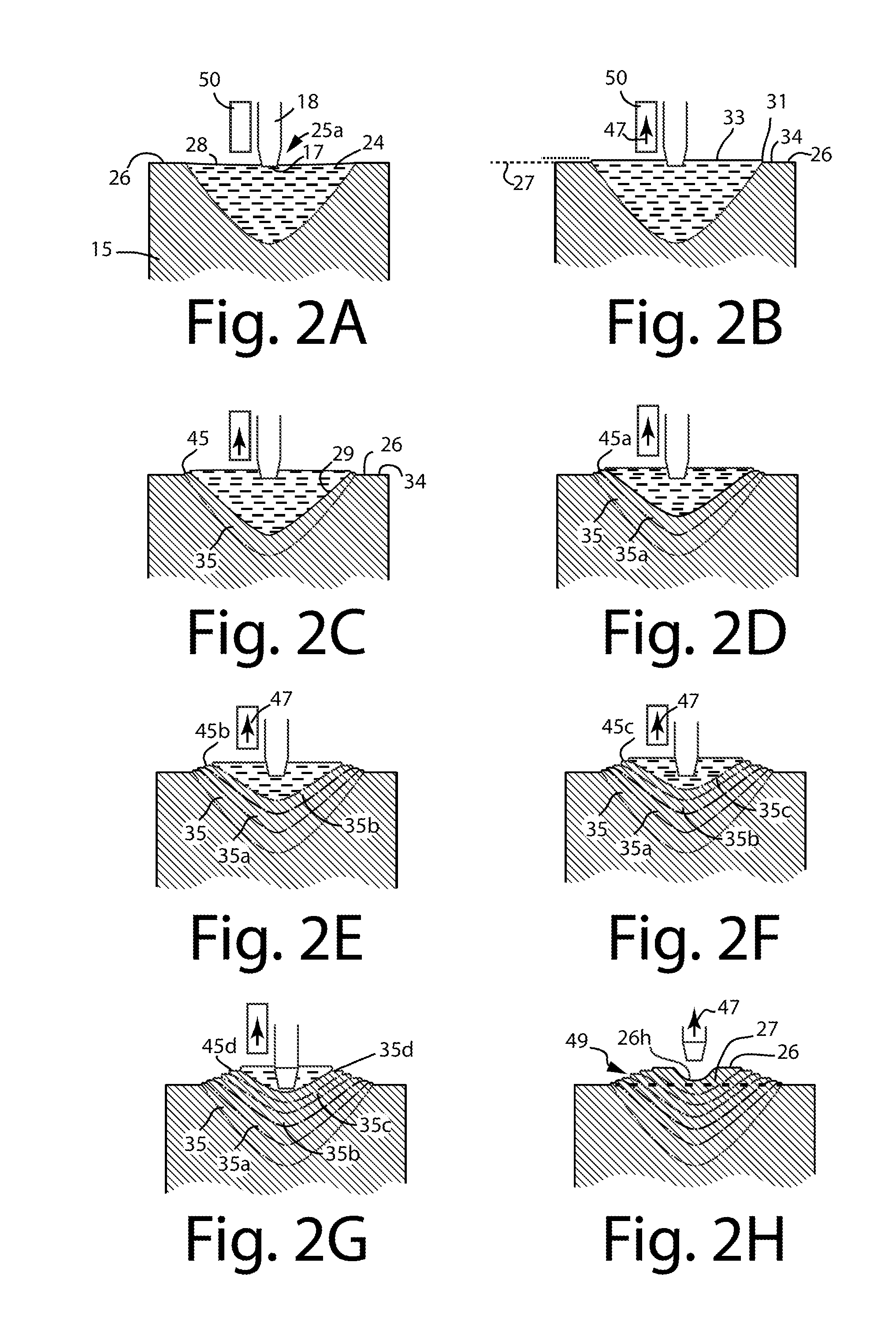

An exemplary embodiment provides a method of eliminating a shrinkage cavity in a metal ingot cast by direct chill casting. The method involves casting an upright ingot having an upper surface at an intended height. Upon completion of the casting, the lower tip of the spout is maintained below the molten metal near the center of the upper surface. The metal flow through the spout is terminated and a partial shrinkage cavity is allowed to form as metal of the ingot shrinks and contracts. Before the partial cavity exposes the lower tip of the spout, the cavity is preferably over-filled with molten metal, while avoiding spillage of molten metal, and then the flow of metal through the spout is terminated. These steps are repeated until no further contraction of the metal causes any part of the upper surface to contract below the intended ingot height.

