Processing device for directly grinding inclined groove and straight groove of plunger piston

A processing device and grinding technology, which is applied in the field of straight groove processing device and direct grinding of plunger chute, can solve the problems of easy burrs, difficult to guarantee the plunger size, and difficult to completely remove, so as to eliminate burrs and ensure Normal use, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the description of the embodiments is not a limitation to the technical solution. Any non-substantial changes should be regarded as the protection scope of the present invention.

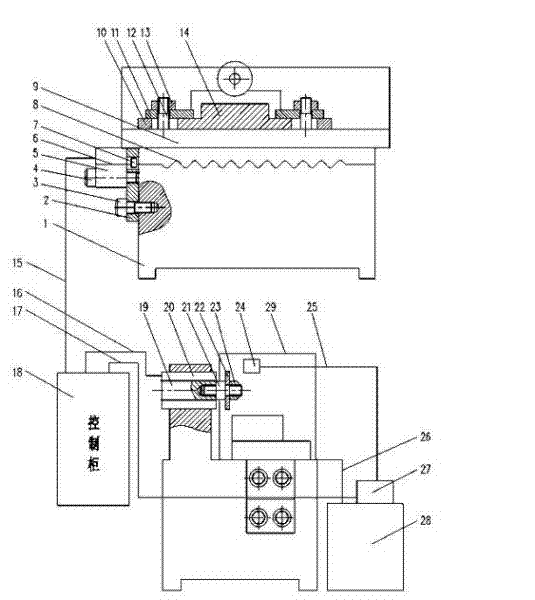

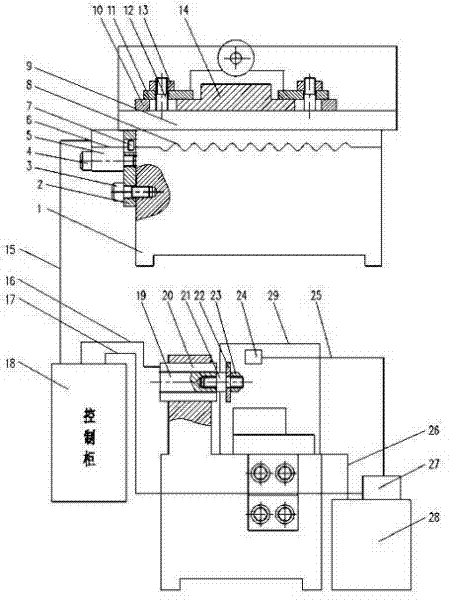

[0013] Such as figure 1 As shown, the direct grinding plunger chute and straight groove processing device includes a machine bed 1, a workbench 9, a transmission device, a grinding device, a grinding fixture, a control cabinet 18 and a cooling device.

[0014] The stepper motor is installed on the machine tool bed 1 through the support plate 2, the grinding jig 14 for installing the plunger is installed and fixed on the workbench 9 through the pressing block 10, the pressing plate 11, the fastening screw 12 and the nut 13, and the stepper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com