Manufacturing method of recombined bamboo sliced veneer

A manufacturing method and technology for reconstituting bamboo are applied in the fields of furniture, reconstituted bamboo slicing veneer, interior decoration, and wood-based panels, and can solve the problem of incomplete key softening process, low resource utilization rate, and large amount of bamboo shaving and other problems, to increase the variety and added value, improve the utilization rate of bamboo resources, and achieve good slicing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

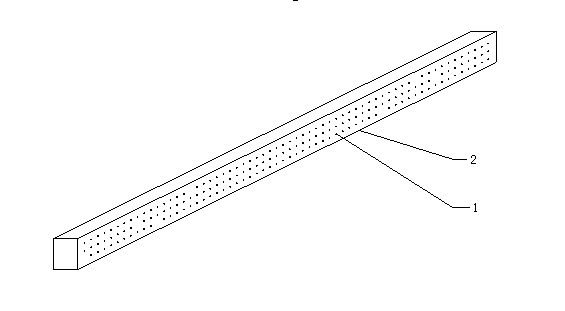

Image

Examples

Embodiment 1

[0023] The production method of the recombined bamboo sliced veneer in this example is:

[0024] 1) Manufacture of bamboo strips: process bamboo into bamboo material, and then cut it into bamboo sections; cut the bamboo sections into bamboo pieces, and then put the bamboo pieces into the cooking pool for 4 hours, remove the bamboo green from the treated bamboo pieces, and the remaining Part of the bamboo strips are made into bamboo strips with a length of 1900mm, a width of 1.0mm, and a thickness of 6mm after being thickened and then rolled and combed; the bamboo strips are not allowed to have defects such as greening, yellowing, insect eyes, mildew, rotten strips, and tender strips;

[0025] 2) Carbonization and drying of bamboo strips: put the prepared bamboo strips into a carbonization tank, the carbonization temperature is 135°C, and the carbonization time is 3 hours; then dry the carbonized bamboo strips at a temperature of 80°C until the moisture content is about 10% ;...

Embodiment 2

[0035] The production method of the recombined bamboo sliced veneer in this example is:

[0036] 1) Manufacture of bamboo strips: process bamboo into bamboo material, and then cut it into bamboo sections; cut the bamboo sections into bamboo pieces, then put the bamboo pieces into the cooking pool for 6 hours, remove the bamboo green from the treated bamboo pieces, and the remaining Part of the bamboo strips are made into bamboo strips with a length of 2530mm, a width of 1.5mm, and a thickness of 6mm after being thickened and then rolled and combed; the bamboo strips are not allowed to have defects such as green, yellow, insect eyes, mildew, rotten strips, and tender strips;

[0037] 2) Drying of bamboo strips: The bamboo strips after decompression are bundled into piles and stacked in a drying room for drying at a drying temperature of 65°C until the moisture content is 10%;

[0038] 3) Impregnation and drying of bamboo strips: immerse the dried bamboo strips in phenolic res...

Embodiment 3

[0047] The production method of the recombined bamboo sliced veneer in this example is different from Example 1: the 3200mm long bamboo strips are made into 3200×100×100mm bamboo squares after dipping, hot pressing and other processes; the bamboo squares are pressurized and water injected , the impregnation pressure is 1.5MPa, and the time is 12h, so that the moisture content of the bamboo timber reaches more than 25%; then it is boiled and softened, the heating rate is controlled at 2°C / min, the temperature is 70°C, and the softening time is 72h; the obtained length is 3200mm , a width of 290mm, a thickness of 0.6mm carbonized recombined bamboo sliced veneer products. The rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com