Owner:NOVELIS INC

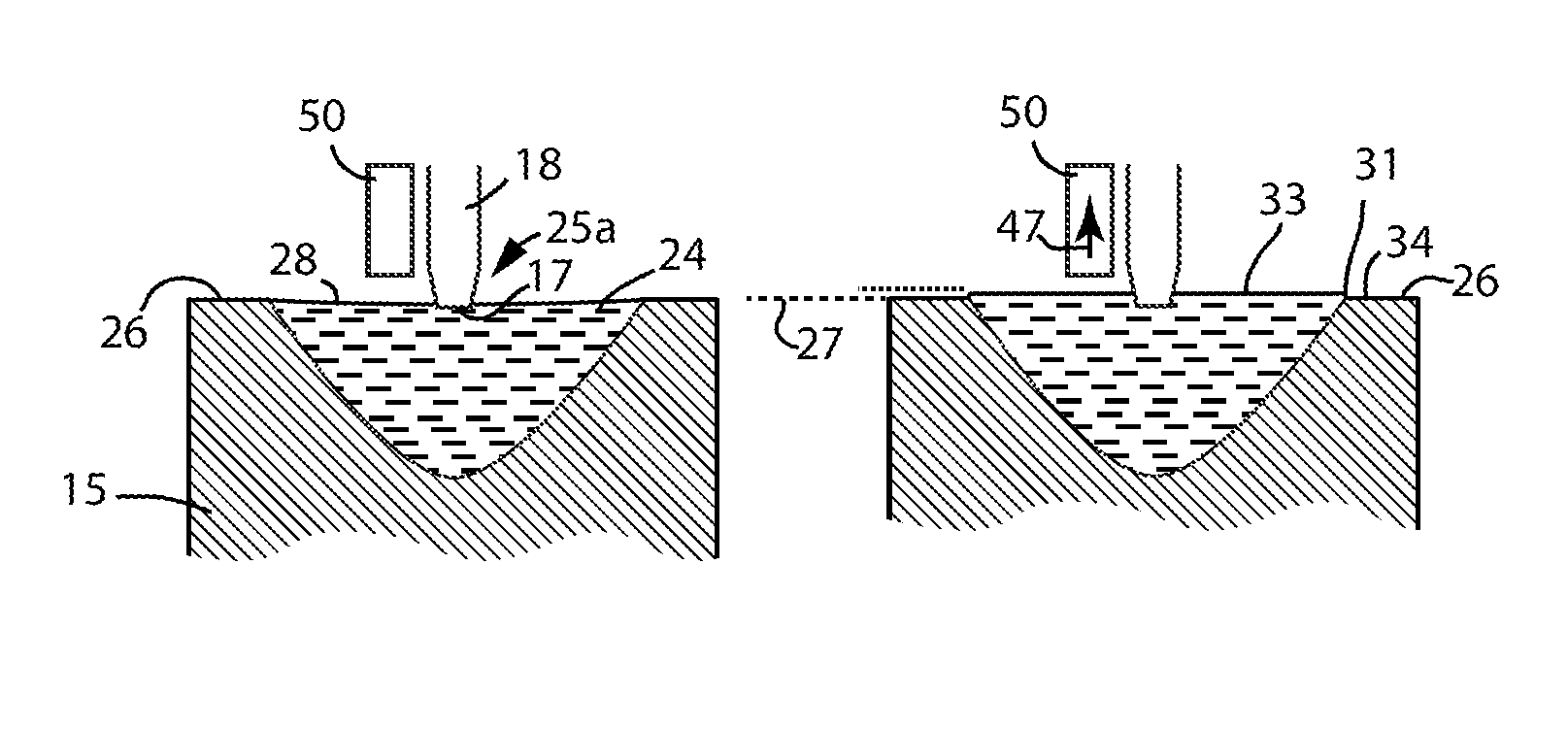

Oxide restraint during co-casting of metals

Owner:NOVELIS INC

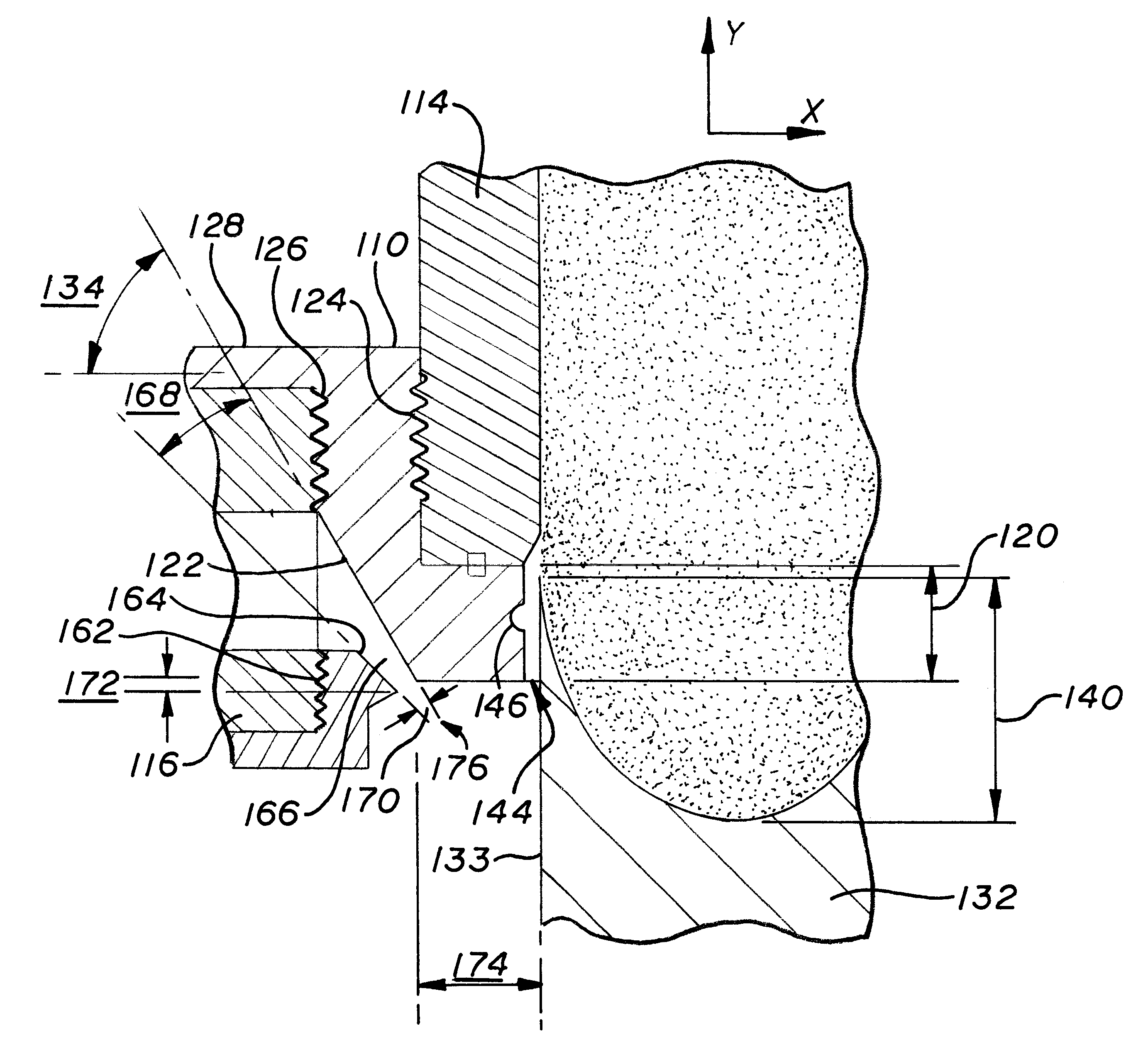

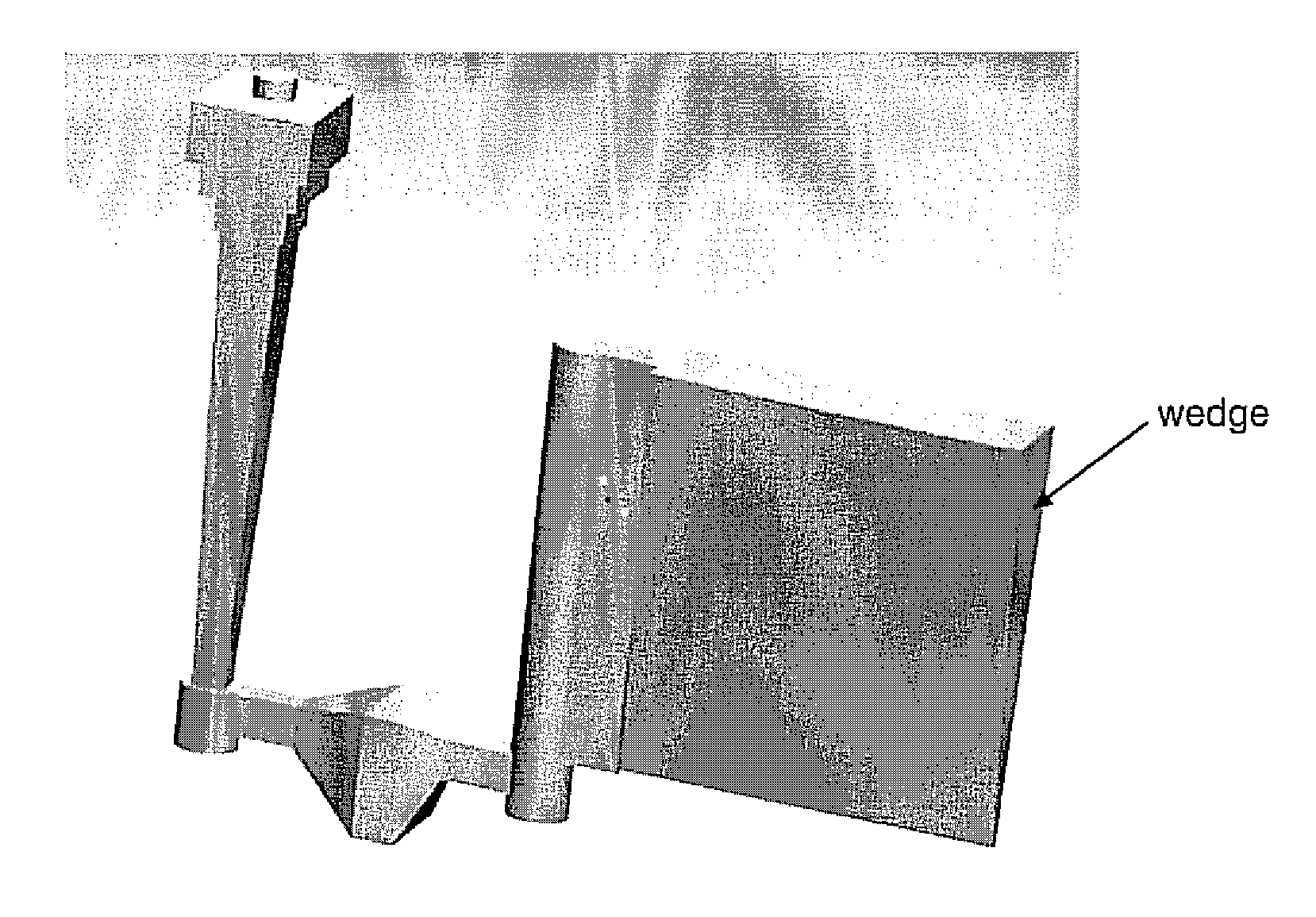

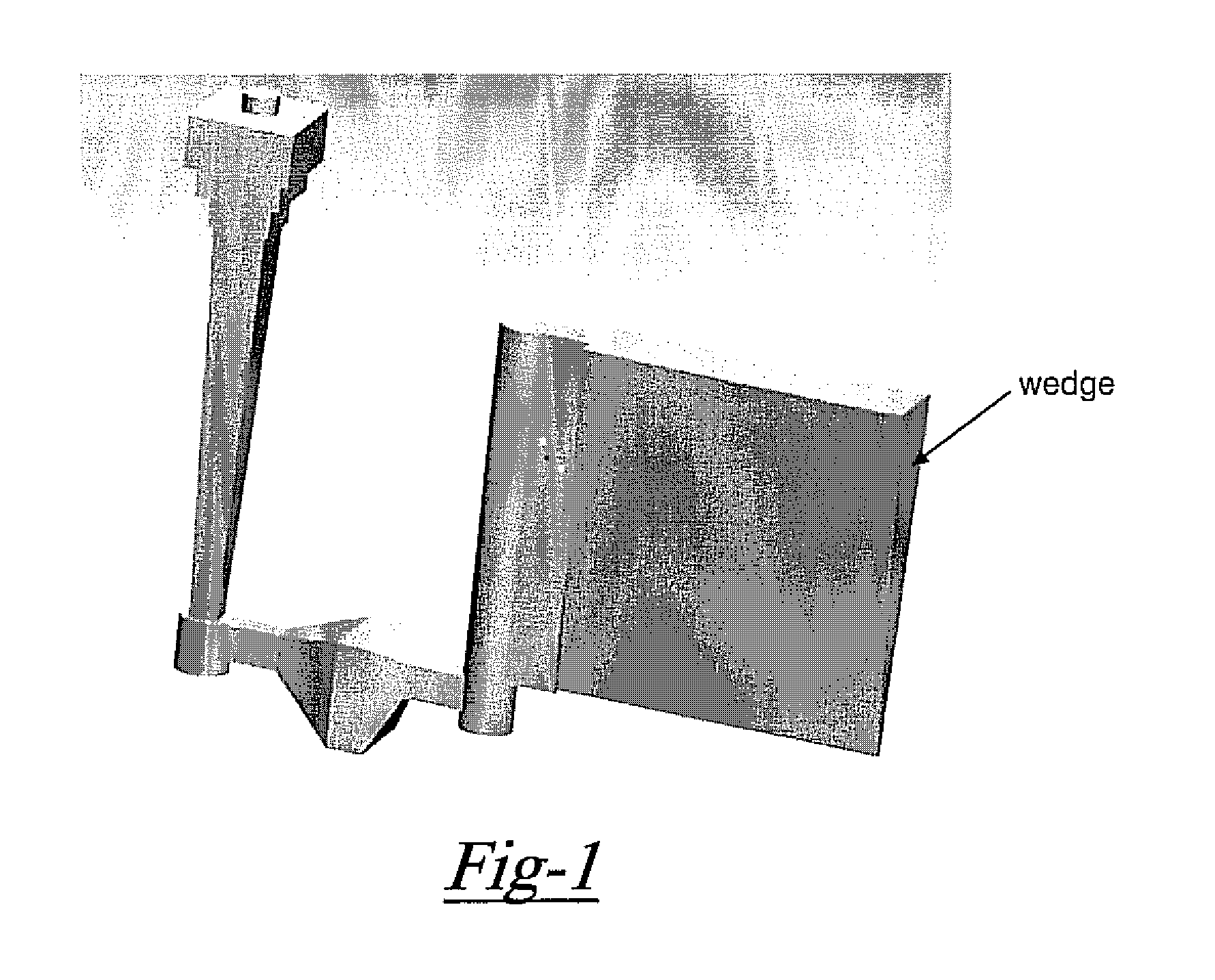

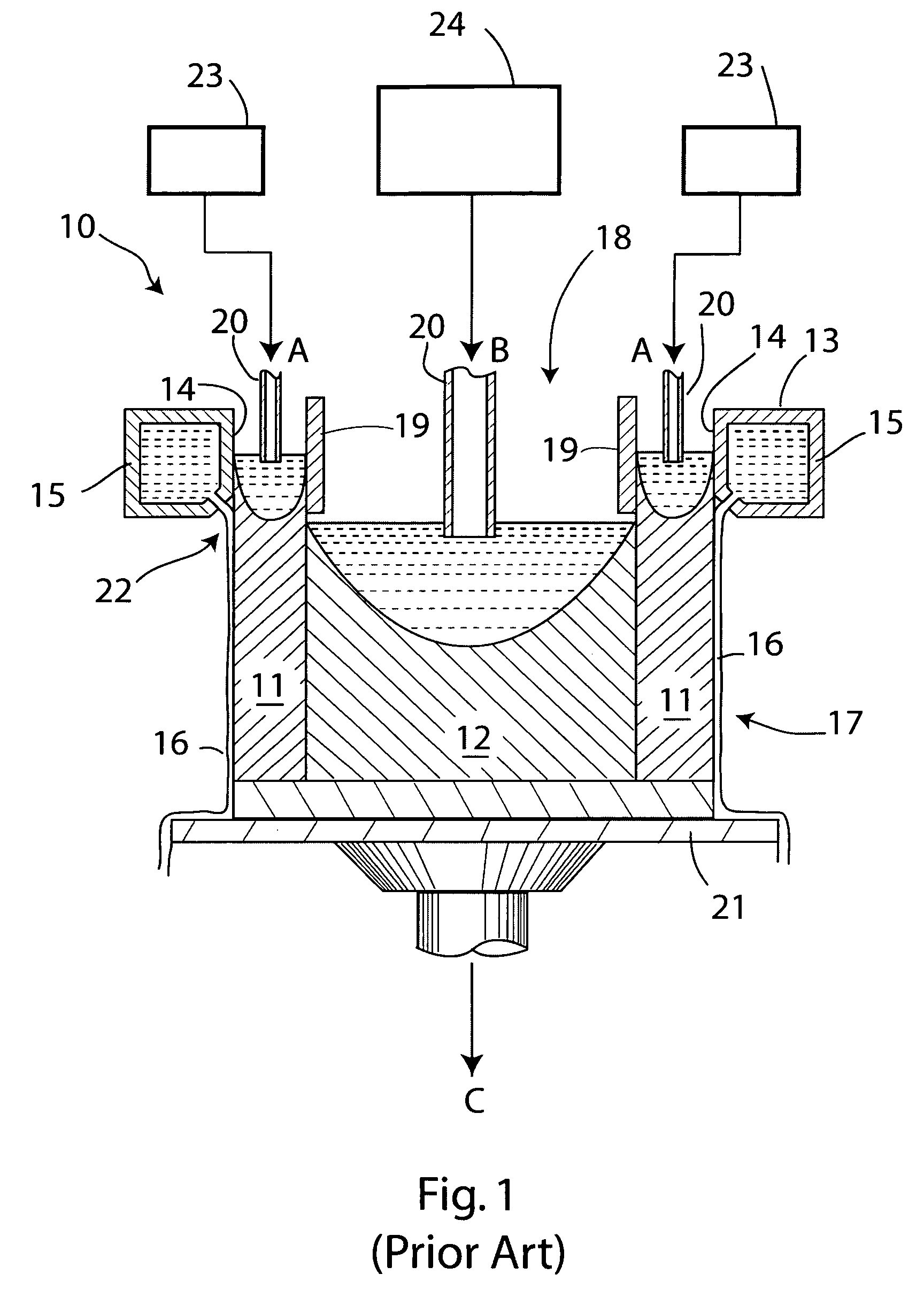

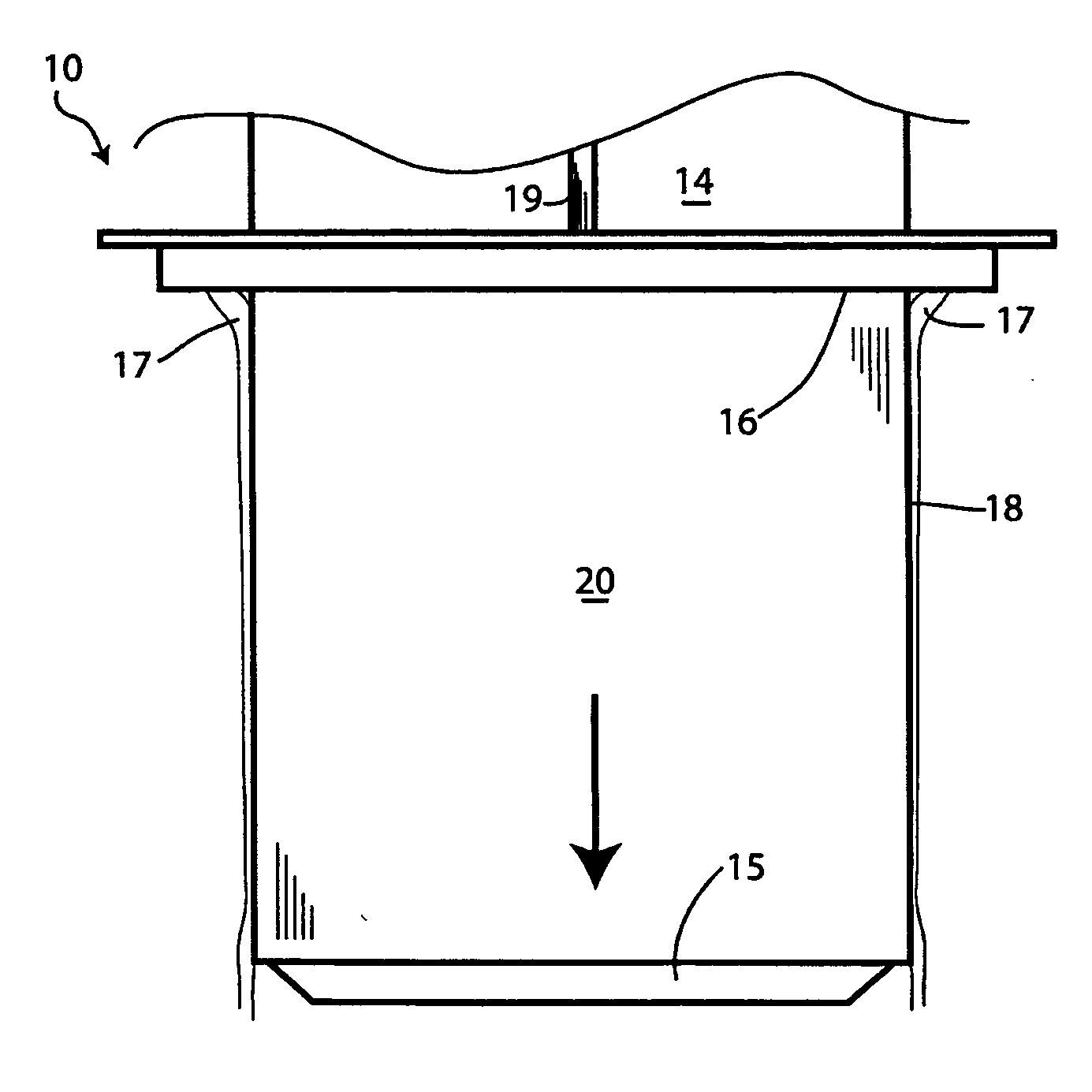

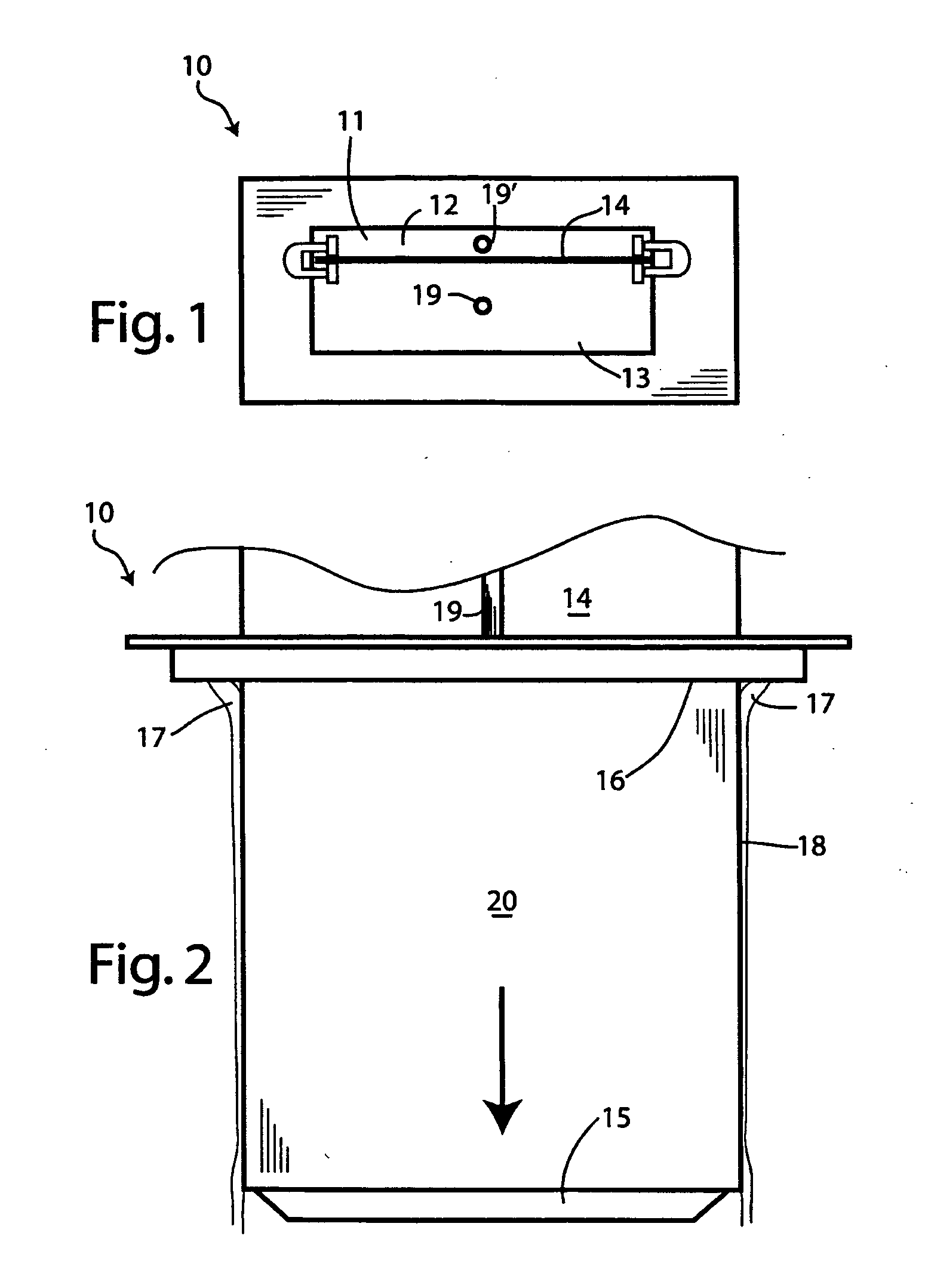

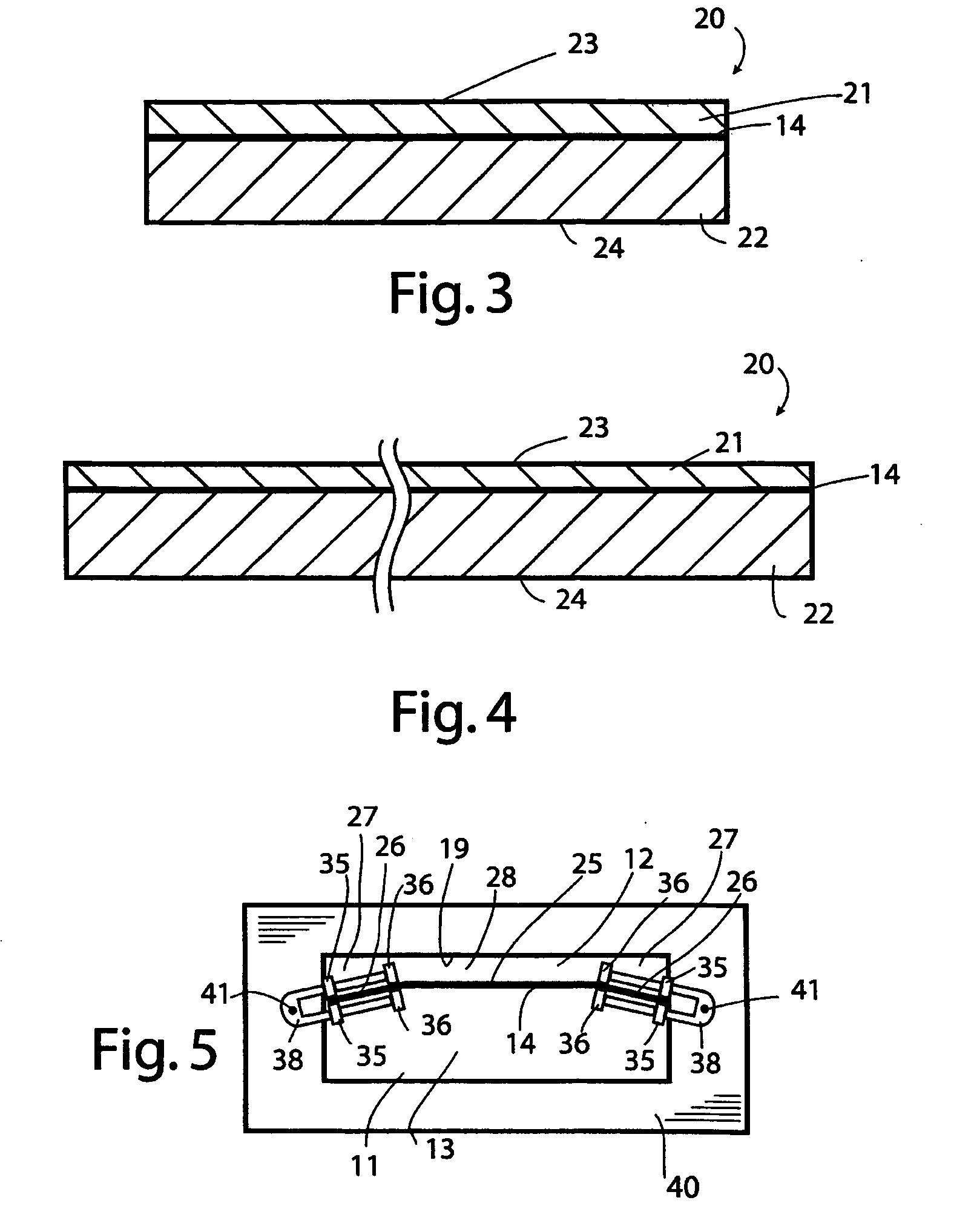

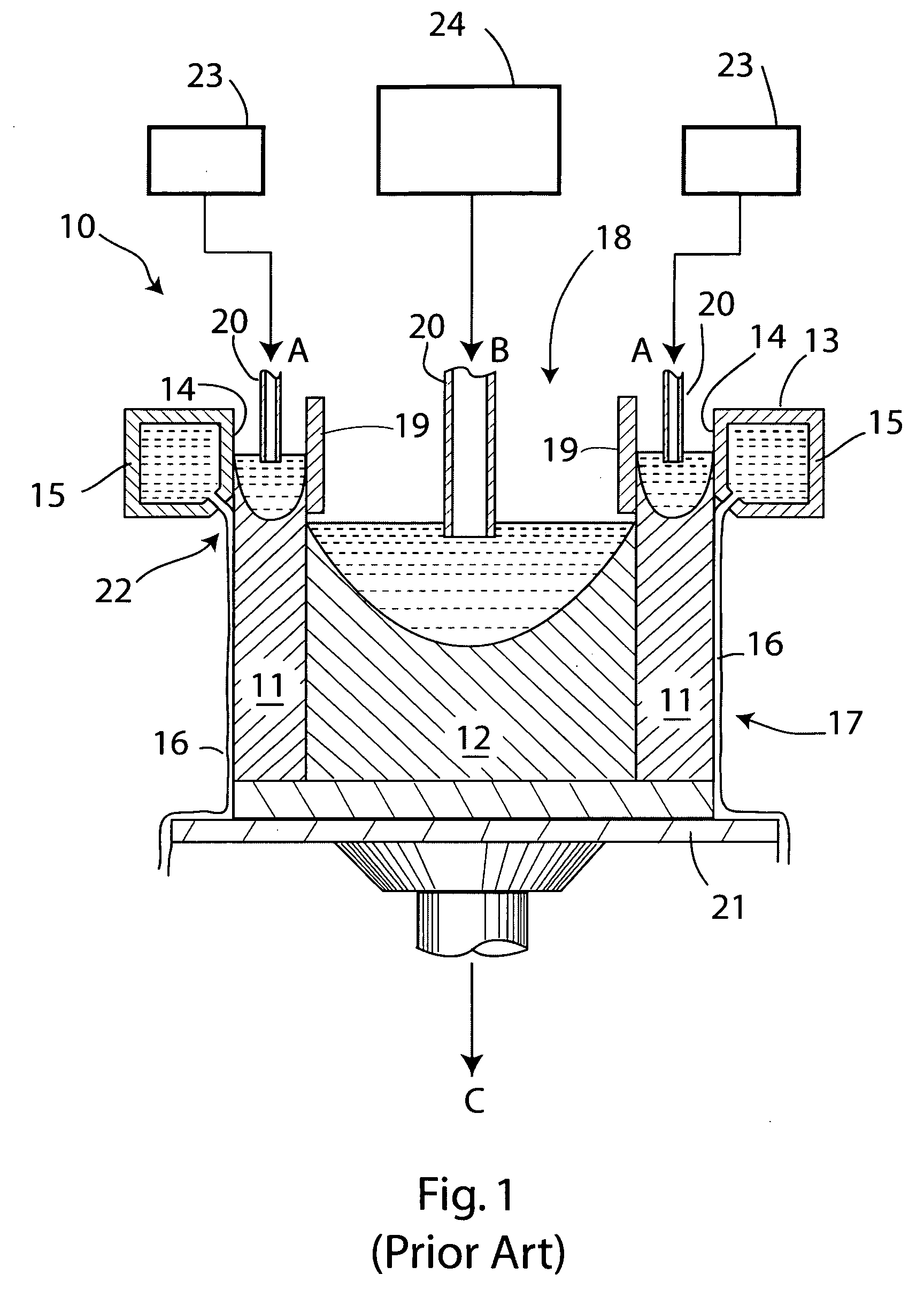

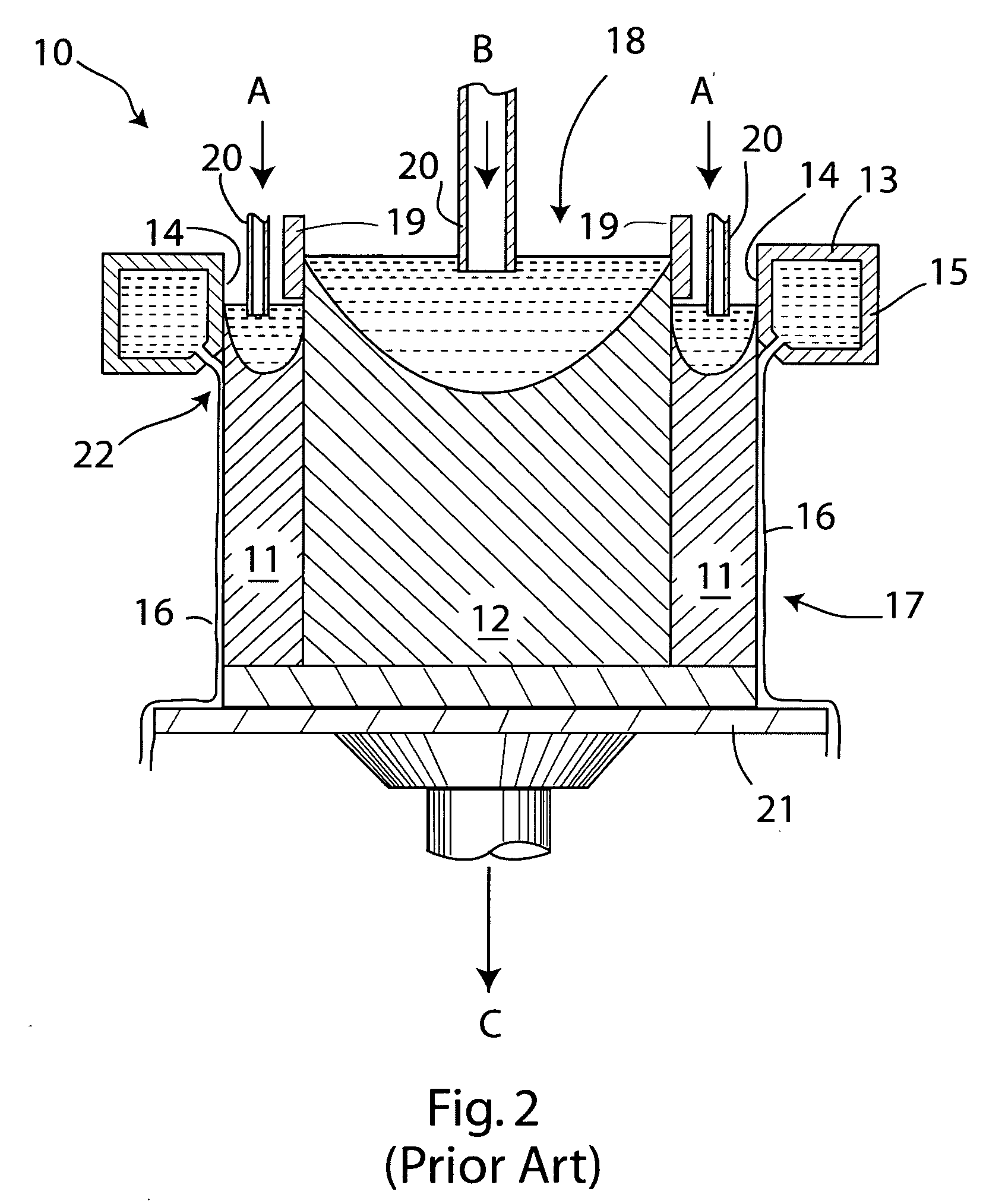

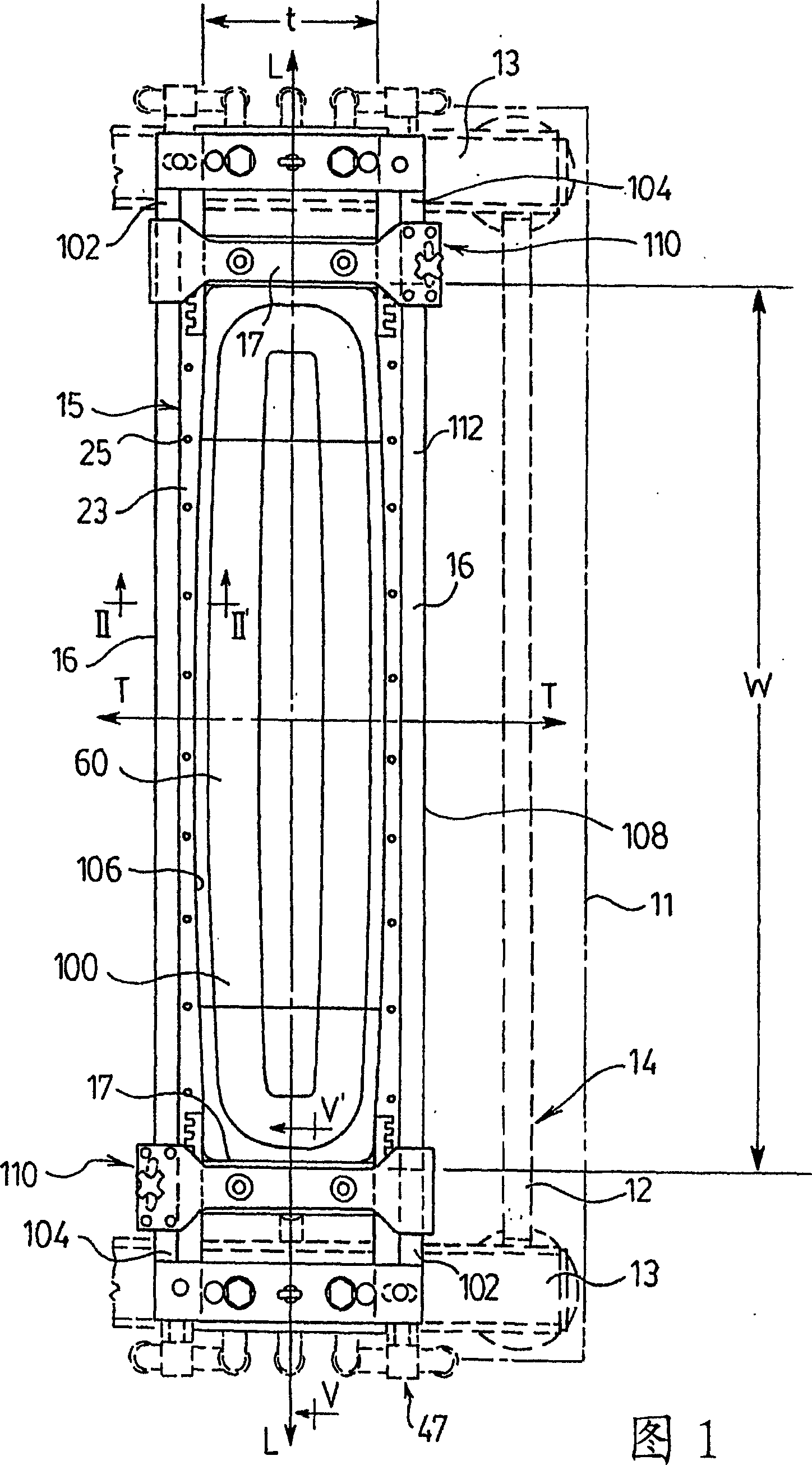

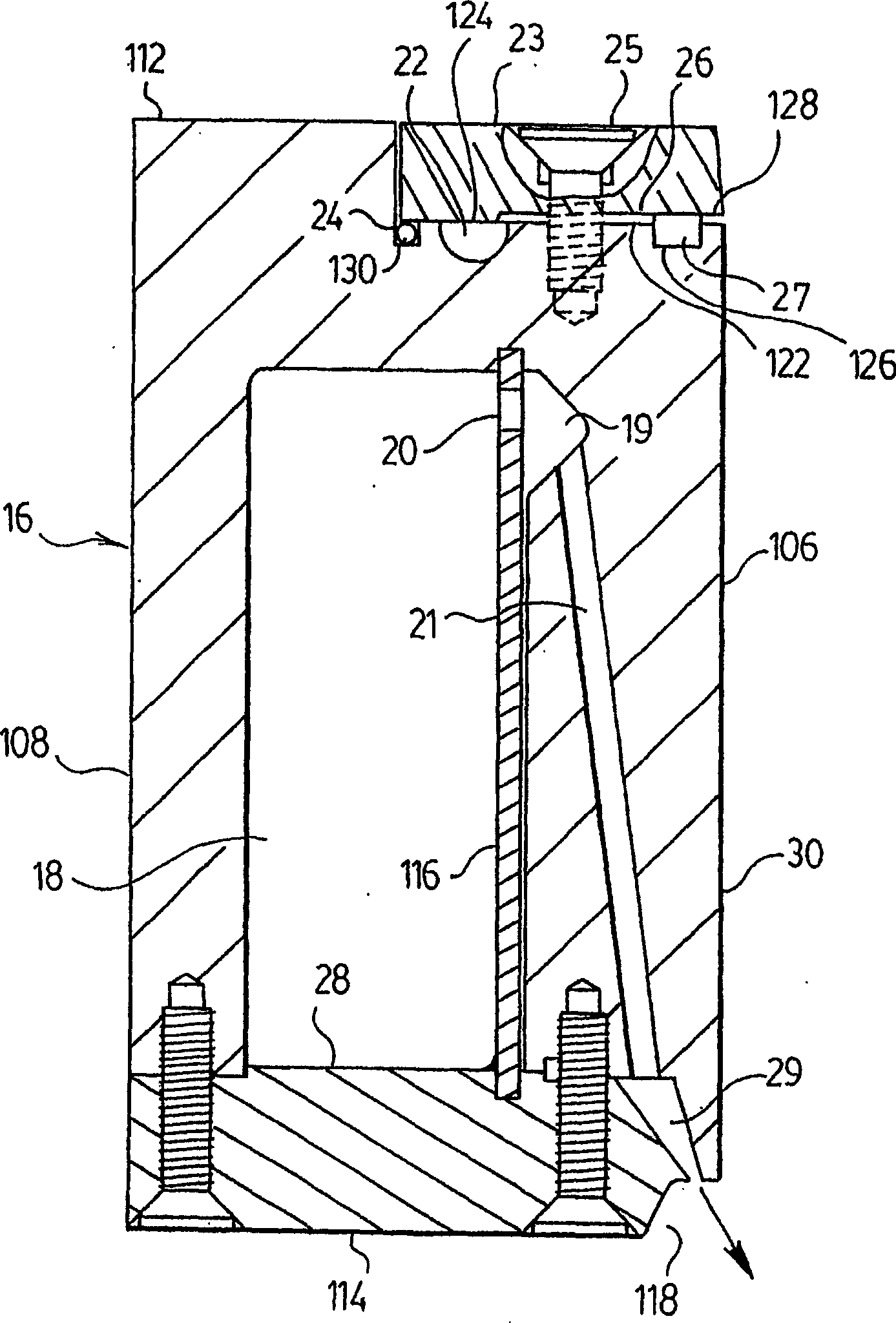

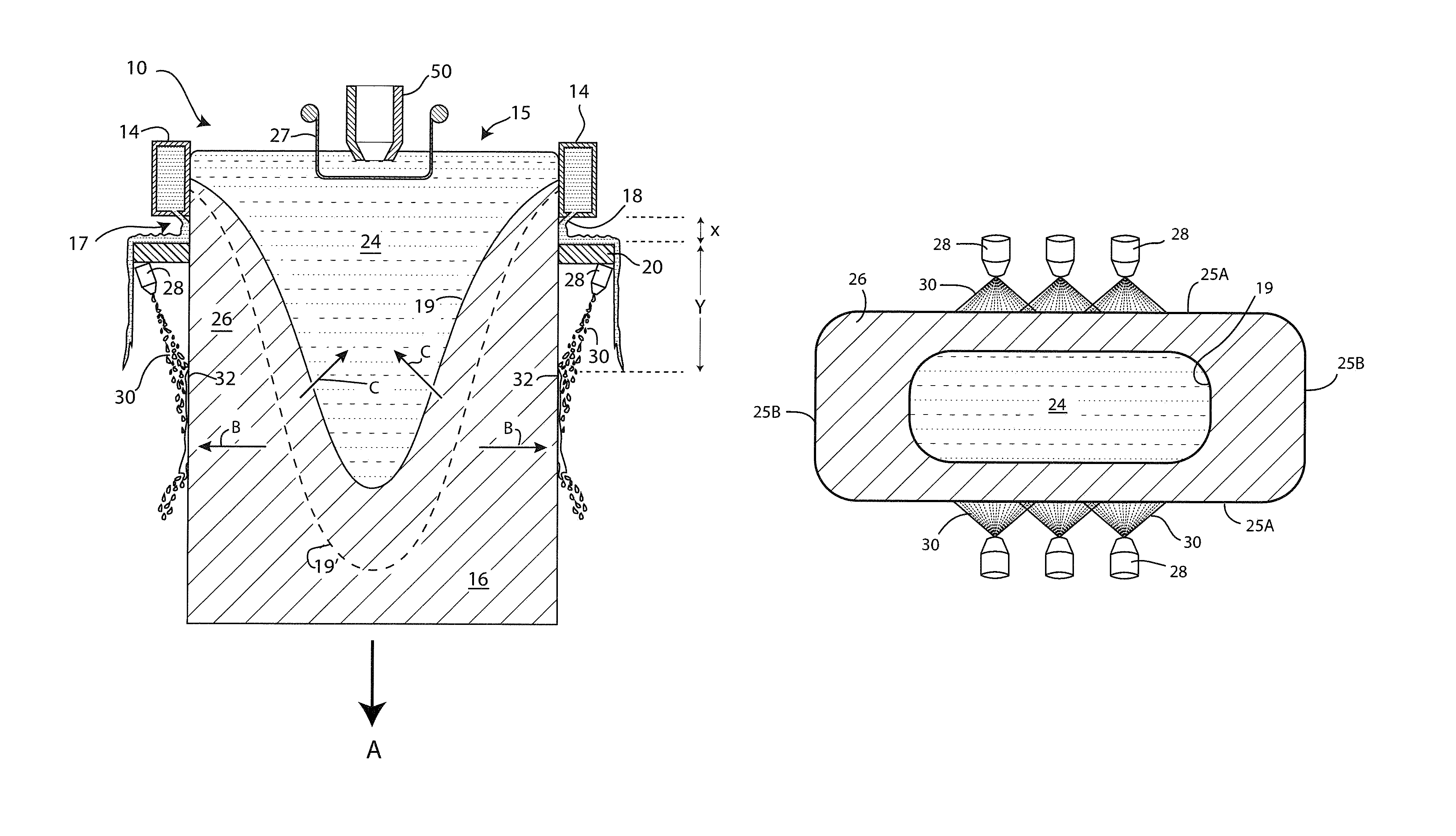

Co-casting of metals by direct chill casting

Apparatus and method of co-casting metal ingots in direct-chill casting apparatus. The apparatus and method employs at least one divider (divider member or divider wall) that separates a casting mold into two or more chambers for receiving molten metal that is combined into a single ingot. The divider may be moved, angled and / or flexed during casting to produce ingots that are designed primarily for rolling into thin plate or sheet. The ingot has at least one outer layer that is thicker adjacent to the side (width) edges than in the center, and / or thicker adjacent to the butt or head regions. This compensates for wiping of the outer layer from the ingot core during rolling. Also, the divider may be outwardly bowed outwardly towards one of the mold walls during the casting run.

Owner:NOVELIS INC

Mould lubricant

A method for preparing a mould lubricant for use in direct chill casting of reactive metals, including magnesium, magnesium alloys, aluminum, and aluminum alloys, proceeds through combining a casting lubricant and a gaseous oxidation-inhibiting agent in a vessel external from the mold under vacuum conditions. The casting lubricant is selected from a variety of casting oils and casting greases. The gaseous oxidation-inhibiting agent is selected from a variety of inert gases, including sulfur hexafluoride (SF6).

Owner:CAST CENT PTY LTD

Oxide restraint during co-casting of metals

A method and apparatus is disclosed for casting a composite ingot made of metals that are susceptible to surface oxide formation when molten. The method involves co-casting at least two metal layers from at least two molten metal pools formed within a direct chill casting apparatus. During the casting operation, movement of metal oxide formed on the upper surface of at least one of the pools towards an edge of the pool is restrained by an oxide skimmer positioned close to an edge of the pool above an external surface or metal-metal interface of the ingot. The apparatus provides a DC caster with at least one oxide skimmer that operates in this manner.

Owner:NOVELIS INC

Apparatus and method for liquid metals treatment

ActiveCN103097846AImprove uniformityGrain refinementStirring devicesCasting apparatusParticulatesGas phase

Owner:BRUNEL UNIVERSITY

Co-casting of metals by direct chill casting

Apparatus and method of co-casting metal ingots in direct-chill casting apparatus. The apparatus and method employs at least one divider (divider member or divider wall) that separates a casting mold into two or more chambers for receiving molten metal that is combined into a single ingot. The divider may be moved, angled and / or flexed during casting to produce ingots that are designed primarily for rolling into thin plate or sheet. The ingot has at least one outer layer that is thicker adjacent to the side (width) edges than in the center, and / or thicker adjacent to the butt or head regions. This compensates for wiping of the outer layer from the ingot core during rolling. Also, the divider may be outwardly bowed outwardly towards one of the mold walls during the casting run.

