Waterproof blind plug automatic insertion device

An automatic insertion and blind plugging technology, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inconsistent insertion depth, easy insertion error, low efficiency, etc., to achieve flexible production, stable insertion, and expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

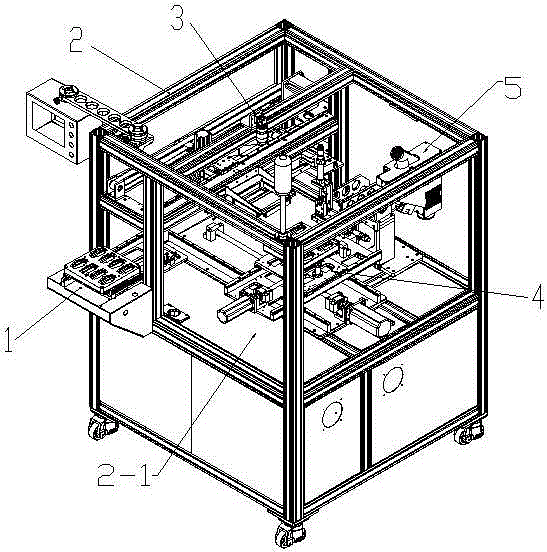

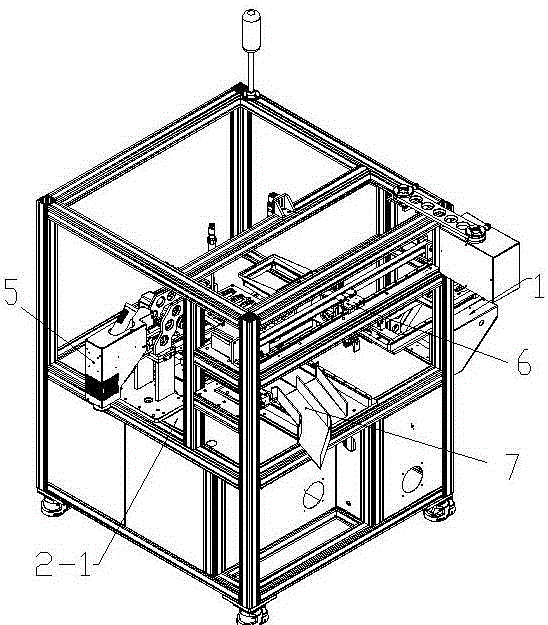

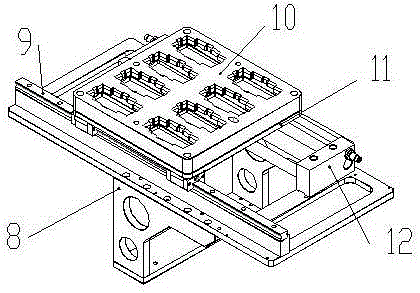

[0022] Embodiment 1: as Figure 1-8 As shown, a waterproof blind plug automatic insertion device includes a plastic case feeding module 1, a frame 2, a visual inspection module 3, an X-Y movement module 4, a waterproof blind plug insertion module 5, and a loading and unloading module 6 and the unloading module 7, the frame 2 is provided with a workbench 2-1, and the workbench 2-1 is provided with a plastic case feed module 1, an X-Y motion module 4, a waterproof blind plug insertion module 5 and an unloading module. Material module 7. The waterproof blind plug insertion module 5 is arranged on one side of the X-Y motion module 4 and cooperates with the X-Y motion module 4 . A loading and unloading module 6 is arranged above the workbench 2 - 1 between the shell feeding module 1 and the unloading module 7 . The bottom plate 19 of the loading and unloading module 6 is perpendicular to the X-axis bottom plate 25 of the X-Y motion module 4 ; the top of the frame 2 is provided wi...

Embodiment 2

[0030] Embodiment 2: A waterproof blind plug automatic insertion device, the X-Y motion module includes an X-axis motor, an X-axis linear guide rail, an X-axis coupling, an X-axis bottom plate, an X-axis screw, a molded case carrier, and a connection Plate, lifting base plate and lifting cylinder Ⅰ. The X-axis bottom plate is installed on the workbench under the loading and unloading module, and is perpendicular to the bottom plate of the loading and unloading module; X-axis linear guide rails are installed on the X-axis bottom plate, and the X-axis bottom plate between the X-axis linear guide rails An X-axis motor is installed at one end, and the output shaft of the X-axis motor is connected to the X-axis screw through the X-axis coupling; the X-axis screw is installed on the bearing box on the X-axis bottom plate; the lower end of the lifting bottom plate is slidingly set on the X-axis On the linear guide rail, it is threadedly connected with the X-axis screw; on the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com