Patents

Literature

34results about How to "To reduce consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

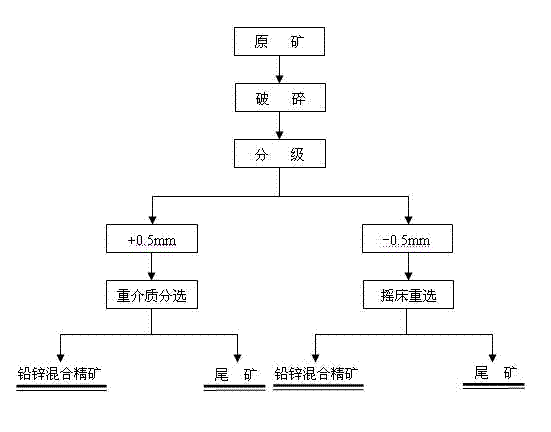

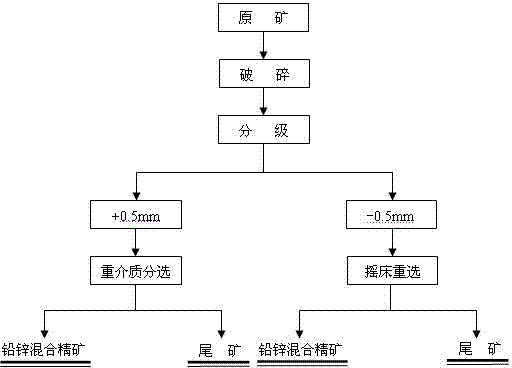

Separation method for treating low-grade refractory zinc lead oxide ores

The invention provides a separation method for treating low-grade refractory zinc lead oxide ores, which adopts a full heavy separation process. The method is implemented in a way that: all raw ores are crushed into particles of which the maximum particle size upper limit is 20-5mm; the crushed ores are screened into two size grades +0.5mm and -0.5mm; and the two size grades of crushed ores are respectively subjected to heavy-media separation and rocker re-separation to obtain lead-zinc mixed concentrate products which can be used as raw materials for the next technical step of oxygen pressure acid leaching. The technical process is simple and easy to operate; and the invention has the advantages of lower ore grinding amount, low separation cost, no need of any reagent, small environmental pollution, favorable technical indexes and the like, can recycle the backwater, greatly enhances the recovery rate of metals lead and zinc, and achieves the goals of energy saving, emission reduction, consumption reduction and comprehensive utilization of resources on the whole.

Owner:青海鸿鑫矿业有限公司

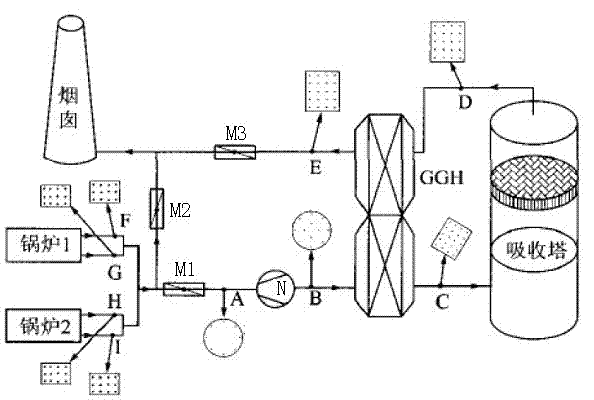

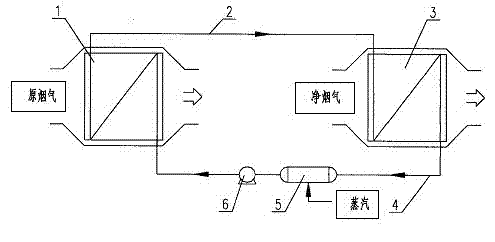

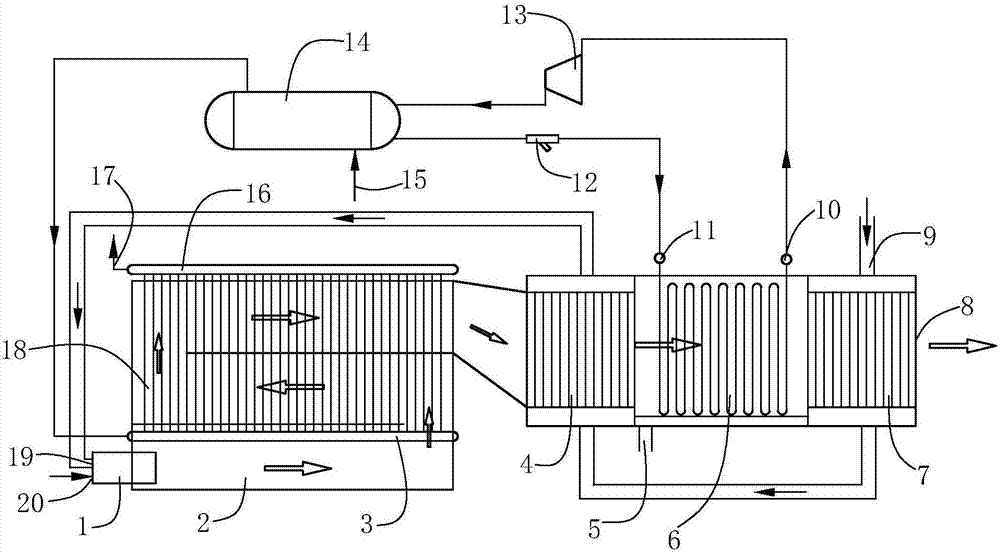

Composite phase change heat exchange system for flue gas heat recovery of boiler

InactiveCN102410549ARealize integrationEfficient recyclingLighting and heating apparatusWater savingHeat conducting

The invention discloses a composite phase change heat exchange system for flue gas heat recovery of boiler, comprising an original coal saving device of the boiler and an air pre-heater, a dust remover and a desulfurization tower; a heat conducting oil heater, a stage I composite phase changer, a stage II composite phase changer, a stage III composite phase changer, and a temperature adjusting system matched with the stage I, state II and stage III composite phase changers are disposed in the flue; the temperature adjusting system can be used for conveniently adjusting the wall surface temperature of the phase change heat exchanger; the heat conducting oil is used as the heat source of the stage III phase change heat exchanger, so as to improve the flue purity and reach the flue discharge requirement. The invention can solve the difficult problem that it is difficult to dispose the evaporation section of the heat exchange round tube in vertical flue or oblique flue, so as to realize the integrated compact arrangements of the evaporation section and condensation section of the phase change heat exchanger; the disadvantage of GGH is overcome; the hazard degree of low-temperature corrosion is decreased, so as to realize the targets of energy saving, water saving and emission reduction.

Owner:王海波

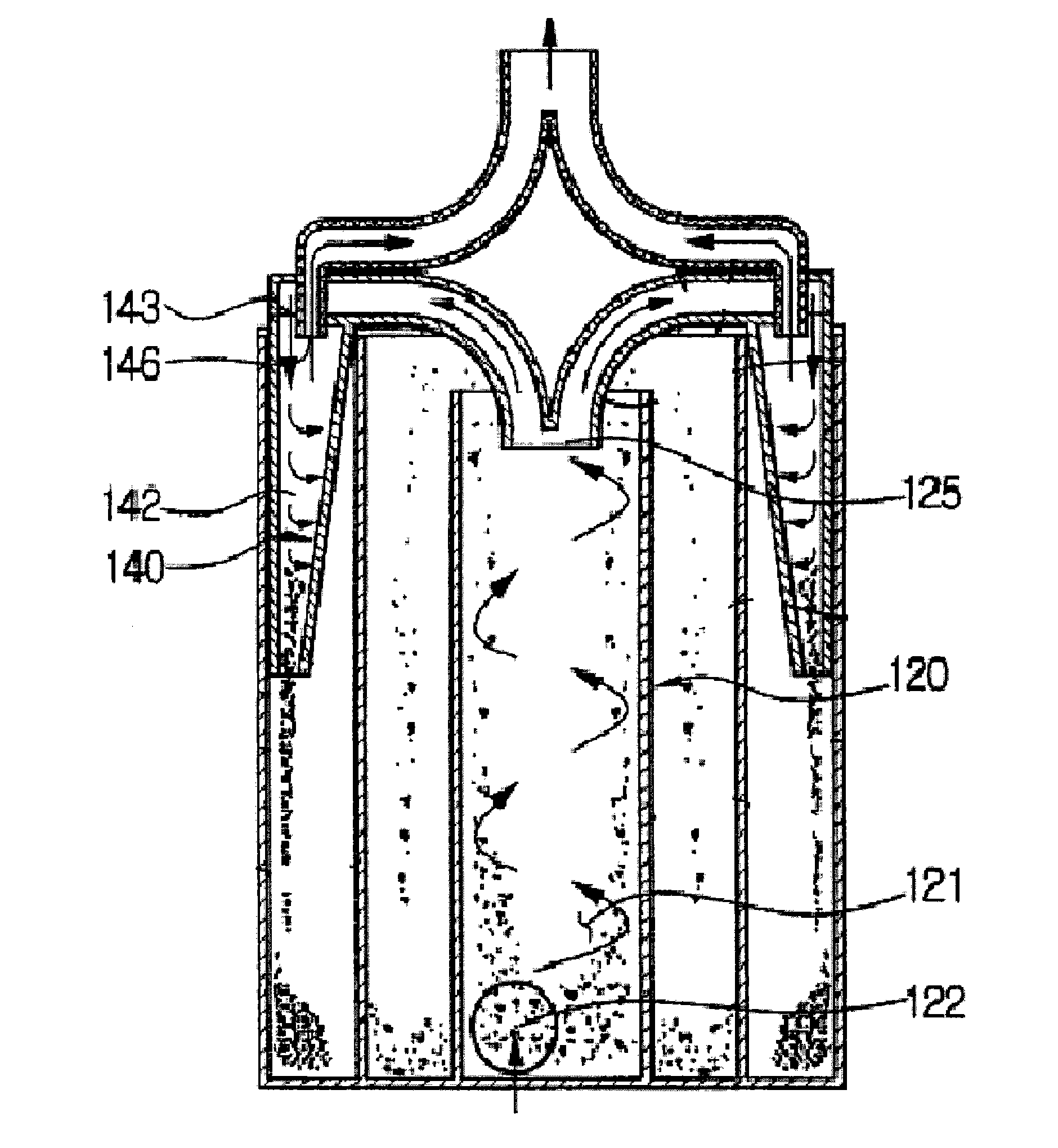

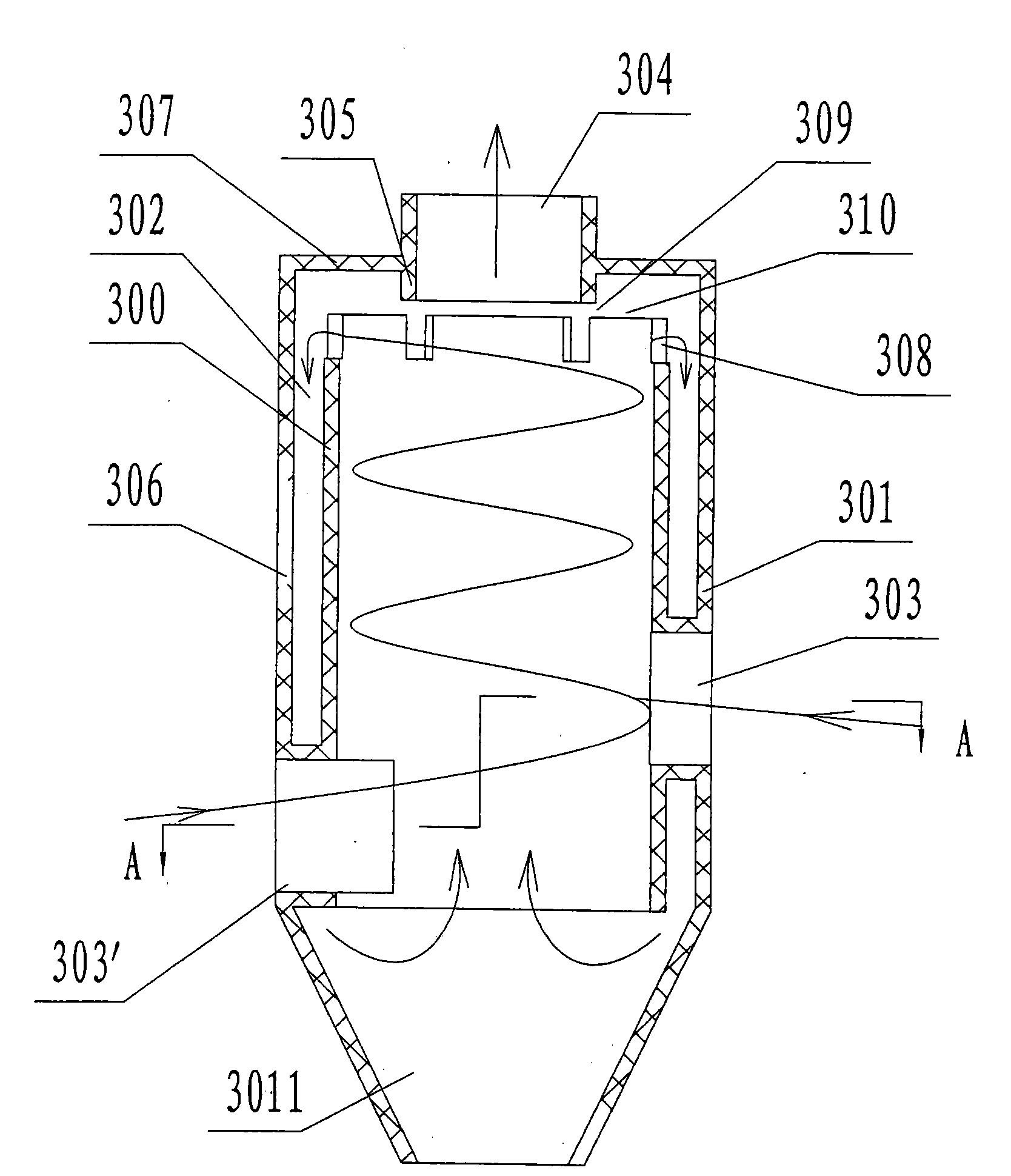

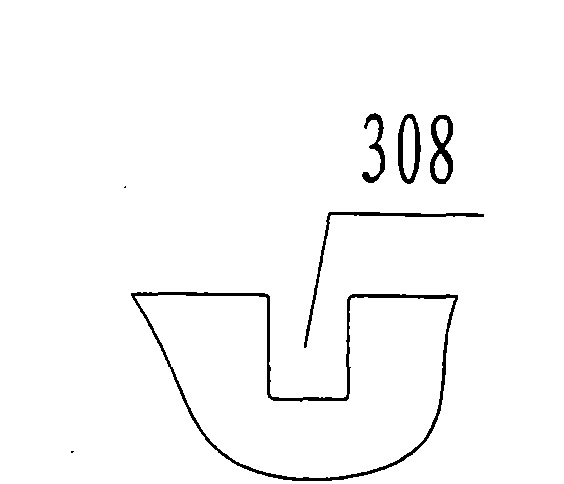

Cyclone separator, cyclone separation device and vacuum cleaner having cyclone separation device