Owner:NOVELIS INC

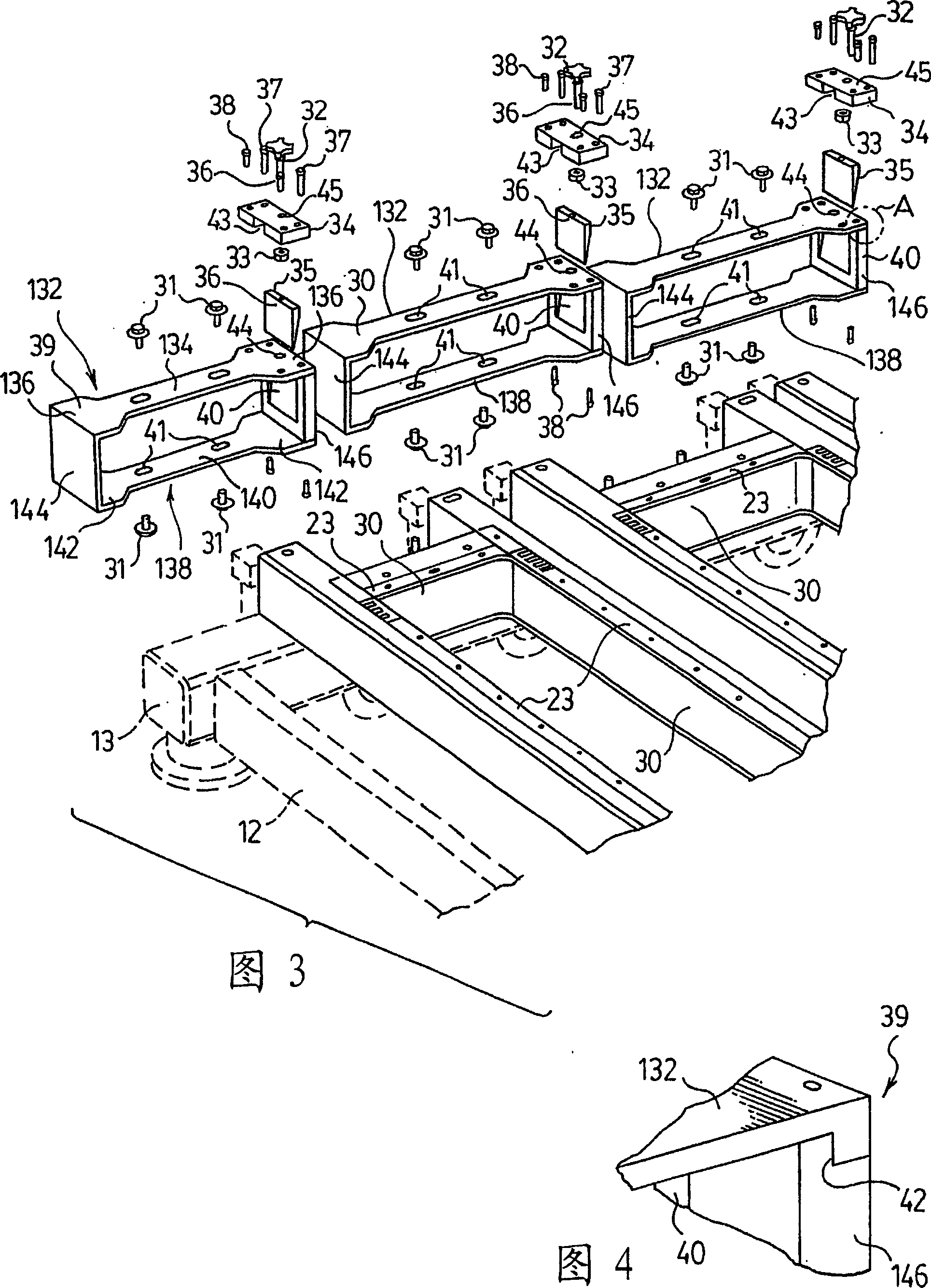

Adjustable casting mold

An adjustable mold for direct chill casting of metals has longitudinally movable end walls which are clamped between the mold side walls during casting. Each end wall is secured to a sliding carriage which supports the end wall and allows it to be moved along the end portions of the side walls. The sliding suspender has a clamping mechanism which applies a clamping force to one or both of the side walls, the force being transversely directed through a center of the end wall. The side walls are pivotable relative to one another to allow clamping and unclamping of the end walls. Preferably, one end of each side wall is pivotable so as to transversely displace the opposite end of the side wall, with the pivoting ends of the respective side walls preferably being opposite one another across the mold.

Owner:HATCH LTD

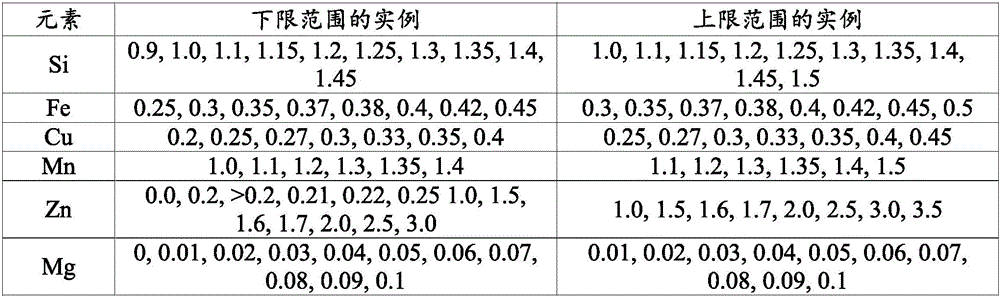

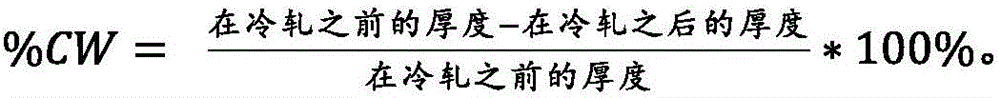

Aluminum alloy for heat exchanger fins

An aluminum alloy fin stock material comprising about 0.9-1.2 wt% of Si, 0.3-0.5 wt% of Fe, 0.20-0.40 wt% of Cu, 1.0-1.5 wt% of Mn, 0-0.1% of Mg and 0.0-3.0% of Zn, with remainder Al and impurities no more than 0.15 wt%. The aluminum alloy fin stock material is produced in a form of a sheet by a process comprising the steps of direct chill casting an ingot, hot rolling the ingot after the direct chill casting, cold rolling the aluminum alloy to an intermediate thickness, inter-annealing the aluminum alloy cold rolled to an intermediate thickness at a temperature between 200 and 400 DEG C, and cold rolling the material after inter-annealing to achieve % cold work (%CW) of 20 to 40%. The aluminum alloy fin stock material possesses an improved combination of one or more of pre- and / or post-brazes strength, conductivity, sag resistance and corrosion potential. It is useful for fabrication of heat exchanger fins.

Owner:NOVELIS INC +1

Sequential casting of metals having similar freezing ranges

A method and apparatus are disclosed for sequentially direct chill casting a composite ingot made of metals having similar freezing ranges. Poor adhesion between the layers and low reliability of casting are addressed by adjusting the position of secondary cooling (created by applying water streams to the emerging ingot) relative to the upper surfaces of the molten metal pools compared to the conventional positions of first application of the secondary cooling. This can be achieved by moving one or more walls of the mold (when the secondary cooling emanates from the bottom of such walls), or adjusting the height of the molten metal pools within the mold and moving cooled divider walls between the pools. The relative temperatures and conditions of the metals at positions where they meet at the metal interface may therefore be optimized.

Owner:NOVELIS INC

Magnesium-contained high-silicon aluminum alloys structural materials and manufacture method thereof

