Polyurethane composite material for refrigeratory spray coating and preparation method thereof

A polyurethane combination material and cold storage technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor stability of polyurethane foam, unfavorable energy saving and consumption reduction, high thermal conductivity, etc., and achieve good adhesion and smooth surface , The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

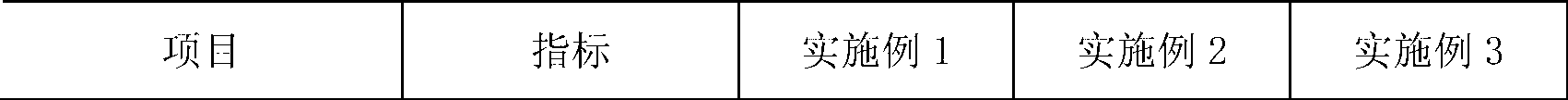

Examples

Embodiment 1

[0029] 1. Prepare component A, 100kg: Weigh sucrose polyether, 10kg, amine ether, 4kg, mixed starter polyether, 3kg, amino-terminated polyether, 3kg, low acid value polyester, 20kg; foam stabilizer B-8538 (Evonik Degussa), 1.0kg, blowing agent 1,1,1,3,3-pentafluorobutane / 1,1,1,2-tetrafluoroethane (1,1,1 , a mixture of 3,3-pentafluorobutane and 1,1,1,2-tetrafluoroethane, the weight ratio of the two is: 1,1,1,3,3-pentafluorobutane: 1,1 , a mixture of 1,2-tetrafluoroethane=93:7), 25kg, cross-linking agent TEA, 6kg, catalyst selection pentamethyldiethylenetriamine, triethylenediamine, 1,3,5-tri(di Methylaminopropyl) - a mixture of hexahydrotriazine and dibutyltin dilaurate, the weights are 1.0kg, 1.5kg, 0.7kg and 0.2kg respectively, flame retardant TCPP, 20kg, other additives choose antioxidant and enhancer Solvent, the weight is respectively 2kg and 2.6kg.

[0030] Add the above-mentioned raw materials that have been weighed into the reaction kettle, stir at room temperature fo...

Embodiment 2

[0034] 1. Prepare component A, 100kg: Weigh sucrose polyether, 15kg, amine ether, 5kg, mixed initiator polyether, 10kg, amino-terminated polyether, 5kg, low acid value polyester, 12kg; foam stabilizer B-8538 (Evonik Degussa), 1.5kg, blowing agent 1,1,1,3,3-pentafluorobutane / 1,1,1,2-tetrafluoroethane (1,1,1 , a mixture of 3,3-pentafluorobutane and 1,1,1,2-tetrafluoroethane, the weight ratio of the two is: 1,1,1,3,3-pentafluorobutane: 1,1 , the mixture of 1,2-tetrafluoroethane=93:7), 8kg, cross-linking agent TEA, 11kg, catalyst selection pentamethyldiethylenetriamine, triethylenediamine, 1,3,5-tri(di A mixture of methylaminopropyl)-hexahydrotriazine and dibutyltin dilaurate, the weights are 1.0kg, 1.8kg, 0.6kg and 0.2kg respectively, and the flame retardant is a mixture of TCPP and DMMP, the weights are 20kg and 5kg respectively , other additives are selected solubilizer and color paste, the weight is 2.7kg and 1.2kg respectively.

[0035] Add the above-mentioned raw materials...

Embodiment 3

[0039]1. Preparation of component A, 100kg: Weigh sucrose polyether, 12kg, amine ether 403, 5kg, mixed starter polyether, 12kg, amino-terminated polyether, 5kg, low acid value polyester, 8kg; the foam is stable Agent B-8538 (Evonik Degussa), 1.5kg, blowing agent 1,1,1,3,3-pentafluorobutane / 1,1,1,2-tetrafluoroethane (1,1, A mixture of 1,3,3-pentafluorobutane and 1,1,1,2-tetrafluoroethane, the weight ratio of the two is: 1,1,1,3,3-pentafluorobutane: 1, The mixture of 1,1,2-tetrafluoroethane=93:7), 24kg, the crosslinking agent TEA, 11kg, the catalysts are pentamethyldiethylenetriamine, triethylenediamine, 1,3,5-tri( Dimethylaminopropyl) - a mixture of hexahydrotriazine and dibutyltin dilaurate, the weights are 1.3kg, 1.8kg, 1kg and 0.4kg respectively, flame retardant TCPP, 12kg, other additives choose antioxidant and enhancer Solvent, the weight is 3.5kg and 1.5kg respectively.

[0040] Add the above-mentioned raw materials that have been weighed into the reaction kettle, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com