ActiveCN101653345AShort flow pathReduce shear stressSuction filtersReversed direction vortexCycloneCyclonic separation

The invention discloses a cyclone separator, which comprises an inner cylinder body (300) and an outer cylinder body (301), wherein an annular gap (302) is preserved between the outer wall of the inner cylinder and the inner wall of the outer cylinder; the lower end of the inner cylinder is an open end; the lower end of the outer cylinder is a closed end; the wall of the outer cylinder is provided with an air inlet (303); the upper end of the outer cylinder is provided air outlets (304); a return part is arranged between the upper end of the inner cylinder and the air outlet; an air flow enters the cyclone separator from the air inlet on the lower end of the outer cylinder along a tangential direction; one part of an air flow obtained after separation is discharged from the air outlet and the other part of the air flow obtained after separation passes through the annular gap from the return part to be separated again; and the returning air flow obtained after separation enters the inner cylinder to be mixed with a fresh incoming air flow for another time of separation. The invention also relates to a cyclone separation device consisting of the cyclone separator and a vacuum cleaner having the cyclone separation device. The vacuum cleaner of the invention is simple in structure and short in flow path of a single-separation air flow, realizes backflow and circulation and greatly improves separation efficiency while saving energy and protecting environment.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

A directional vibration jaw crusher

InactiveCN103908986ASimple structureEnvironmental production efficiencyCement productionGrain treatmentsBuilding materialRefuse Disposals

The invention relates to a directional vibration jaw crusher. The jaw crusher comprises s rack, a vibration source, a vibration jaw assembly, vibration dampers, a fixed jaw assembly and adjusting mechanisms. The fixed jaw assembly is connected to the rack through the adjusting mechanisms. The vibration source and the vibration jaw assembly are connected, and are connected to the rack through the vibration dampers. The vibration jaw assembly and the fixed jaw assembly form an ore crushing cavity. The vibration source and the vibration jaw assembly form a force applying mechanism for smashing ore. Problems of low crushing efficiency, large energy consumption, low energy utilization rate, and the like of traditional jaw crushers adopting an extrusion manner are overcome by the jaw crusher provided by the invention. The jaw crusher is suitable for crushing operation of ore, stones, bricks, cement blocks, and other solid materials, and can be widely used in the ore field, the metallurgy field, the building material field, the chemical field, the building garbage processing field, and the like.

Owner:HUNAN INSTITUTE OF ENGINEERING

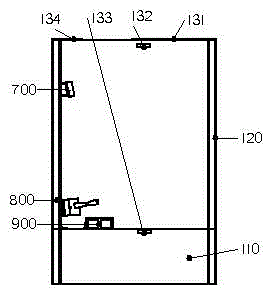

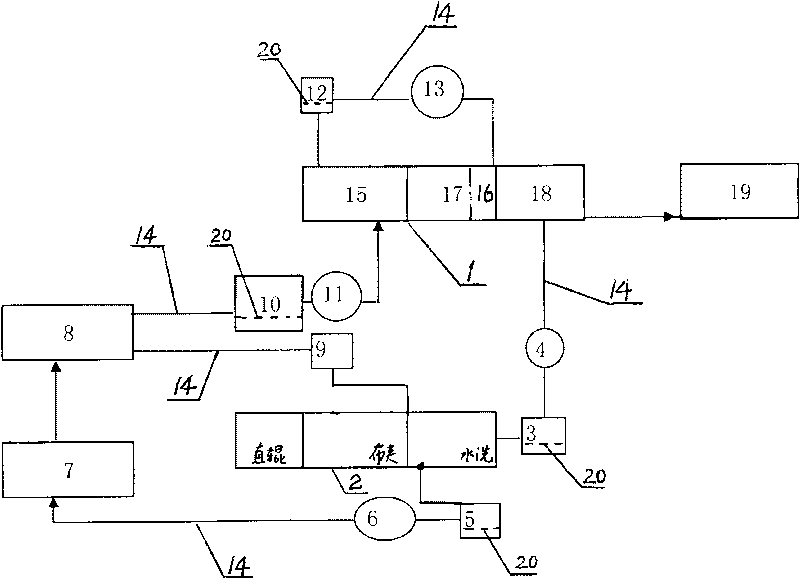

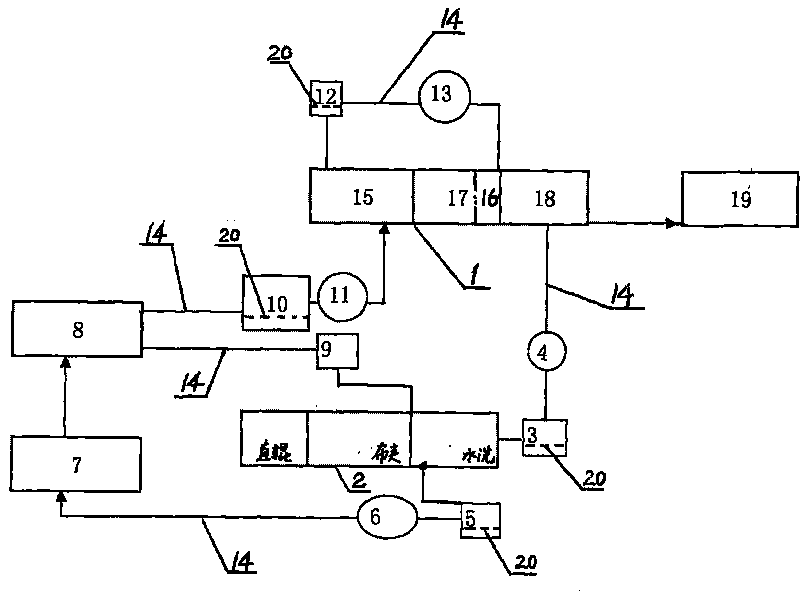

Waste water recycling pad dyeing long machine and waste water recycling method thereof

InactiveCN101748576AEmission reductionReduce dosageTextile treatment machine arrangementsHigh concentrationWater discharge

The invention discloses a waste water recycling pad dyeing long machine and a waste water recycling method thereof. The waste water recycling pad dyeing long machine comprises a desizing, scouring and bleaching combined machine, a mercerizer, a first recovery processing box, a second recovery processing box, a third recovery processing box, a first recovery pump, a second recovery pump, a third recovery pump, a light alkali recovery pool, a dilatation evaporator, an alkali dosing pool, a recovery pool, a recovery pump and connecting pipelines. The method comprises the following steps: a. introducing washing waste water into the first recovery processing box and then pumping into a scouring machine after filtering; b. introducing light alkali with high alkali concentration into the dilatation evaporator for processing through the recovery pool, then introducing processed high-concentration alkali liquor into the mercerizer for reuse and introducing processed water into an oxygen bleaching washing box for use; and c. introducing oxygen bleaching process water into the second recovery processing box and then introducing into a desizing machine washing box for use after filtering. The invention has the advantages of small waste water discharge, high efficiency, energy conservation, etc., saves a large amount of production water and alkali, and meets requirements of energy saving and emission reduction.

Owner:李传海

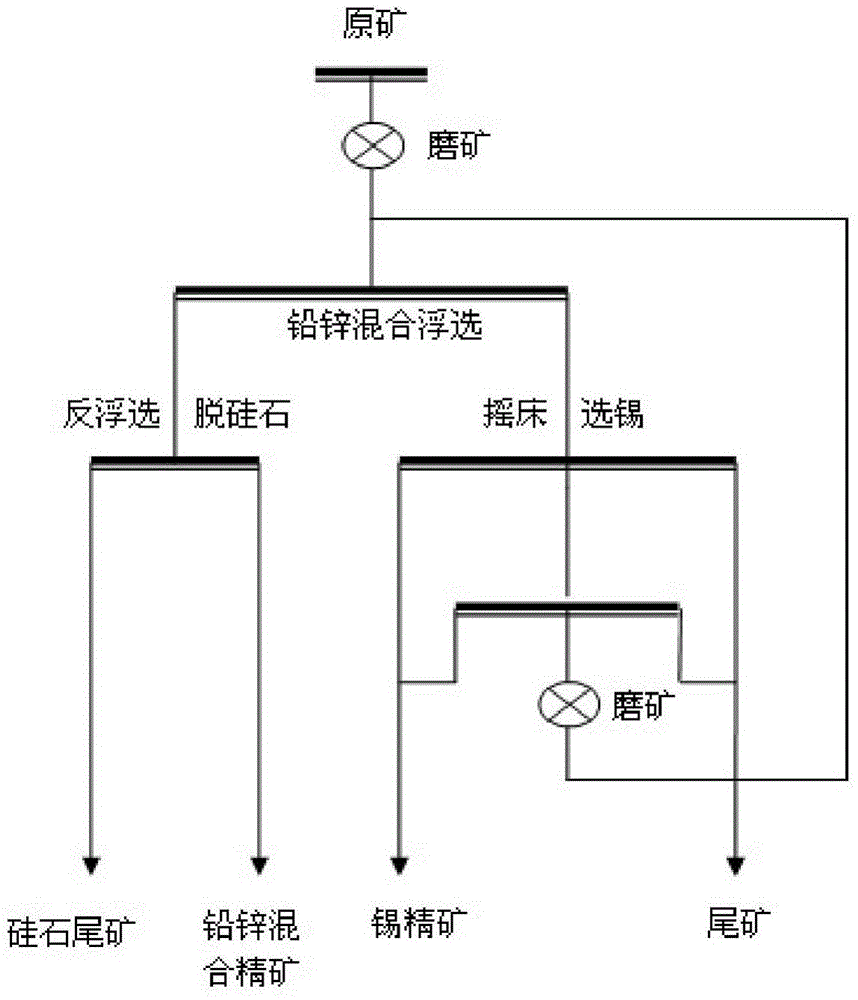

Ore selection method for treating tin, lead and zinc polymetallic oxidized ore

The invention discloses an ore selection method for treating tin, lead and zinc polymetallic oxidized ore. The ore selection method includes: firstly, crushing and ball-milling raw ore; then directly subjecting the raw ore subjected to ball-milling to lead and zinc oxide ore mixed floatation and feeding floating ore into foam products; feeding products in a floatation tank to a primary table concentrator for gravity concentration to obtain tin concentrate, first-section middlings and tailings; feeding the first-section middliings to a secondary table concentrator for gravity concentration to obtain tin concentrate, second-section middlings and tailings; subjecting the second-section middlings to grinding and then combining the same into the ore subjected to lead and zinc oxide mixed floatation. The foam products which are silica tailings are subjected to reverse floatation to get rid of silica, so that the products in the flotation tank are final lead and zinc mixed concentration. By the adoption of lead and zinc mixed floatation and reverse flotation of the lead and zinc mixed concentrate to get rid of the silicon, recovery rate of useful metals is increased in the mixed floatation, types and dosage of medicament are reduced, environmental pollution is low, and purposes of conforming to the state policy of cleaner production and circular economy and achieving energy conservation, emission reduction, consumption reduction and comprehensive utilization of resources are achieved.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

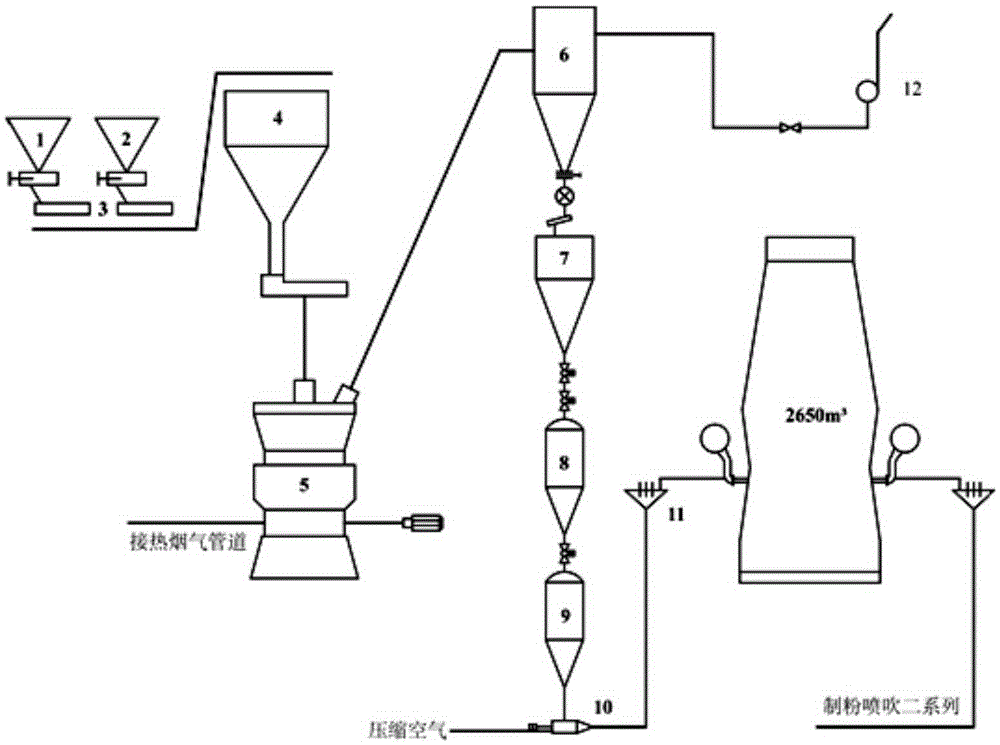

Method for achieving furnace protection through tuyere titanium injection with utilization of blast furnace coal injection system

The invention provides a method for achieving furnace protection through tuyere titanium injection with utilization of a blast furnace coal injection system. Prepared titanium fine powder with the main components being TiO2 and iron fine powder and the particle size being smaller than or equal to -200 meshes is hoisted and conveyed to a coal distribution bin. The titanium fine powder is added onto a coal feeding belt in batches through a coal feeder at the bin bottom of the coal distribution bin and enters a coal grinding system together with raw coal powder through a coal mill raw coal bin. The titanium fine powder and the raw coal powder enter a coal powder bin after mixed evenly in the coal grinding system. The evenly mixed titanium fine powder and raw coal powder entering the coal powder bin are together injected into a blast furnace through a tuyere by a blast furnace injection system. According to the method, additional equipment is not needed, the titanium fine powder and the coal powder can be mixed evenly through an existing power making coal injection system of the blast furnace, the titanium fine powder is injected into the blast furnace along with the coal powder through the tuyere of the blast furnace by a coal injection gun pertinently and safely in time according to the titanium load requirement needed by furnace protection of the blast furnace, and the furnace protection purpose is achieved.

