High performance creep resistant magnesium alloys

An alloy and lightweight alloy technology, applied in the field of creep-resistant magnesium-based alloys, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

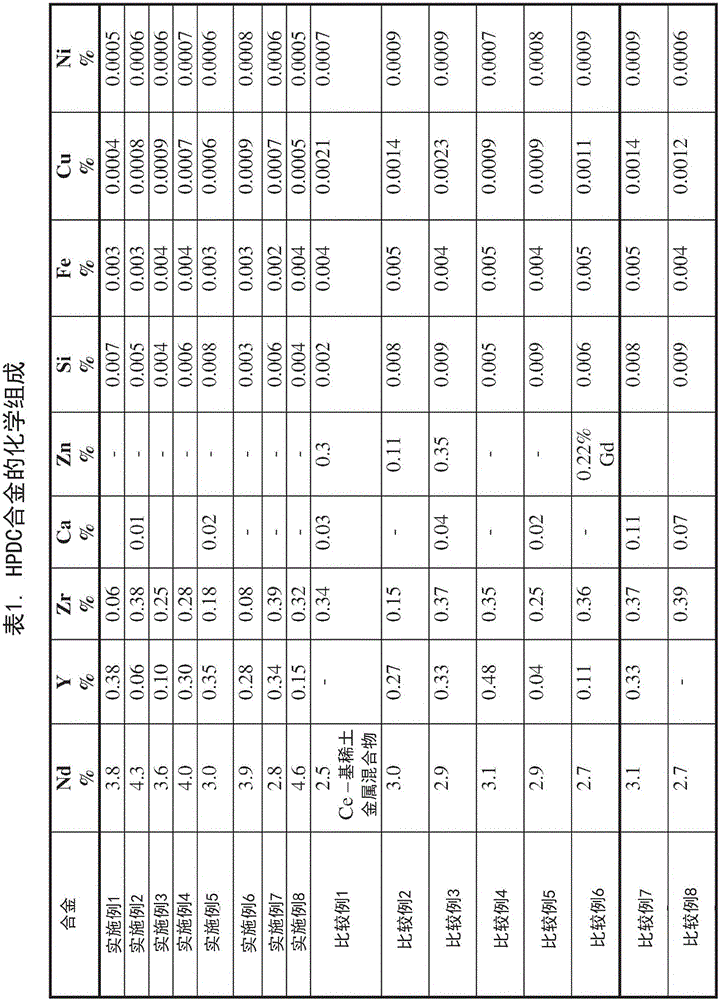

[0050] The alloys of the present invention were prepared in 150 1 crucibles made of mild steel. CO 2 A mixture of +0.5% HFC134a was used as a protective atmosphere. The raw materials used are as follows:

[0051] Magnesium (Mg) - Pure magnesium, grade 9980A, containing at least 99.8% magnesium.

[0052] Neodymium (Nd) - Commercially available pure Nd (less than 0.5% impurity).

[0053] Zirconium (Zr) - Zr95 tablet containing at least 95% Zr.

[0054] Yttrium (Y) - Commercially available pure Y (less than 1% impurity).

[0055] Calcium (Ca) - Pure Ca (less than 0.1% impurity).

[0056] Unlike the alloying process described in CN1752251 which uses intermediate Mg-Nd, Mg-Ca and Mg-Zr master alloys, the alloy of the present invention is prepared with pure Nd and pure Ca, which significantly simplifies the process and reduces the duration of the process And significantly reduce the cost of the alloy. The neodymium and zirconium are added with vigorous stirring of the melt, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com