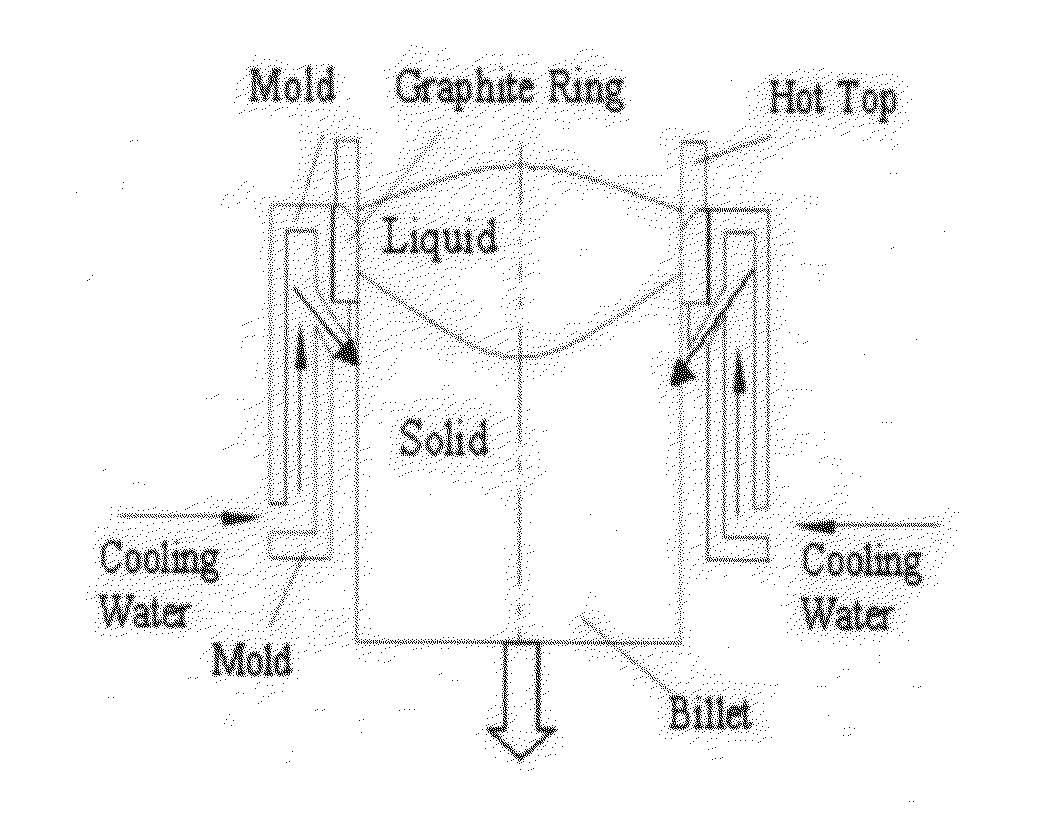

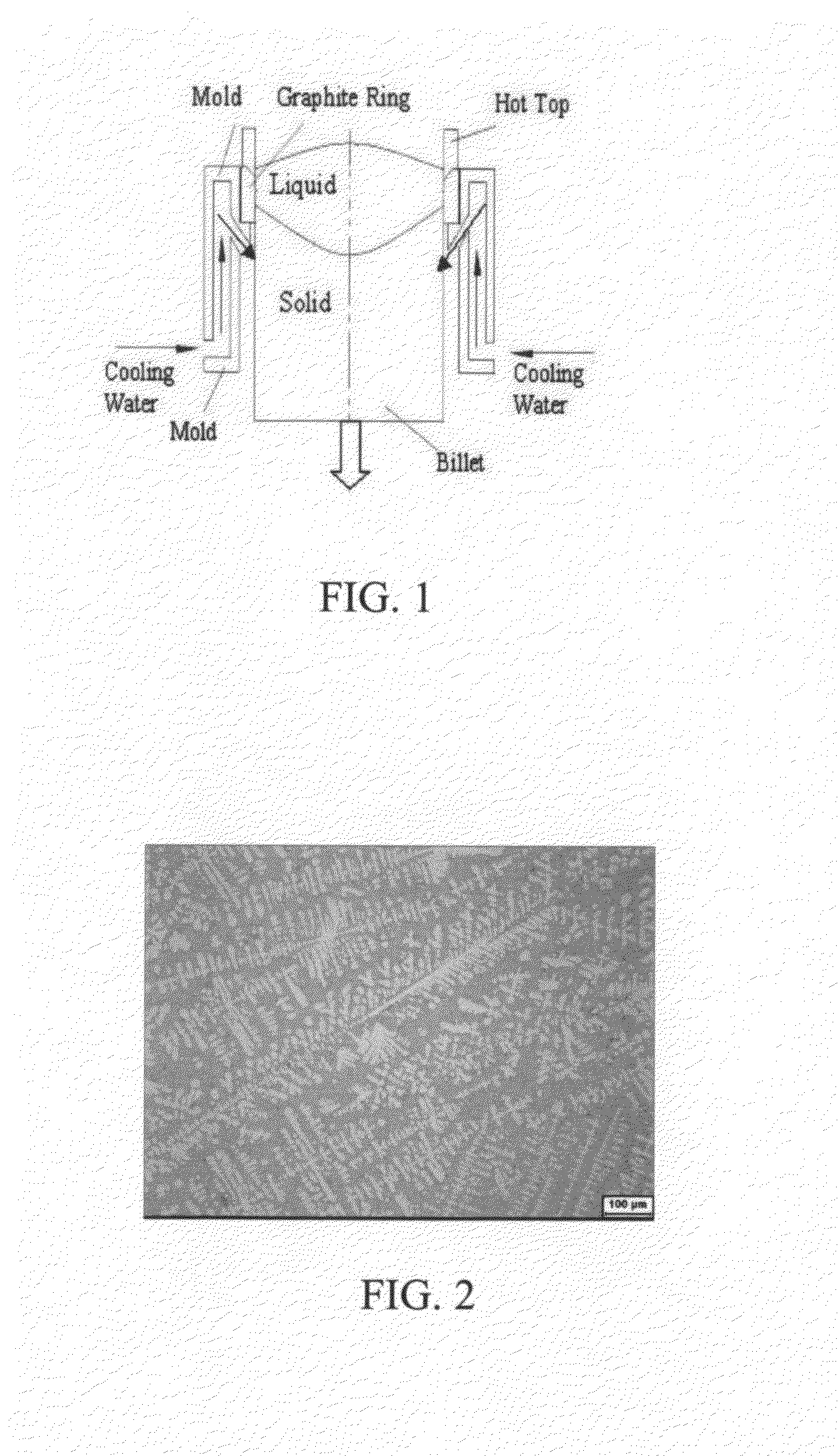

The magnesium-contained high-silicon aluminum alloys for use as structural materials, including profiles, bars, sheets, and forgings, are manufactured by a process including the steps of: casting an alloy ingot by direct chill casting, preheating the ingot to disperse eutectic Si phase particles, and thermal-plastic processing and heat-treating to obtain the product with a final shape and a modified microstructure. The aluminum alloys contain 0.2˜2.0 wt % of Mg and 8˜18 wt % of Si, and have homogeneous and fine microstructure, wherein the aluminum matrix is equiaxed with an average grain size less than 6 μm, and the silicon and second phase particles are dispersed with an average size less than 5 μm. Without adding any modifiers, they are low-costly produced by incorporating the direct chill casting with thermal-plastic processing and heat treatment, which give rise to good plasticity and relatively high strength.

Owner:NORTHEASTERN UNIV

Multi-alloy vertical semi-continuous casting method

The invention relates to a method for the vertical semi-continuous direct chill casting of composite billets or plates comprising at least two layers of aluminum alloys, using a separator which is in contact with the solidification front and which provides a seal between the two alloys during casting, said separator being vibrated while it is in contact with the solidification front, so that the separator is not frozen in and entrained by the solid metal. The invention also relates to a device that can be used to carry out said method.