Owner:金康 +1

Coal-burning energy releasing powder and its prepn

The present invention discloses one kind of coal-burning energy releasing powder and its preparation process. The coal-burning energy releasing powder consists of saltpeter 0.5-1.5 weight portions, ferric dicyclopentadiene or allyl cyanurate 1-2 weight portions, potassium permanganate or potassium bromide 0.3-0.7 weight portions, sodium nitrate or calcium nitrate 0.3-0.7 weight portions, potassium permanganate or potassium persulfate 1.5 -2.5 weight portions, strontium nitrate or sodium bichromate 0.5-1.5 weight portions, calcium fluoride 1.5-2.5 weight portions, coal slag or char slag 1.5-2.5 weight portions, loess or lime 1.5-2.5 weight portions, potassium chlorate or potassium persulfate 0.5-1.5 weight portions, potassium nitrate 0.5-1.5 weight portions, and sodium chloride 80-90 weight portions. It can promote combustion of coal to convert the latent energy of coal into heat completely.

Owner:张学义

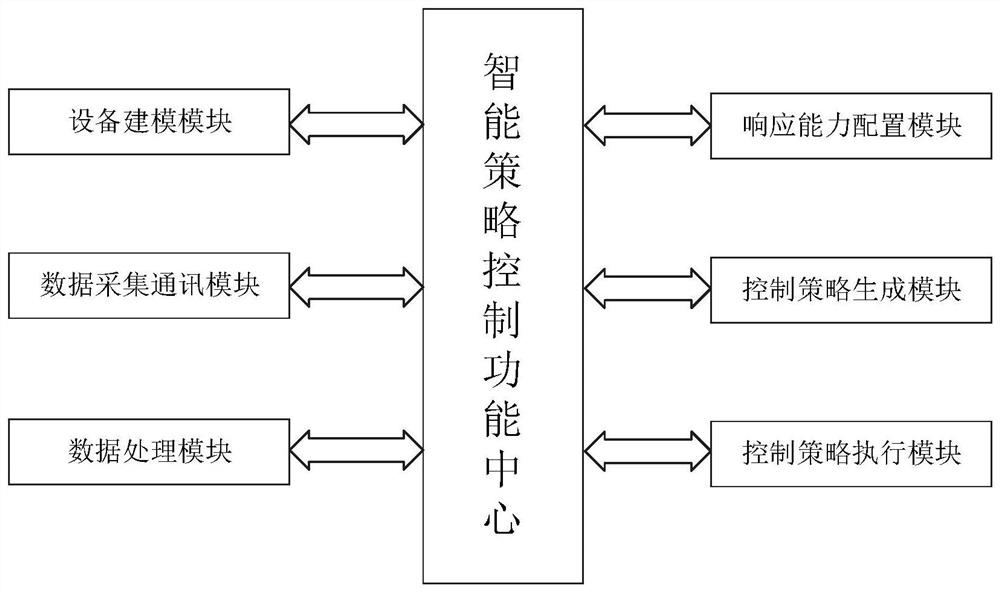

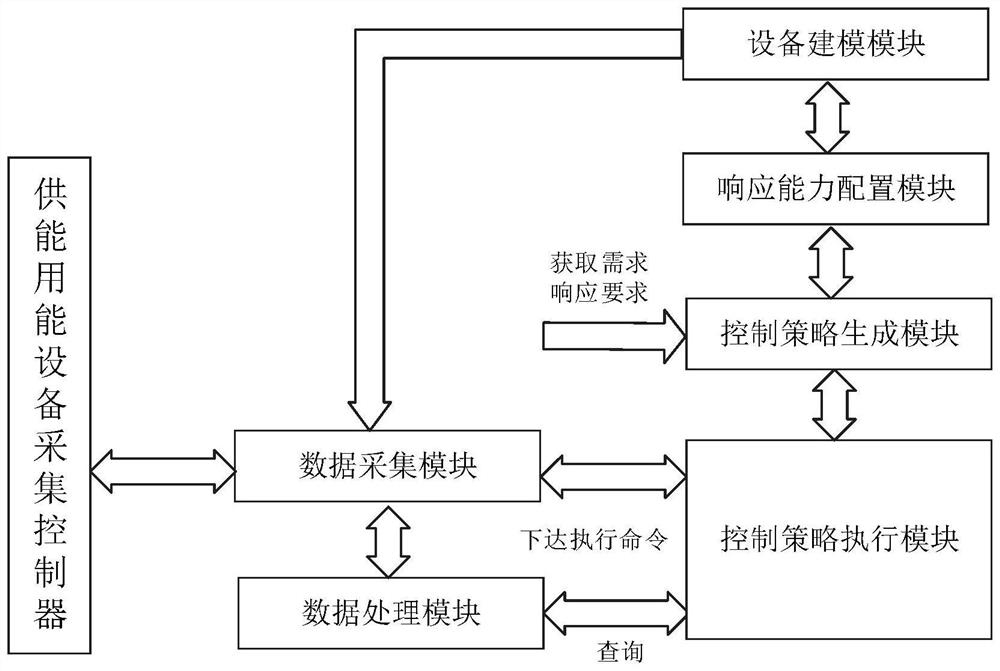

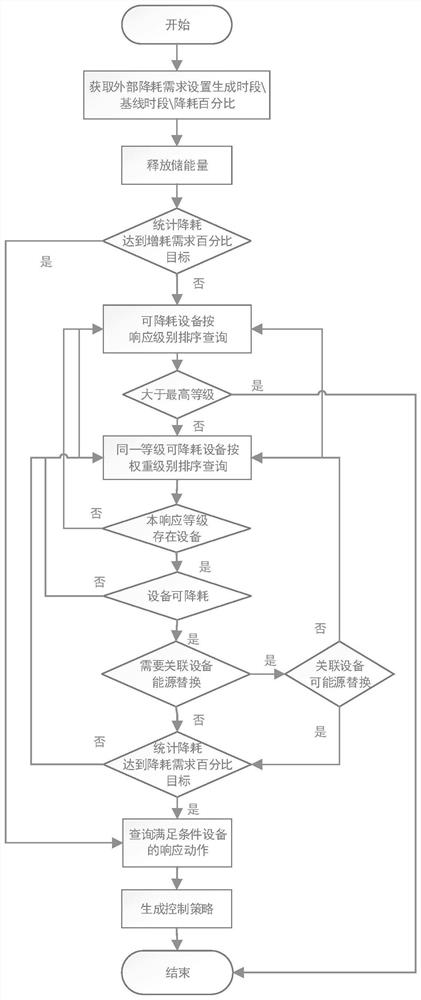

Comprehensive energy monitoring system and method based on multi-energy cooperation

PendingCN111968008AControl switchingDosage controlTechnology managementResourcesReal-time dataMonitoring system

The invention discloses a comprehensive energy monitoring system and method based on multi-energy cooperation, and the system comprises a server which communicates with a processor, and the processorreceives the energy consumption data, collected in real time, of various types of energy consumption equipment, carries out the consumption statistics and charging statistics of the real-time data ofall types of energy consumption equipment, and carries out the minute-level storage; the server generates a control strategy in real time for consumption reduction and consumption increase in different time periods based on the data stored in the processor and the response capability configuration data of the energy consumption equipment and the energy supply equipment; and the server analyzes therunning states of the equipment and the associated equipment in real time, performs serialized operation control on the associated equipment according to a control strategy, and controls the switching and consumption of various energy consumption equipment, thereby achieving the purpose of consumption reduction or increase.

Owner:SHANDONG LUNENG SOFTWARE TECH

Blast furnace titanium injection furnace protection material using waste flue gas denitrification catalyst and preparing method of blast furnace titanium injection furnace protection material

ActiveCN105238892ASolve processing problemsFulfil requirementsBlast furnace detailsResource utilizationCoal

The invention provides a blast furnace titanium injection furnace protection material using a waste flue gas denitrification catalyst and a preparing method of the blast furnace titanium injection furnace protection material. A vanadium-titanium system waste flue gas denitrification catalyst is reused, the purposes of resource utilization and environmental protection are achieved, the effect of furnace protecting is obvious, and meanwhile the production cost of ton iron is reduced. The blast furnace titanium injection furnace protection material comprises, by weight percentage, 60-65% of used vanadium-titanium system waste flue gas denitrification catalyst and 35-40% of fine iron powder. The preparing method includes the steps that firstly, the used vanadium-titanium system waste flue gas denitrification catalyst is broken and ground into fine powder with the granularity smaller than or equal to -200 meshes; secondly, the fine iron powder is ground into fine powder with the granularity smaller than or equal to -200 meshes; and thirdly, two kinds of fine powder obtained in the first step and the second step are mixed evenly to be prepared into the blast furnace protection raw material. The blast furnace protection material prepared through the method serves as the raw material to enter a pulverized coal bunker when used and is sprayed into a blast furnace through a coal spraying gun of a blast furnace air opening by a blast furnace injection system.

Owner:金康 +1

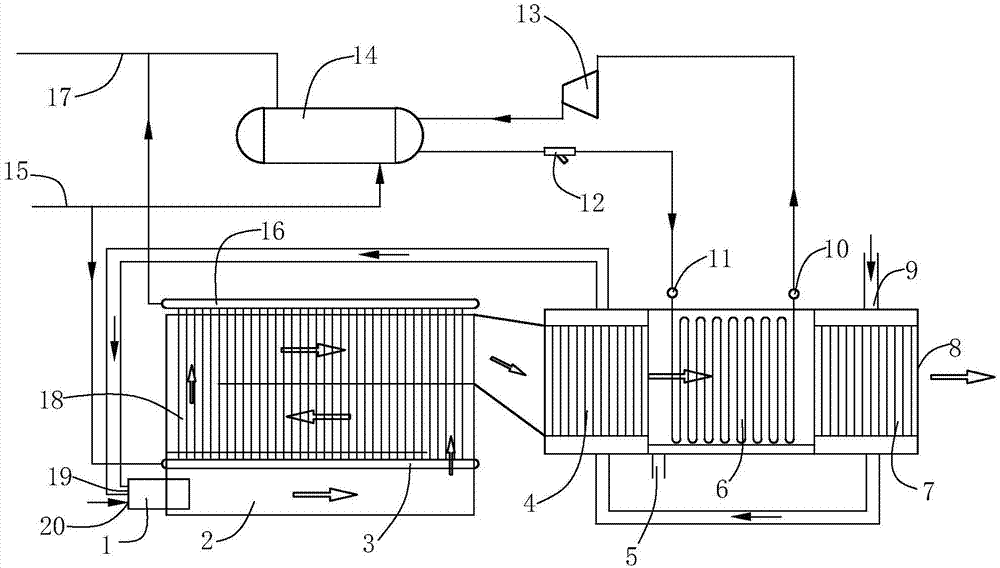

Condensing boiler and heat pump combined heating system

PendingCN107477647AImprove qualityRealize energy savingLighting and heating apparatusSpace heating and ventilation detailsAir preheaterWater vapor

The invention discloses a condensing boiler and heat pump combined heating system. A combustor is installed in an inlet of a hearth, gas / fuel and hot air are sprayed out from the combustor according to the flow ratio and burn in the hearth to form high temperature flame; flue gas passes through a boiler tube bundle heat exchanger and transfers heat to water; and the flue gas after heat releasing passes through a high-temperature air preheater, and air flowing through the high temperature air preheater is further heated. The flue gas passes through a condensing flue gas deep waste heat recovery device, and sensible heat of the fuel gas and latent heat of vaporization of water vapor are released, an organic working medium of a heat pump device is heated and gasified, the waste heat of the flue gas at the tail of the heat pump device is absorbed, and heating water is heated through the organic working medium circulation. According to the condensing boiler and heat pump combined heating system, the waste heat of fuel gas exhausting of the flue gas boiler is recovered deeply by using the low-temperature organic working medium the heat pump, the waste heat quality is improve to generate a high temperature working medium, the heating water is further heated, and the purpose of energy saving, consumption reducing and emission reducing is achieved.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

