Sequential casting of metals having similar freezing ranges

一种金属、复合金属锭的技术,应用在铝和铝合金领域,能够解决合金组合困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

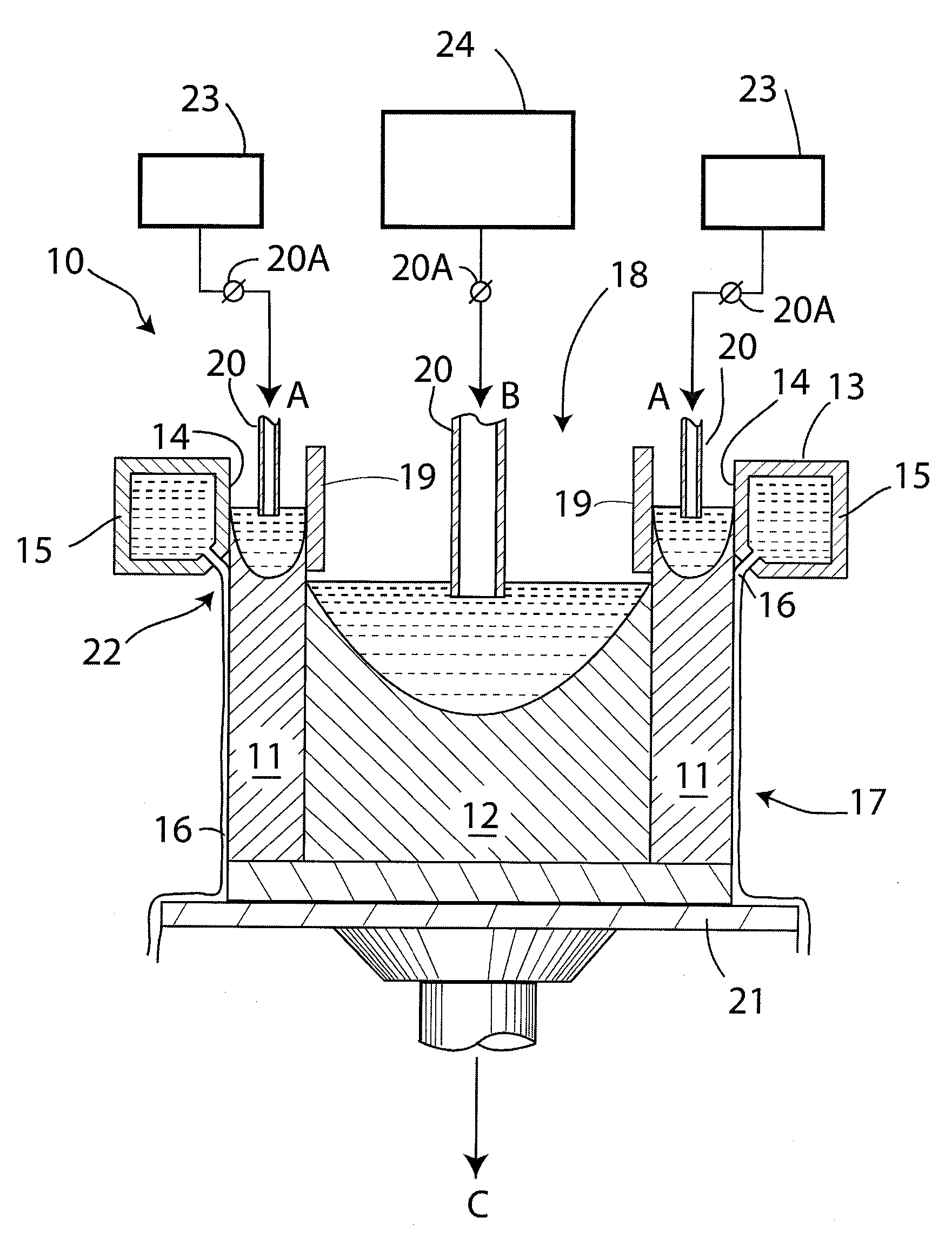

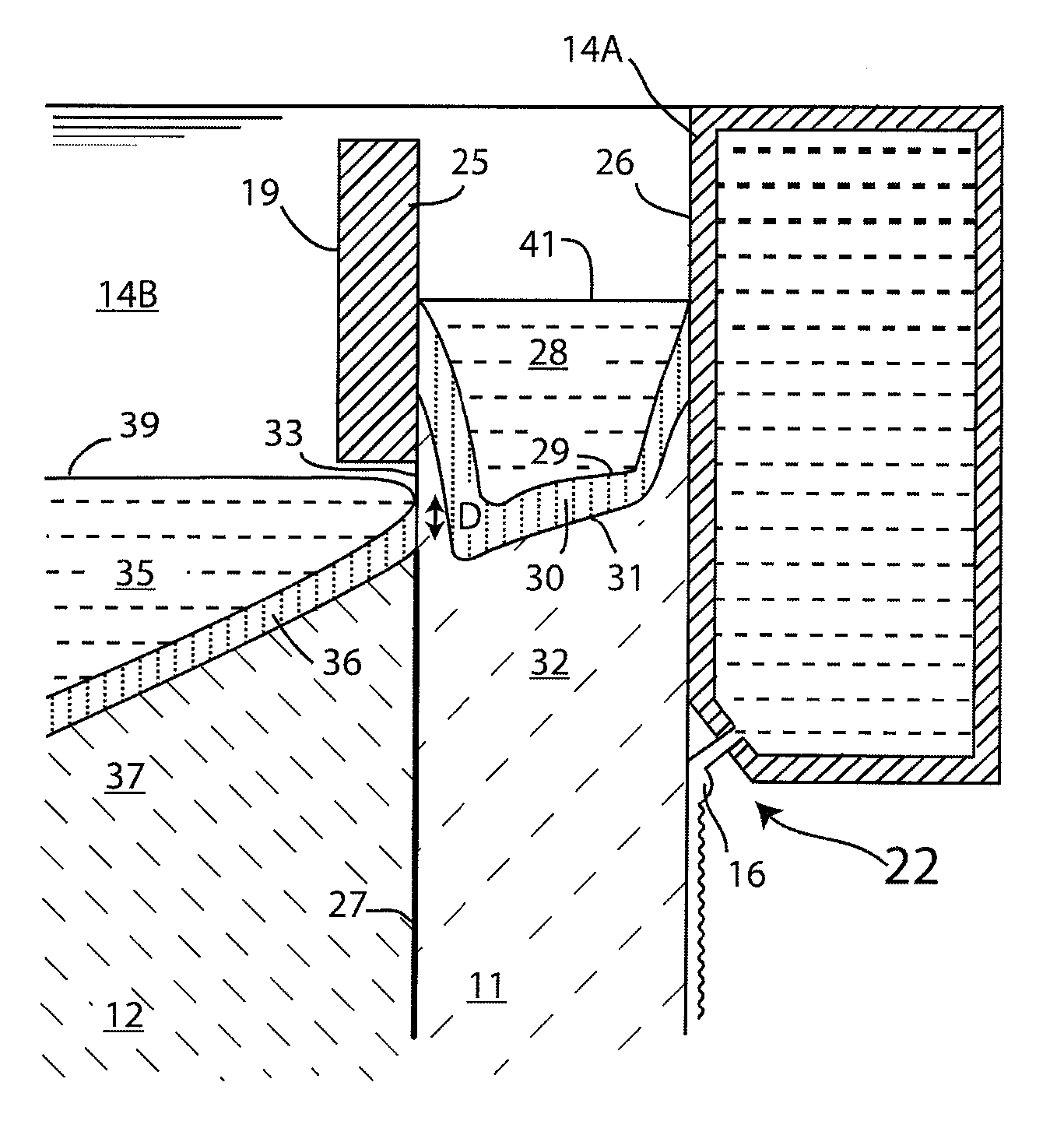

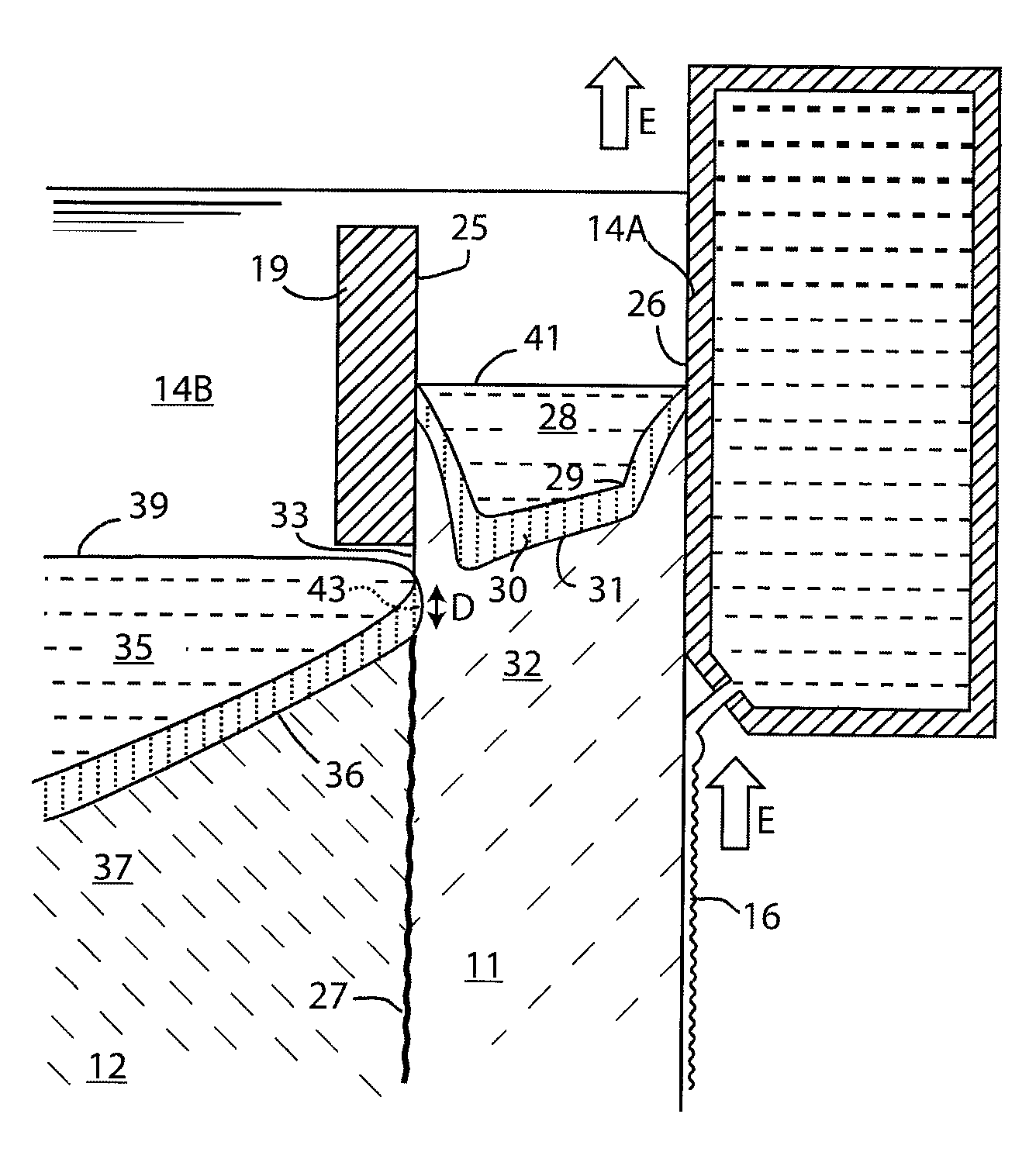

[0023]The present invention may employ casting apparatus of the general type described, for example, in U.S. Patent Publication No. 2005 / 0011630, issued January 20, 2005, to Anderson et al., which is incorporated herein by reference. , but modified from what is described in this article. The present invention also relates to the techniques described in Wagstaff, US Patent No. 6,260,602 (also incorporated herein by reference).

[0024] It is well known that, unlike pure metals, metal alloys do not melt instantly when brought to a specific melting point or temperature (unless the alloy happens to have a eutectic composition). Conversely, when the temperature of the alloy is increased, the metal remains completely solid until the temperature reaches the alloy's solidus temperature, and then the metal enters a semi-solid state (a mixture of solid and liquid) until the temperature reaches the alloy's liquidus temperature , at which temperature the metal will be completely liquid. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com