Owner:CONSTELLIUM ISSOIRE

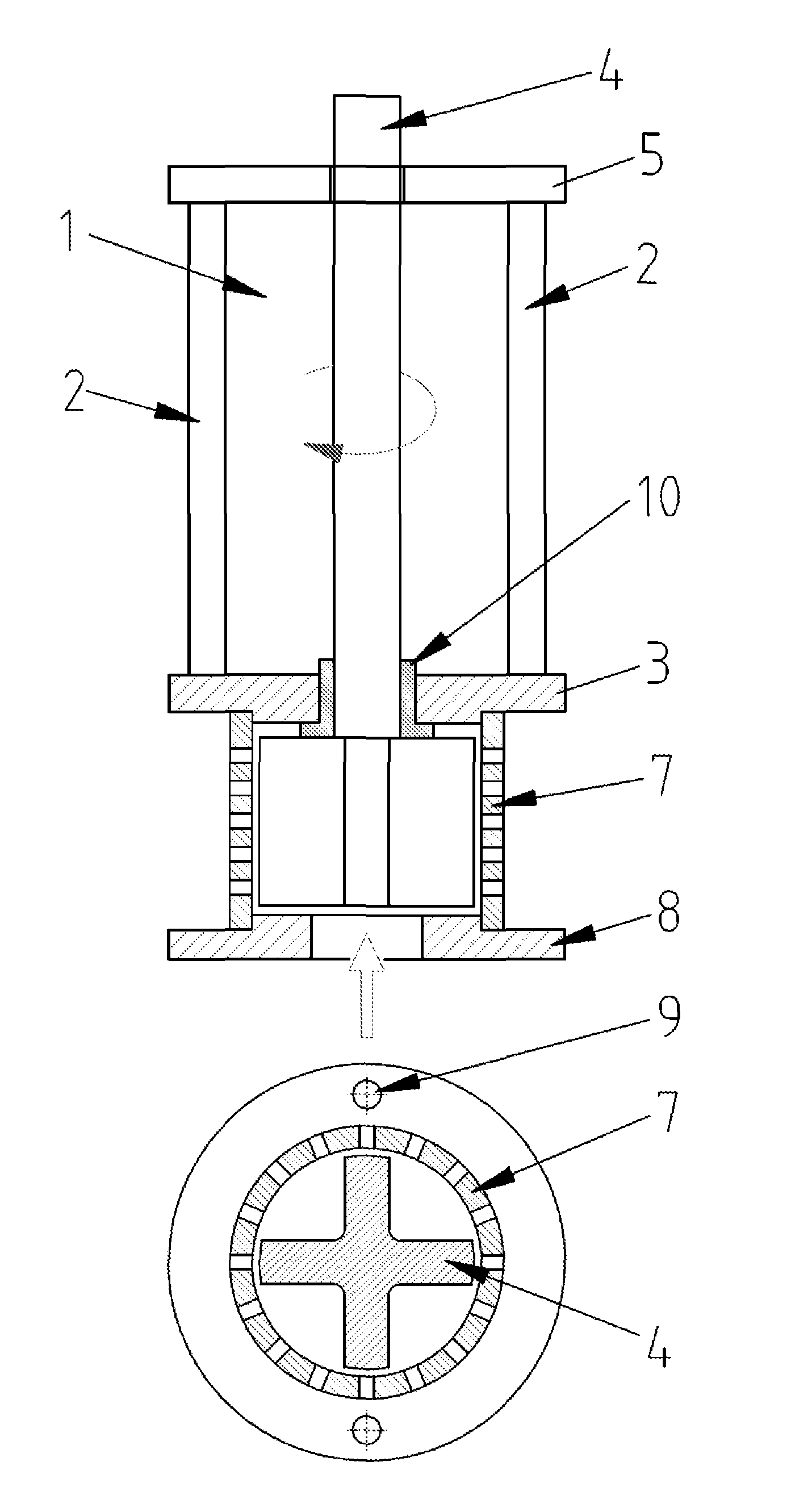

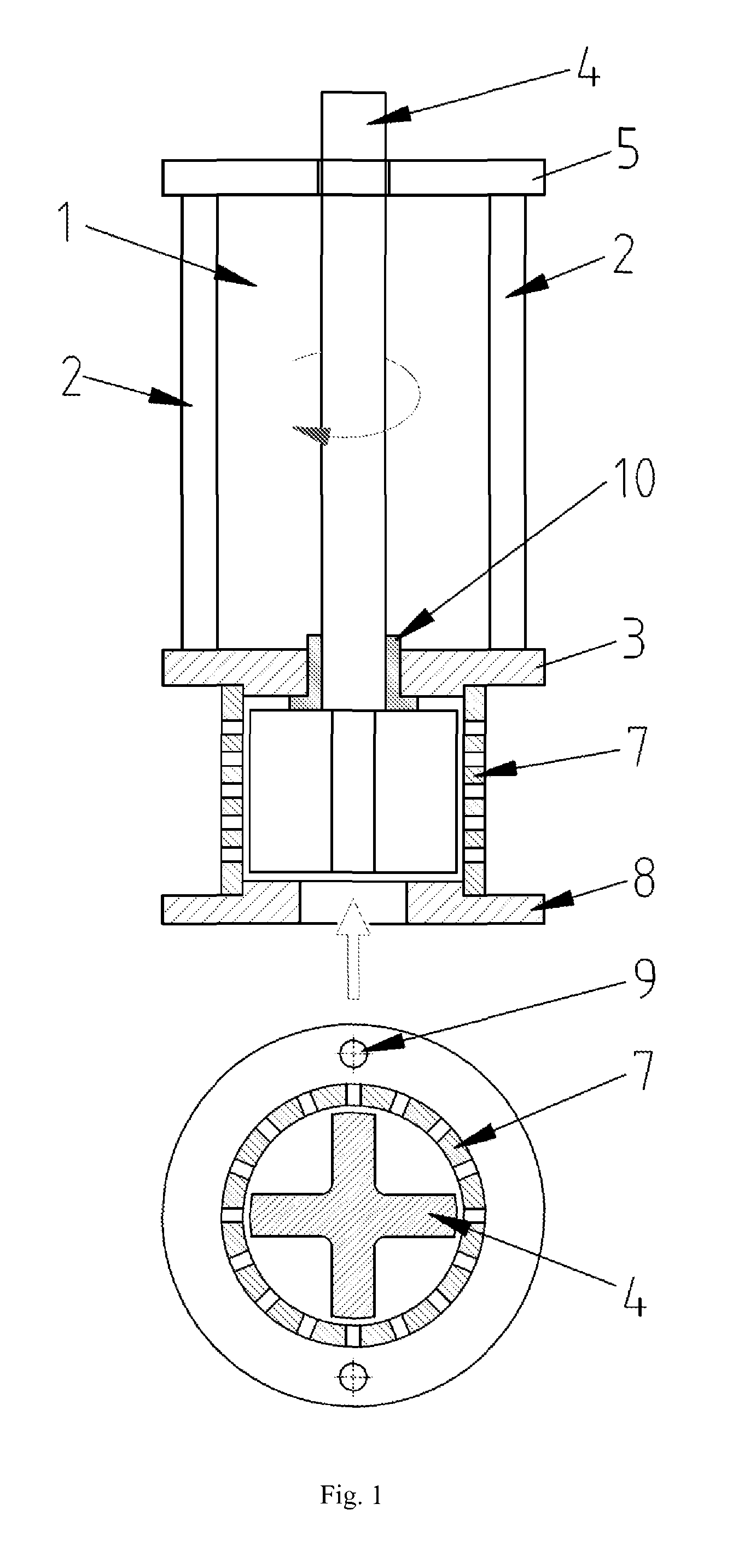

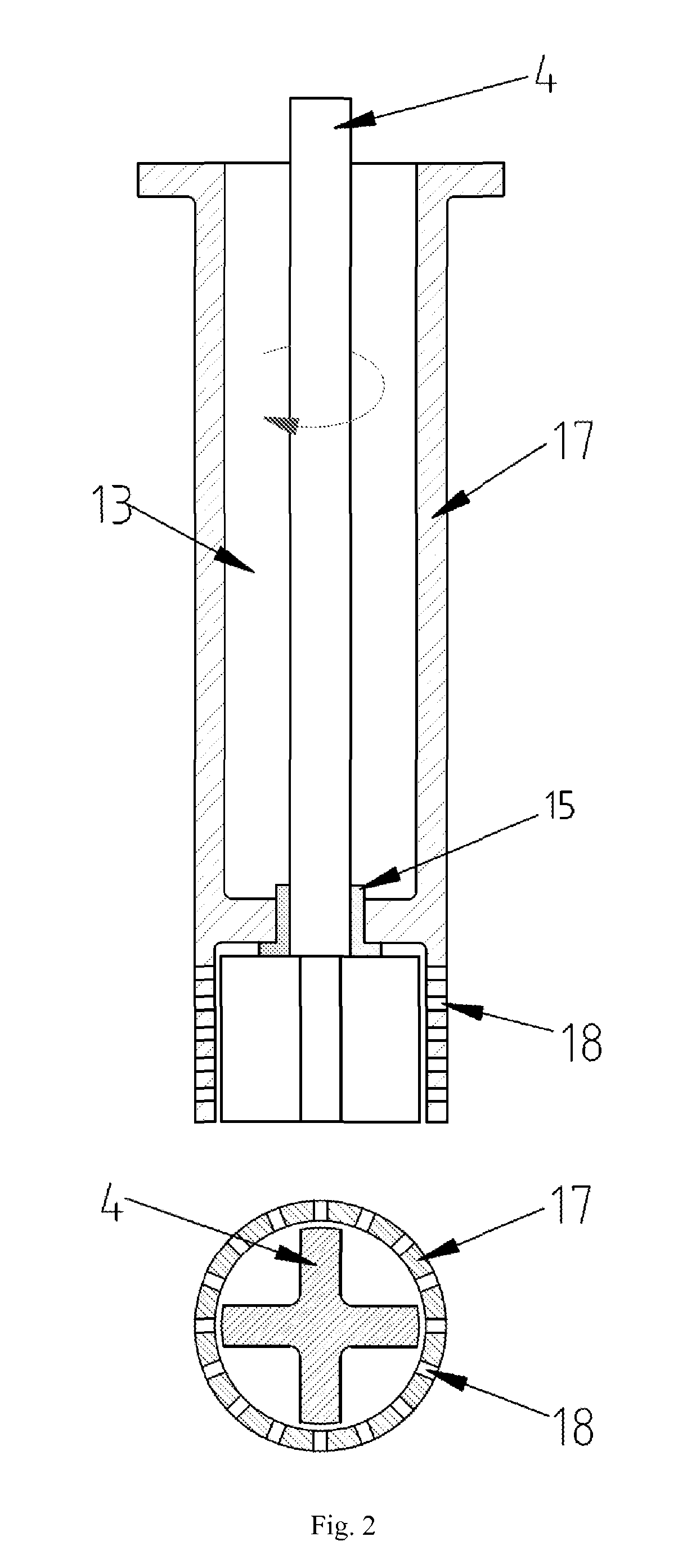

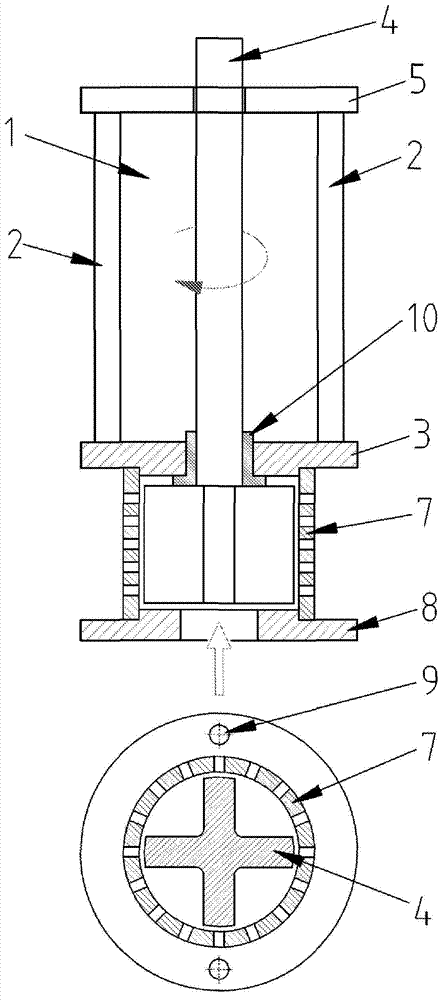

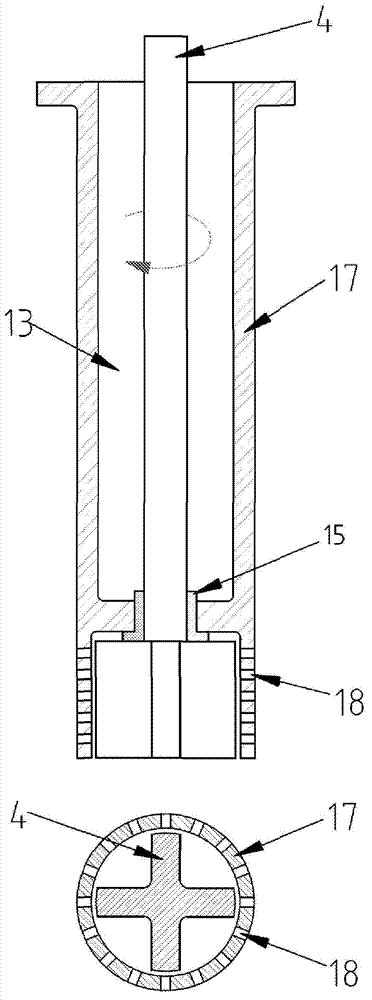

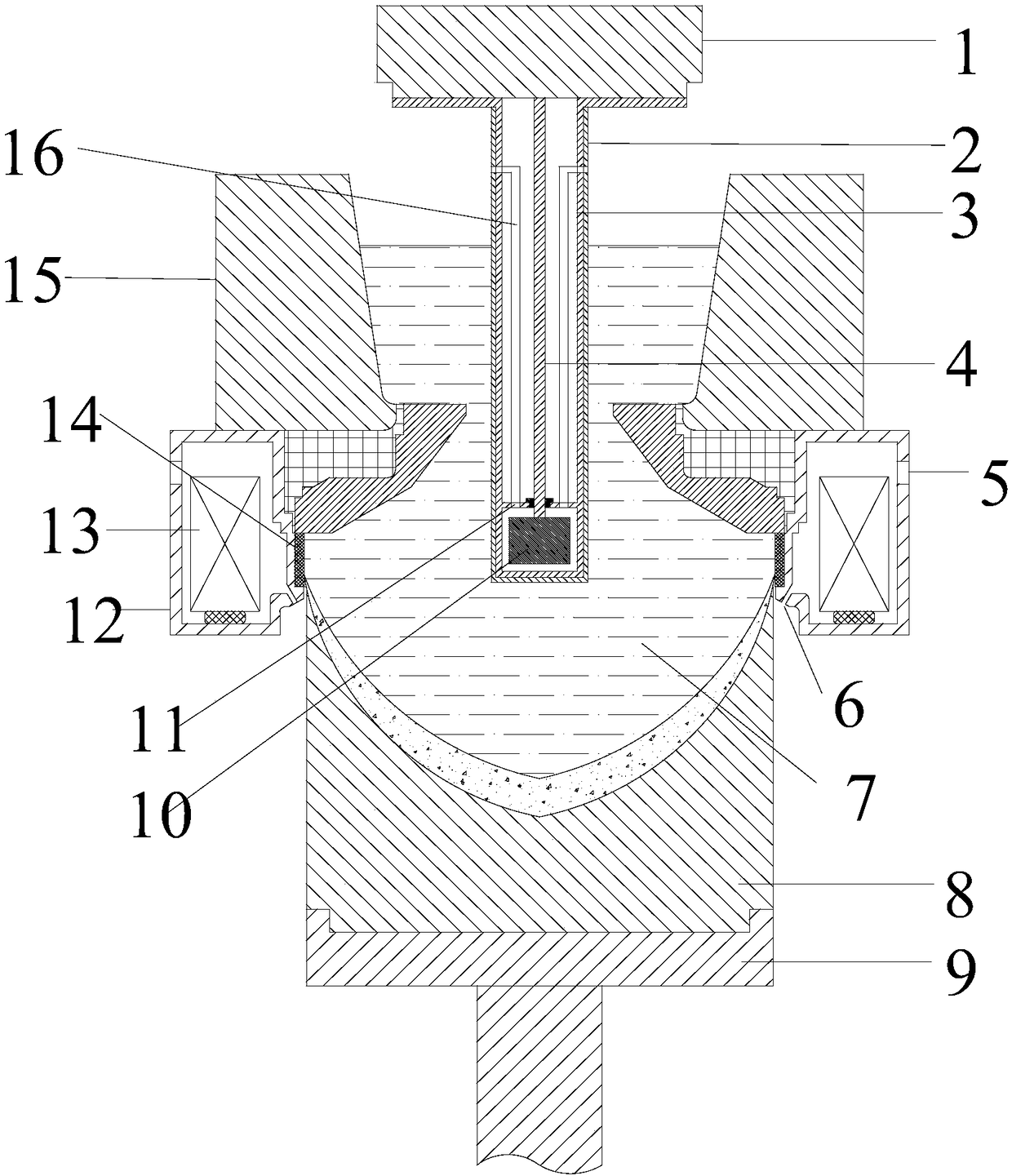

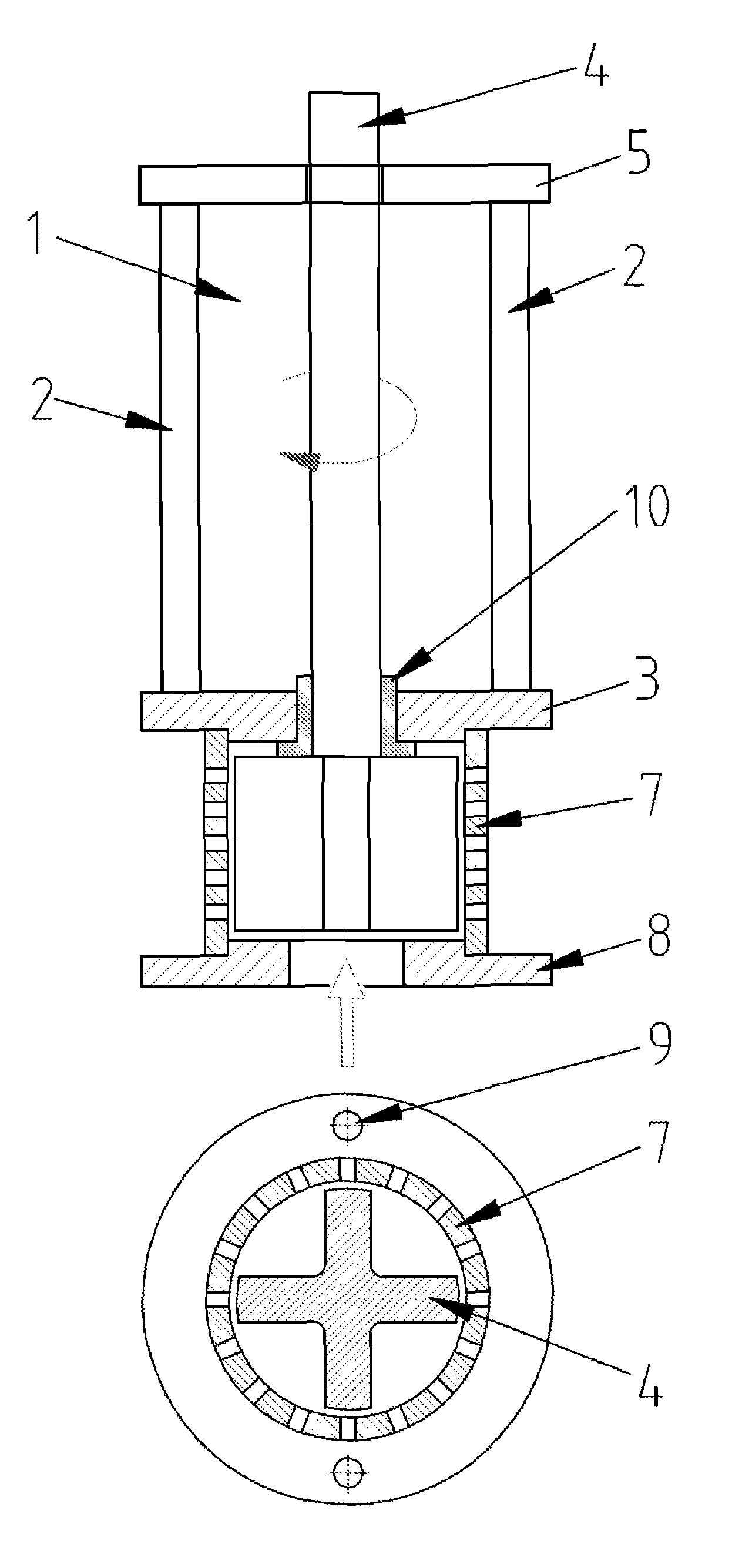

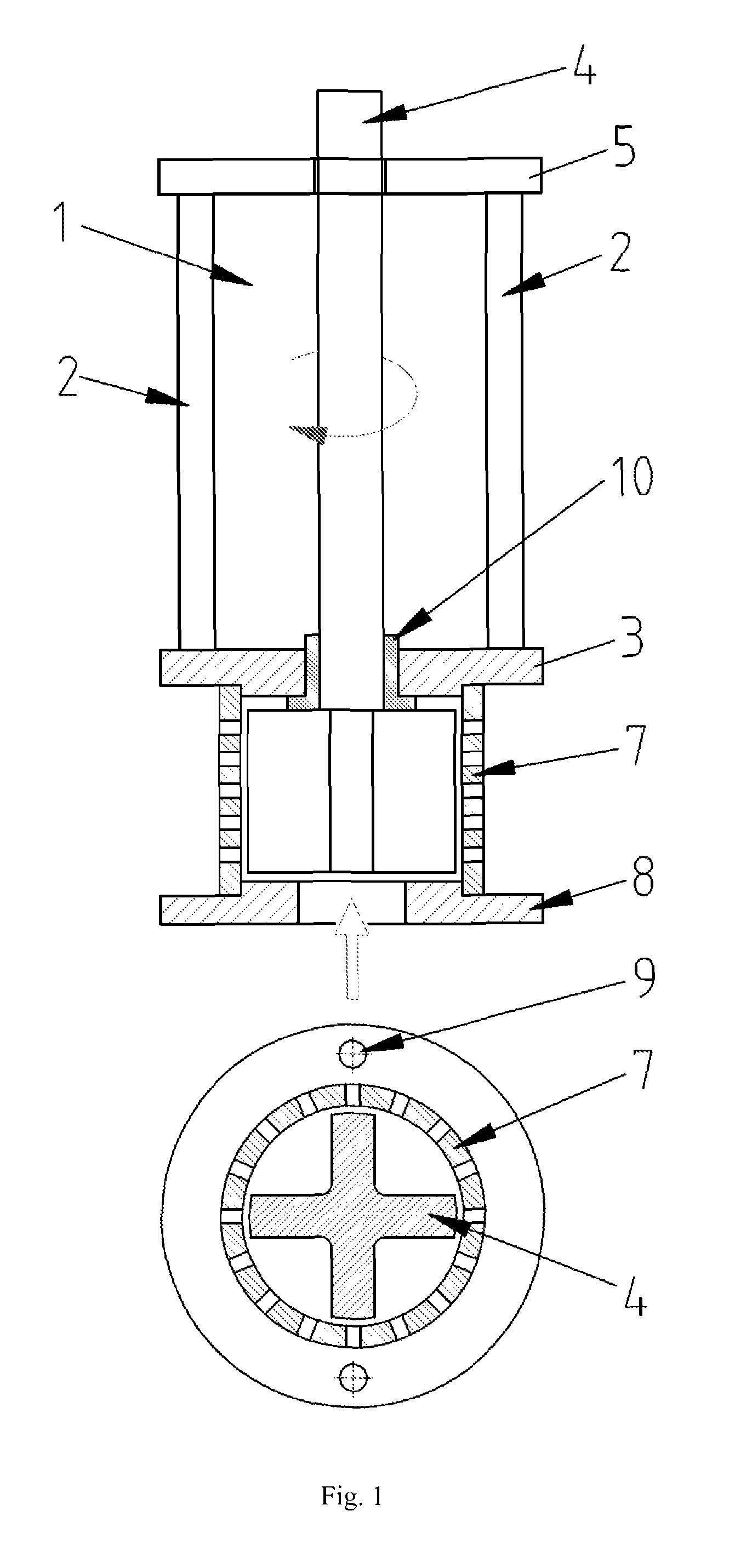

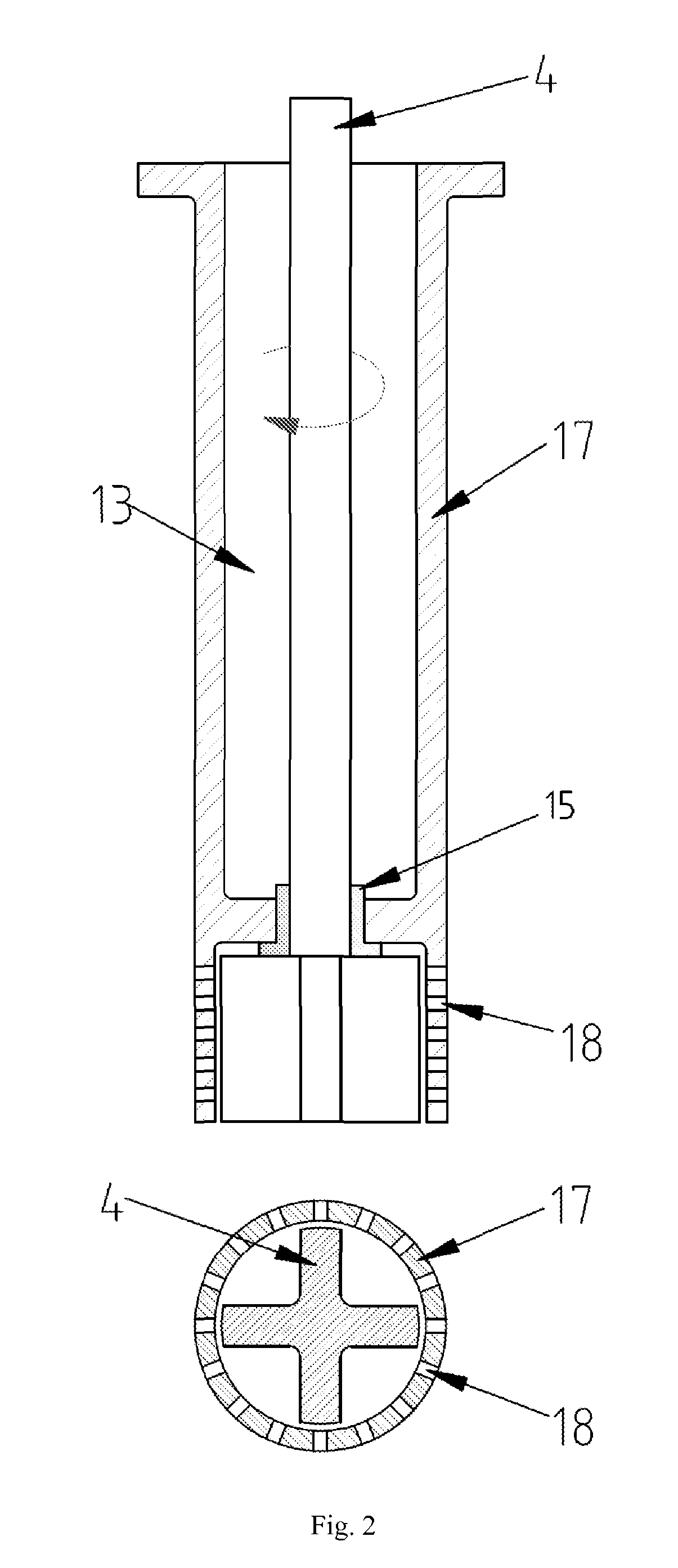

Device for preparing aluminum alloy cast ingot by using induction coil and permanent magnetism mixing in combination with DC

The invention discloses a device for preparing an aluminum alloy cast ingot by using an induction coil and permanent magnetism mixing in combination with DC (Direct chill Casting). The device comprises a crystallizer, the induction coil and a permanent magnet mixing unit; the induction coil is located in a crystallizer cooling jacket; a driving motor is arranged at the upper part of the permanentmagnet mixing unit; a magnetism-conductive sleeve is arranged below the driving motor; the magnetism-conductive sleeve is sleeved with a heat insulation jacket; the driving motor and a connecting shaft are assembled together; the bottom end of the connecting shaft is fixedly connected with a permanent magnet; and the connecting shaft and the permanent magnet are located in the magnetism-conductivesleeve. The device can simultaneously utilize the induction coil to generate an electromagnetic field and the permanent magnet to generate a magnetic field in the direct chill casting process, composite field casting is realized through adjustment on parameters of the induction coil and the permanent magnet, uniformity of a melt temperature field and a component field is ensured, uniform and fineingot structures are obtained, center negative segregation and cast ingot cracking phenomena are reduced.