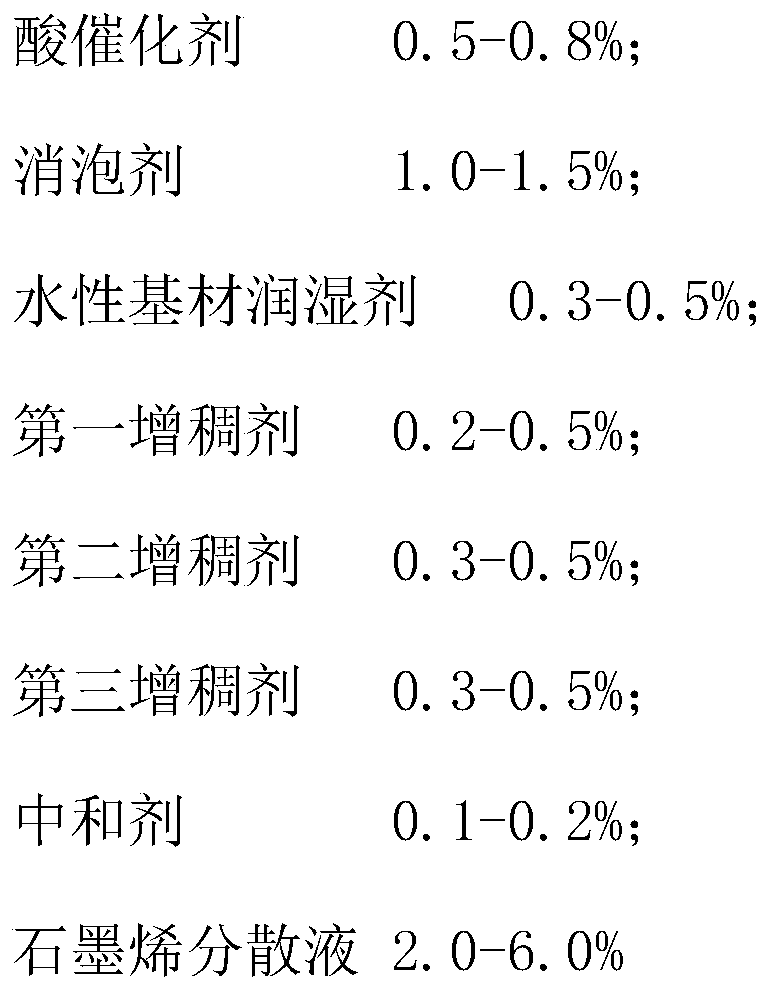

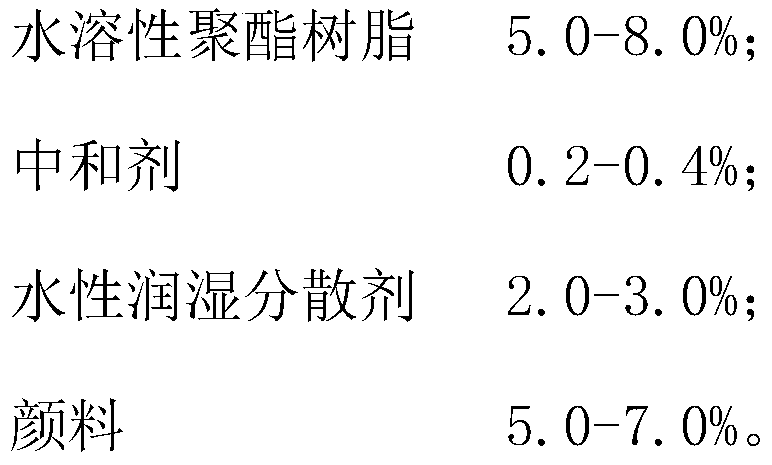

Aqueous finishing-free high-gloss solid color paint for vehicles

InactiveCN111234630ASolve the problem of excessive emissionsHigh glossCoatingsPtru catalystAcid catalyzed

The invention discloses an aqueous finishing-free high-gloss solid color paint for vehicles. The paint comprises a main film-forming substance, an assistant, deionized water and color paste, and the main film-forming substance comprises an aqueous acrylic acid dispersion, an aqueous polyester resin, a fully methylated amino resin and an aqueous blocked isocyanate; wherein the assistant comprises graphene dispersion liquid, an acid catalyst, a defoaming agent, an aqueous base material wetting agent, a first thickening agent, a second thickening agent, a third thickening agent, a neutralizing agent, an aqueous wetting dispersing agent and a coalescing agent; and the color paste comprises aqueous polyester resin, an aqueous wetting dispersant, a defoaming agent, a neutralizer and a pigment. Graphene is added into a coating; a resin system capable of generating a synergistic effect with graphene is screened out; on the premise of satisfying various physicochemical properties of the traditional aqueous solid color paint for vehicles matched with an oil-based finishing varnish film, the production process of coating the oil varnish on the traditional solid color paint is reduced, the VOCs emission is reduced by more than 95%, the energy consumption is reduced by more than 30%, the working hours are reduced by more than 20%, and the national requirements on energy conservation, emission reduction and consumption reduction are met.

Owner:重庆亿隆涂料股份有限公司

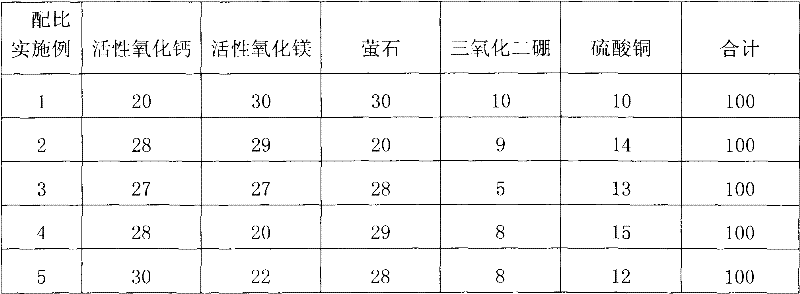

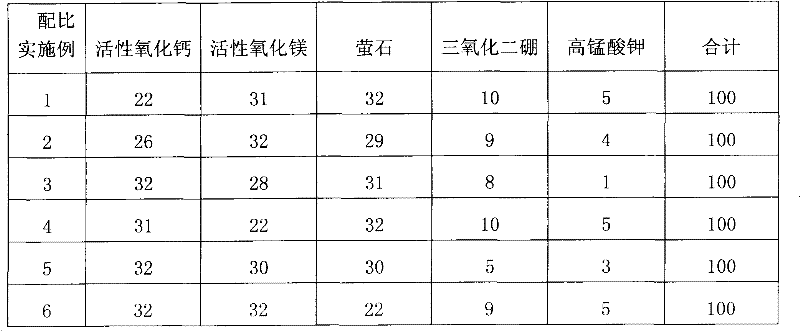

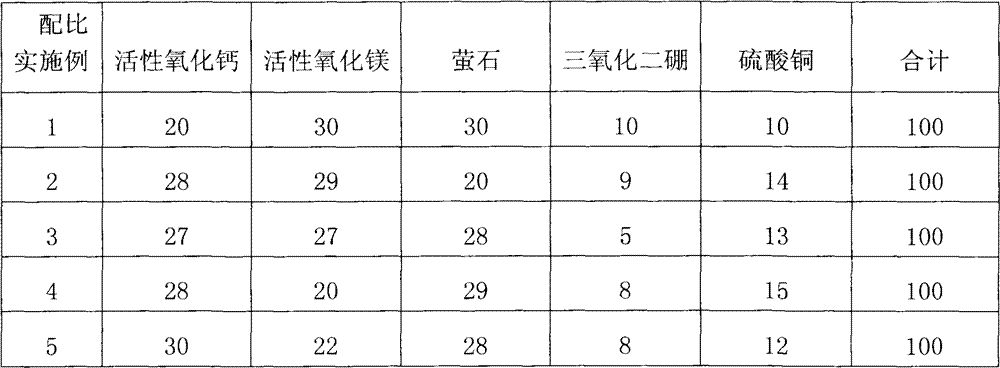

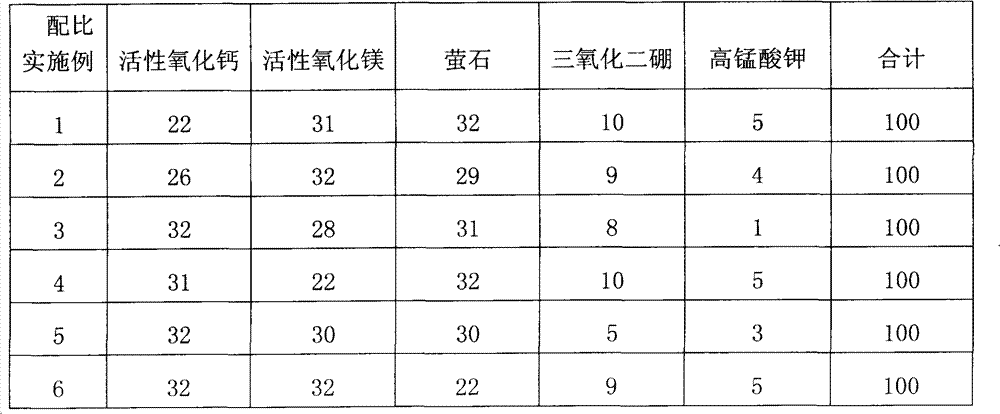

Sintering synergistic agent and use method thereof

The invention discloses a sintering synergistic agent comprising the following components in percentage by weight: 20-30% of active calcium oxide with the activity of more than or equal to 280 ml / 4N-HCl, 20-30% of active magnesium oxide with the activity of more than or equal to 180 ml / 4N-HCl, 20-30% of fluorite, 5-10% of diboron trioxide with the purity of more than or equal to 99% and 5-15% of copper sulfate with the purity of more than or equal to 95%, wherein the content of the active calcium oxide with the granularity of 0.074 mm is more than or equal to 70%; the content of the active magnesium oxide with the granularity of 0.074 mm is more than or equal to 60%; and the content of the fluorite with the granularity of 0.147 mm is more than or equal to 60%;. In the sintering synergistic agent disclosed by the invention, the copper sulfate can be replaced by 1-5% of potassium permanganate with the purity of more than or equal to 96%; the components are uniformly stirred in the proportions so as to form a product; in a sintering production process, 0.04-0.045 % of the sintered feeding material is added at back of a fuel bin; 5-8% of solid fuel consumption can be reduced; the utilization factor of a sintering machine is increased by about 1%; and the drum strength is improved by 1-2%.

Owner:MAANSHAN JIUPENG JIATENG MACHINERY IND

Energy-saving integral bathroom

InactiveCN106052120AIncrease temperatureSufficient heat exchangeFluid heatersSpecial buildingWater storage tankEngineering

The invention relates to the technical field of bathrooms, in particular to an energy-saving integral bathroom. The energy-saving integral bathroom comprises a bathroom body. A water storage tank is arranged at the bottom of the bathroom body. First heat exchangers are arranged in the water storage tank. A heat preservation water tank and a heat pump unit are arranged in the bathroom body. A hot water outlet is formed in the upper portion of the bathroom body. The top of the bathroom body is provided with a steam outlet, an exhaust fan and second heat exchangers. The second heat exchangers are arranged in the position of the steam outlet. One end of each first heat exchanger is connected with a tap water inlet, and the other end of each first heat exchanger is connected with the heat preservation water tank. The second heat exchangers are connected with the heat pump unit. The heat pump unit is connected with the heat preservation water tank. Compared with the prior art, the energy-saving integral bathroom has the advantages that waste heat of hot water in a shower can be recovered, the waste heat of steam after a shower can also be recovered, and the effects of increasing the temperature, saving energy, reducing consumption and reducing emission are achieved; and compared with a conventional bathroom, the energy-saving integral bathroom can save energy by 80%-90% and is extremely remarkable in effect.

