Apparatus and method for adjusting shears gap for circle shearing machine

A disc shearing and scissors technology is applied to shearing devices, shearing machine control devices, cutters used for shearing machine devices, etc. Convenient and flexible, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

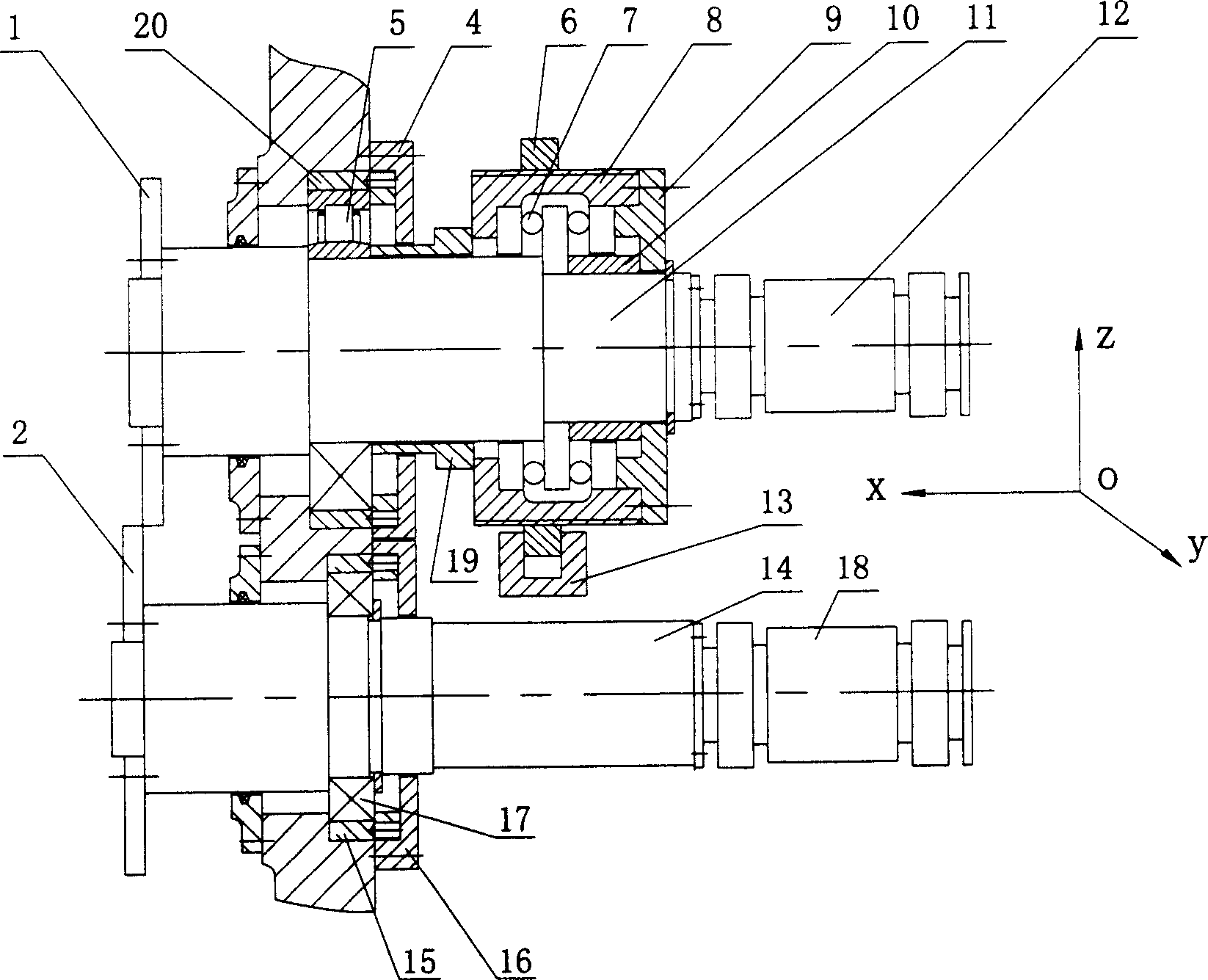

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

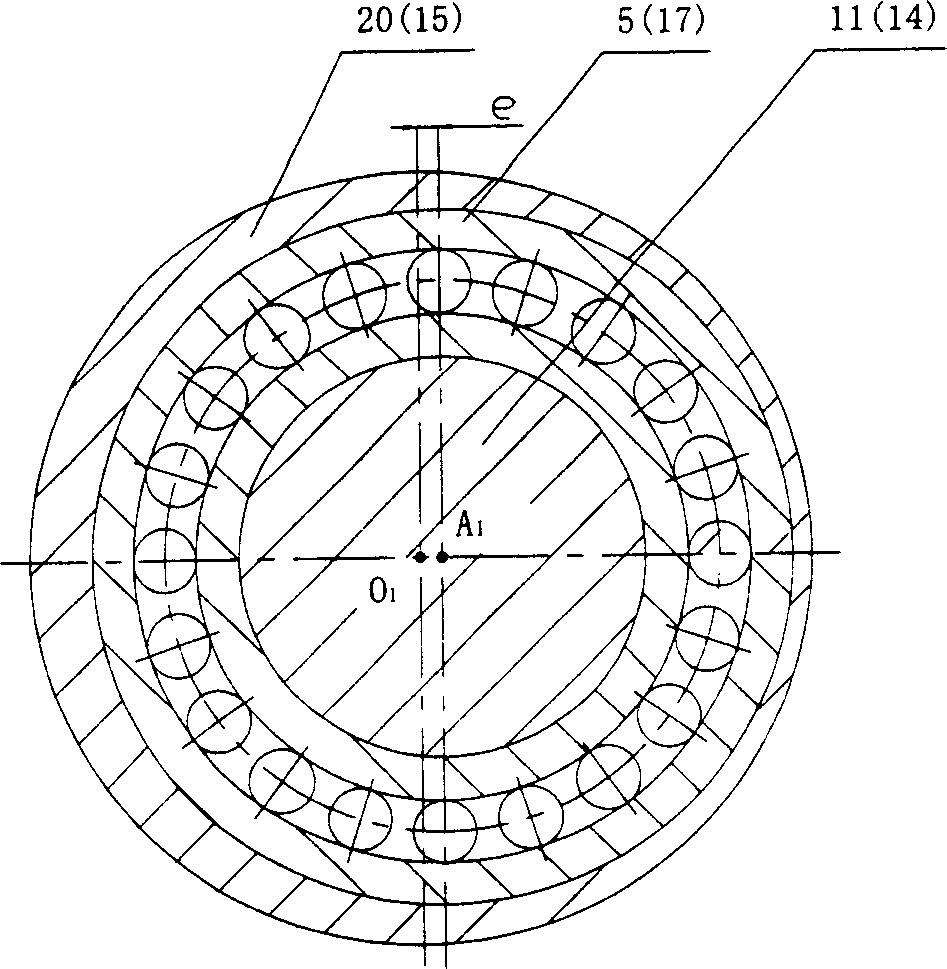

[0024] The technical scheme of the present invention for freely adjusting the gap of the scissors is to realize the adjustment of the radial gap of the blade by using the working principle of the eccentric sleeve, and to realize the adjustment of the axial gap of the blade by using the screw mechanism.

