Vortex compressor with balancing and energy saving device

A scroll compressor and energy-saving device technology, applied in the field of compressors, can solve problems such as failure to meet energy-saving requirements and single exhaust port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

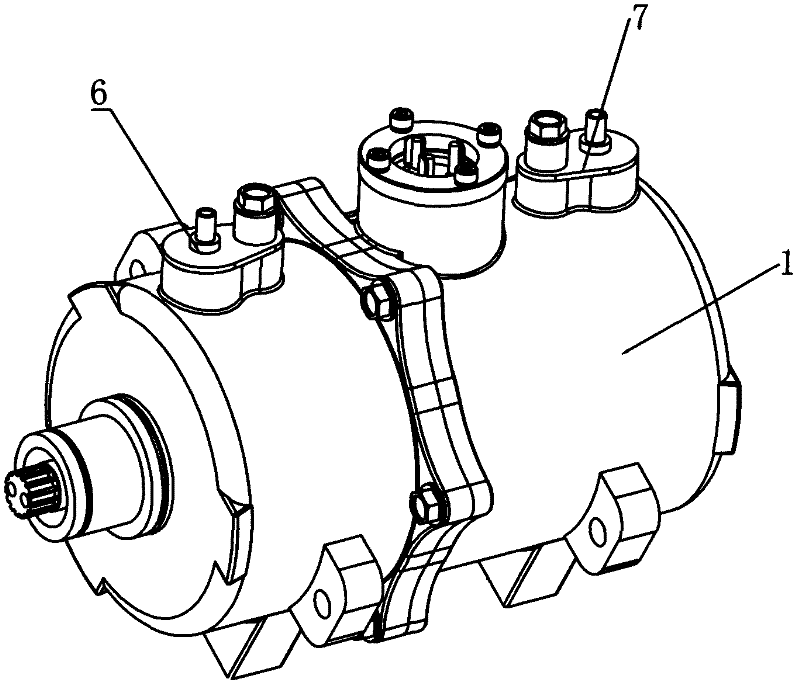

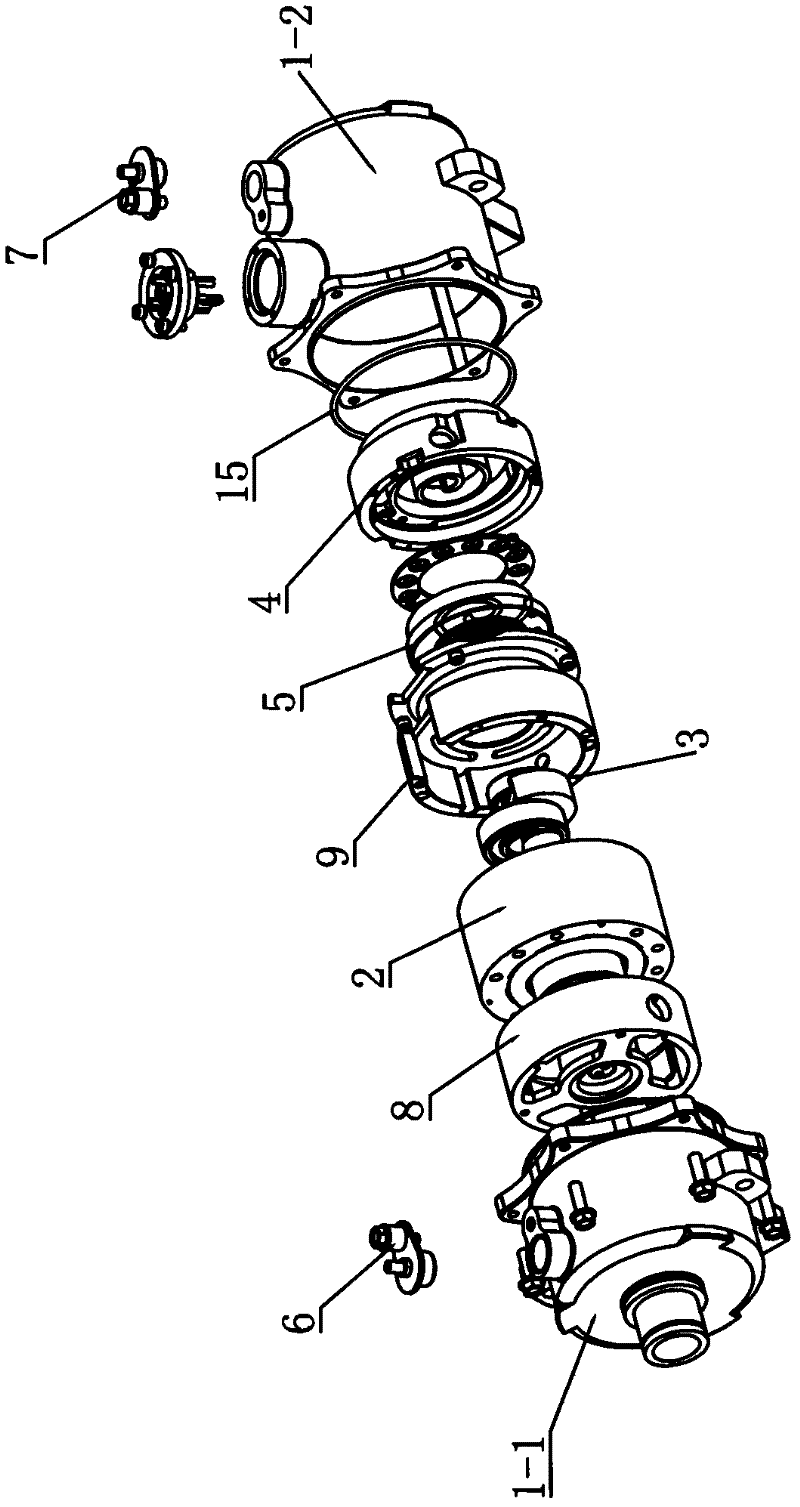

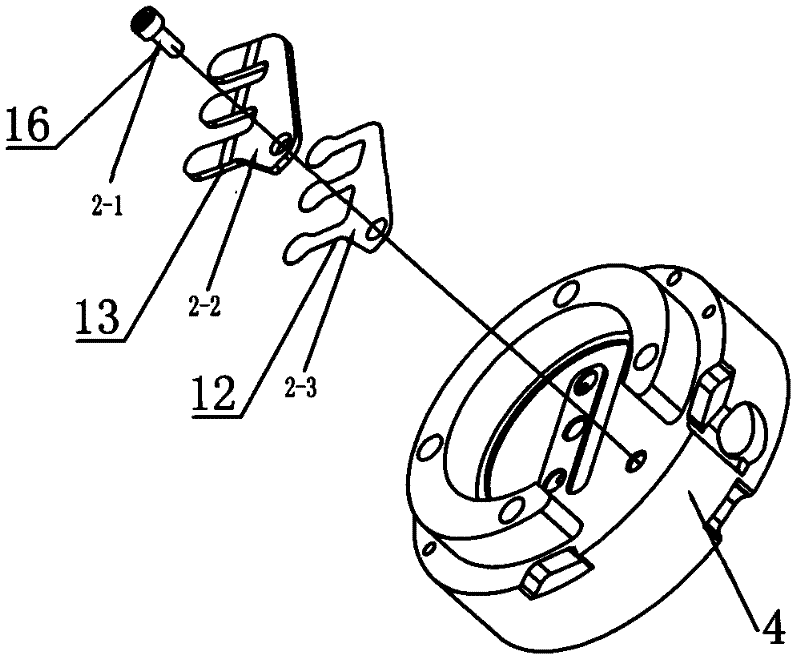

[0022] Figure 1-Figure 7 As shown, a scroll compressor balance energy-saving device of the present invention includes a fixed scroll 4 and a movable scroll 5 driven by a motor 2 and an eccentric wheel assembly 3 arranged inside a casing 1, and the casing 1 is formed by a front casing The assembly 1-1 and the rear casing assembly 1-2 are composed, the front casing assembly 1-1 is provided with an air intake sealing assembly 6, the rear casing assembly 1-2 is provided with an exhaust sealing assembly 7, and the two ends of the motor 2 The front and rear end covers 8 and 9 are respectively provided, and the fixed scroll 4 and the movable scroll 5 are respectively provided with mutually meshing worm gears 4-1 and 5-1, and the worm gears generally adopt a circular involute structure. The movable scroll and the fixed scroll are divided into multiple compression chambers 10 whose volumes change with the movement of the scroll teeth. The fixed scroll 4 is provided with more than two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com