Owner:HUIZHOU JIANGMING MECHANICAL & ELECTRICAL TECH CO LTD

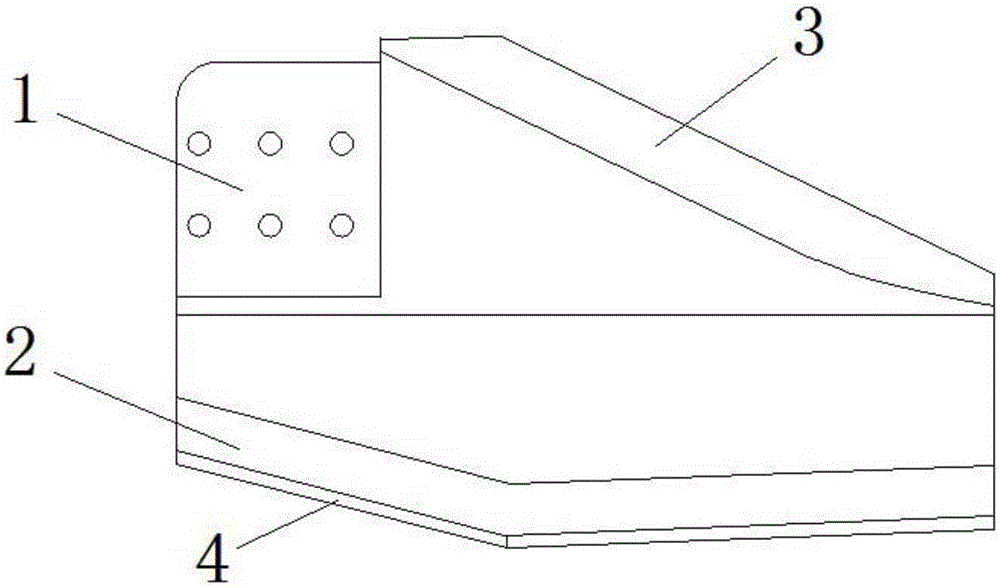

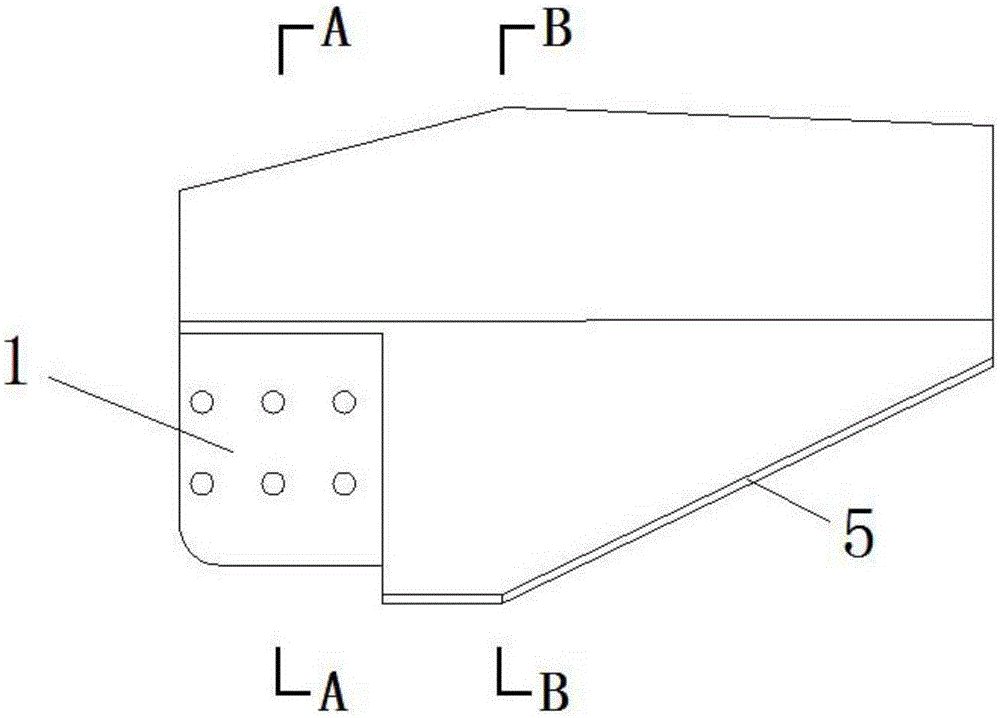

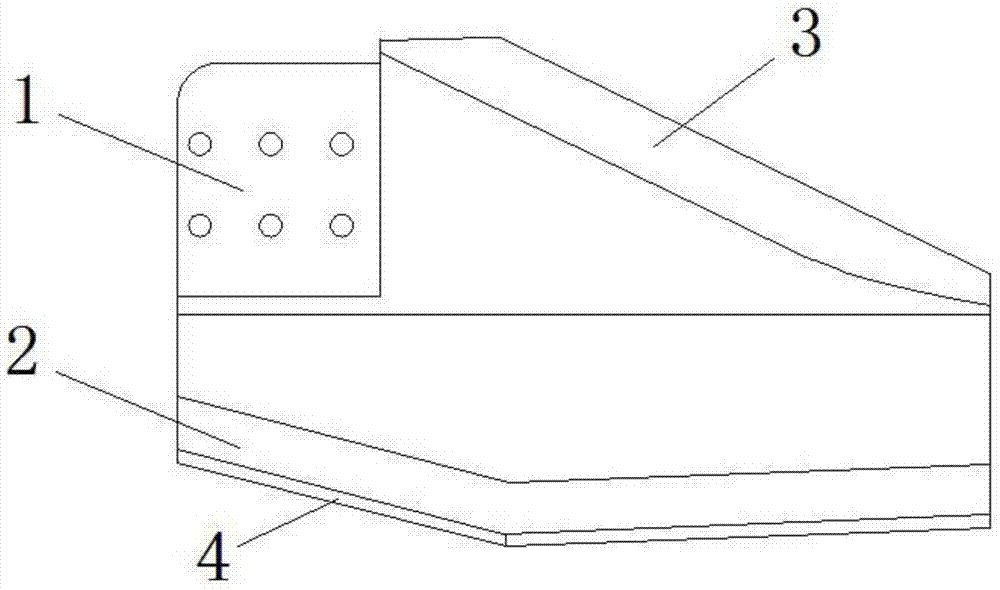

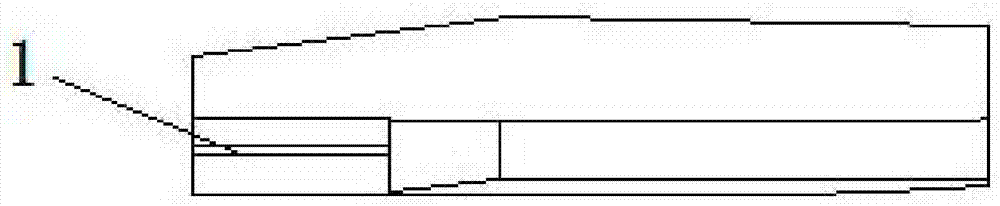

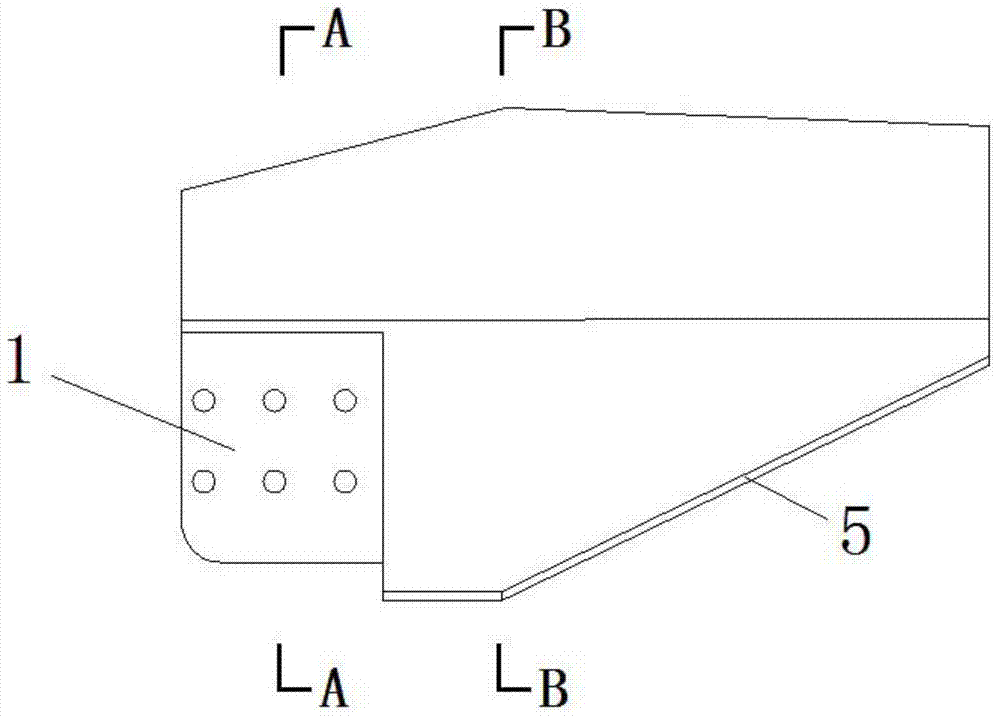

Chamfer angle arc-shaped swirl anticorrosion blade and chamfer angle arc-shaped swirl anticorrosion stirring paddle

ActiveCN105126693ARunning weight reductionReduce operating currentMixer accessoriesPower savingConcave surface

The invention discloses a chamfer angle arc-shaped swirl anticorrosion blade and a chamfer angle arc-shaped swirl anticorrosion stirring paddle. The upper portion convex surfaces of two side surfaces of the arc-shaped blade are chamfer angles, and the upper portion convex surfaces and the lower portions of right angle approaching edges of the two side surfaces commonly form the upper liquid entrance surface and the lower liquid poking surface of the blade, and the side edge of the upper liquid entrance surface is formed by two angle lines with similar lengths; the root of the convex surface of the arc-shaped blade is a part close to a stirring shaft, the middle and the tail of the convex surface of the arc-shaped blade are parts far from the stirring shaft, and the cross sections of the three parts are arc surfaces formed by circles with different radii; and the root of the concave surface of the arc-shaped blade is a part close to the stirring shaft, the middle and the tail of the concave surface of the arc-shaped blade are parts far from the stirring shaft, and the cross sections of the three parts are arc surfaces formed by circles with different radii. The chamfer angle arc-shaped swirl anticorrosion blade and the chamfer angle arc-shaped swirl anticorrosion stirring paddle, provided by the invention, can widen the flow path stretching force and number-shaped strong swirling force of a stirring blade, and have the advantages of power saving, consumption reduction, yield increase and long service life.

Owner:李兴国 +2

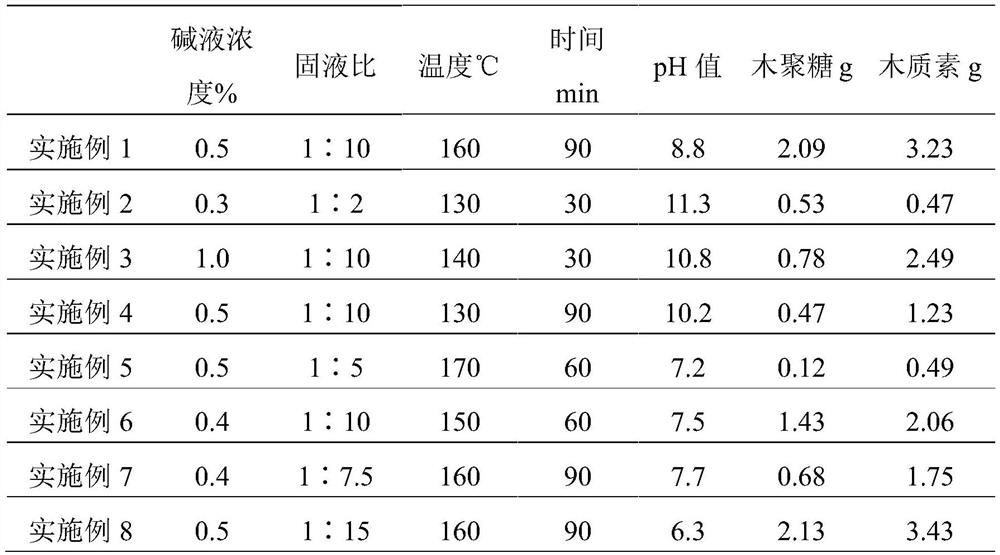

Method for preparing xylan and high-purity lignin by taking gramineous plants as raw materials

PendingCN112680991AGood removal effectReduce processPulping with inorganic basesEnvironmental chemistryCellulose

Owner:ZHEJIANG FORESTRY UNIVERSITY

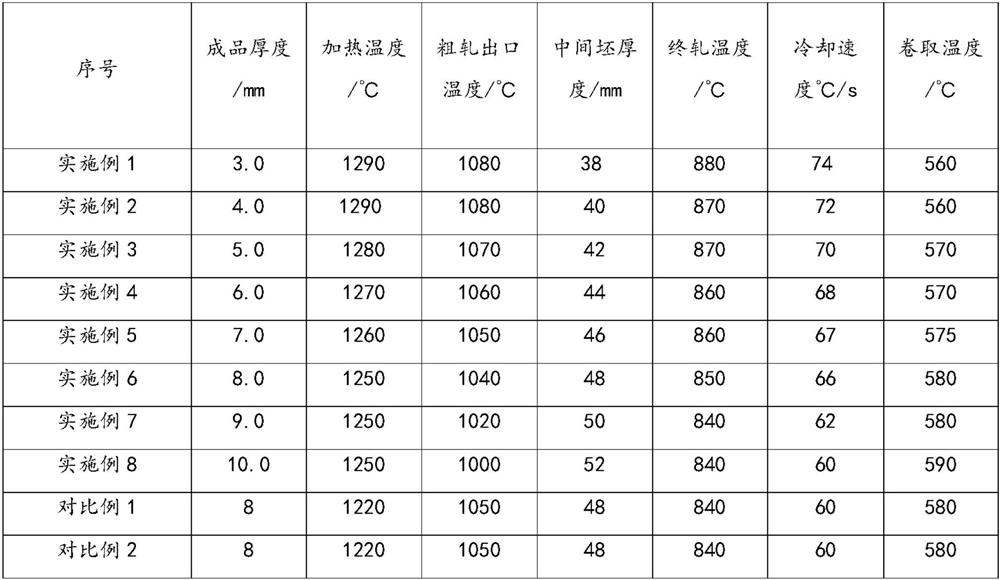

Ultrahigh-strength precipitation strengthening steel and preparation process and application thereof

The invention provides ultrahigh-strength precipitation strengthening steel, and belongs to the technical field of steel production. The ultrahigh-strength precipitation strengthening steel comprises the following chemical components in percentage by mass: 0.17%-0.22% of C, 0.35%-0.55% of Si, 1.70%-2.00% of Mn, 0.015%-0.060% of Alt, less than or equal to 0.015% of P, less than or equal to 0.004% of S, 0.30%-0.60% of Cr, 0.18%-0.26% of Ti, 0.0012%-0.0023% of B, 0.035%-0.055% of Sn and the balance of iron and inevitable impurities. The metallographic structure of the steel comprises, by area fraction, 83%-95% of bainite and / or acicular ferrite and 3%-17% of polygonal ferrite. The steel has high strength, high wear resistance and high corrosion resistance. The invention further provides a preparation process and application of the ultrahigh-strength precipitation strengthening steel.

Owner:SHOUGANG CORPORATION

Aluminum electrolysis prebaked anode carbon block coating anti-oxidation method

The invention discloses an aluminum electrolysis prebaked anode carbon block coating anti-oxidation method. The surface of a pre-baked anode carbon block is coated with a layer of metal foil or carbonfiber cloth by adopting an adhesive, and the surface of the metal foil or carbon fiber cloth is coated with an anti-oxidation layer. The aluminum electrolysis prebaked anode carbon block coating anti-oxidation method has the beneficial effects that the surface of the carbon block is isolated from air flowing in an electrolytic cell, reliable prevention or alleviation of oxidation of the surface of the carbon block is realized, normal use can be realized in the high-temperature electrolysis environment, the use amount is small, the influence on the quality of aluminum water is small, the environment is protected, energy is saved, and consumption is reduced.

Owner:贵州铝城铝业原材料研究发展有限公司

A mineral processing method for processing low-grade refractory lead-zinc oxide ore

The invention provides a separation method for treating low-grade refractory zinc lead oxide ores, which adopts a full heavy separation process. The method is implemented in a way that: all raw ores are crushed into particles of which the maximum particle size upper limit is 20-5mm; the crushed ores are screened into two size grades +0.5mm and -0.5mm; and the two size grades of crushed ores are respectively subjected to heavy-media separation and rocker re-separation to obtain lead-zinc mixed concentrate products which can be used as raw materials for the next technical step of oxygen pressure acid leaching. The technical process is simple and easy to operate; and the invention has the advantages of lower ore grinding amount, low separation cost, no need of any reagent, small environmental pollution, favorable technical indexes and the like, can recycle the backwater, greatly enhances the recovery rate of metals lead and zinc, and achieves the goals of energy saving, emission reduction, consumption reduction and comprehensive utilization of resources on the whole.