Owner:NORTHEASTERN UNIV

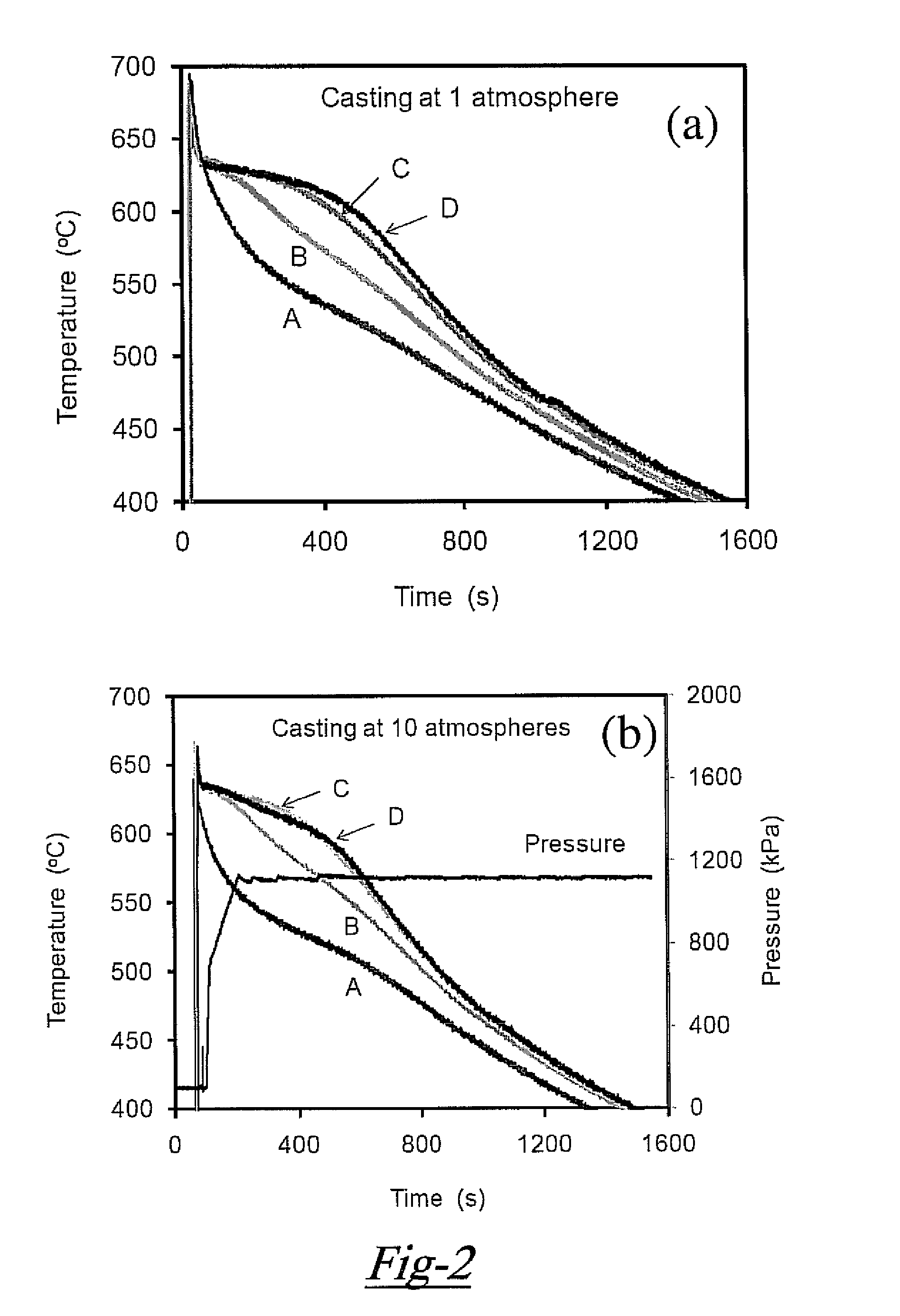

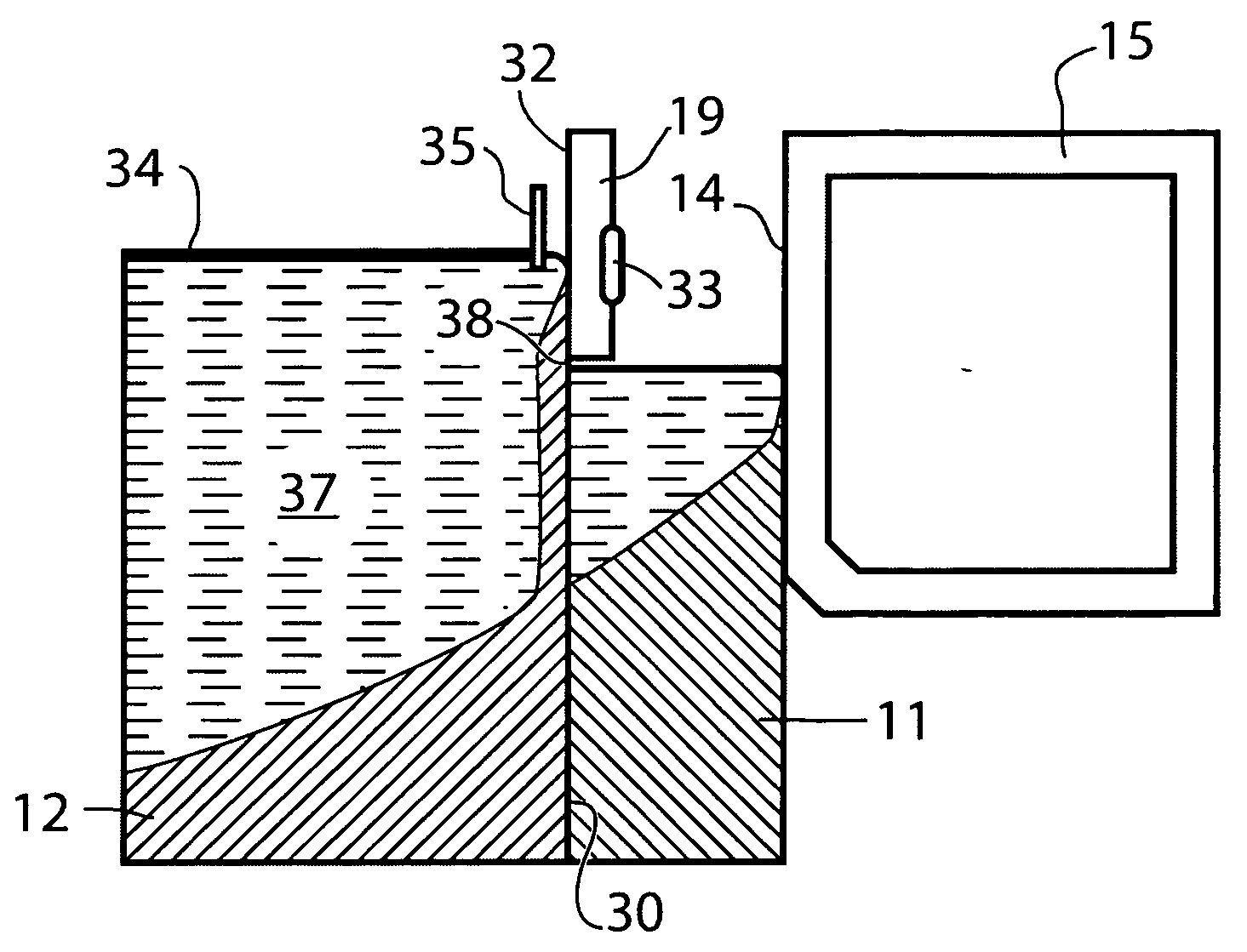

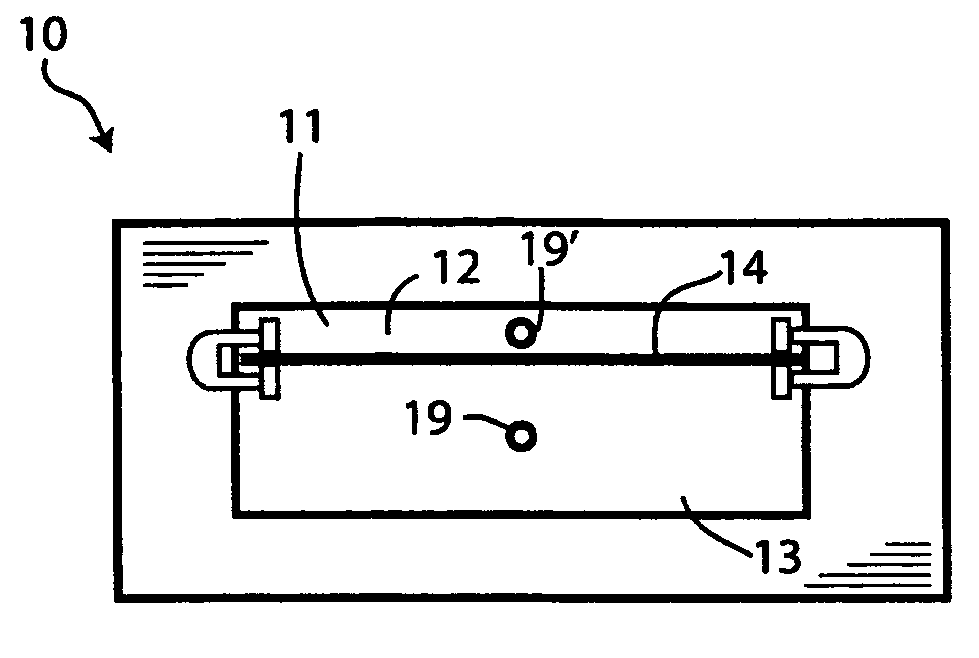

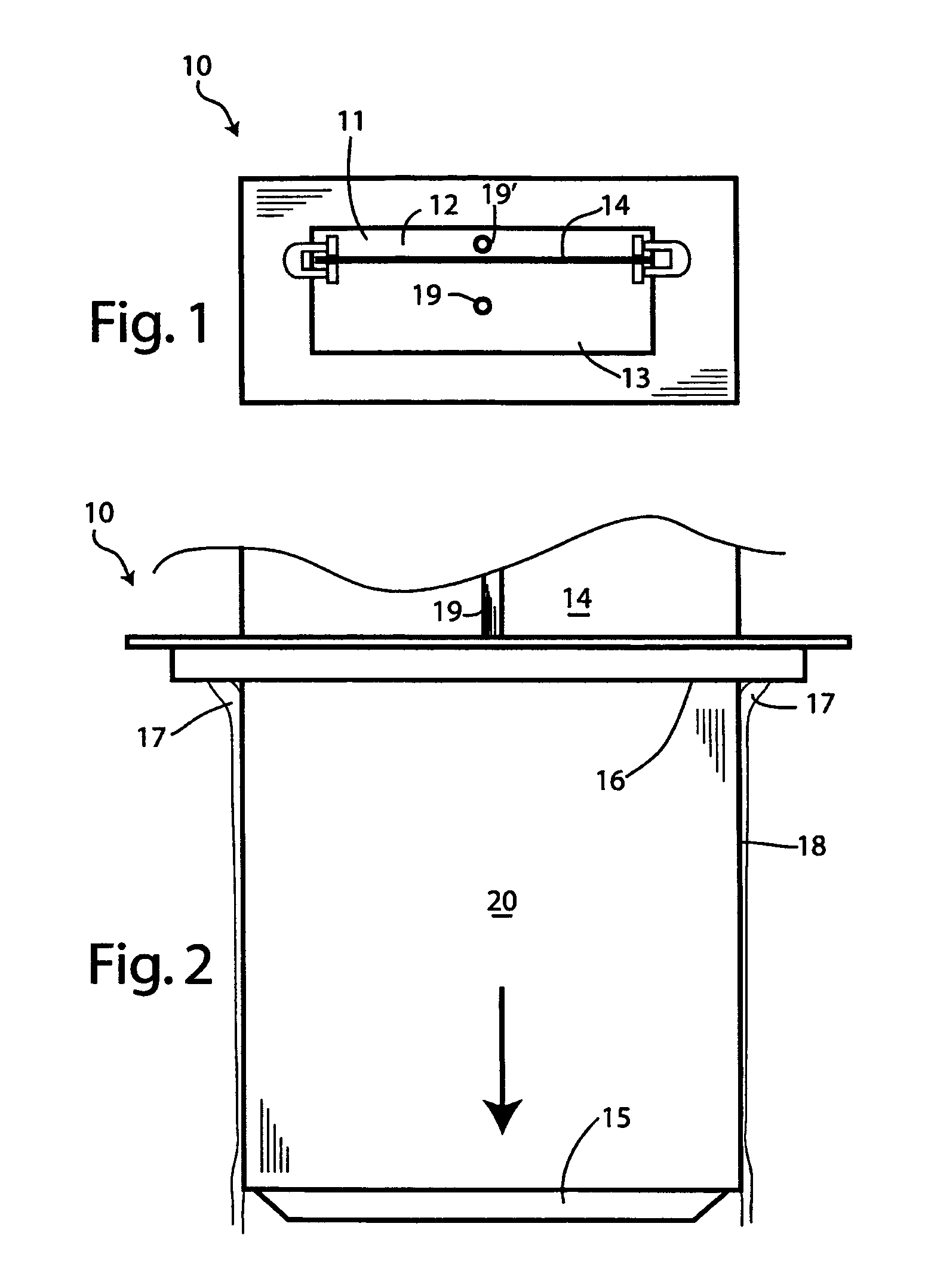

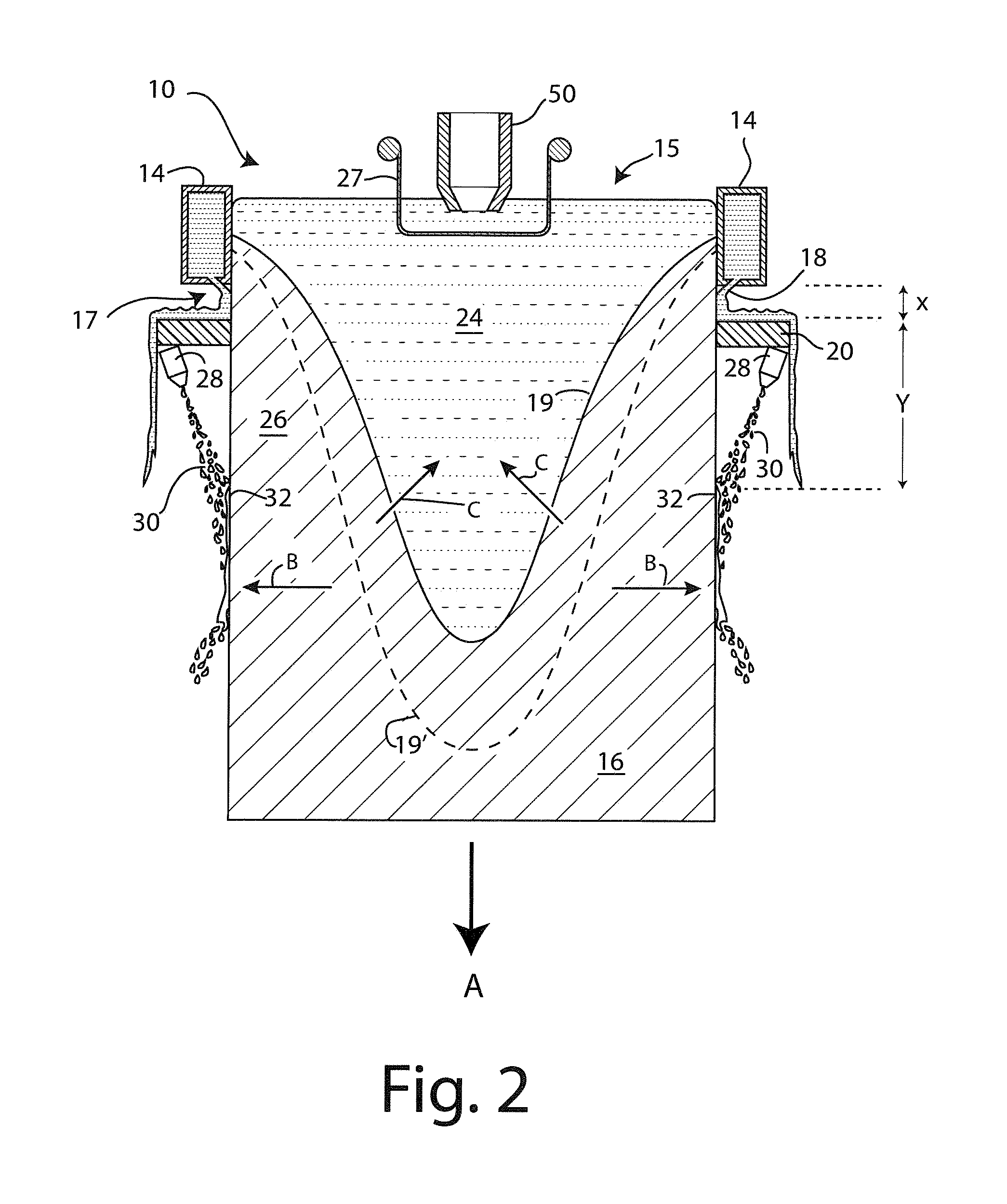

In-situ homogenization of DC cast metals with additional quench

The invention relates to a method and apparatus for direct chill casting ingots with in-situ homogenization. Large particles of eutectic material may form in the solid ingot and the metal may exhibit macrosegregation of alloying components, especially when large ingots are cast in this way. This can be alleviated by applying a first liquid coolant to the ingot emerging from the mold, removing the first liquid coolant at a certain distance along the ingot by means of a wiper, and then applying a second liquid coolant to perform a quench at a greater distance along the ingot. The quench raises the level of the molten sump in the ingot, which helps to overcome the indicated problems, without affecting the desired temperature rebound of the ingot shell (usually at least 425° C. (797° F.)) for a time effective to cause in-situ homogenization.

