High-efficiency combined torch head

A combination and torch head technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problems of easy backflow of air into the cylinder, unstable flame combustion, and low corrosion resistance, so as to avoid black smoke Phenomenon, realize energy-saving effect, avoid the effect of tempering and flashback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the technical content of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

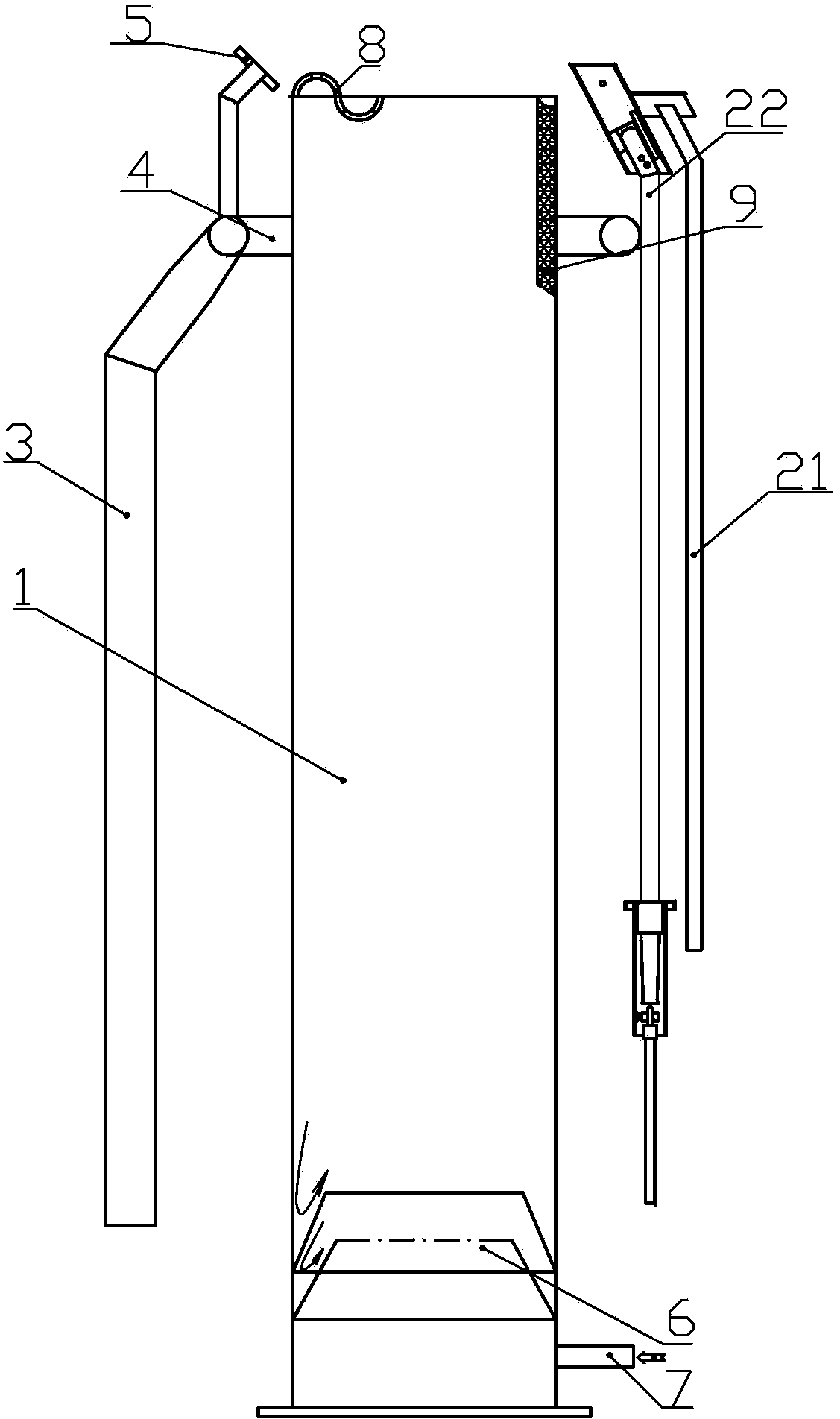

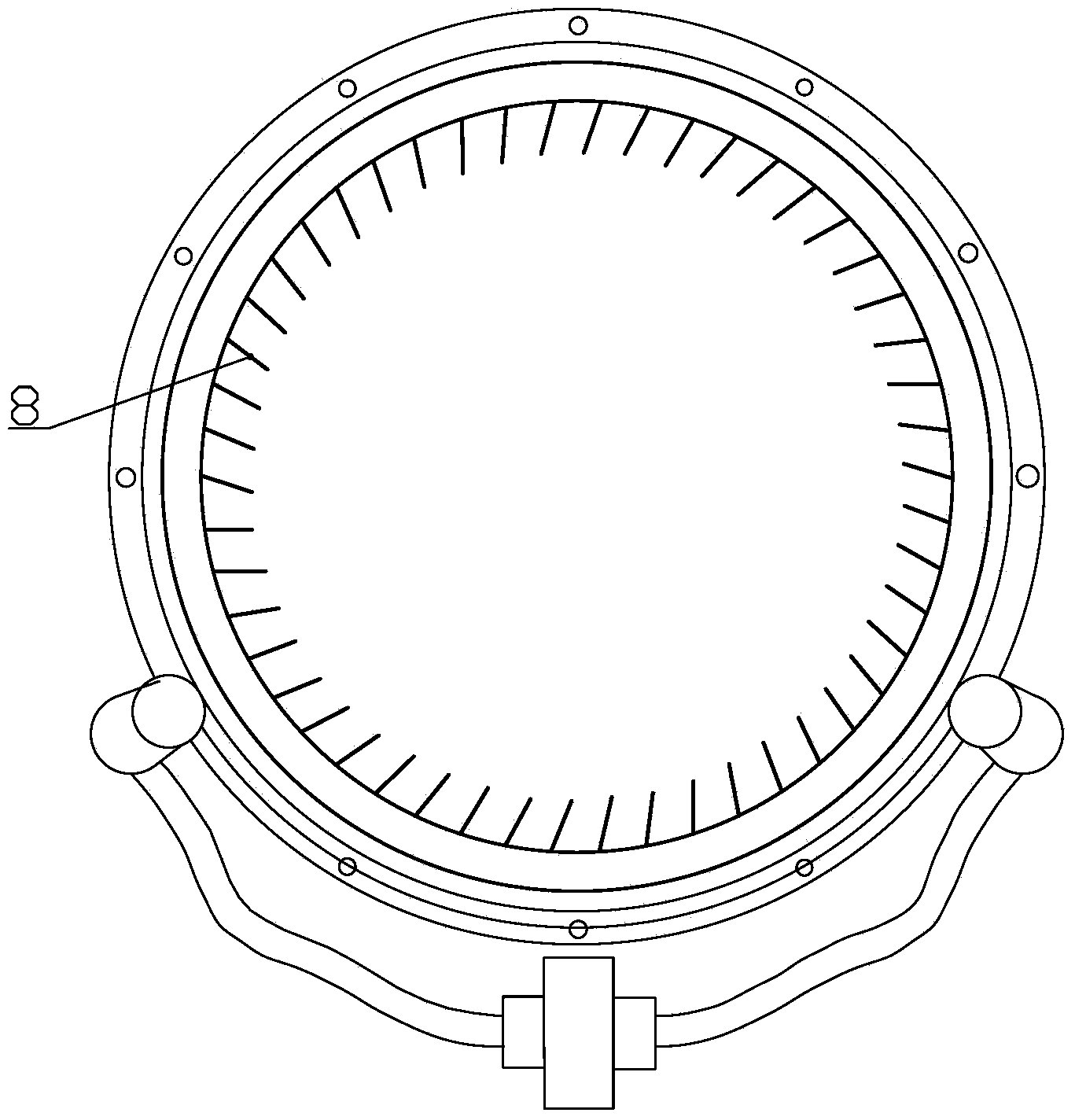

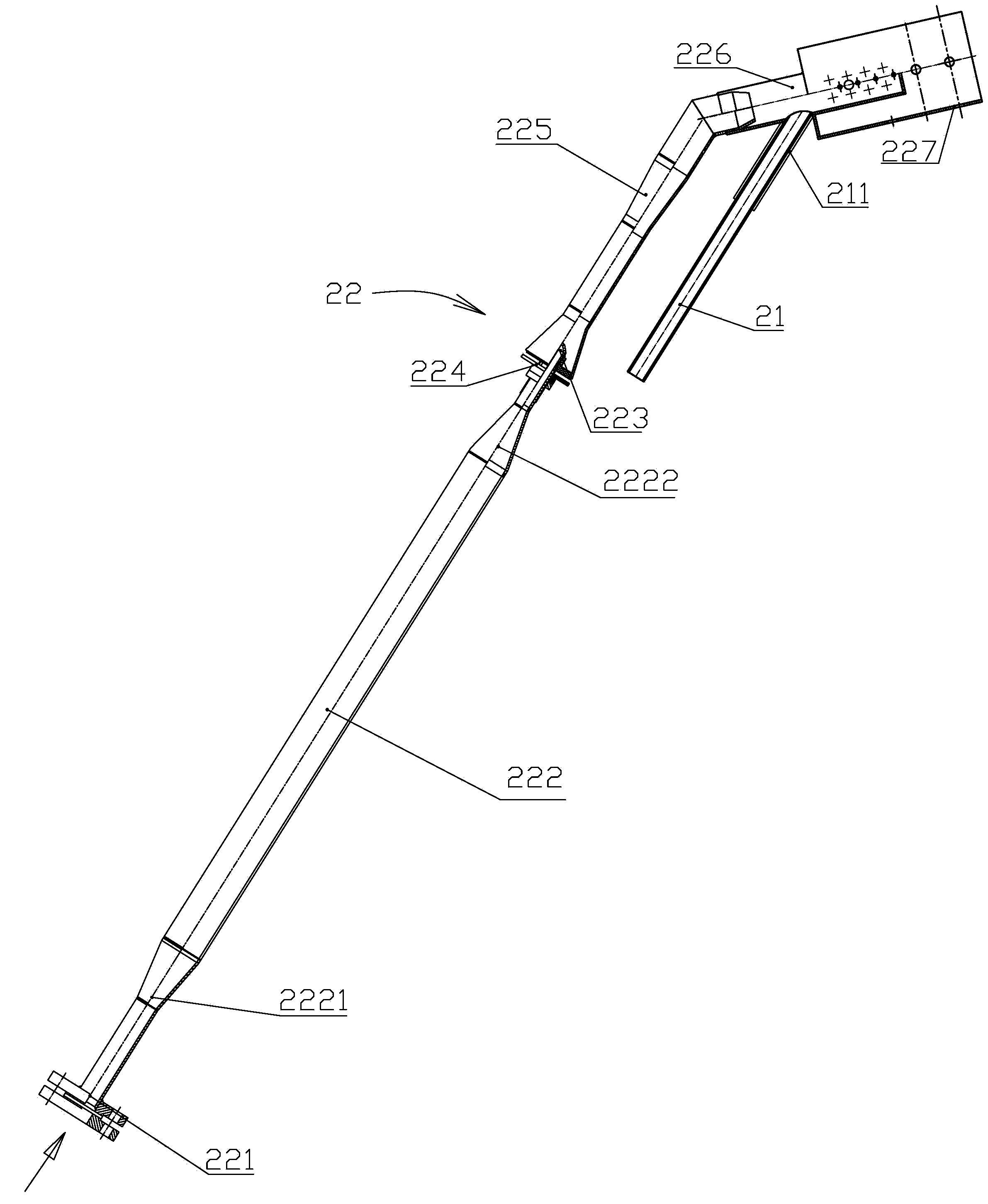

[0026] Such as figure 1 with figure 2 As shown, a high-efficiency combined flare head includes a cylinder body 1, an ignition device, a steam riser 3, a steam ring pipe 4, a quincunx-shaped steam nozzle 5, a combustion stabilization device, and a jet sealer capable of forming refracted jets 6. There is a windshield covering the upper part of the cylindrical body 1 , and a layer of refractory lining 9 is solidified on the inner wall of the upper part of the cylindrical body 1 . The windshield installed on the upper part of the cylinder body 1 can not only use the rising air flow to inject air during combustion, but also can prevent the wind, so that the flame can burn stably above the torch; The high temperature resistance of the cylinder prolongs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com