Owner:青海鸿鑫矿业有限公司

Technology for sowing and cultivating broom corn millet before winter

PendingCN112913604AImprove yield and qualityPromote Diversified DevelopmentFertilising methodsCereal cultivationPesticideEnvironmental geology

The invention discloses a technology for sowing and cultivating broom corn millet before winter. The technology includes the steps of preparing before sowing, selecting land, selecting flat land which is deep in soil layer, fertile in soil texture, strong in water and fertilizer retention capability and good in drainage and ventilation, selecting wheat stubble without using high-residual pesticide and corn stubble and potato stubble which are good in cultivation condition as previous stubbles, and avoiding continuous cropping and alternate cropping; selecting varieties and treating seeds; sowing the seeds; conducting field management; controlling diseases, pests and birds; and in the jointing and booting stage of the broom corn millet, spraying 40-50 kg / mu of a 0.2%-0.3% monopotassium phosphate aqueous solution on leaf surfaces of plants in sunny days, and the situation that the broom corn millet can absorb and utilize the solution as soon as possible is guaranteed. According to the technology for sowing and cultivating the broom corn millet before winter, the major problems that sowing in spring is dry and less in rain, the emergence rate is low, late-maturing varieties cannot be mature and the like can be effectively solved, meanwhile, the yield and quality of the broom corn millet can be improved, diversified development of the broom corn millet is enhanced, and the income of farmers is effectively guaranteed.

Owner:GUYUAN BRANCH NINGXIA AGRI & FORESTRY SCI

Inverted long-angle arc swirl anti-corrosion paddle and inverted long-angle arc swirl anti-corrosion stirring paddle

ActiveCN105126693BEnhanced inversion forceIncrease inversion forceMixer accessoriesImpellerConvex side

Owner:李兴国 +2

Sintering synergistic agent and use method thereof

Owner:MAANSHAN JIUPENG JIATENG MACHINERY IND

Anti-oxidation method of aluminum electrolytic prebaked anode carbon block covered with foil

Owner:贵州铝城铝业原材料研究发展有限公司

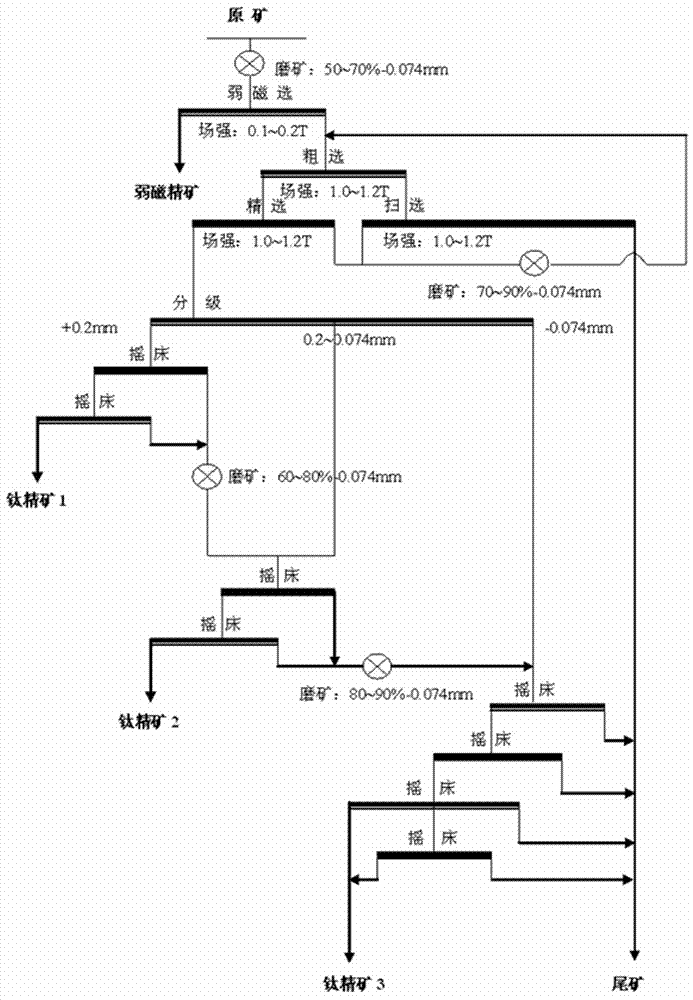

A beneficiation process of rock-type primary ilmenite

ActiveCN105057089BSimple processRealize energy savingWet separationFerromagnetismMagnetic separation

The invention discloses a beneficiation process for rock-type primary ilmenite, which includes the steps of pre-treatment, weak magnetic separation, strong magnetic separation, classification and post-treatment. After the ferromagnetic minerals are removed, the weak magnetic separation tailings are obtained; the weak magnetic separation tailings are magnetically separated with a high gradient strong magnetic separator to obtain strong magnetic separation concentrates and strong magnetic separation tailings; the strong magnetic separation concentrates are classified , divided into coarse-grained products, medium-grained products, and fine-grained products; the final titanium concentrate and final tailings of the invention are obtained after post-processing. Aiming at the rock-type primary ilmenite ore that has not been used industrially at present, the present invention adopts the above-mentioned technical scheme for beneficiation, and the technological process is simple. The gravity separation and magnetic separation process flow adopted by the invention does not require any medicament, conforms to the national policy of clean production and circular economy, and achieves the goals of energy saving, emission reduction, consumption reduction and comprehensive utilization of resources.

Owner:KUNMING METALLURGY INST

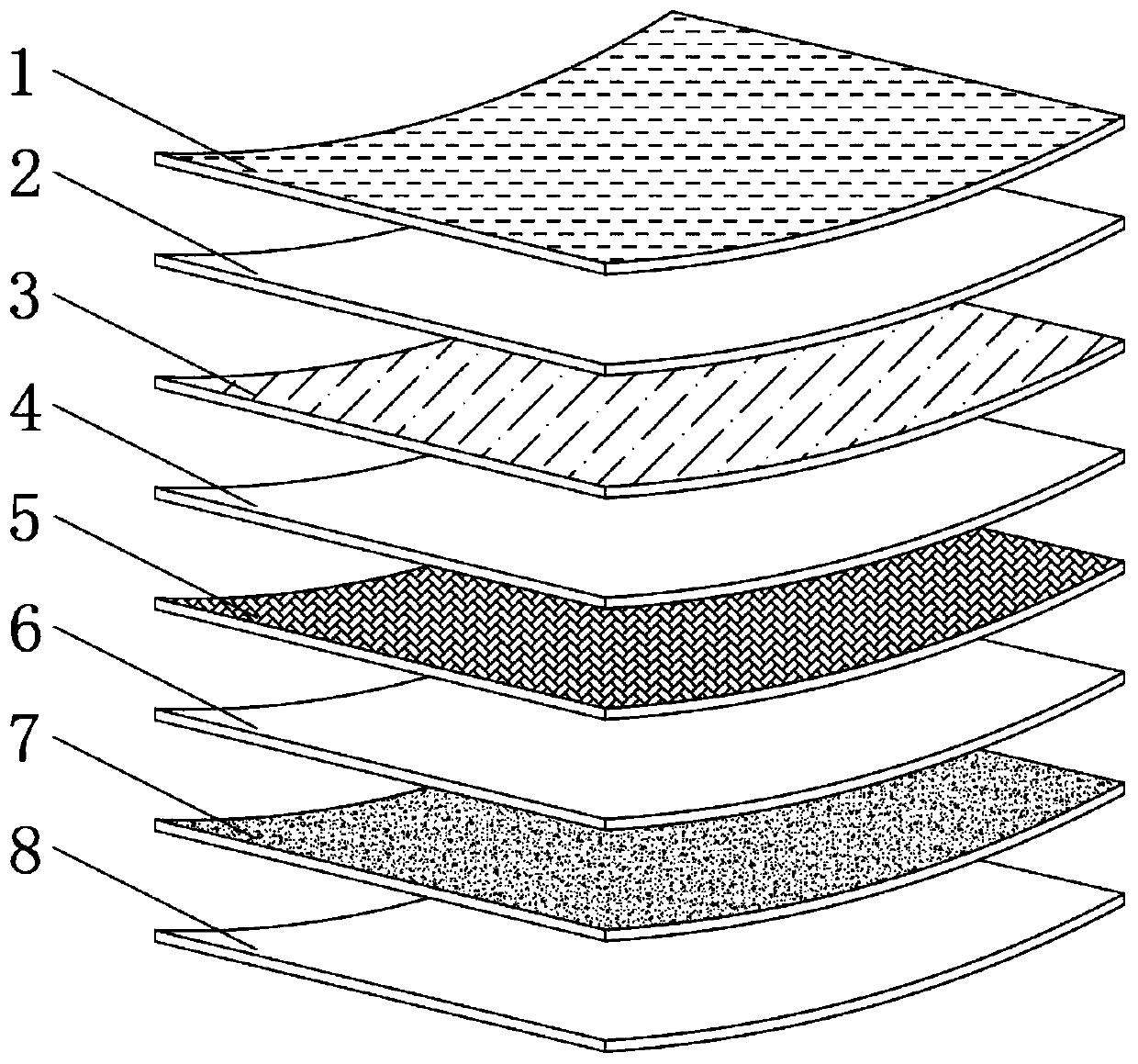

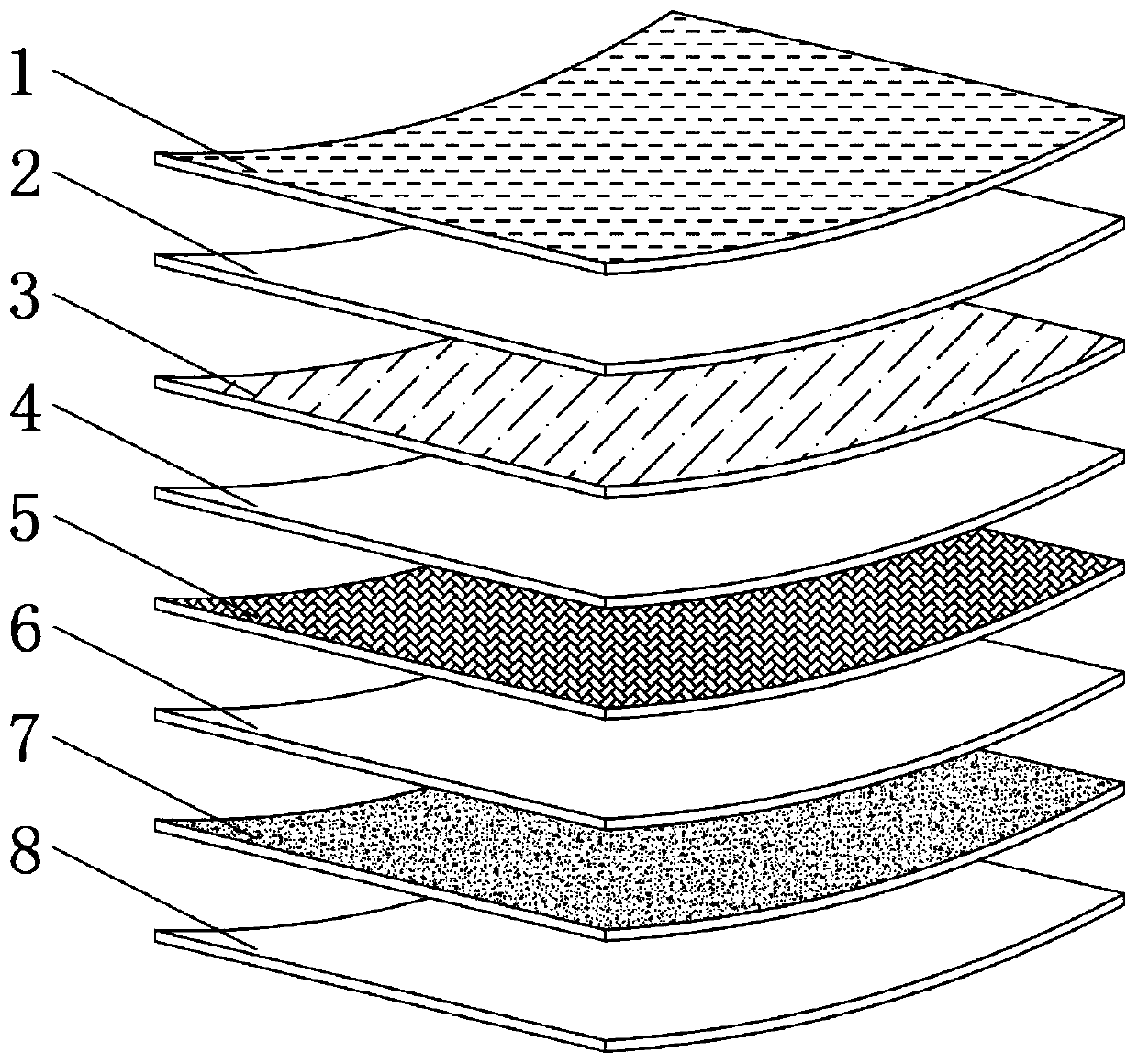

Novel nano energy-saving film

PendingCN111154423AImprove barrier propertiesImprove protectionFilm/foil adhesivesHigh concentrationReaction layer

The invention relates to the technical field of glass films, and in particular, relates to a novel nano energy-saving membrane. The novel nano energy-saving membrane comprises a negative ion reactionlayer, an HC anti-glare layer, a glass substrate, an HC nano anti-infrared barrier layer, a nano UV-resistant layer, a pressure-sensitive adhesive layer and a release layer, wherein the HC anti-dazzlelayer covers the top surface of the glass substrate, the top surface of the HC anti-dazzle layer is fixedly connected with the negative ion reaction layer, and an HC nano anti-infrared barrier layer,the nano UV-resistant layer, the pressure-sensitive adhesive layer and the release layer are sequentially arranged on one side, deviating from the HC anti-dazzle layer, of the glass substrate outwards. The HC anti-infrared barrier layer is arranged, so heat energy invasion can be blocked to the maximum extent, the temperature balance in the relative space is maintained, the real effects of energyconservation, consumption reduction and emission reduction are achieved, and the environment is well protected; through the arrangement of the negative ion reaction layer, the negative ion reaction layer can be decomposed and release high-concentration negative oxygen ions when meeting light, and air in the space can be kept fresh at any time.

