Automatic shearing device for cold-rolled variable-thickness plates and shearing method based on automatic shearing device

A technology of variable thickness and automatic plate, applied in shearing machine equipment, shearing device, metal processing equipment and other directions, can solve the problem of not mentioning shearing realization method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

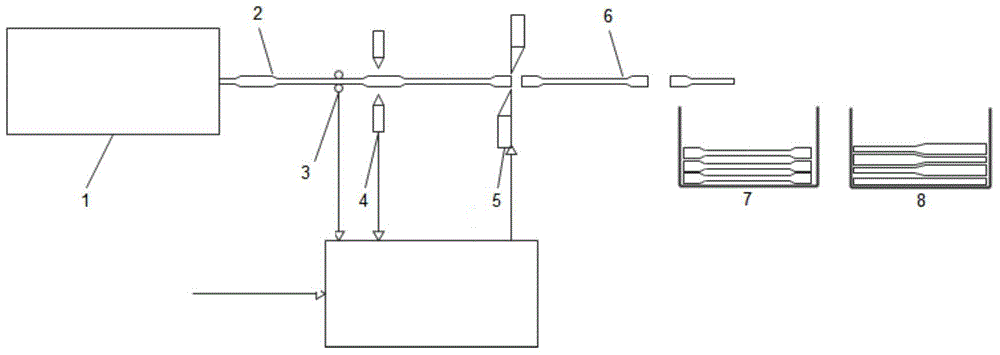

[0029] The structure of a device for automatic shearing of cold-rolled variable thickness plates provided by this embodiment is as follows Figure 4 As shown, it includes: a control device and a straightening device 1, a length measuring device 3, a thickness gauge 4, and a scissors 5 arranged in sequence. The length measuring device 3, the thickness gauge 4 and the scissors 5 are controlled by the control device.

[0030] The cutting method based on this embodiment is as follows: a thickness measuring device 4 is arranged in front of the scissors 5, and a length measuring device 3 is arranged in front of the thickness gauge. The control system recognizes that the thickness measuring device passes through the length tracking data and the actual thickness measurement value. The contour of the strip and determine the position of the strip at the scissors. At the beginning of the cutting, the cutting head is the lead that passes through the scissors. At this time, the size is often f...

Embodiment 2

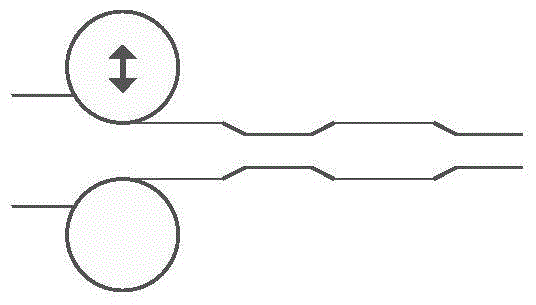

[0032] The structure of a device for automatic shearing of cold-rolled variable thickness plates provided by this embodiment is as follows Figure 5 As shown, the difference from Embodiment 1 is that the equipment for automatic shearing of cold-rolled variable-thickness plates also includes a mark detector, which is arranged between the length measuring device and the thickness gauge, and is configured by Control device control.

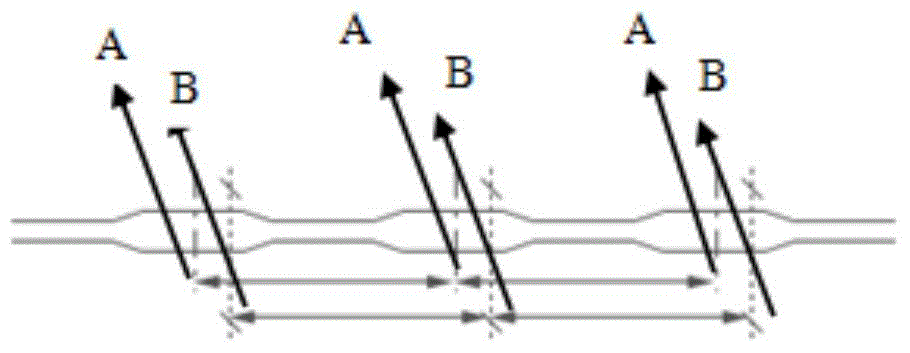

[0033] The difference between this method and method one is that the marks made on the strip 2 during rolling (such as Figure 7 Shown) to judge. Therefore, a thickness measuring device 4 is arranged in front of the scissors 5, a length measuring device 3 is arranged before the thickness measuring device, and a mark recognition device 9 is arranged after the length measuring device. At the beginning of the cutting process, the cutting head is passed through the scissors, and there is no cutting point mark on the strip 2. The control system will control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com