Aqueous finishing-free high-gloss solid color paint for vehicles

A water-based, over-glazing technology, applied in coatings and other directions, can solve problems such as excessive exhaust gas and pollute the environment, and achieve the effect of simplifying the production process and improving the sharpness of the image.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A water-based gloss-free high-gloss solid color paint for vehicles, comprising a main film-forming substance, an auxiliary agent, deionized water and a color paste, and the main film-forming substance includes a water-based acrylic dispersion, a water-soluble polyester resin, and a full methyl ether Amino resin and water-based blocked isocyanate; the additives include graphene dispersion, acid catalyst, defoamer, water-based substrate wetting agent, the first thickener, the second thickener, the third thickener Thickener, neutralizing agent and film-forming aid; the color paste includes water-soluble polyester resin, neutralizing agent, deionized water, water-based wetting and dispersing agent and pigment. Described raw material adopts following proportioning to obtain:

[0025] Aqueous acrylic dispersion 55.0%;

[0026] Full methyl etherified amino resin 6.0%;

[0027] Water-based blocked isocyanate 3.0%;

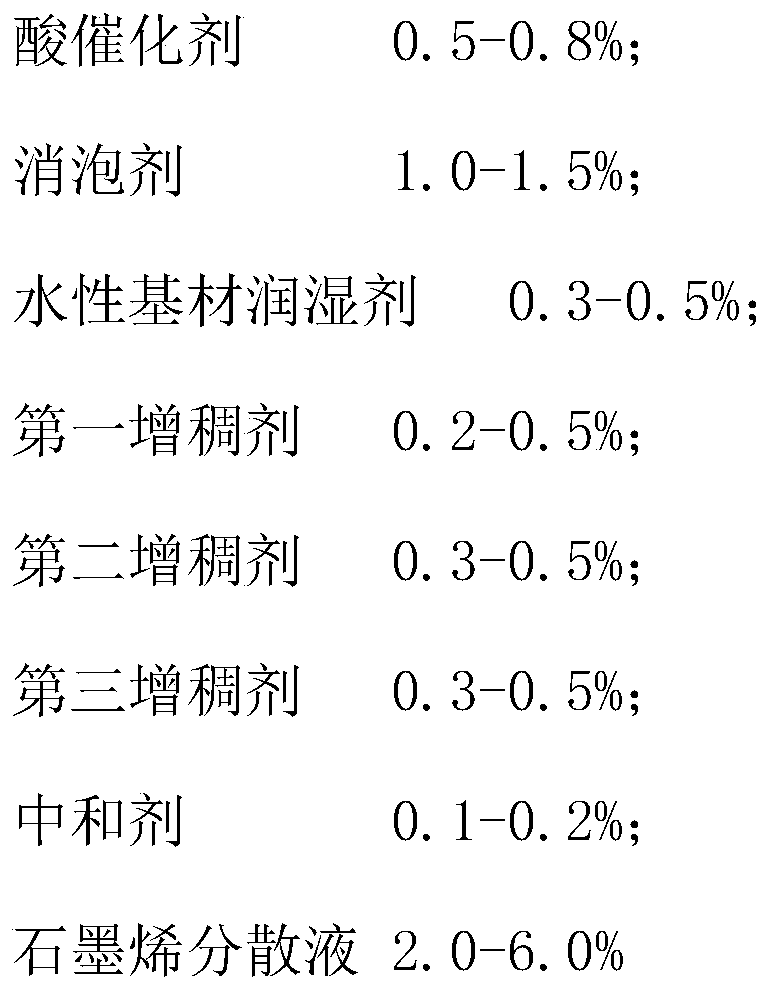

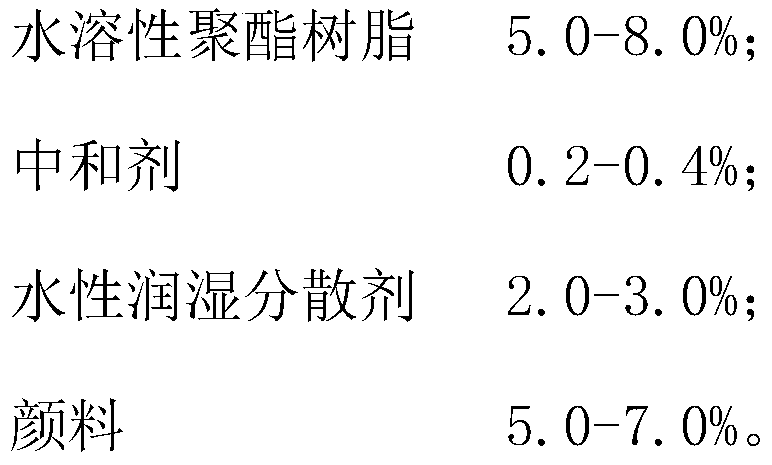

[0028] Described auxiliary agent adopts following proportio...

Embodiment 2

[0033] A water-based gloss-free high-gloss solid color paint for vehicles, comprising a main film-forming substance, an auxiliary agent, deionized water and a color paste, and the main film-forming substance includes a water-based acrylic dispersion, a water-soluble polyester resin, and a full methyl ether Amino resin and water-based blocked isocyanate; the additives include graphene dispersion, acid catalyst, defoamer, water-based substrate wetting agent, the first thickener, the second thickener, the third thickener Thickener, neutralizing agent and film-forming aid; the color paste includes water-soluble polyester resin, neutralizing agent, deionized water, water-based wetting and dispersing agent and pigment. Described raw material adopts following proportioning to obtain:

[0034] Waterborne acrylic dispersion 53.0%;

[0035] Full methyl etherified amino resin 5.5.0%;

[0036] Aqueous blocked isocyanate 2.5%;

[0037] Described auxiliary agent adopts following proporti...

Embodiment 3

[0043] A water-based gloss-free high-gloss solid color paint for vehicles, comprising a main film-forming substance, an auxiliary agent, deionized water and a color paste, and the main film-forming substance includes a water-based acrylic dispersion, a water-soluble polyester resin, and a full methyl ether Amino resin and water-based blocked isocyanate; the additives include graphene dispersion, acid catalyst, defoamer, water-based substrate wetting agent, the first thickener, the second thickener, the third thickener Thickener, neutralizing agent and film-forming aid; the color paste includes water-soluble polyester resin, neutralizing agent, deionized water, water-based wetting and dispersing agent and pigment. Described raw material adopts following proportioning to obtain:

[0044] Aqueous acrylic dispersion 50.0%;

[0045] Full methyl etherified amino resin 5.0%;

[0046] Aqueous Blocked Isocyanate 2.0%.

[0047] Described auxiliary agent adopts following proportioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com