Owner:厦门悦客乐家网络科技有限公司

A waste flue gas denitrification catalyst used as a blast furnace spray titanium protection material and its preparation method

ActiveCN105238892BSolve processing problemsFulfil requirementsBlast furnace detailsResource utilizationCoal

The invention provides a blast furnace titanium injection furnace protection material using a waste flue gas denitrification catalyst and a preparing method of the blast furnace titanium injection furnace protection material. A vanadium-titanium system waste flue gas denitrification catalyst is reused, the purposes of resource utilization and environmental protection are achieved, the effect of furnace protecting is obvious, and meanwhile the production cost of ton iron is reduced. The blast furnace titanium injection furnace protection material comprises, by weight percentage, 60-65% of used vanadium-titanium system waste flue gas denitrification catalyst and 35-40% of fine iron powder. The preparing method includes the steps that firstly, the used vanadium-titanium system waste flue gas denitrification catalyst is broken and ground into fine powder with the granularity smaller than or equal to -200 meshes; secondly, the fine iron powder is ground into fine powder with the granularity smaller than or equal to -200 meshes; and thirdly, two kinds of fine powder obtained in the first step and the second step are mixed evenly to be prepared into the blast furnace protection raw material. The blast furnace protection material prepared through the method serves as the raw material to enter a pulverized coal bunker when used and is sprayed into a blast furnace through a coal spraying gun of a blast furnace air opening by a blast furnace injection system.

Owner:金康 +1

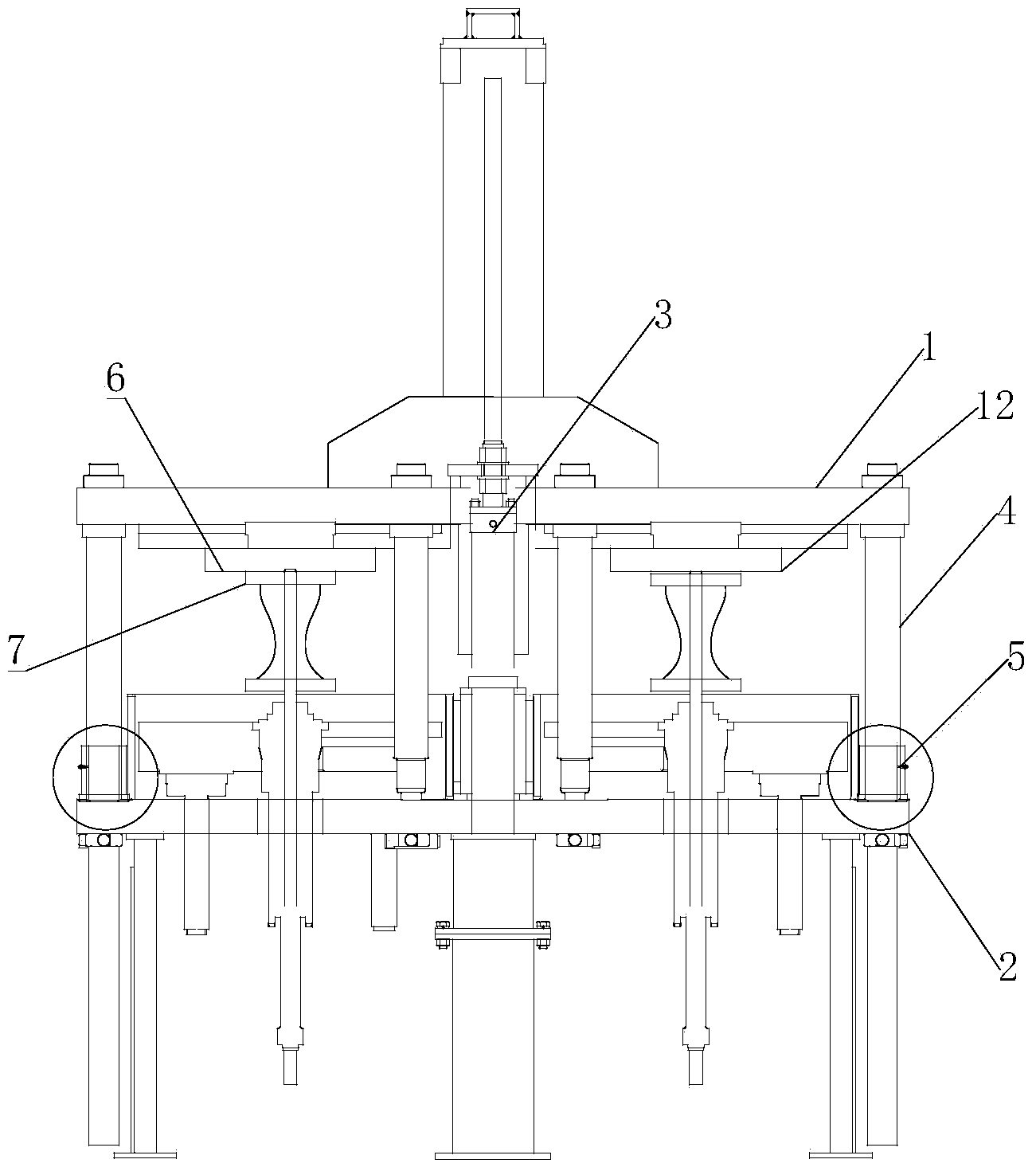

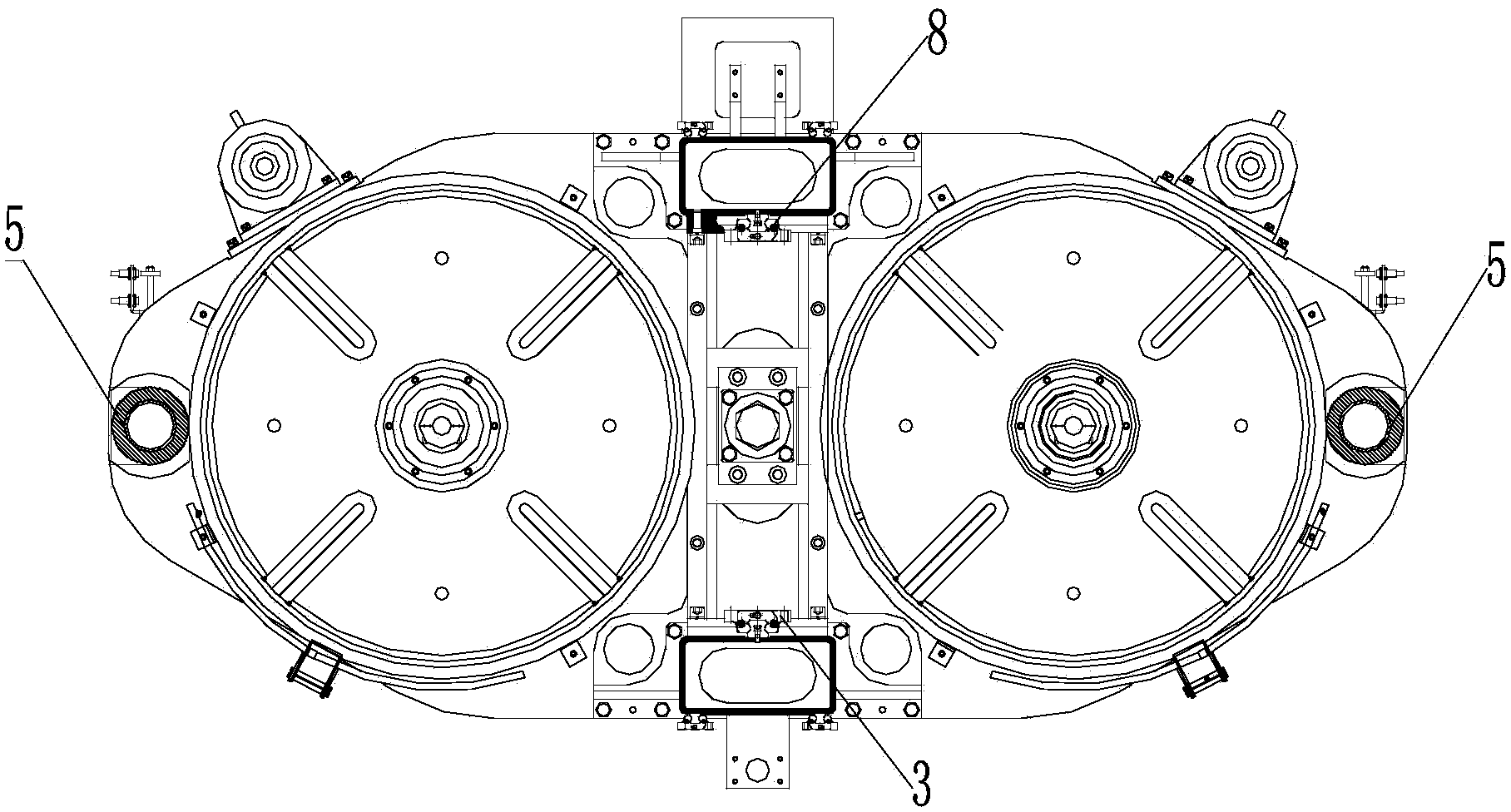

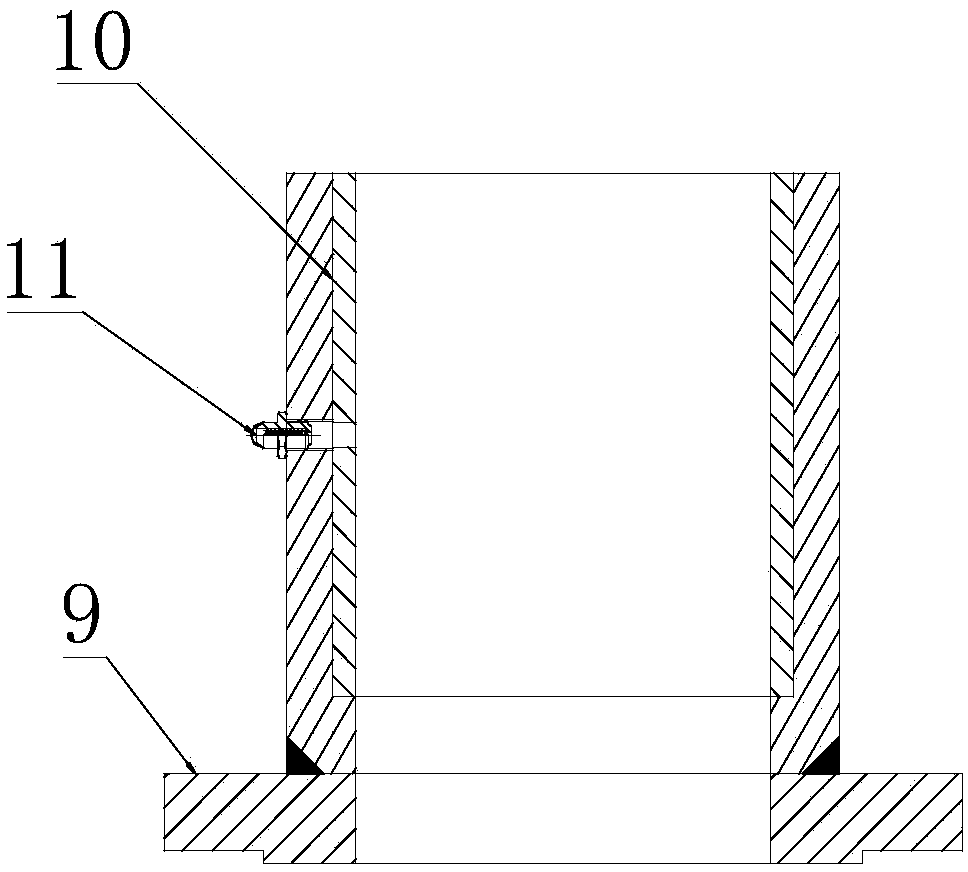

Balance type hydraulic double-mold vulcanizer positioning-guiding device

The invention discloses a balance type hydraulic double-mold vulcanizer positioning-guiding device. The vulcanizer positioning-guiding device comprises a rack on which an upper support plate and a lower support plate are arranged, wherein a lower support surface of an upper left mold and a lower support surface of an upper right mold are symmetrically arranged on the upper support plate, and the two lower support surfaces are provided with upper capsule chucks. The vulcanizer positioning-guiding device is characterized in that the upper support plate and the lower support plate are horizontal plates, and a linear guide rail and a positioning-guiding device are arranged between the upper support plate and the lower support plate. By virtue of the vulcanizer positioning-guiding device, the problems that the upper mold swings left and right and the centering property is poor during mold closing of a balance type hydraulic double-mold tire-forming vulcanizer are thoroughly solved, and the positioning-guiding device allows equipment to run steadily and be stressed uniformly, thereby not only well protecting mechanical equipment and prolonging the service life of the equipment, but also achieving the aims of energy conservation, environment protection, quality improvement and consumption reduction.

