Pneumatic contact pin push bending machine

A pin insertion and top bending technology, which is applied in the field of pneumatic pin top bending machines, can solve the problems of affecting product appearance quality, uneven radian, slow processing speed, etc., achieve small error, high shape consistency, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

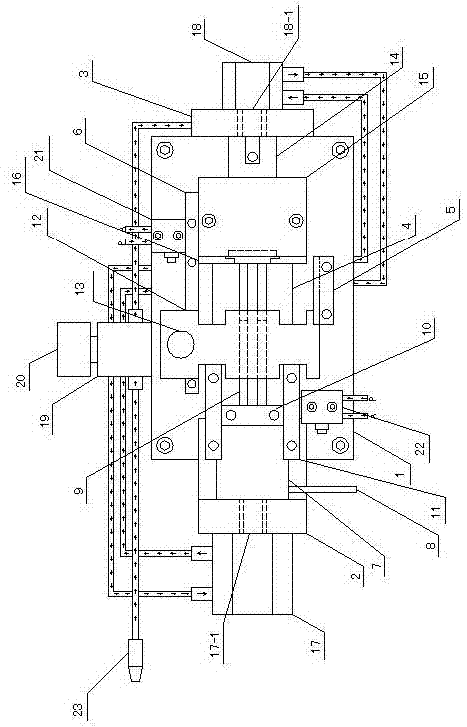

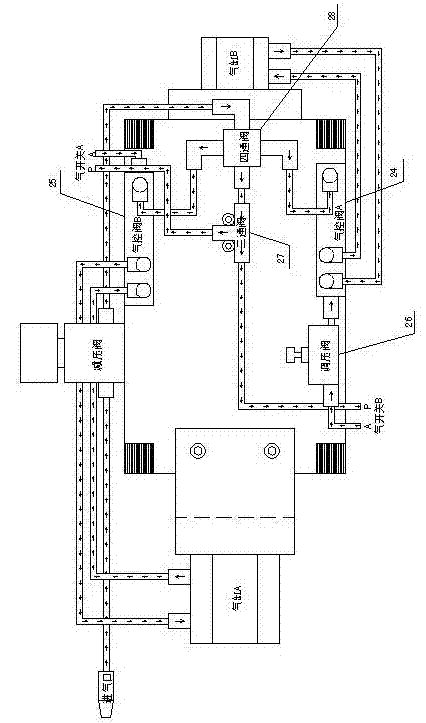

[0017] Below in conjunction with accompanying drawing, the present invention will be further described: with reference to Figure 1 to Figure 10 , a pneumatic pin bending machine includes workbench 1, cylinder A 17, cylinder B 18, cylinder A fixing plate 2, cylinder B fixing plate 3, thimble fixing plate 4, slideway fixing frame 5, slideway supporting frame 6 , thimble push plate 7, push rod 8, thimble plate 9, thimble press plate 10, thimble push plate slider 11, sliding cover plate 12, switch lever 13, looper push plate 14, looper cover plate 15 and skeleton positioning plate 16 ; Cylinder A 17 and cylinder B 18 are respectively fixed on both sides of workbench 1 through cylinder A fixing plate 2 and cylinder B fixing plate 3, and cylinder column A 17-1 and cylinder column B 18-1 are on the same horizontal line, and the thimble pushes Plate 7 is screwed to cylinder column A 17-1.

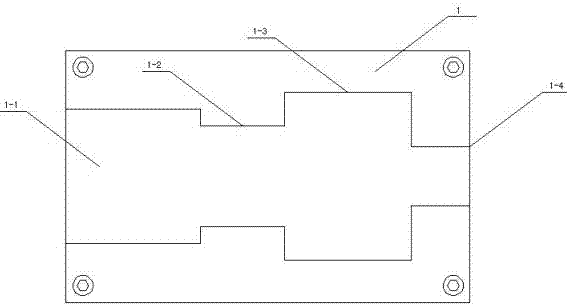

[0018] refer to image 3 , The table of the workbench 1 is respectively provided with a thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com