Imitation skinless sausages

A sausage and skin technology, which is applied in the direction of undressed sausage making machines, sausage casings, food forming, etc., can solve the problems of lack of adhesion, undesired deformation and discoloration of the surface layer, and insufficiently cooked products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

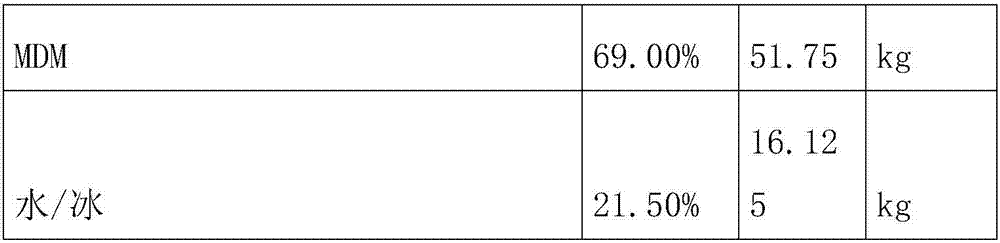

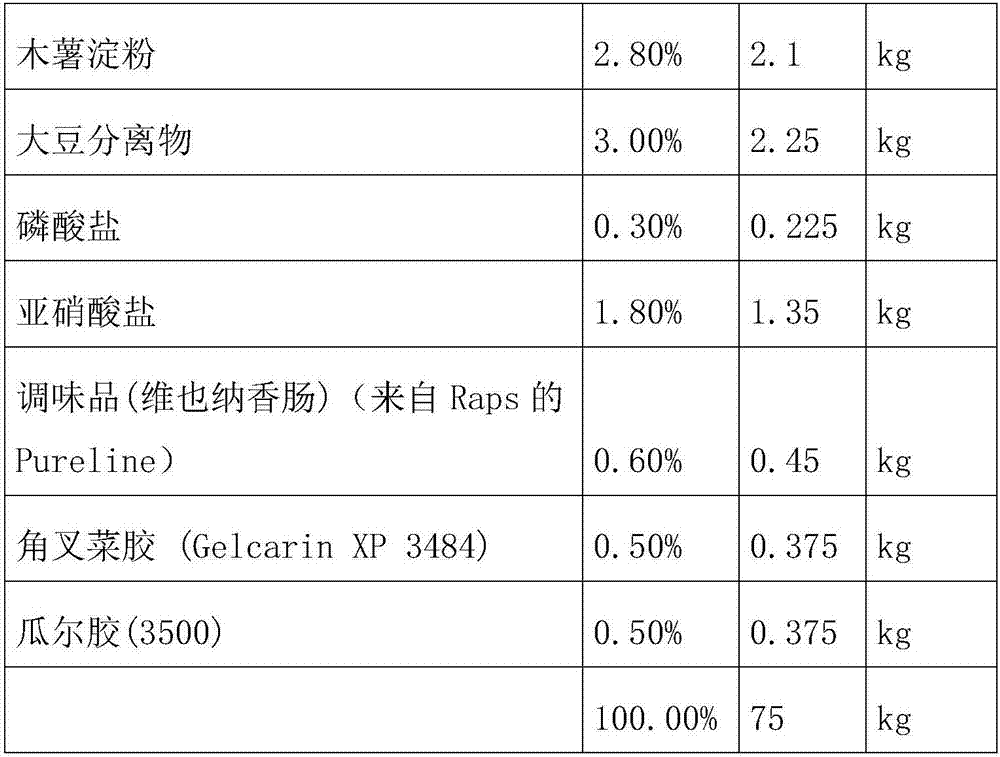

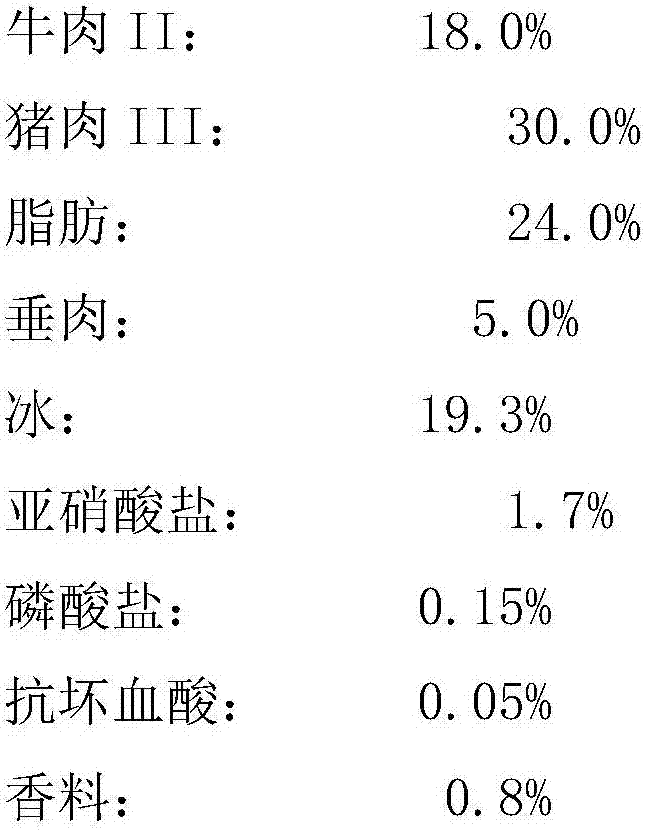

[0044] Prepare hot dogs using gnocchi with the following ingredients:

[0045]

[0046]

[0047] Test process:

[0048] • Casing: A paste with 7% PROTANAL ME 5147 (a commercial mixture of alginate, starch and phosphate) was made by mixing 1.34 kg PROTANAL ME 5147 with 17.8 kg water / ice. The pKa of PROTONAL ME 5147 is about 3.5.

[0049] Calcium bath: 30% CaCl 2 , 2% 80% acetic acid (Brix: 45) The bath has been calculated to have a pH of about 2.6, although the pH meter may give lower values due to the high calcium ion concentration.

[0050] ·Standard configuration:

[0051] ·Caliber 19, 110mm, with 5 blades (forming end). The test is carried out at full speed, and the 110mm sausage is

[0052] 0.7% paste on sausage (~0.03mm casing layer)

[0053] Cooked at 75°C in a water bath containing 1% CaCl2 and 0.07% of 80% acetic acid

[0054] After cooking in water, treat with diluted cold smoked liquid (soak for 1-2 seconds) then dry at 85°C for 5 minutes (preheat ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com