Equipment and method for casting plurality of aluminum alloy ingots with small diameters by using vertical direct chilling casting (DC)

An aluminum alloy ingot, small-diameter technology, applied in the field of equipment and methods for casting aluminum alloy ingots, can solve the problems of poor liquid metal temperature consistency, poor water cooling uniformity, ingot suspension, etc., to improve the quality of ingots, Improve the casting yield and prevent the effect of cracking and running out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

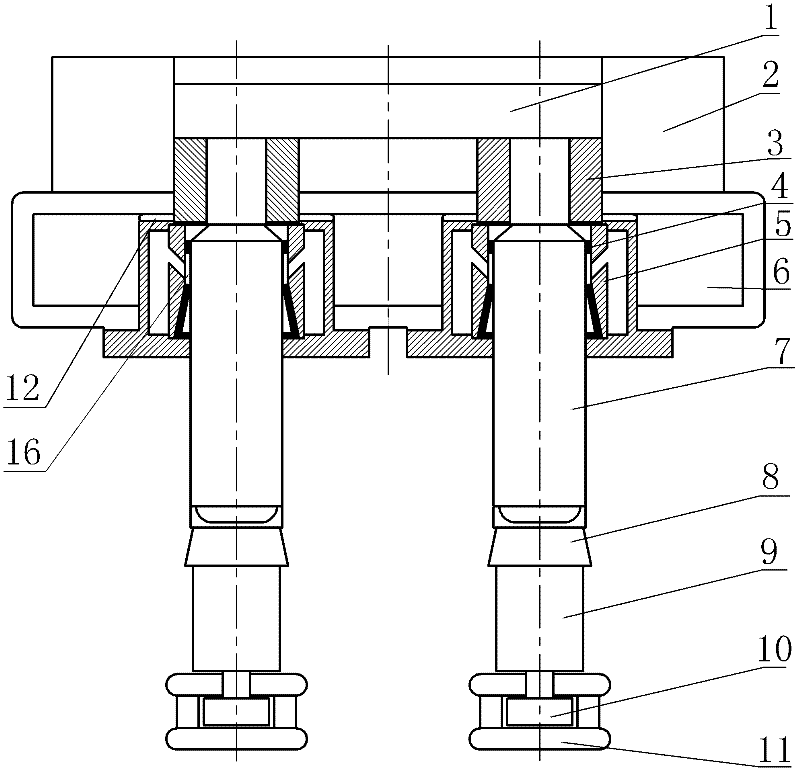

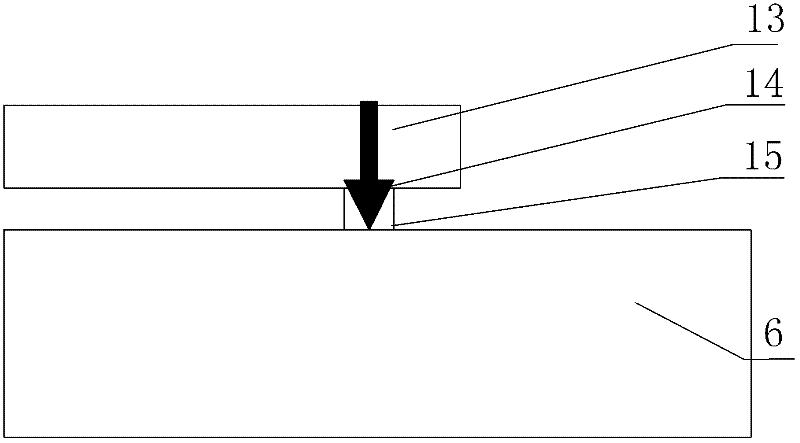

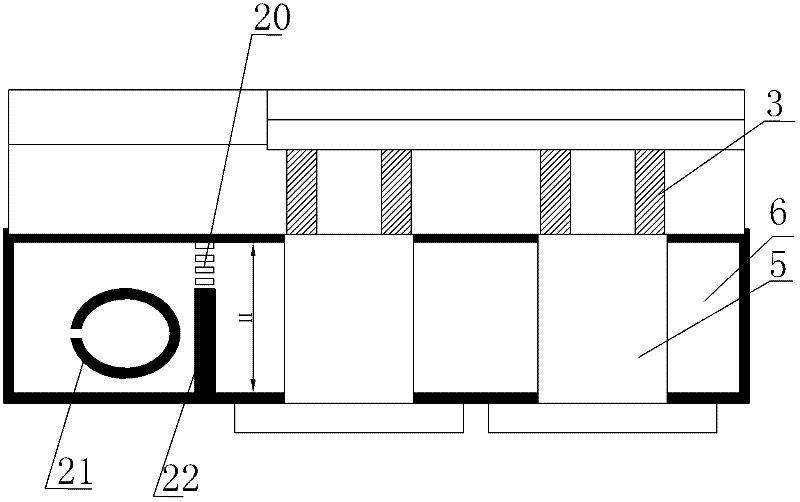

[0022] Specific implementation mode one: as Figure 1-7 As shown, the equipment for vertical DC casting of multiple small-diameter aluminum alloy ingots described in this embodiment includes a casting system, a flow supply and distribution system, and a water supply system. The casting system includes a thermal insulation cover 2 and A plurality of hot top hats 3, a plurality of long graphite rings 4, a plurality of crystallizers 5 and a plurality of dummy ingot devices arranged in the same number; the flow distribution system includes a flow storage tank 15 and a flow channel 1; the flow flow channel 1 is a planar pipe network in which the branch flow channels at all levels are vertically and horizontally intersected and connected. The plurality of thermal top caps 3 are evenly distributed and vertically arranged in the insulation cover 2, and the branch flow channels 1 are horizontally placed in the insulation cover 2 and located in multiple The upper end of the heat top cap...

specific Embodiment approach 2

[0024] Specific implementation mode two: as Figure 1-7 As shown, the length of the long graphite ring 4 in this embodiment is 1.0-2.0 times the diameter of the ingot, which can further ensure uniform cooling, and ensure that all parts of the ingot are fully solidified to prevent runaway. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: as Figure 1-7 As shown, several water inlet holes 5-2 and water outlet holes 5-3 are evenly distributed on the crystallizer 5 in the present embodiment, and the total area of the water inlet holes 5-2 is 1.1-1. 2.0 times. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com