Assembled integrated type prefabricated concrete floor slab and connection method thereof

A prefabricated concrete and concrete slab technology, applied in floors, building components, buildings, etc., can solve problems such as limiting the continuity of vertical components, and achieve the effects of saving manpower, high precision, and fast installation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

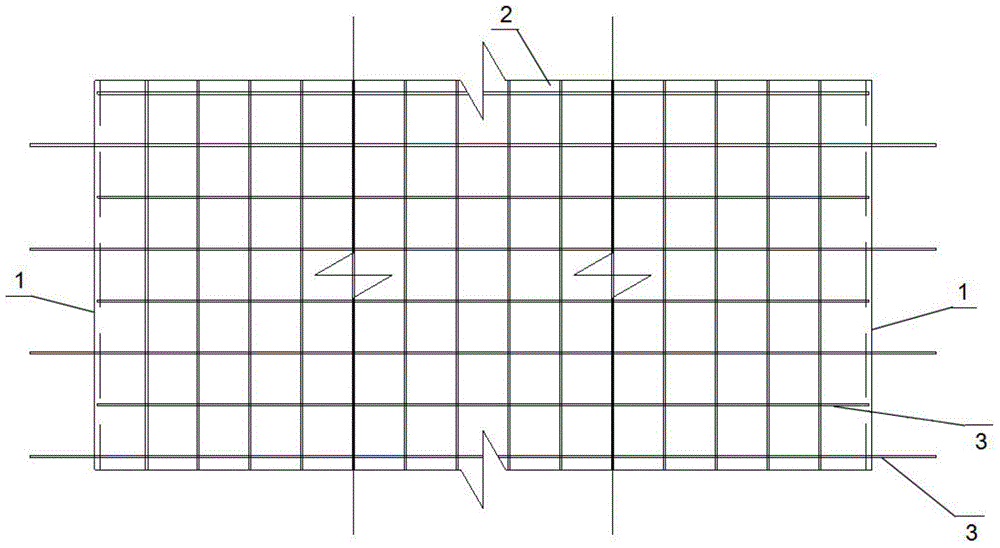

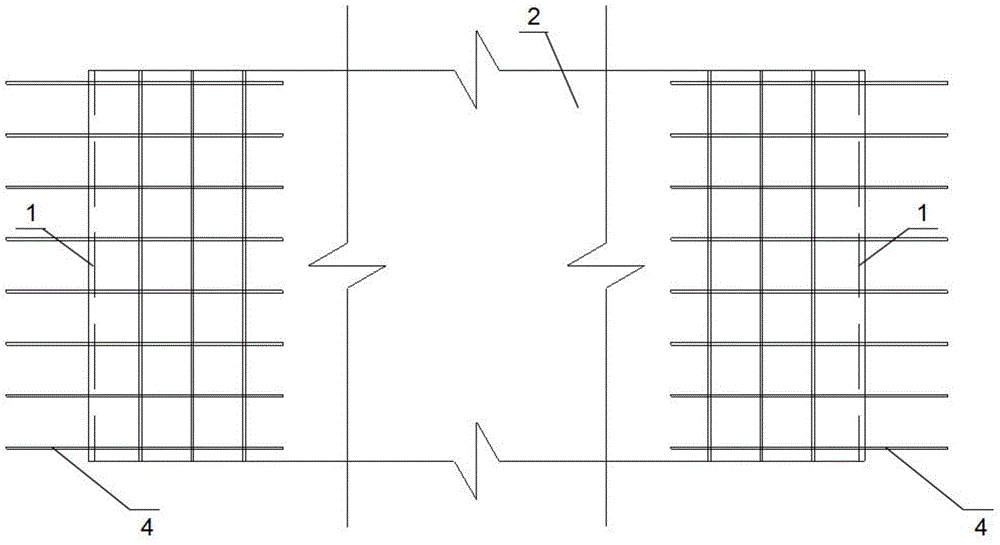

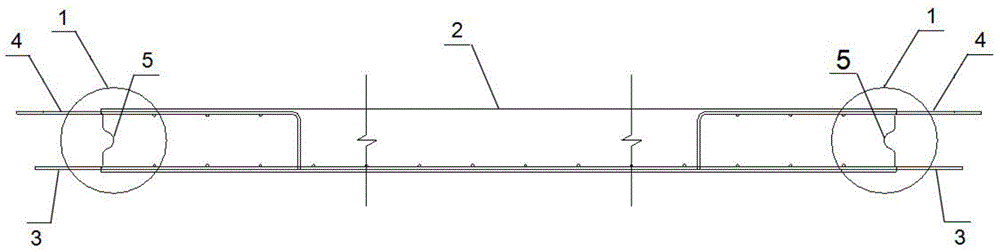

[0043] An assembled integral prefabricated concrete floor as shown in the figure is characterized in that: assembled integral precast concrete floor ( Figure 11 , Figure 12 ) consists of one prefabricated concrete floor 2 or a plurality of prefabricated concrete floors 2, passing through the nodes at the support ( Figure 9 ) and stitching nodes ( Figure 10 ), a precast concrete floor 2 or a plurality of precast concrete floors 2 are connected to form an assembled integral precast concrete floor; The support end 1; the other end is the precast concrete floor slab of the floor splicing end 6 of two precast concrete floor slabs 2, and the precast concrete floor slab 2 of the floor splicing end 6 of two precast concrete floor slabs 2 at both ends;

[0044] The two ends are the prefabricated concrete floor 2 ( figure 1 , figure 2 , image 3 ), the bottom reinforcing bar 3 and the top negative moment reinforcing bar 4 have a certain distance between them; The bottom steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com