Multipoint unit direct jetting staged combustion chamber

A combustion chamber, direct technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of increasing inlet temperature and inlet pressure, shortening the ignition time of fuel spontaneous combustion, and unstable combustion, so as to reduce emissions and avoid spontaneous combustion and flashback phenomenon, the effect of avoiding spontaneous combustion and flashback problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

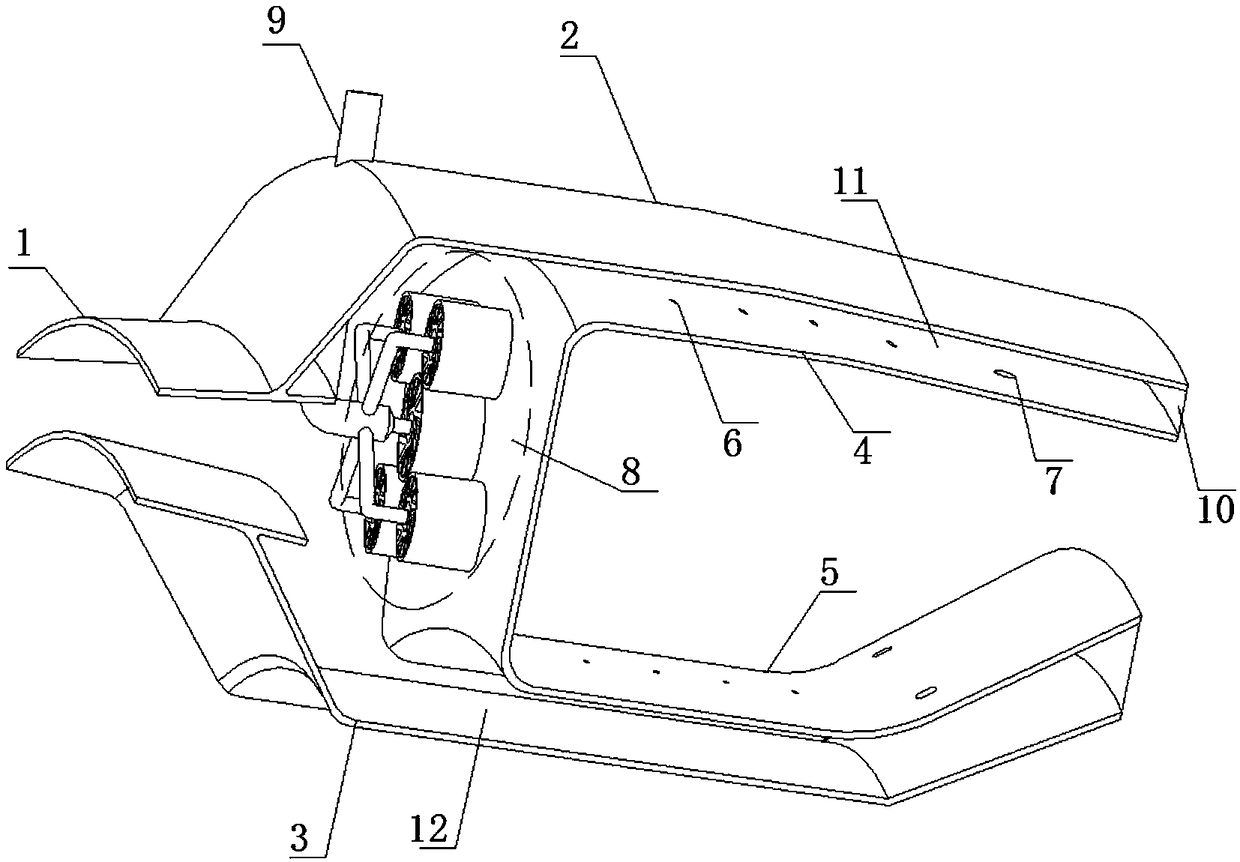