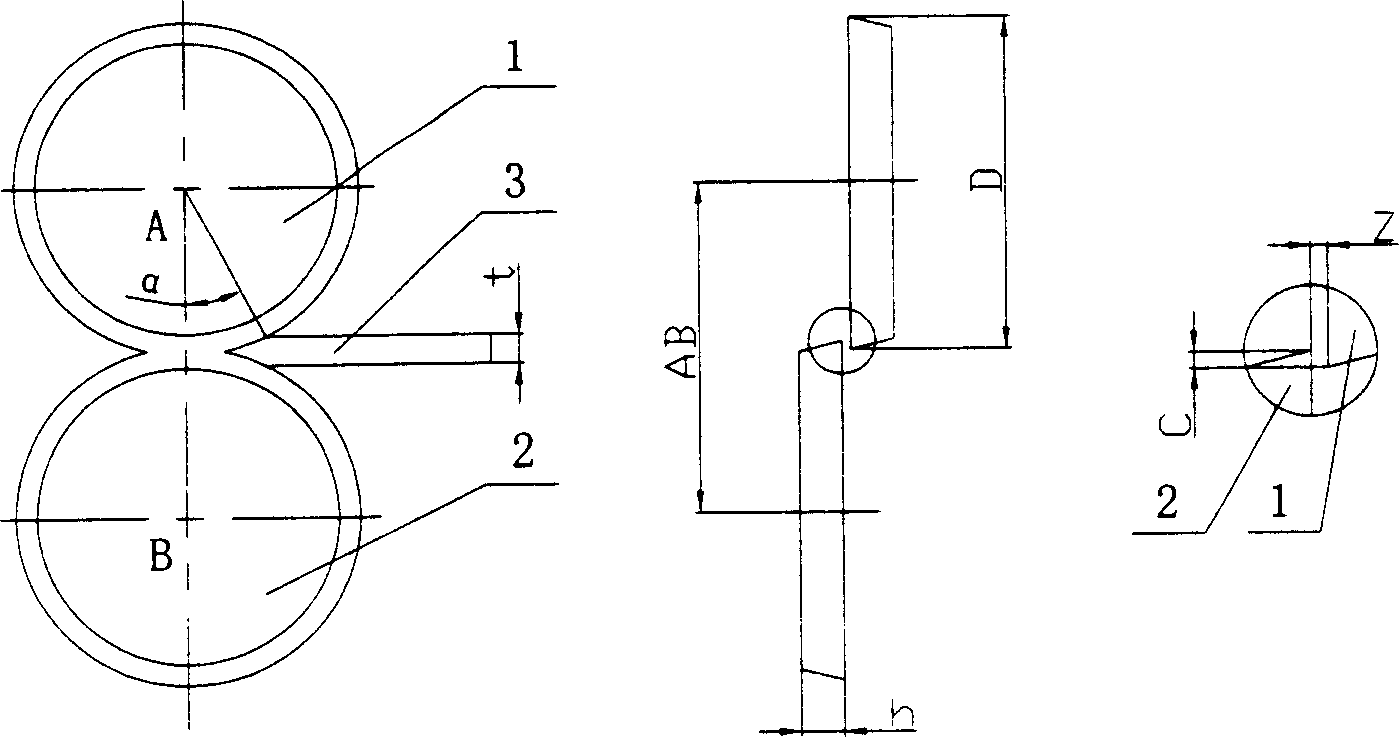

[0025] Such as figure 1 As shown, when cutting the sheet 3, in order to improve the cutting accuracy, the scissors 1 and 2 need to have a reasonable gap when they work, and the gap depends on the thickness t of the sheet to be cut. Therefore, due to the different thickness t of the sheared plate 3, the relative position of the blades 1 and 2 is also required to change accordingly. The change is mainly manifested in the blade side clearance Z and the overlap C in addition to the diameter D of the cutter head. In order to meet the needs of different thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com