High strength aluminum casting alloy

a casting alloy, high-tensile technology, applied in the field of aluminum casting alloys, can solve the problems of difficult casting of high-tensile 7xxx series alloys, and achieve the effects of improving mechanical properties, high strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023]A cast aluminum (Al) alloy having the chemical composition shown in Table 1 was melted and cast at Universal Alloy Corporation, located in Anaheim, Calif. by direct chill (DC) casting in the form of 178 millimeter (mm) diameter billets.

TABLE 1Cast Alloy Composition.AlZnMgCuMnSiFeZrScTiOtherBal.7.122.011.620.330.010.030.170.28

After casting, the billets were homogenized by holding at 475° C. for 23 hours, then were slow cooled from 475 C to 250° C. within 14 hours and then cooled to room temperature in air. The homogenized billets were ultrasonically tested using an AMS standard AMS-STD-2154 N / C, Type I, Class A, and no cracks or porosity were detected. Tensile samples were extracted from the homogenized billets in three orthogonal directions. The longitudinal direction was parallel to the main axis of the billet. The radial direction was directed along the billet radius, and the transverse direction was perpendicular to the longitudinal and radial directions...

example 2

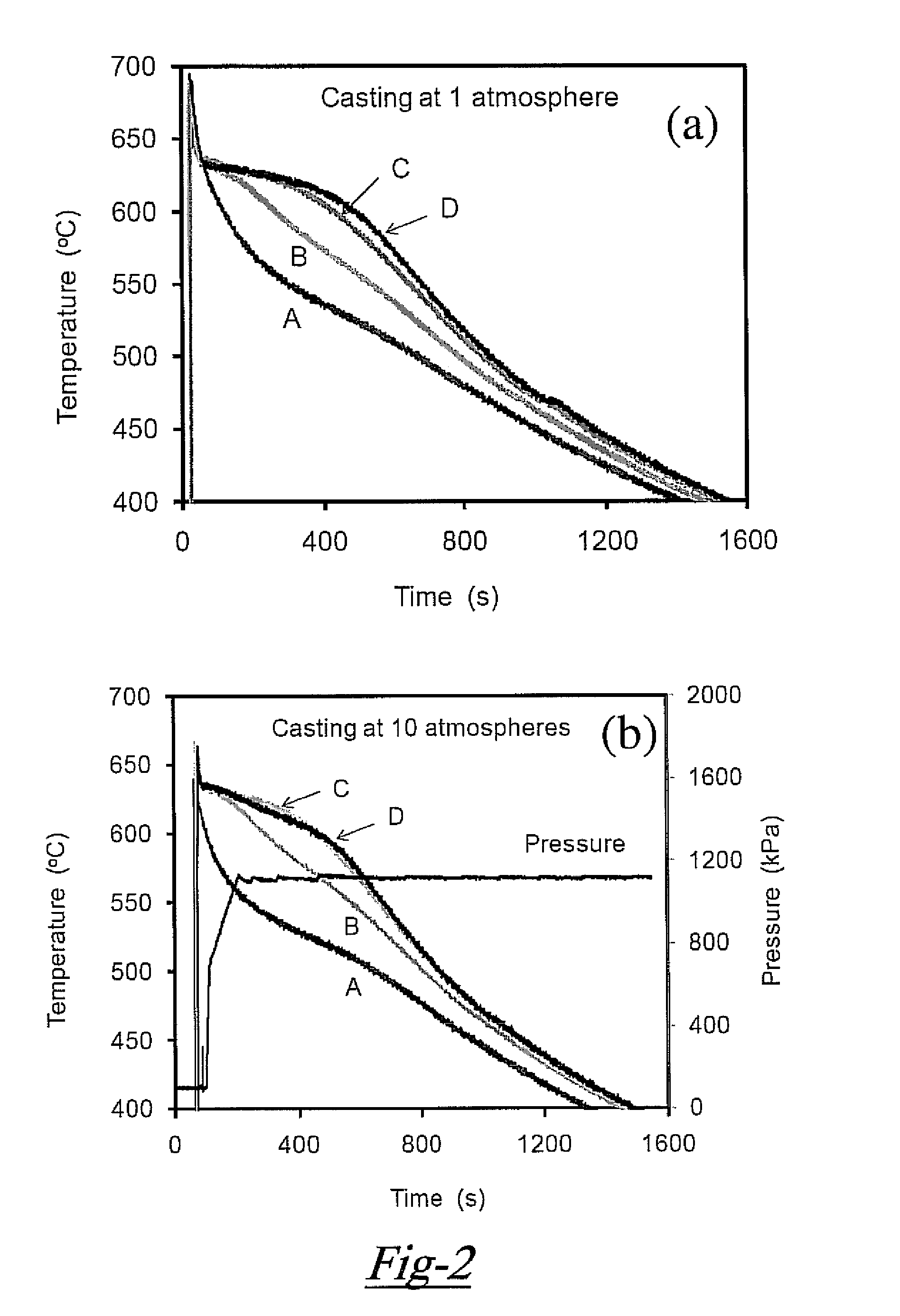

Sand Casting Under Hydrostatic Pressure

[0026]In this example, charges of the DC cast billets described in Example 1, of approximately 11.5 kilograms (kg) each, were re-melted in an electrically heated crucible furnace at 760° C., degassed using argon gas for 3 minutes, and poured into two wedge sand molds. One mold was kept in air under the normal atmospheric pressure, while another mold was immediately placed inside a pressure vessel. The pressure vessel was 1.2 meter (m) in diameter and 1.8 m in height, and pressure was applied via a near-equal mixture of dry compressed air and compressed nitrogen gas. The peak pressure of 10 atm was achieved within the pressure vessel approximately 90 seconds after pouring of a wedge. In this manner, one cast wedge of the Al alloy was solidified at 1 atm and another wedge was solidified at 10 atm of pressure.