[0034] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

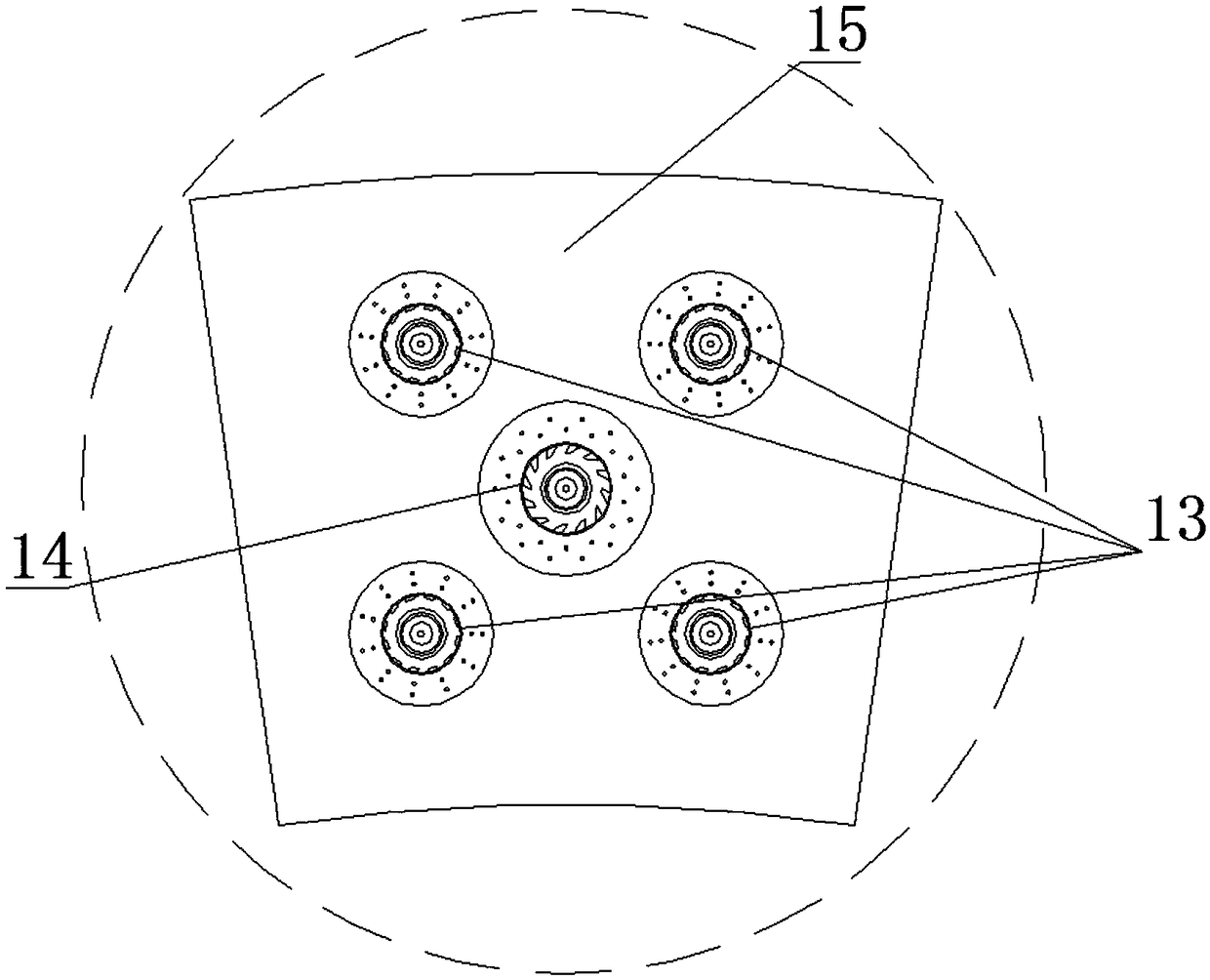

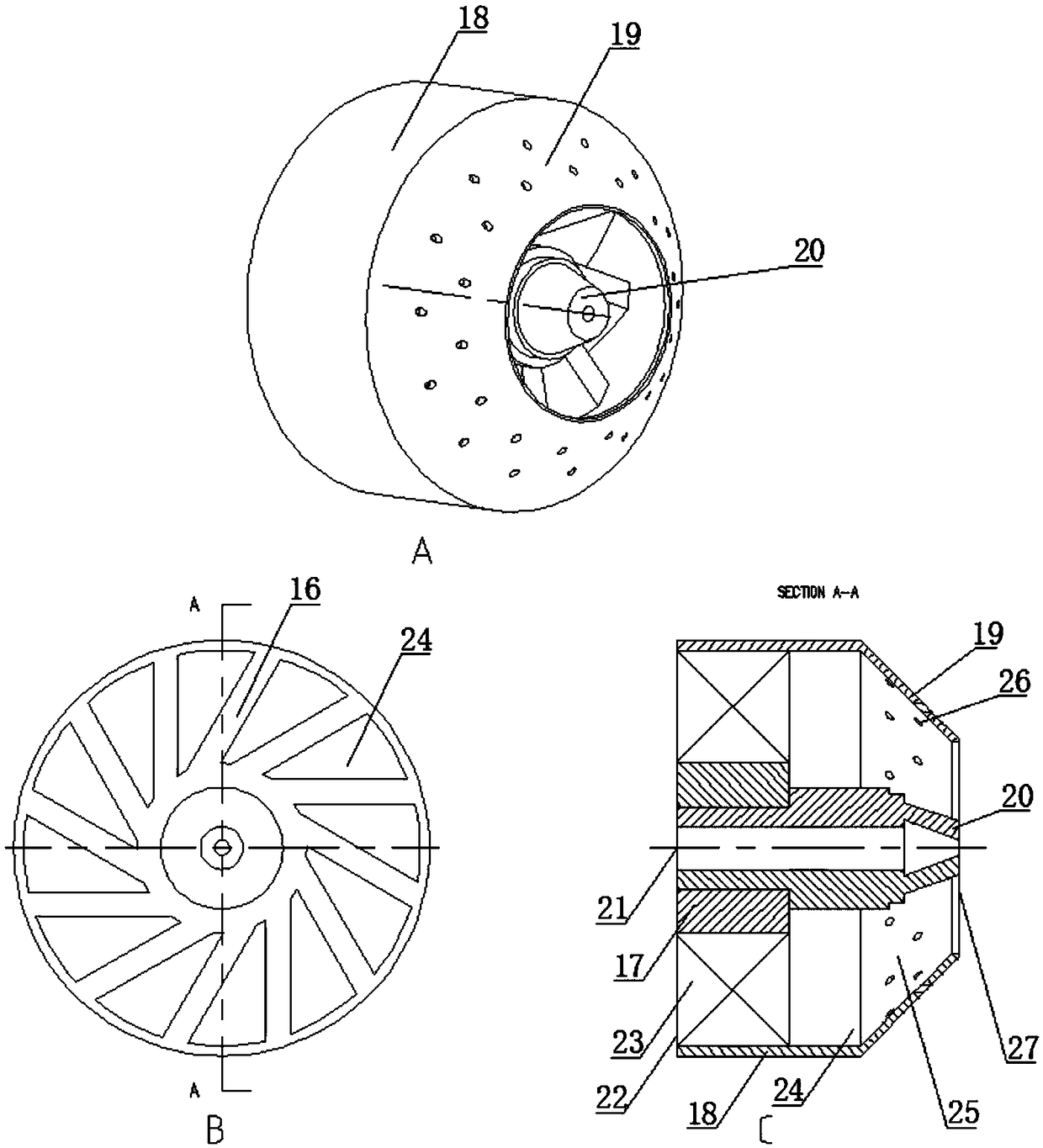

[0035] The technical solution adopted by the present invention for the purpose of achieving stable combustion and effectively reducing pollutants is: a multi-point direct injection staged combustion chamber, including a diffuser, an outer casing of the combustion chamber, a casing inside the combustion chamber, the outer wall of the flame tube, a flame The inner wall of the barrel, the cooling hole, the mixing hole, the head of the combustion chamber and the fuel supply line. The high-speed airflow compressed by the compressor is divided into three streams after being decelerated and diffused by the diffuser. One airflow enters the combustion zone formed by the outer wall of the flame tube and the inner wall of the flame tube from the head of the combustion chamber, and all the combustion air enters from the head of the combustion chamber; A stream of air flows i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com