Owner:QINGDAO SHENGHUALONG RUBBER MACHINERY

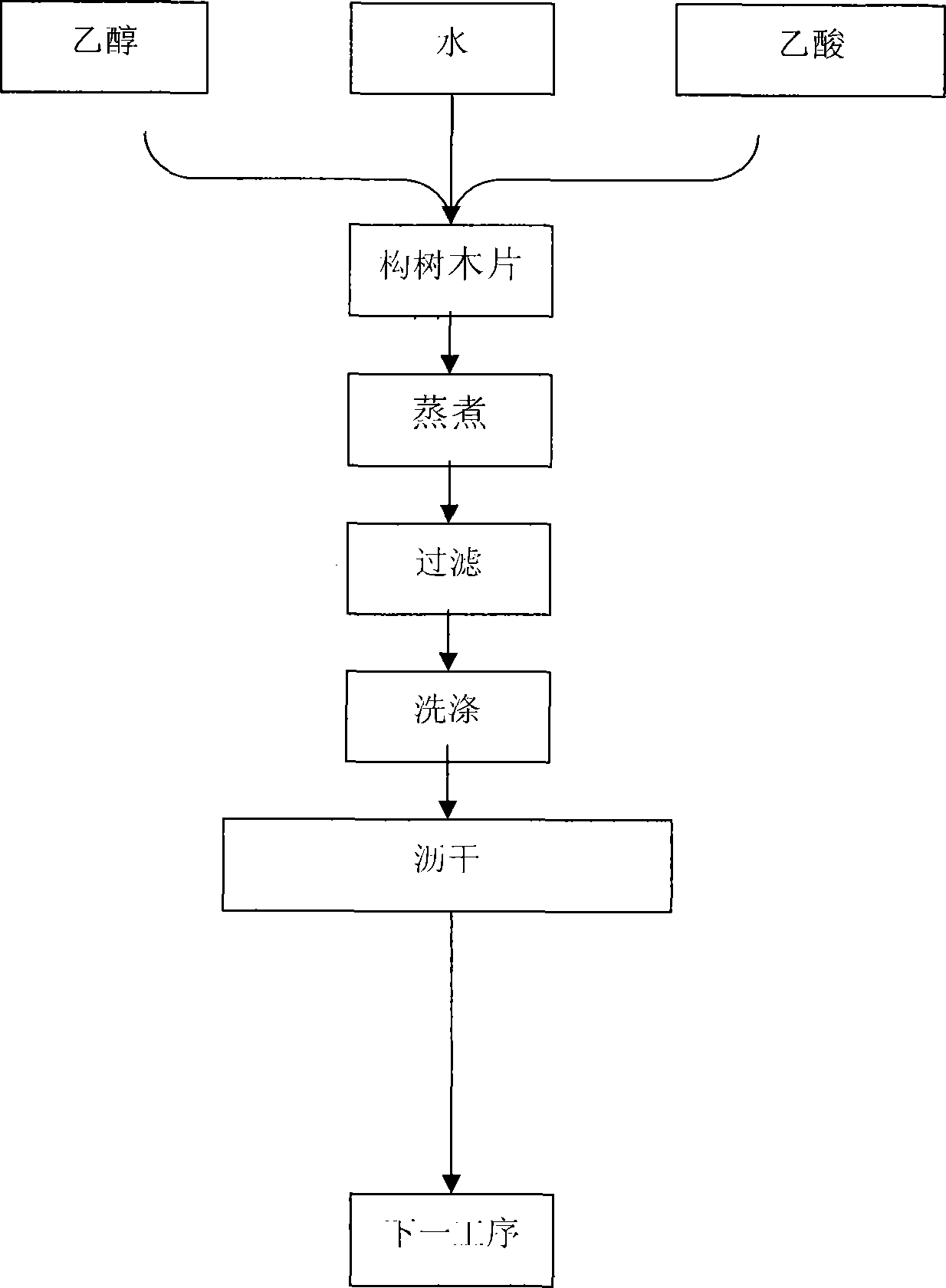

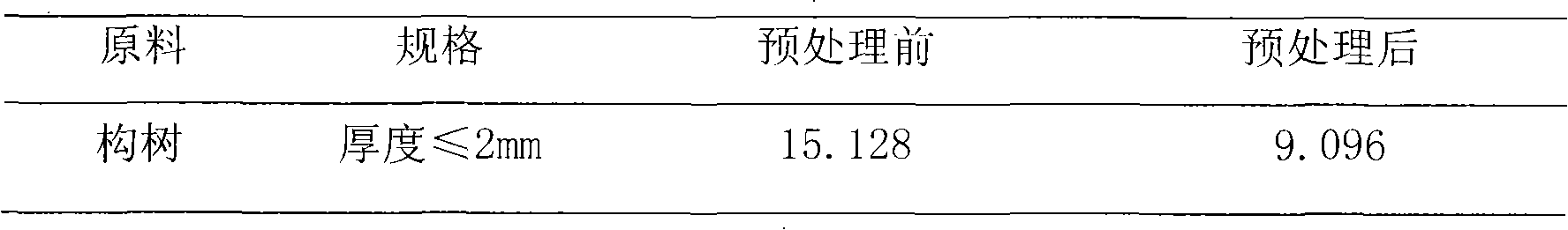

Pre-processing method in process of producing paper pulp

InactiveCN102277760BAvoid damageReduce pollutionPretreatment with acid reacting compoundsPulping with acid salts/anhydridesAcetic acidPretreatment method

The invention relates to a pre-processing method in the process of producing paper pulp, belonging to the field of papermaking. The method provided by the invention comprises the following steps of: mixing water, ethanol and acetic acid in the volume ratio of 1 to 1-5 to 1-5; uniformly agitating raw materials to prepare pre-processing liquid; adding the pre-processing liquid into a reactor and adding paper mulberry wood chips in the mass ratio of the paper mulberry wood chips to the pre-processing liquid of 1 to 1-1.5, wherein the total volume of the material and the liquid is not more than 1 / 2 of the volume of the reactor; closing the reactor and then heating and boiling for 20-25 min at a temperature in a range of 100-110 DEG C; standing and reducing the temperature; filtering to obtain the pre-processed raw materials and carrying out the next processing procedure after washing the pre-processed raw materials. Compared with the traditional papermaking boiling process by utilizing an alkaline method and an acidic method, the method provided by the invention greatly reduces the waste liquid pollution, saves energy source and reduces production cost; the method provided by the invention can be independently utilized and also can be united with the traditional method, so that the effects of saving energy, reducing emission and reducing consumption are reached.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

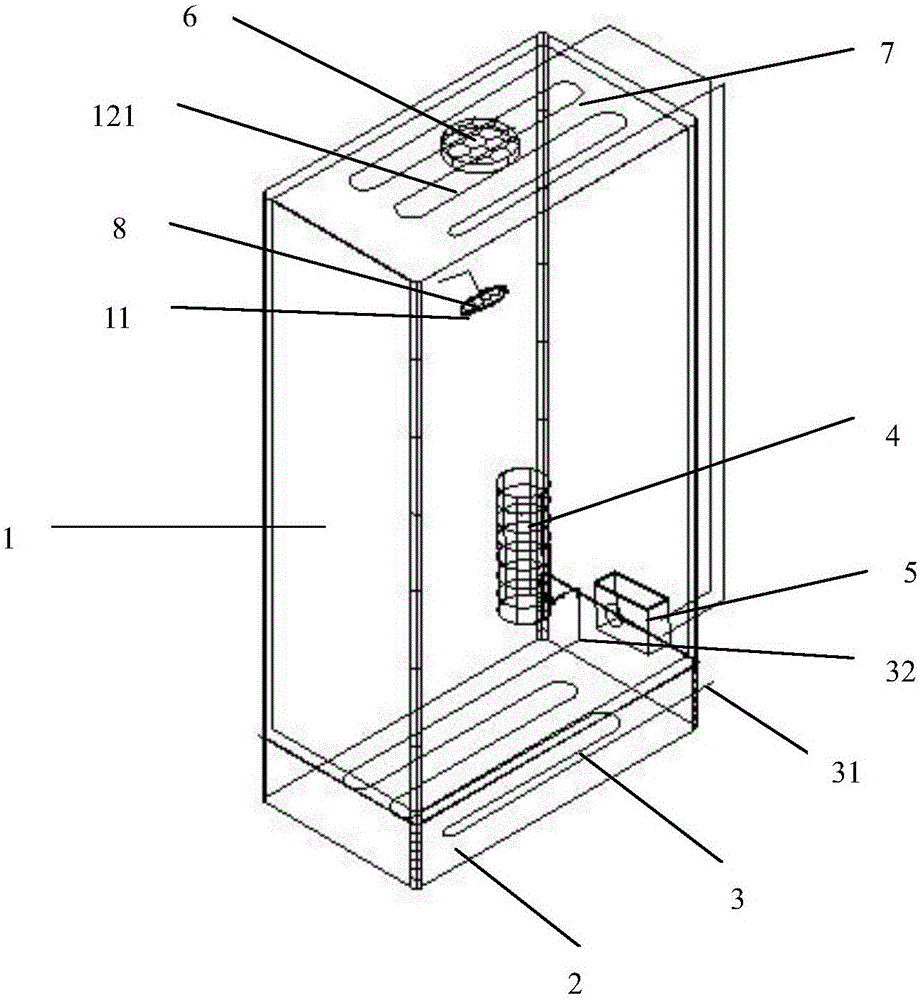

Multi-point single-injection lubricating oil adding device and method for Raymond mill

PendingCN114576541AShorten filling timeAvoid enteringConduits/junctionsDistribution equipmentThermodynamicsMaterial supply

The invention relates to a multi-point single-injection lubricating oil adding device and method for a Raymond mill. An existing Raymond mill is short in reliable operation time period, so that powder conveying material supply is insufficient, oil needs to be added once after equipment operates for 6 hours, the actual oil adding time is 2 hours, the production requirement is seriously restricted, and the system operation time is short. The device comprises a universal pipe distributor installed on the upper portion of an internal main machine of the Raymond mill, and is characterized in that the universal pipe distributor is connected with an outward pipe, the diameter of the outward pipe is 22 mm, the universal pipe distributor is connected with an oil cavity through the universal pipe, the oil cavity is a bearing oil conveying cavity of a lifting roller assembly of the Raymond mill, and the diameter of the bearing oil conveying cavity is 20 mm. The Raymond mill lifting roller assembly comprises an oil cavity, a group of oil supply branch pipes are arranged on the oil cavity, the Raymond mill lifting roller assembly comprises a group of grinding rollers, bearing oil nozzles are fixed on the grinding rollers, and the oil supply branch pipes are in pipe connection with the bearing oil nozzles. The multi-point single-injection lubricating oil adding device is used for the Raymond mill.

Owner:大唐鸡西第二热电有限公司

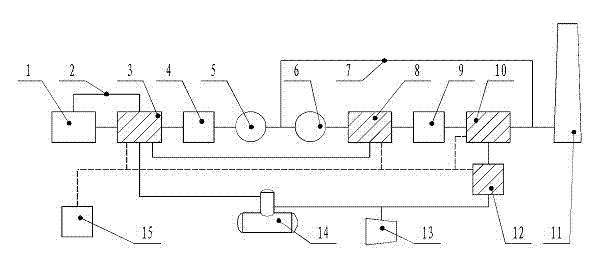

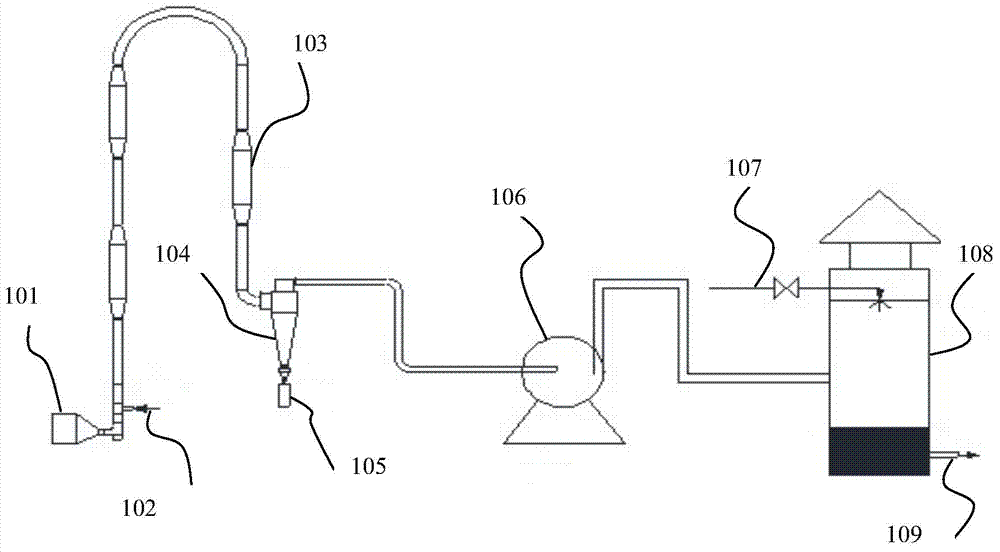

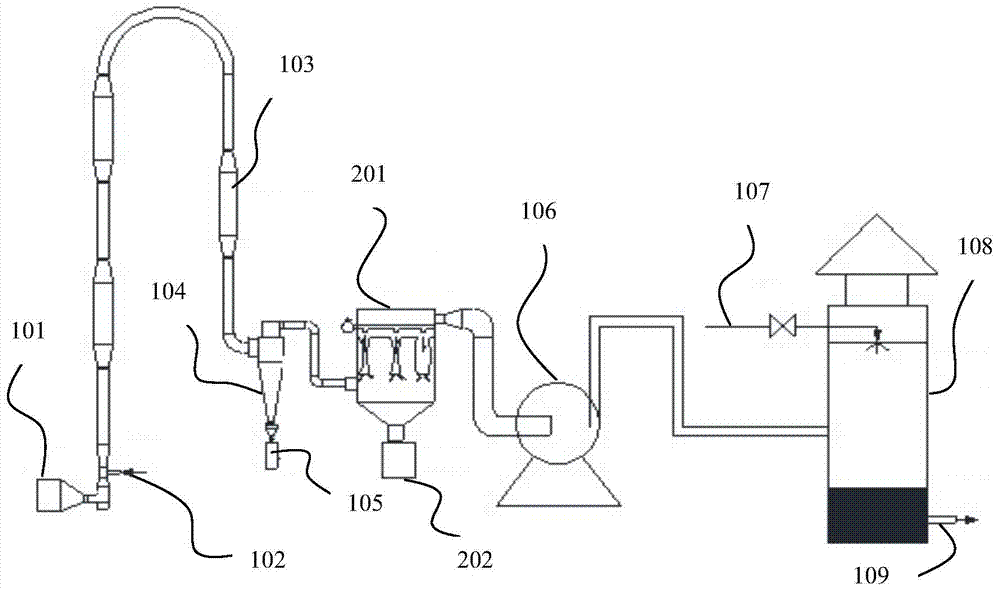

Air flow drying system for catalyst production

InactiveCN104515375ARealize energy savingTo reduce consumptionDrying solid materialsBaghouseProcess engineering

The invention provides an air flow drying system for catalyst production. The air flow drying system comprises a heat source, an air flow dryer, a hot air separator, an induced draft fan and a tail gas absorption tower, the heat source is connected with the air flow dryer through a pipeline, the air flow dryer is connected with the heat source and the hot air separator, the hot air separator is connected with the air flow dryer and the induced draft fan, and the induced draft fan is connected with the hot air separator and the tail gas absorption tower. The air flow drying system is characterized in that a pulsed jet cloth filter is arranged between the hot air separator and the induced draft fan. The air flow drying system has the advantages that the pulsed jet cloth filter is additionally arranged on an air flow drying unit, tail gas passes the pulsed jet cloth filter and then enters the tail gas absorption tower, so that dust in the tail gas is basically adsorbed by the pulsed jet cloth filter, the tail gas is recovered, placed into a gelling unit and used, energy is saved, consumption is reduced, and environments are protected.

Owner:天津民祥医药销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com