Owner:NOVELIS INC

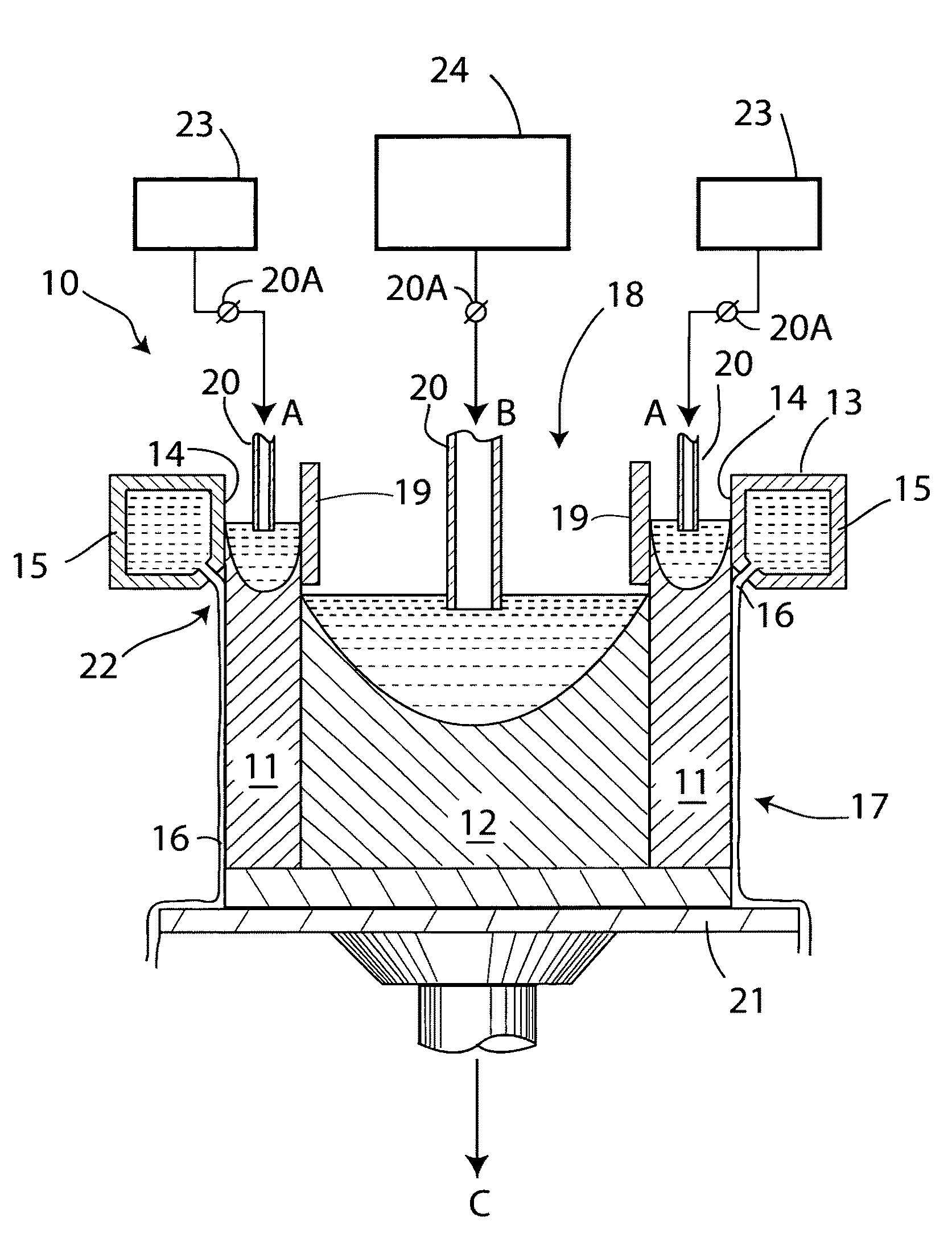

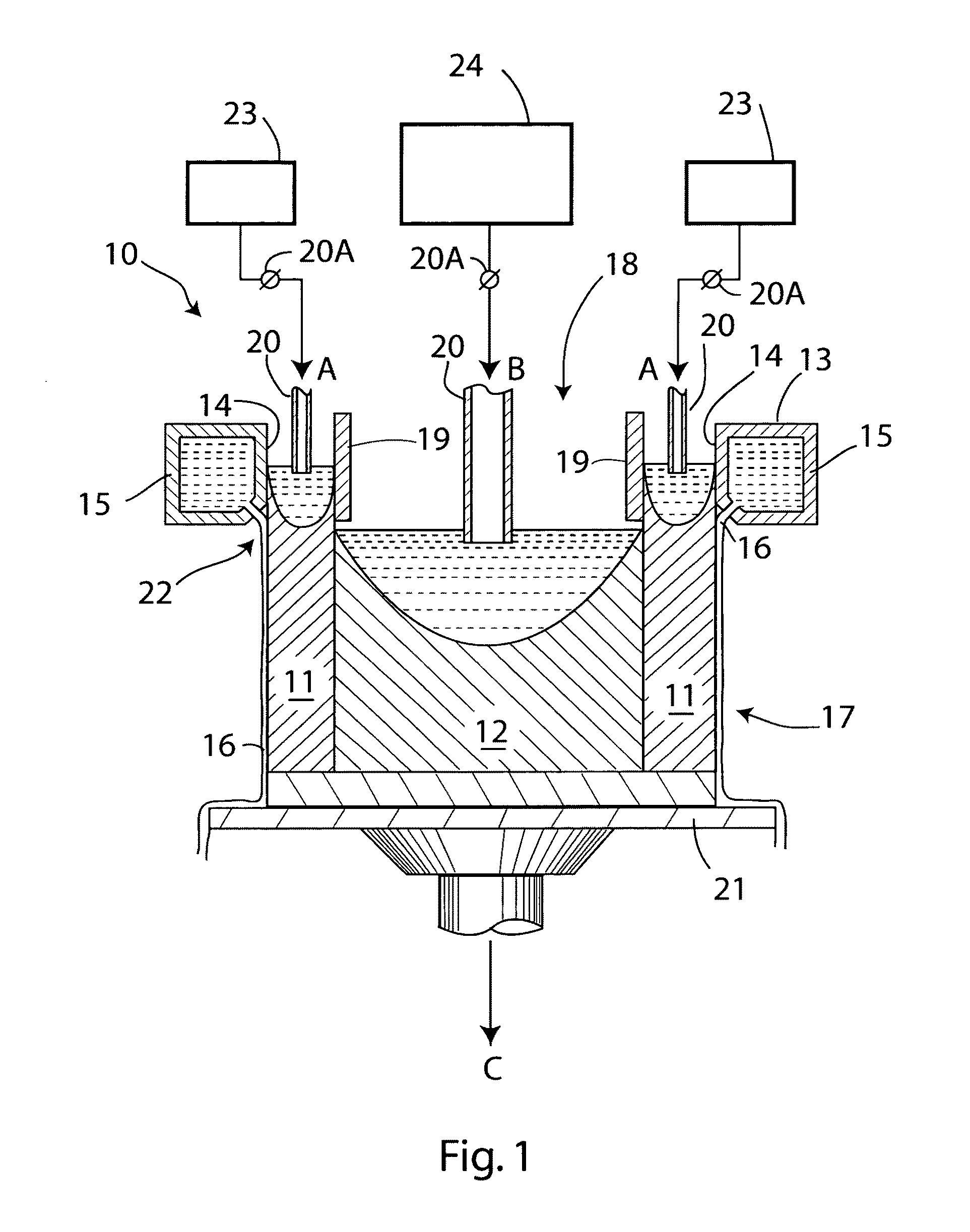

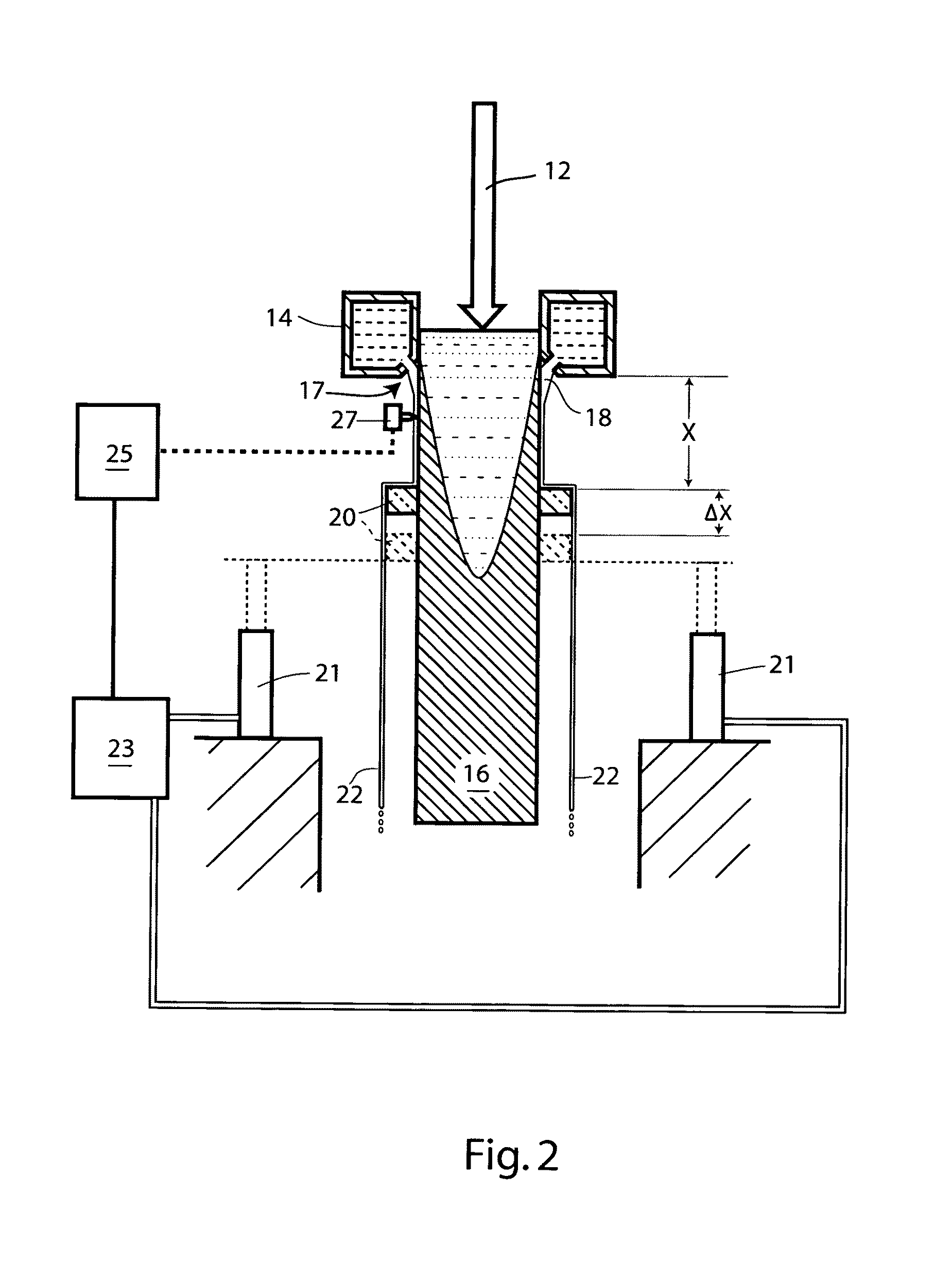

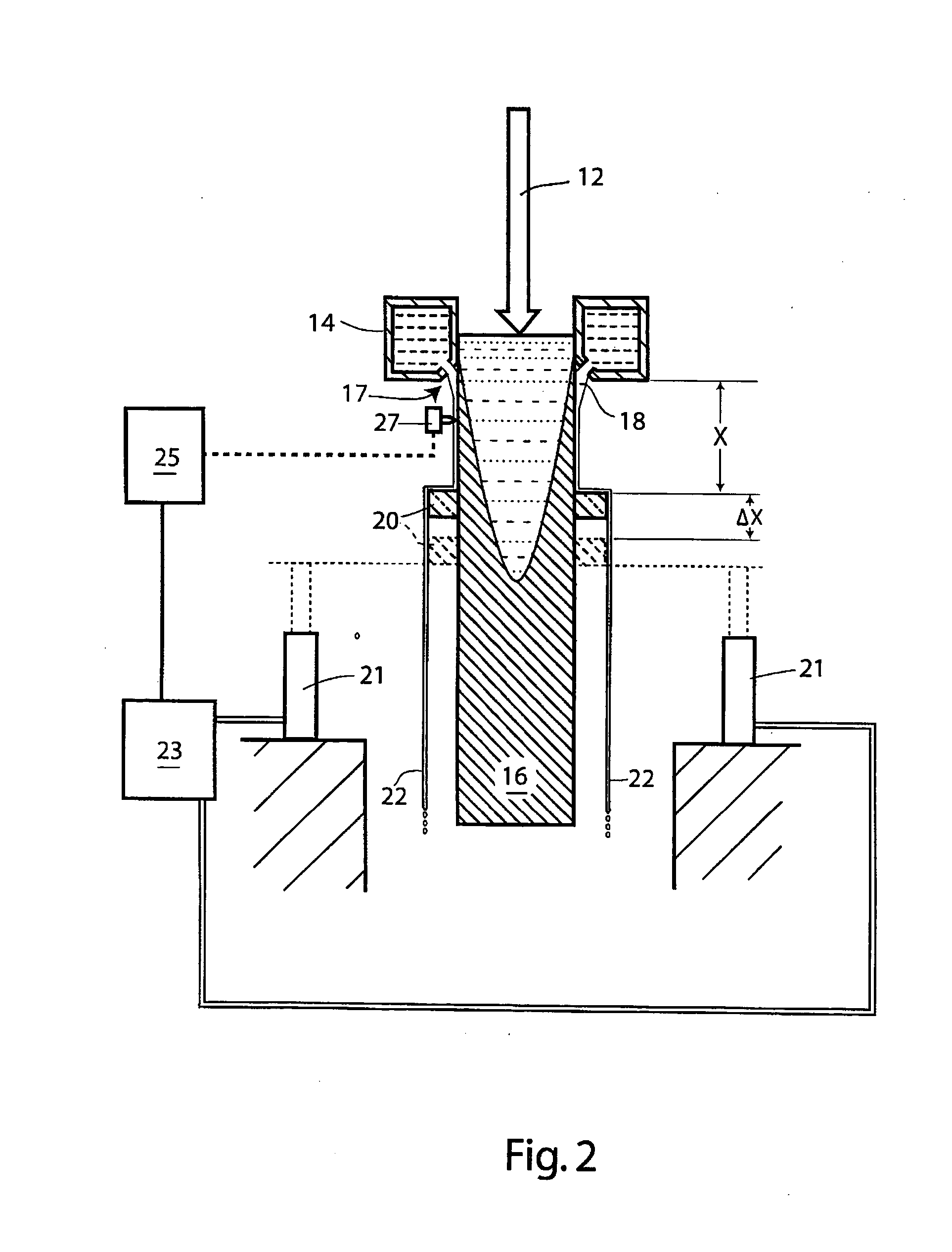

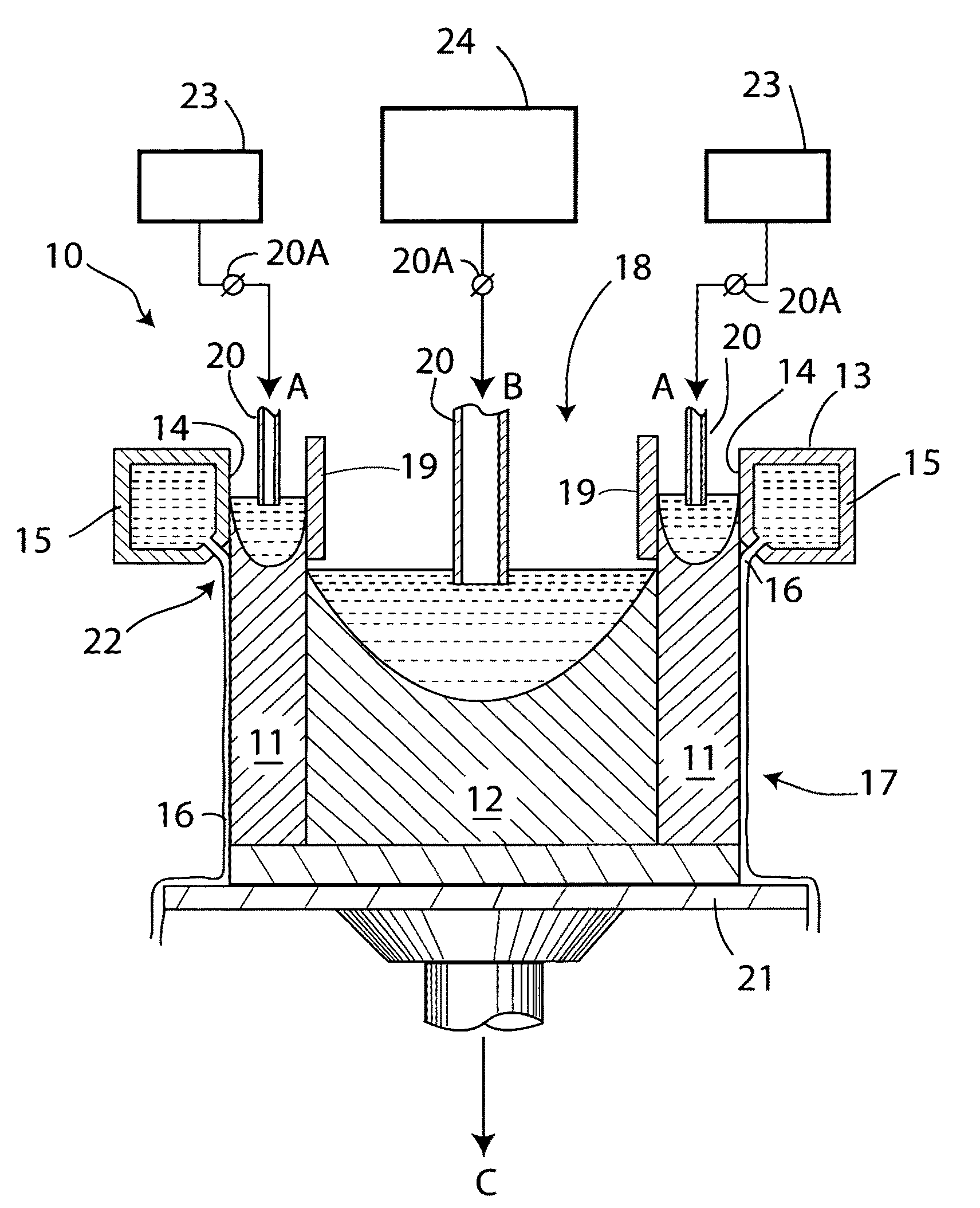

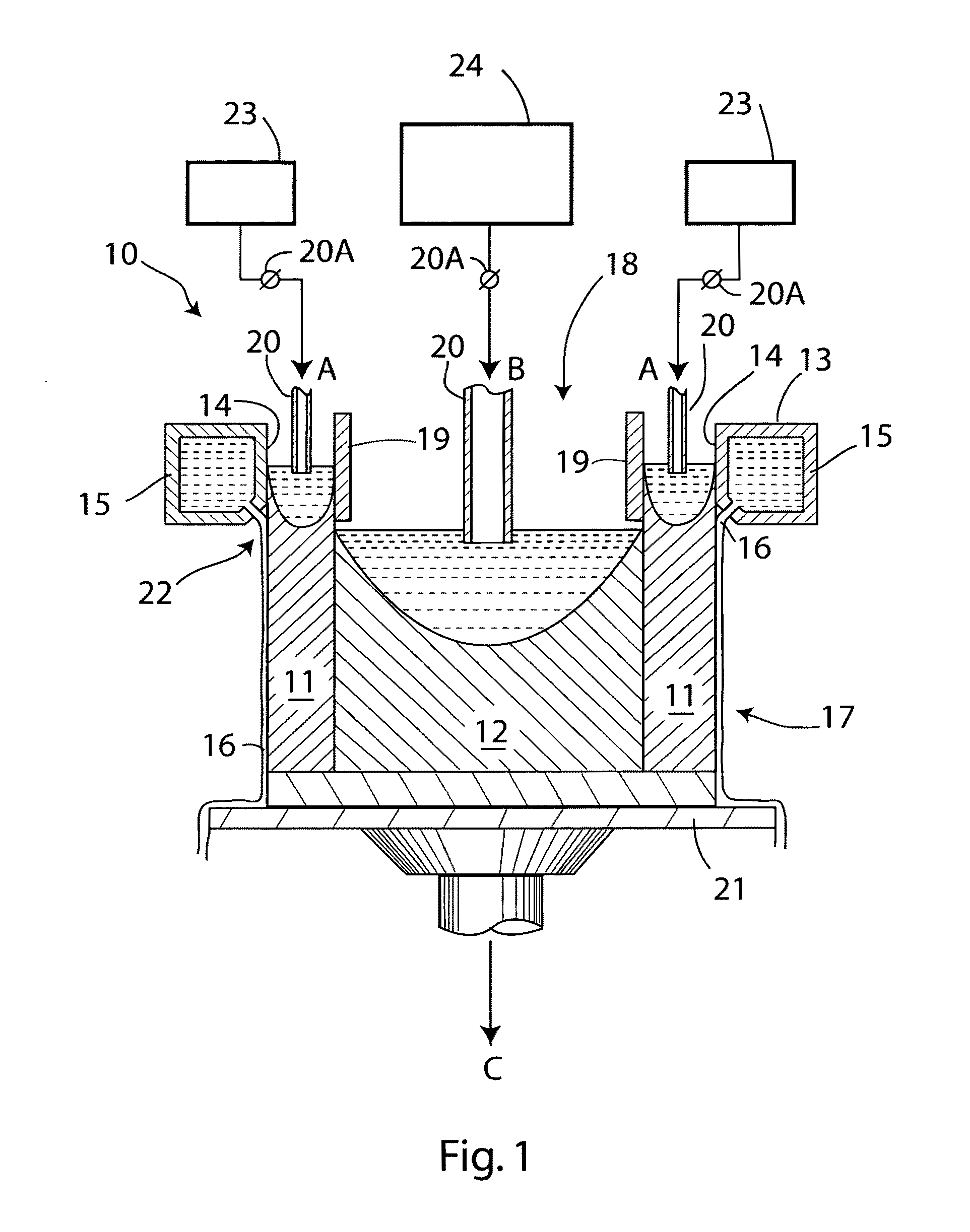

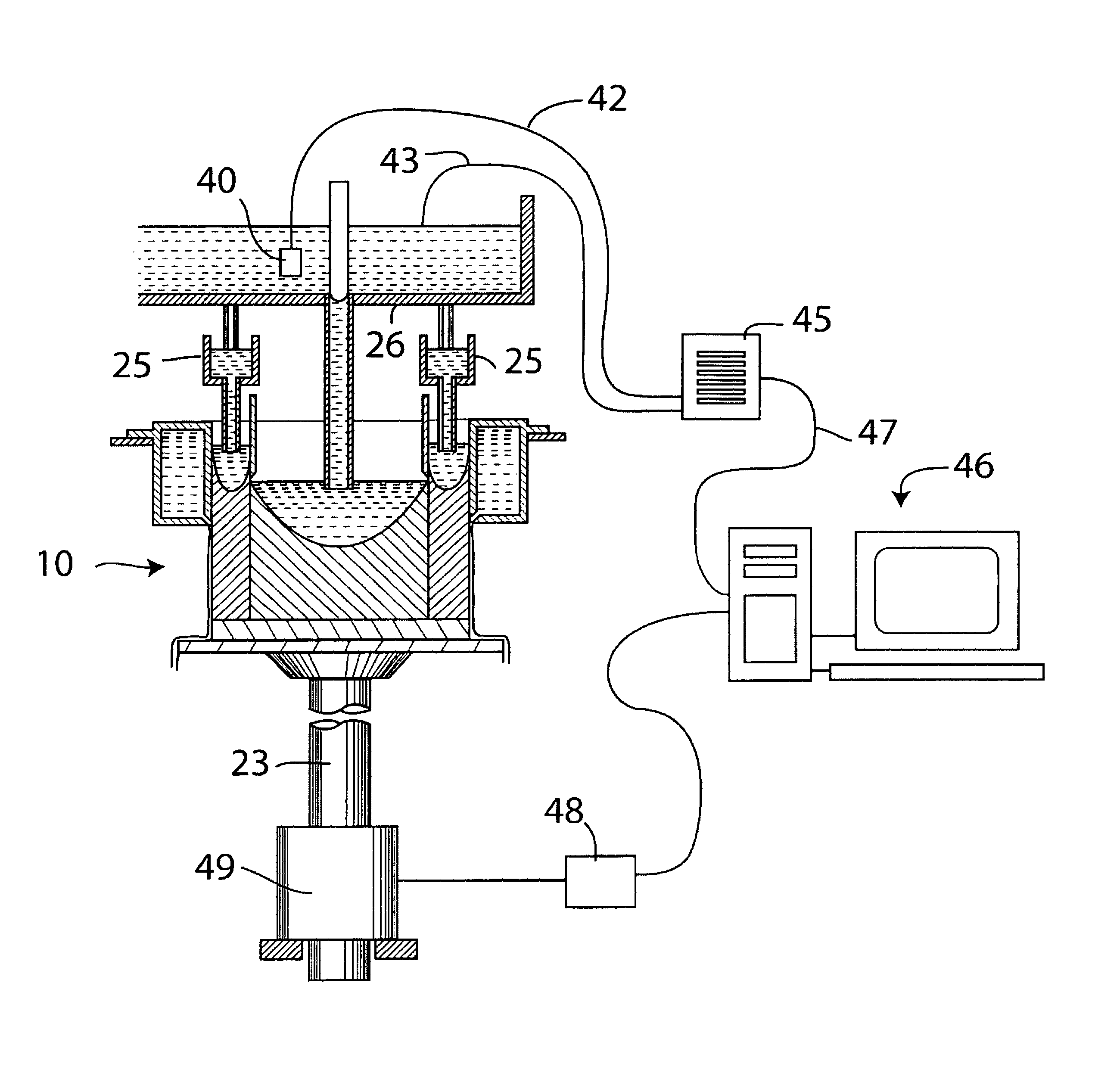

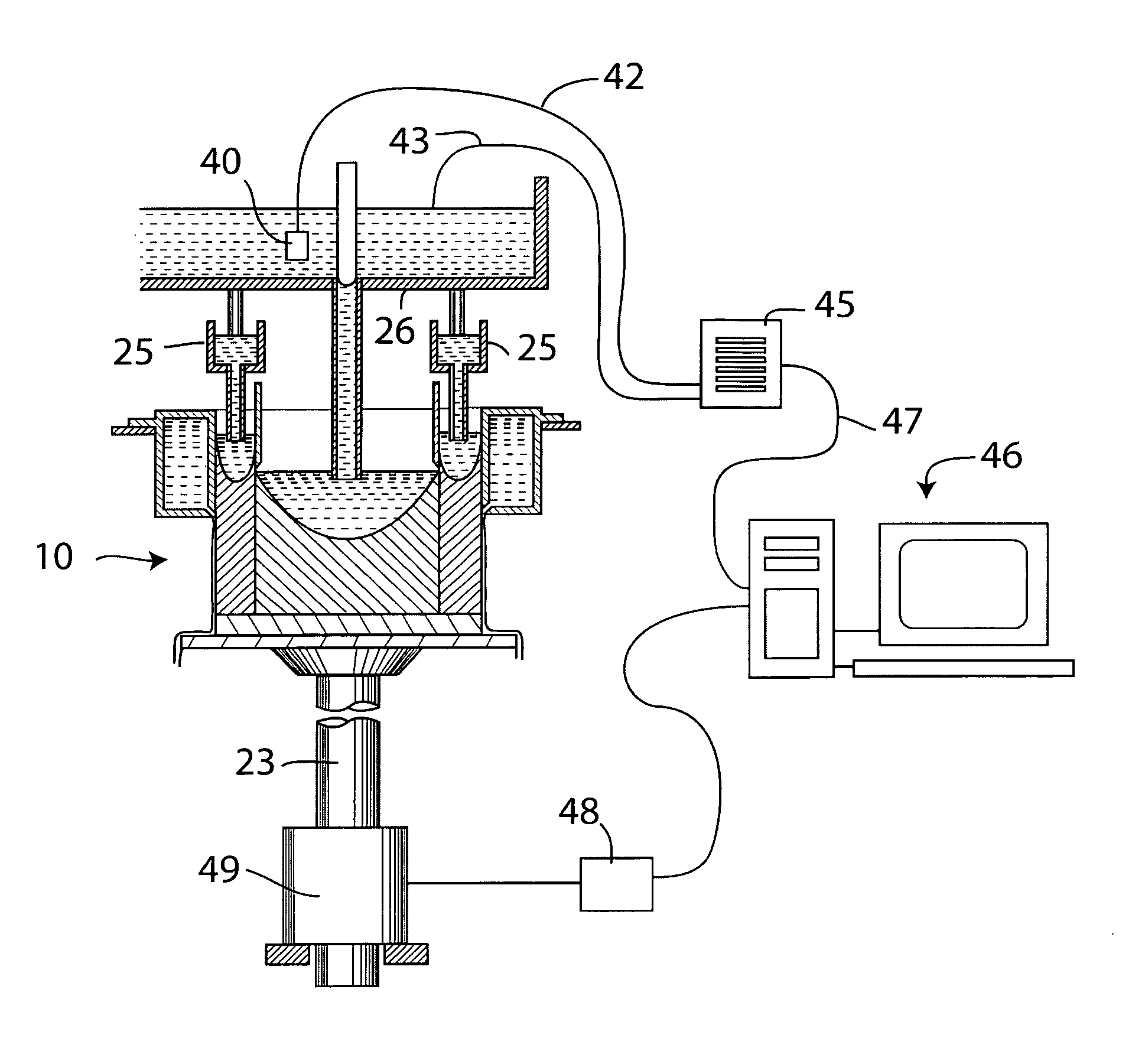

Casting composite ingot with metal temperature compensation

ActiveUS8418748B2Increase and decreases amount of heatSpeed up coolingCasting safety devicesMoulding machine componentsMetallurgyDirect chill casting

An exemplary embodiment of the invention provides a method of direct chill casting a composite metal ingot. The method involves sequentially casting two or more metal layers to form a composite ingot by supplying streams of molten metal to two or more casting chambers within a casting mold of a direct chill casting apparatus. Inlet temperatures of one or more of the streams of molten metal are monitored at a position adjacent to an inlet of a casting chamber fed with the stream, and the inlet temperatures are compared with a predetermined set temperature for the stream to determine if there is any difference. A casting variable that affects molten metal temperatures entering or within the casting chambers (e.g. casting speed) is then adjusted by an amount based on the difference of the compared temperatures to eliminate adverse casting effects caused by the difference of the inlet temperature and the set temperature. Preferably an adjustment is selected that causes the monitored temperature to approach the set temperature. Another exemplary embodiment provides equipment for operation of the method.

Owner:NOVELIS INC

Sequential casting of metals having similar freezing ranges

A method and apparatus is disclosed for sequentially direct chill casting a composite ingot made of metals having similar freezing ranges. Poor adhesion between the layers and low reliability of casting are addressed by adjusting the position of secondary cooling (created by applying water streams to the emerging ingot) relative to the upper surfaces of the molten metal pools compared to the conventional positions of first application of the secondary cooling. This can be achieved by moving one or more walls of the mold (when the secondary cooling emanates from the bottom of such walls), or adjusting the height of the molten metal pools within the mold and moving cooled divider walls between the pools. The relative temperatures and conditions of the metals at positions where they meet at the metal interface may therefore be optimized.

