High-strength heat-resisting and cold-heading steel wire rod and production method thereof

A production method and high-strength technology, applied in the field of high-strength heat-resistant cold heading steel wire rod and its production, can solve the problems of poor gas content control, high cost, and no consideration of delayed fracture resistance of heat-resistant steel, etc., to achieve Good strength and toughness index, good strength and heat strength, excellent effect of gas content control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

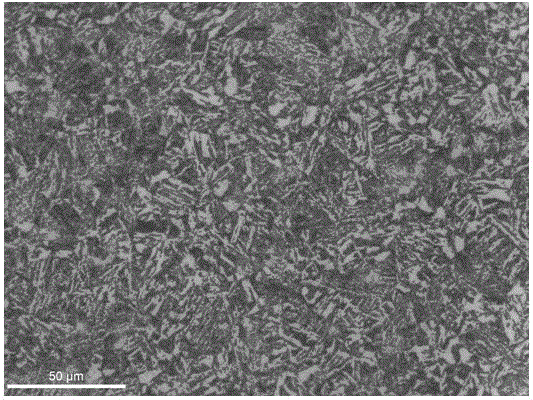

Image

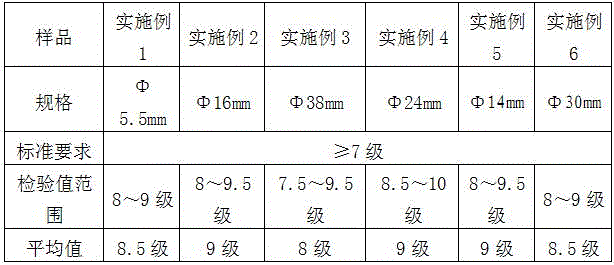

Examples

Embodiment 1

[0040] Embodiment 1: The high-strength heat-resistant cold heading steel wire rod is produced by the following process.

[0041] (1) Steelmaking and billet opening process: Converter smelting is used, and the temperature before argon is controlled at 1570°C; the LF furnace is refined outside the furnace, and the arrival temperature is controlled at 1490°C; the RH furnace is vacuum degassed, and the incoming temperature is controlled at 1680°C; Bloom continuous casting, the casting speed is controlled at 0.6m / min; the composition of the obtained continuous casting slab by weight percentage is: C 0.38%, Si 0.35%, Mn 0.85%, P 0.010%, S 0.002%, Cr 0.94 %, Mo 0.40%, V 0.31%, [O] 8ppm, [N] 30ppm, and the rest are iron and trace impurities.

[0042] (2) Billet opening process: the continuous casting billet is heated to 1150°C, and then rolled into a billet.

[0043] (3) Rolling and cooling process: the billet is heated to 1150°C; the spinning temperature is controlled at 750°C; the ...

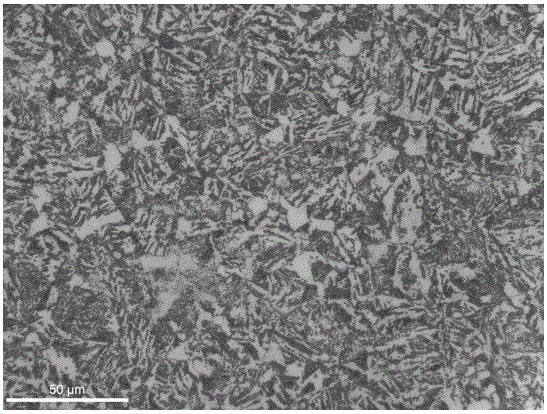

Embodiment 2

[0045] Embodiment 2: The high-strength heat-resistant cold heading steel wire rod is produced by the following process.

[0046] (1) Steelmaking and blanking process: Converter smelting is used, and the temperature before argon is controlled at 1580°C; the LF furnace is refined outside the furnace, and the arrival temperature is controlled at 1500°C; the RH furnace is vacuum degassed, and the incoming temperature is controlled at 1690°C; Bloom continuous casting, the casting speed is controlled at 0.7m / min; the composition of the obtained continuous casting slab by weight percentage is: C 0.48%, Si 0.40%, Mn 0.75%, P 0.010%, S 0.010%, Cr 0.97 %, Mo 0.39%, V 0.30%, [O] 9ppm, [N] 35ppm, and the rest are iron and trace impurities.

[0047] (2) Billet opening process: the continuous casting billet is heated to 1200°C, and then rolled into a billet.

[0048] (3) Rolling and cooling process: the billet is heated to 1170°C; the spinning temperature is controlled at 780°C; the coolin...

Embodiment 3

[0050] Embodiment 3: The high-strength heat-resistant cold heading steel wire rod is produced by the following process.

[0051] (1) Steelmaking and blanking process: Converter smelting is used, and the temperature before argon is controlled at 1590°C; the LF furnace is refined outside the furnace, and the arrival temperature is controlled at 1510°C; the RH furnace is vacuum degassed, and the incoming temperature is controlled at 1700°C; Bloom continuous casting, the casting speed is controlled at 0.9m / min; the composition of the obtained continuous casting slab by weight percentage is: C 0.40%, Si 0.38%, Mn 0.85%, P 0.012%, S 0.005%, Cr 1.20 %, Mo 0.45%, V 0.28%, [O] 10ppm, [N] 45ppm, and the rest are iron and trace impurities.

[0052] (2) Billet opening process: the continuous casting billet is heated to 1230°C, and then rolled into a billet.

[0053] (3) Rolling and cooling process: the billet is heated to 1200°C; the spinning temperature is controlled at 790°C; the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com