700MPa grade twisted steel and production method thereof

A threaded steel bar and manufacturing method technology, applied in the field of iron and steel metallurgy and steel rolling, can solve the problems of high alloy cost, welding difficulty, high cost, etc., and achieve the effects of lowering the dissolution temperature, facilitating precipitation and precipitation, and improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

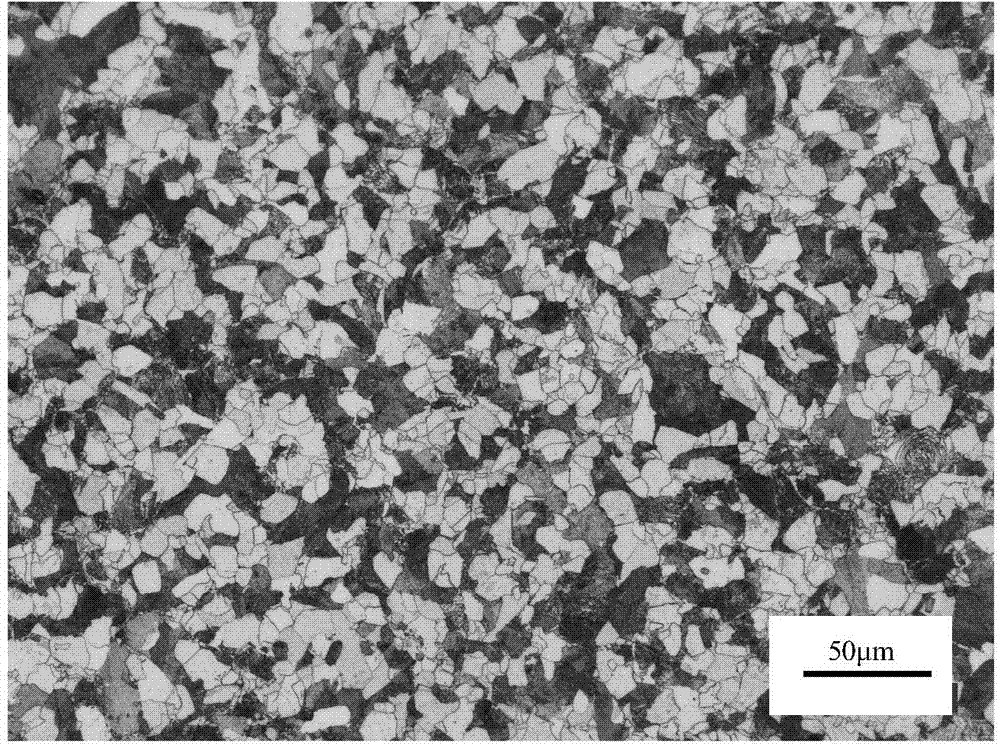

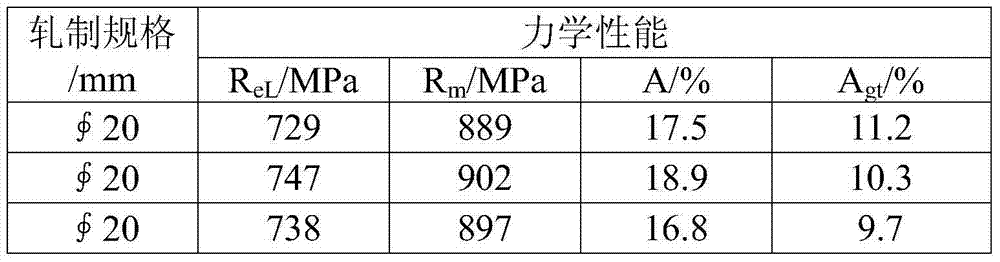

[0020] It is smelted by converter, refined by LF, and continuously cast into 150mm×150mm billets; the heating temperature of the soaking section in the heating furnace is 1170-1250°C; The rolling temperature is 1050-1080 ℃, after rough rolling, middle rolling, and after a period of water cooling, it enters finishing rolling. The bed is naturally cooled to room temperature to obtain 700MPa grade rebar. The chemical composition of the steel bar is: C0.29%, Si0.72%, Mn1.51%, V0.19%, Nb0.03%, Ni0.04%, N220ppm, Ti0.02%. Table 1 shows the mechanical properties, yield strength> 700MPa, tensile strength> 850MPa, elongation after fracture> 14%, the structure is ferrite and pearlite, specific as figure 1 shown.

[0021] Table 1 Mechanical properties of ∮20mm700MPa grade steel bars

[0022]

Embodiment 2

[0024] It is smelted by converter, refined by LF, and continuously cast into 150mm×150mm billets; the heating temperature of the soaking section in the heating furnace is 1170-1220℃; the rolling is carried out by a continuous bar and wire rolling mill, the rolling specification is ∮25mm, and the opening The rolling temperature is 1060-1080 ℃, after rough rolling, middle rolling, and after a period of water cooling, it enters the finishing rolling. The bed is naturally cooled to room temperature to obtain 700MPa grade rebar. The chemical composition of the steel bar is: C0.31%, Si0.72%, Mn1.51%, V0.23%, Nb0.03%, Ni0.04%, N230ppm, Cu0.05%. Table 2 shows the mechanical properties, yield strength> 700MPa, tensile strength> 850MPa, elongation after fracture> 14%.

[0025] Table 2 Mechanical properties of ∮25mm700MPa grade steel bars

[0026]

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com