Owner:NOVELIS INC

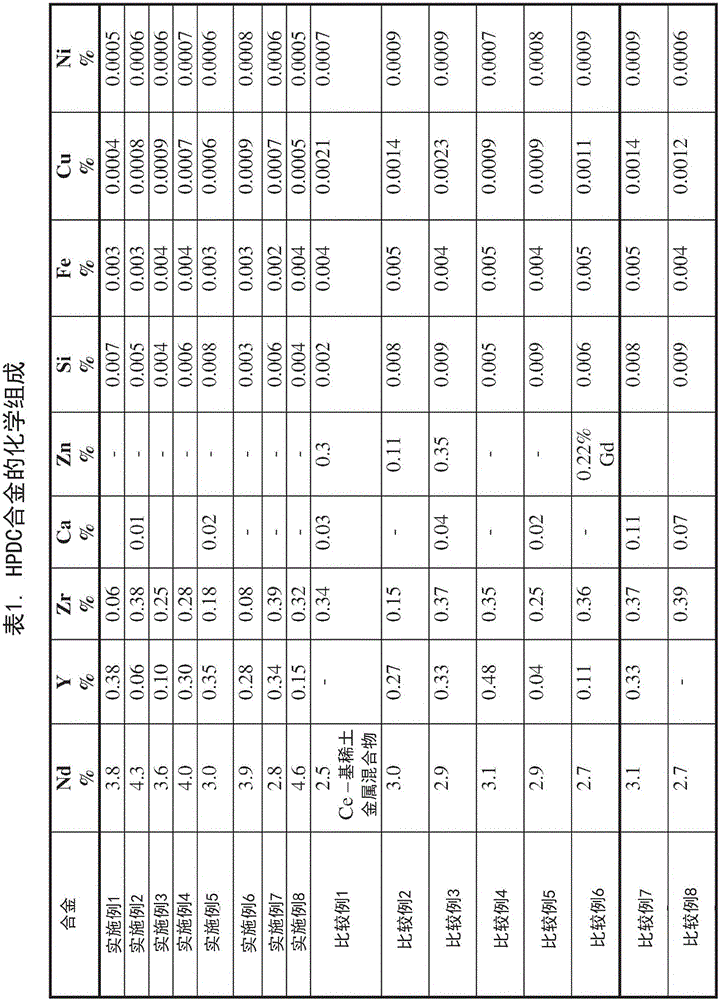

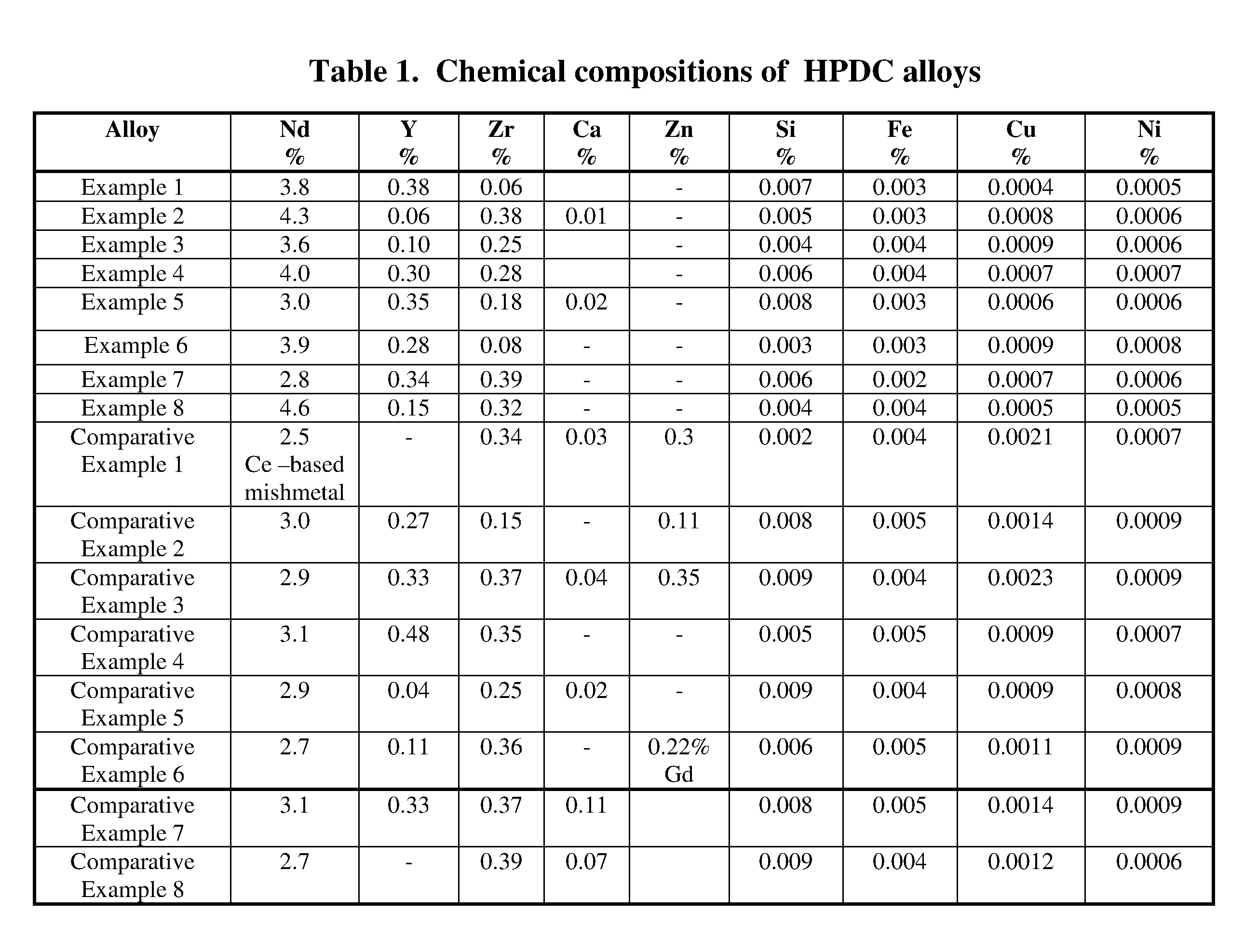

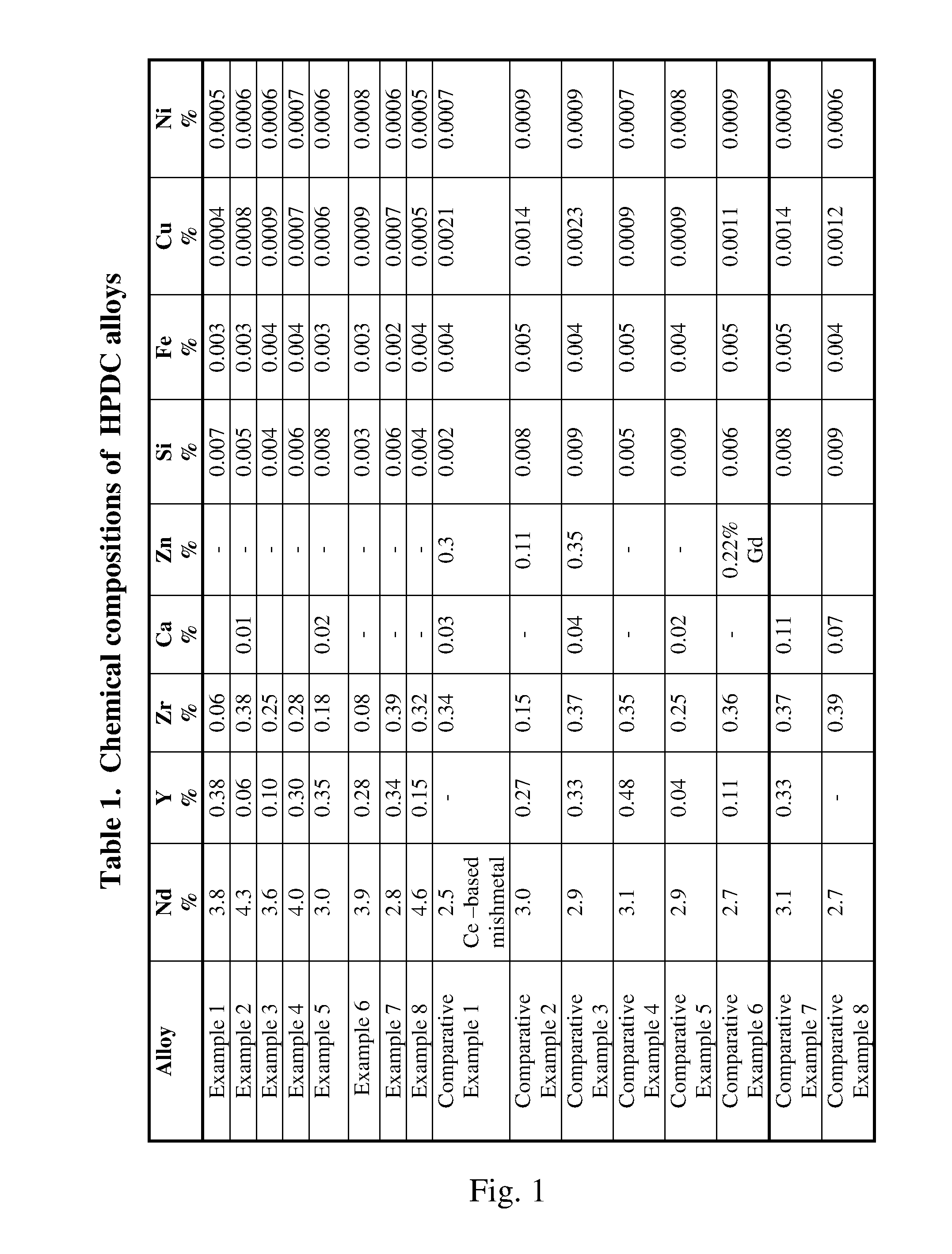

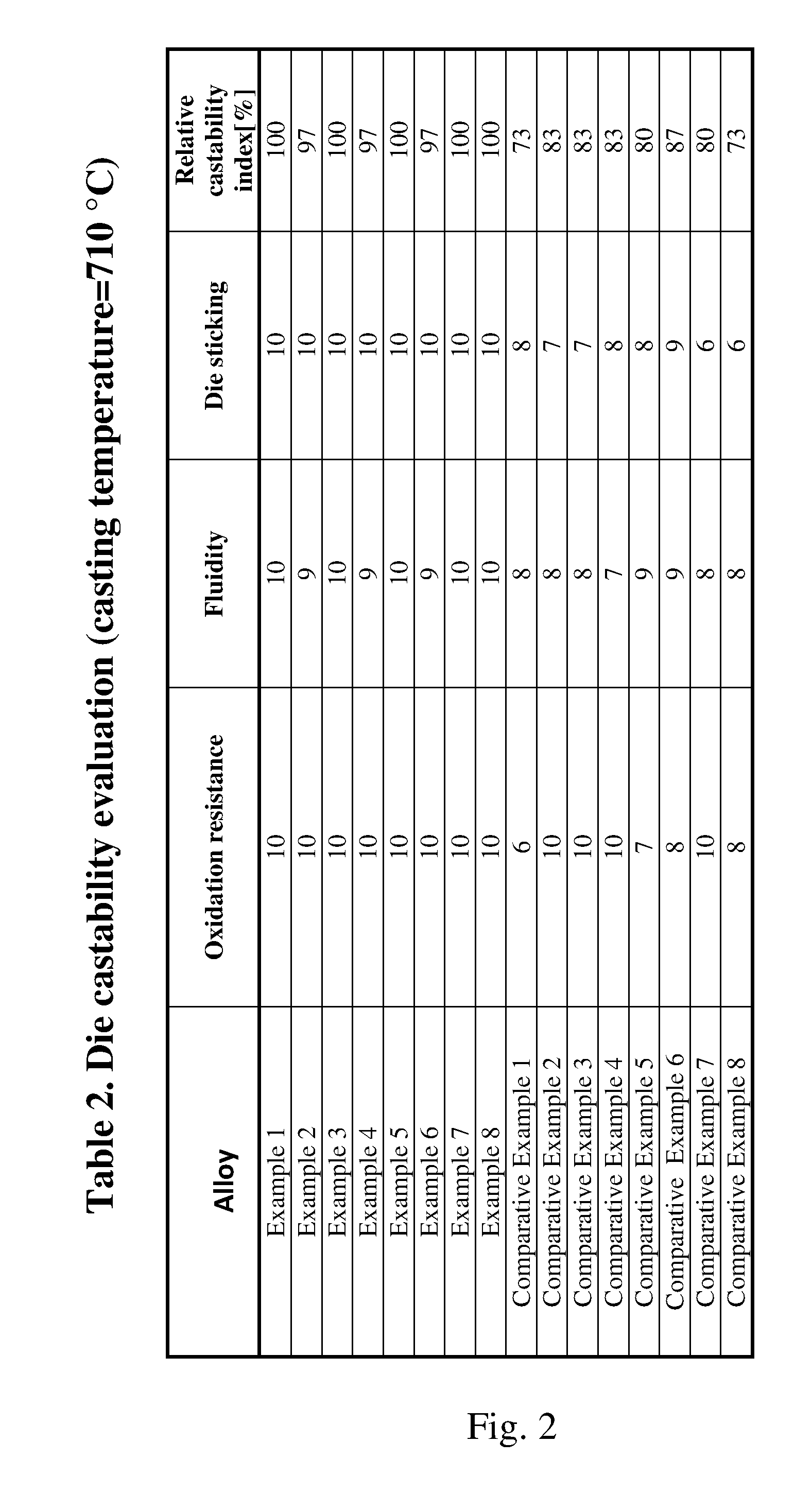

High performance creep resistant magnesium alloys

A magnesium based alloy consisting of, by weight: at least 94.8% magnesium, 2.5-4.6% neodymium, 0.05-0.40% yttrium, and 0.03-0.65% zirconium and incidental impurities. Optionally, the alloy further contains up to 0.02wt% calcium. The alloy is suitable for high pressure die casting (HPDC) as well as for sand casting, investment casting, permanent mold casting, twin roll casting and direct chill casting. The disclosed alloy exhibits good castability, high strength, high corrosion resistance and high creep resistance at room temperature, as well as in high temperatures.

Owner:DEAD SEA MAGNESIUM

Apparatus and method for liquid metals treatment

ActiveUS9498820B2Effective dispersionEvenly distributedStirring devicesCasting apparatusParticulatesMetallic materials

This invention relates to an apparatus (high shear device) and method for treating liquid metals by intensive melt shearing. The apparatus comprises a stator and a rotor with a small gap between them to provide intensive melt shearing for dispersing efficiently and distributing uniformly gas, liquid and solid phases in liquid metals without severe turbulence at the melt surface. The device can be extended to a multistage high shear pump by arranging individual rotor / stator assemblies either concentrically (one in another) or vertically. The device and high shear pump can be readily integrated into existing casting processes. The device is suitable for use in casting processes including high pressure die casting, low pressure die casting, gravity die casting, sand casting, investment casting, direct chill casting, twin roll casting, and any other casting process which requires liquid metal as a feedstock. In addition, the device is particularly suitable for providing conditioned liquid metal for both shape casting and continuous (or semi-continuous) casting of metallic materials, preparing high quality semi-solid slurries, solidification processing of particulate reinforced metal matrix composites, mixing immiscible metallic liquids and degassing of liquid metals prior to any casting processes.

Owner:BRUNEL UNIVERSITY

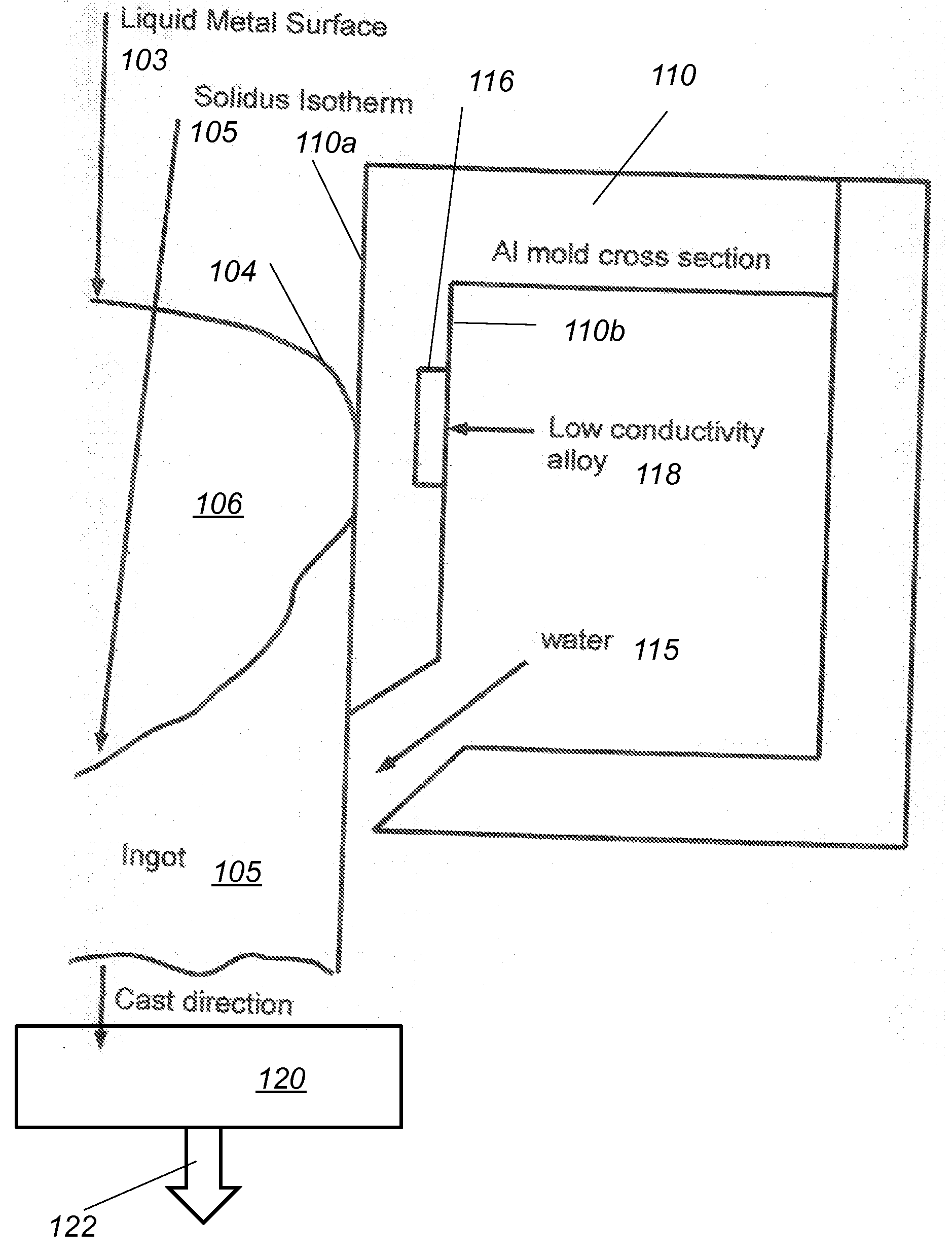

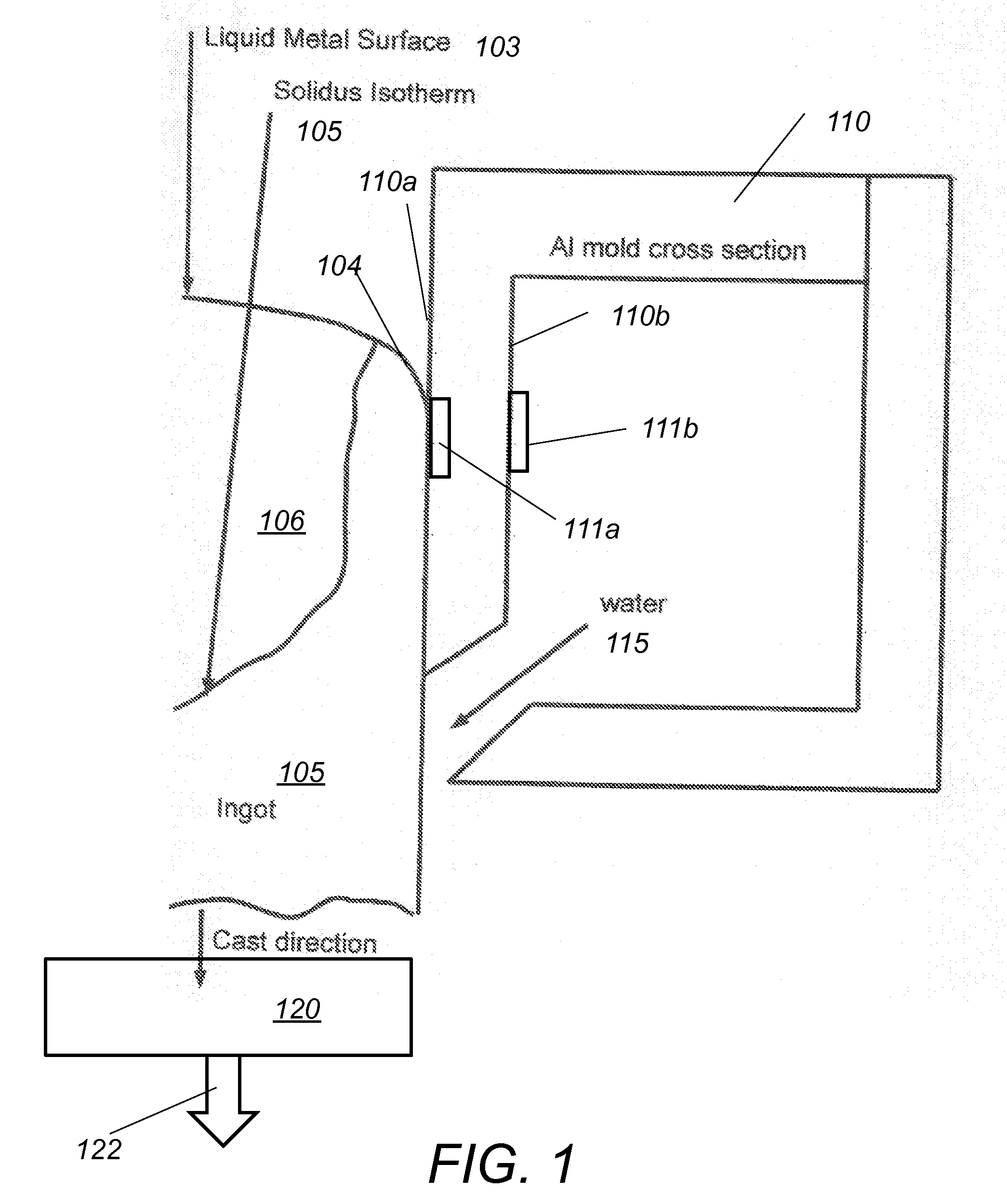

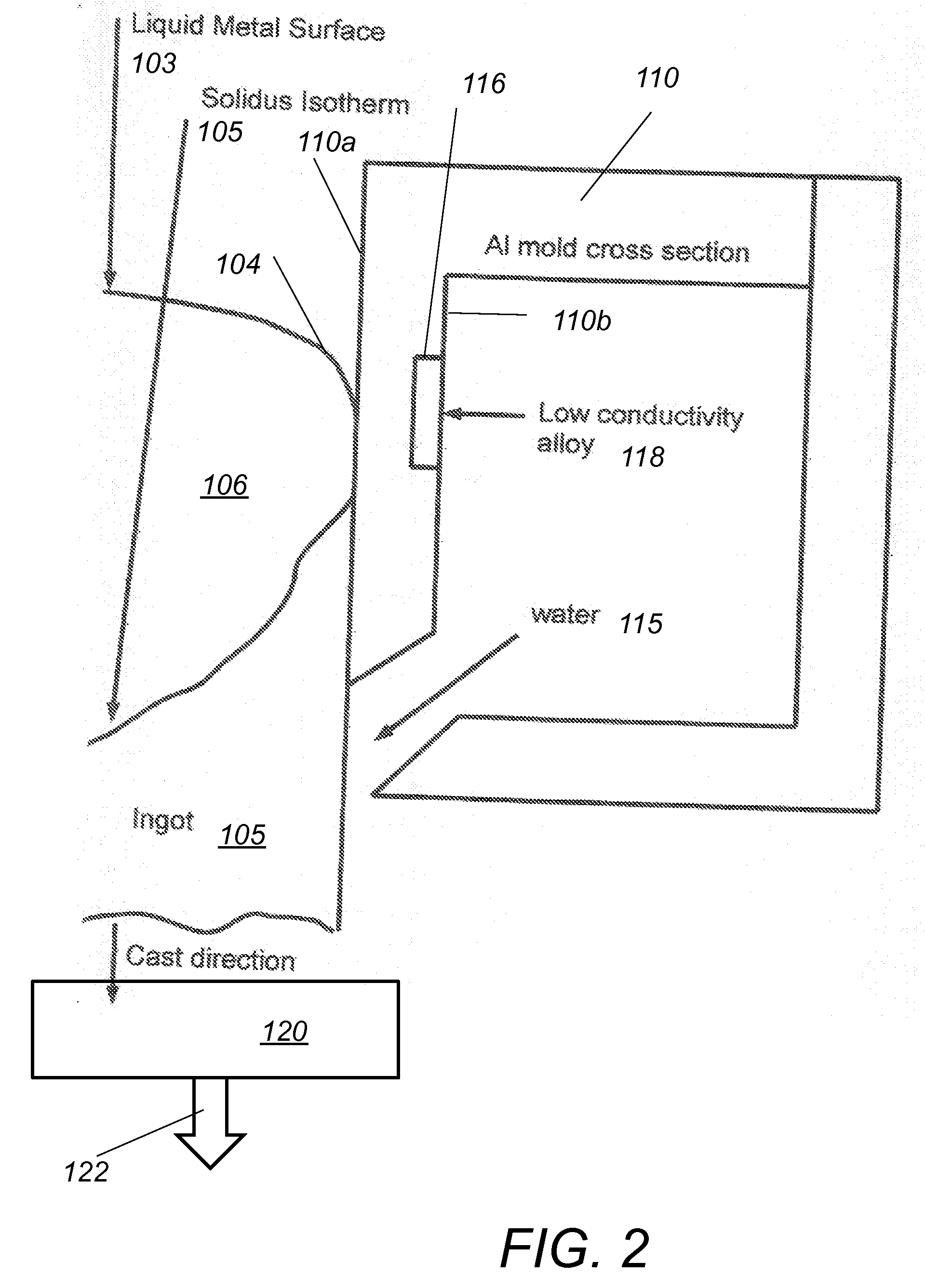

Process and apparatus for direct chill casting

ActiveUS20100269999A1Low thermal conductivityInhibit thermal stressMelt-holding vesselsDirect chill castingMolten metal

An improved apparatus for direct chill casting of metals includes a mold, a bottom block assembly and a coolant. The mold is configured to surround a molten metal with a mold wall and the mold wall has an outer surface and an inner surface being in contact with the molten metal. The bottom block assembly is arranged at the bottom of the mold and includes a direct chill casting block configured to move away from the mold as the casting forms a solidifying shell of the molten metal. The coolant surrounds the outer surface of the mold wall and is arranged to remove heat away from the molten metal via the inner surface of the mold wall. The outer surface of the mold wall has a circumferential groove filled with a brazing alloy.

Owner:DUNN EDMUND M

Casting composite ingot with metal temperature compensation

ActiveUS20110198050A1Increase and decreases amount of heatSpeed up coolingCasting safety devicesMoulding machine componentsMetallurgyDirect chill casting

An exemplary embodiment of the invention provides a method of direct chill casting a composite metal ingot. The method involves sequentially casting two or more metal layers to form a composite ingot by supplying streams of molten metal to two or more casting chambers within a casting mold of a direct chill casting apparatus. Inlet temperatures of one or more of the streams of molten metal are monitored at a position adjacent to an inlet of a casting chamber fed with the stream, and the inlet temperatures are compared with a predetermined set temperature for the stream to determine if there is any difference. A casting variable that affects molten metal temperatures entering or within the casting chambers (e.g. casting speed) is then adjusted by an amount based on the difference of the compared temperatures to eliminate adverse casting effects caused by the difference of the inlet temperature and the set temperature. Preferably an adjustment is selected that causes the monitored temperature to approach the set temperature. Another exemplary embodiment provides equipment for operation of the method.

Owner:NOVELIS INC

High performance creep resistant magnesium alloys

The invention provides a magnesium based alloy consisting of at least 94.8% magnesium, 2.5-4.6% neodymium, 0.05-0.40% yttrium, and 0.03-0.65% zirconium, exhibiting good castability, high strength, high corrosion resistance and high creep resistance even at high temperatures. The alloy is suitable for high pressure die casting, sand casting, investment casting, permanent mold casting, twin roll casting, or direct chill casting.

Owner:DEAD SEA MAGNESIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com