Method for achieving furnace protection through tuyere titanium injection with utilization of blast furnace coal injection system

A system implementation, blast furnace coal injection technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as coal mill damage, coal mill spitting, and inability to ensure the stability of mixed powder composition, to improve utilization, reduce The effect of the focal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

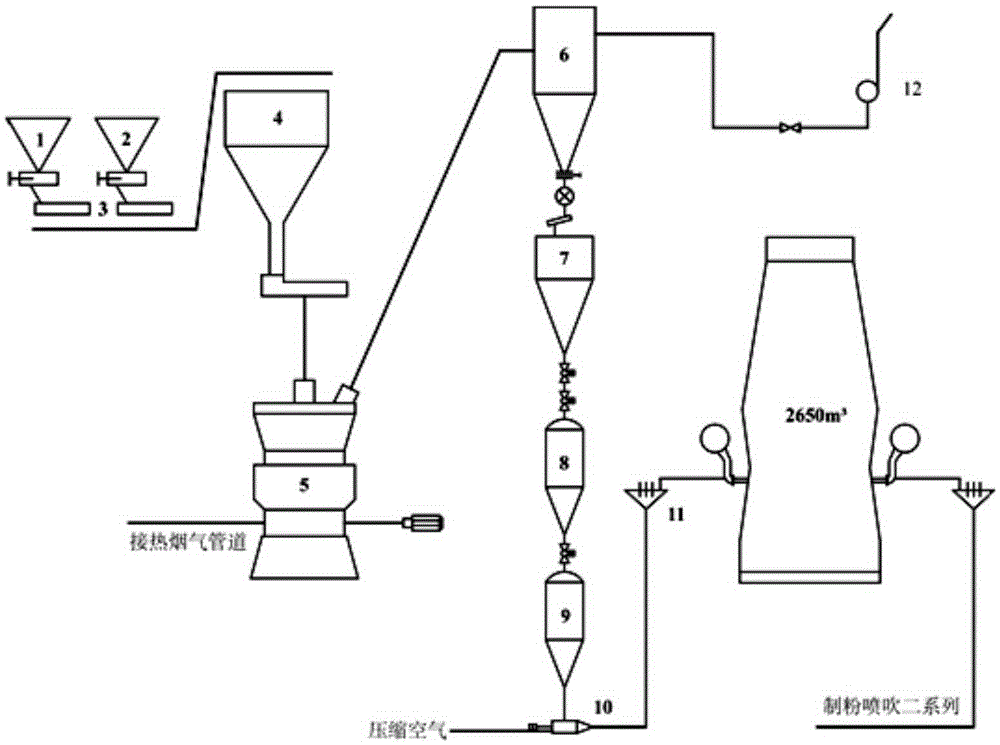

[0023] In a 2650m 3 On the blast furnace, the original titanium load when adding titanium ore from the top of the furnace is 10kg / t. After 24 hours of stopping the addition of titanium ore from the top of the blast furnace, according to figure 1 The system provided is to spray titanium fine powder into blast furnace tuyere according to different titanium loads to check the implementation effect.

[0024] The titanium fine powder is crushed and ground into a fine powder with a particle size of ≤-200 mesh by a vanadium-titanium-based waste flue gas denitrification catalyst, and the iron fine powder is ground into a fine powder with a particle size of ≤-200 mesh; the two fine powders obtained are mixed evenly Made into titanium powder for blast furnace injection.

[0025] When the waste flue gas denitrification catalyst used is a plate-type denitrification catalyst, the plate-type denitrification catalyst is first mechanically crushed into particles with a particle size of less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com