Combustor used for gas stove

A technology for burners and gas stoves, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of many parts to be processed, high material cost, thick wall thickness of the fire cover, etc., and achieves high cost and stable flame. Good effect, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

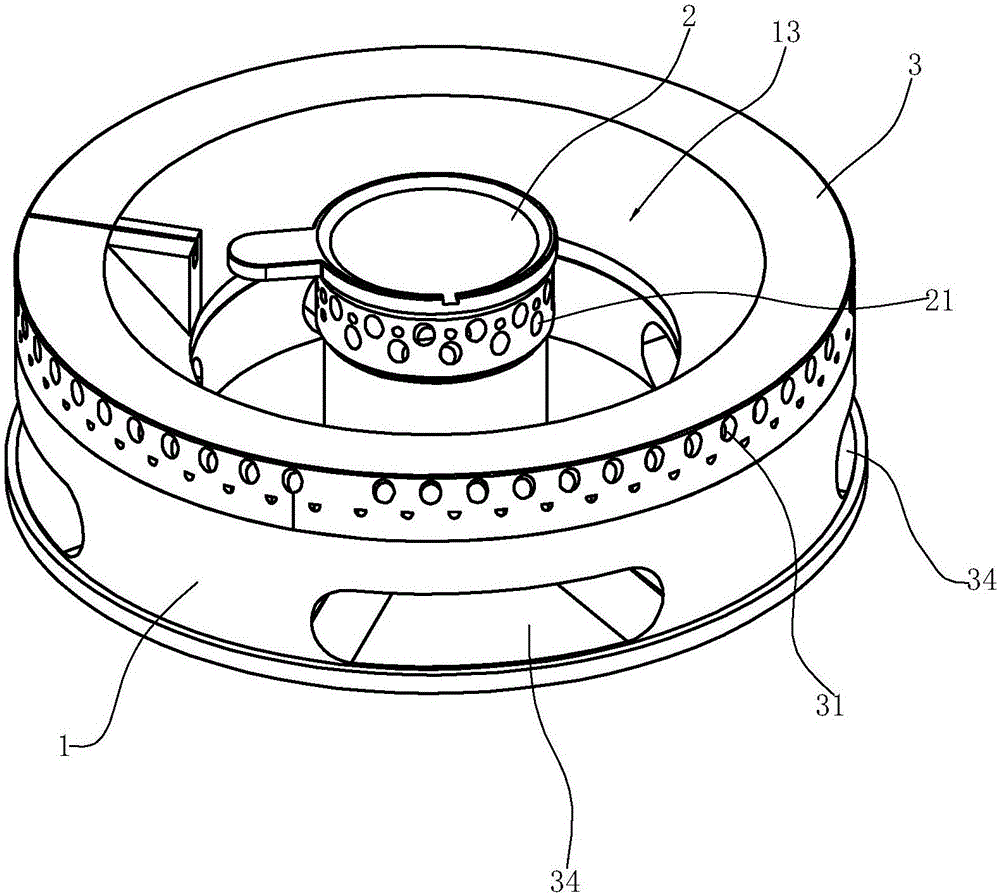

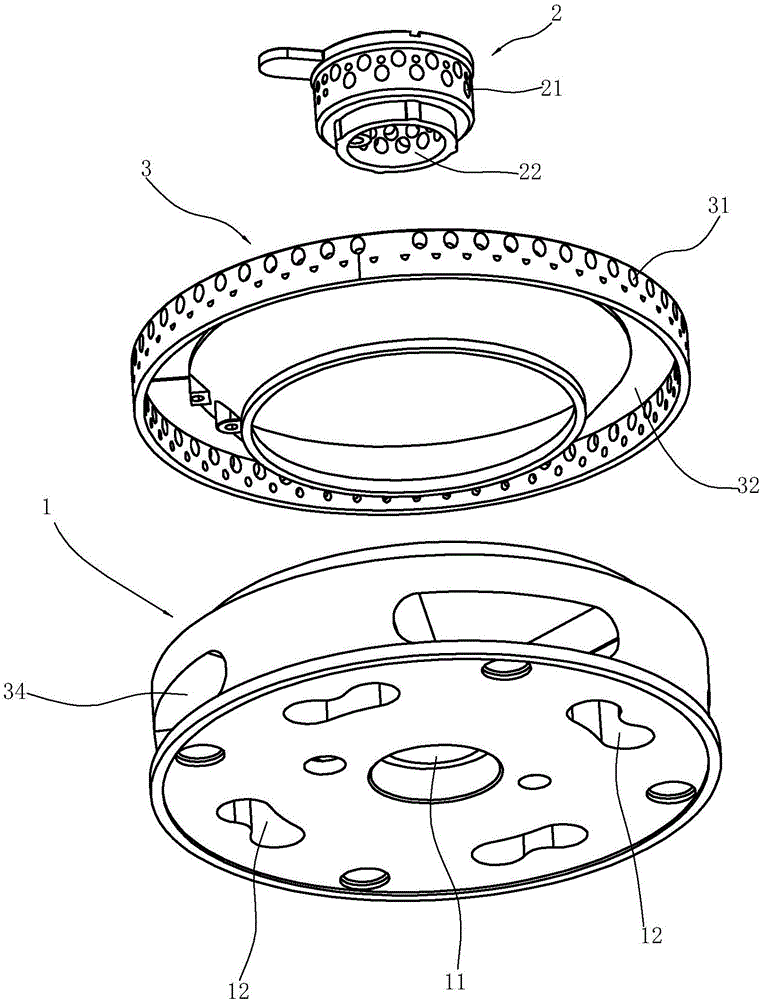

[0019] like Figure 1 to Figure 4 Shown, the burner for gas hobs includes:

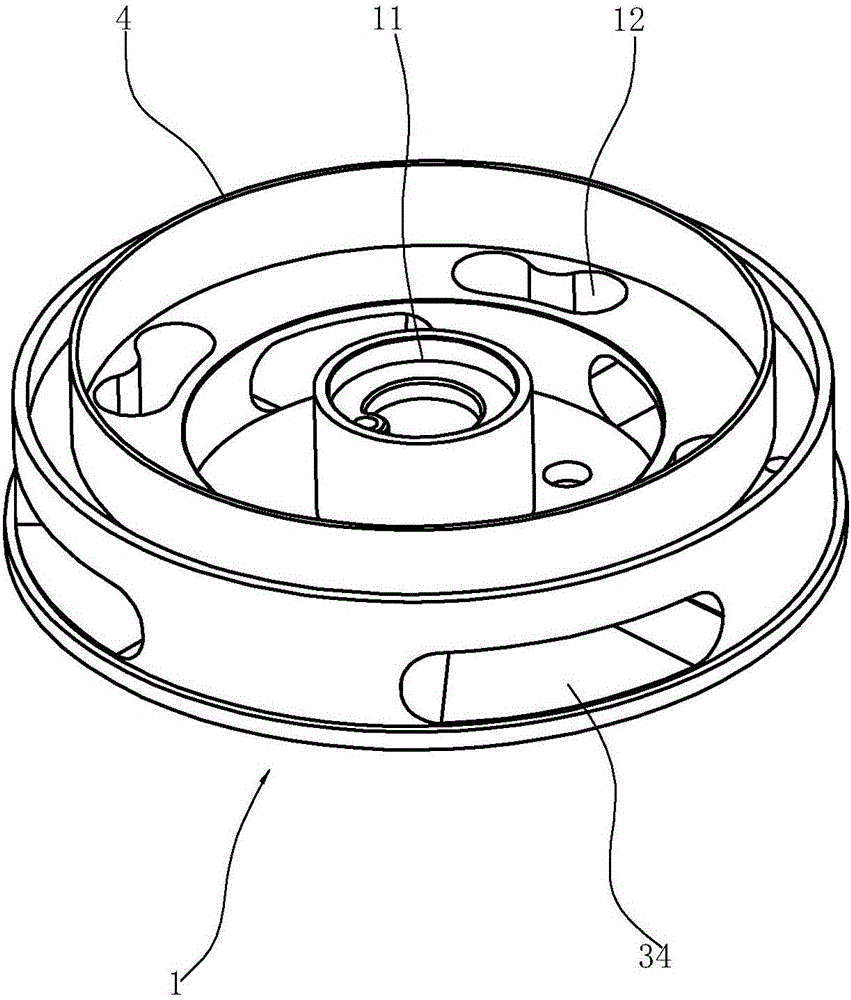

[0020] The base 1 is the supporting seat of the fire cover, made of aluminum; it is used to connect the injection pipe (not shown in the figure) and the gas mixing chamber of the fire cover. The middle part of the base 1 is provided with a central gas passage 11, and on the base 1, a plurality of outer ring gas passages 12 are arranged at intervals on the periphery of the central gas passage 11; Air supply chamber 13 is formed therebetween.

[0021] The central gas passage 11 communicates with the first injection pipe (not shown in the figure), and the outer ring gas passage 12 communicates with the second injection pipe (not shown in the figure).

[0022] In this embodiment, each outer ring gas channel 12 axially penetrates the base 1 and is evenly arranged along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com