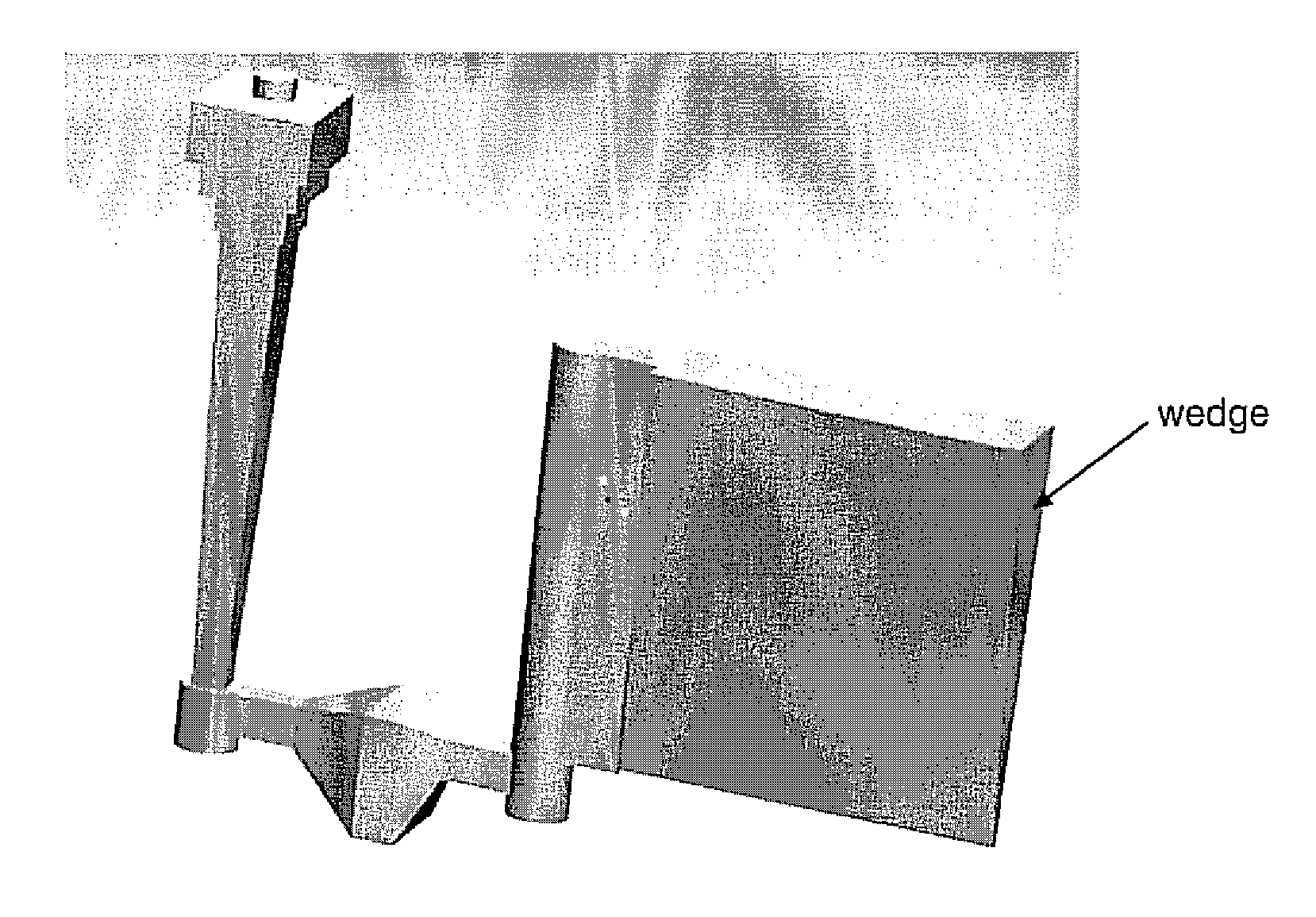

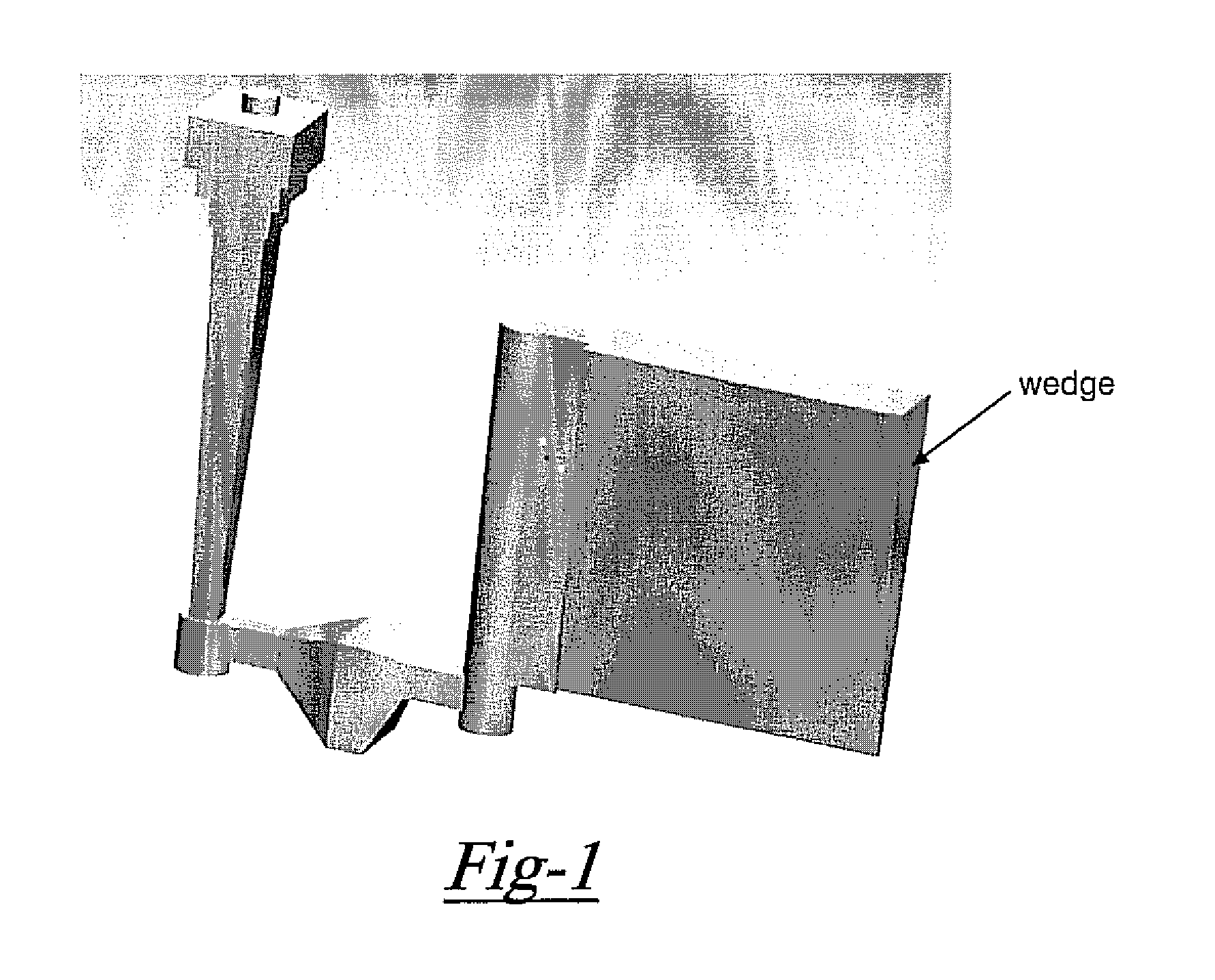

[0027]A schematic of the wedge casting and gating system is shown in FIG. 1. The wedge thickness increased from 6.4 mm at the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com