Method and apparatus for cement rotary kiln flue gas denitration and desulfurization

A cement rotary kiln and denitrification technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as difficult simultaneous denitrification and desulfurization, no emission reduction effect, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

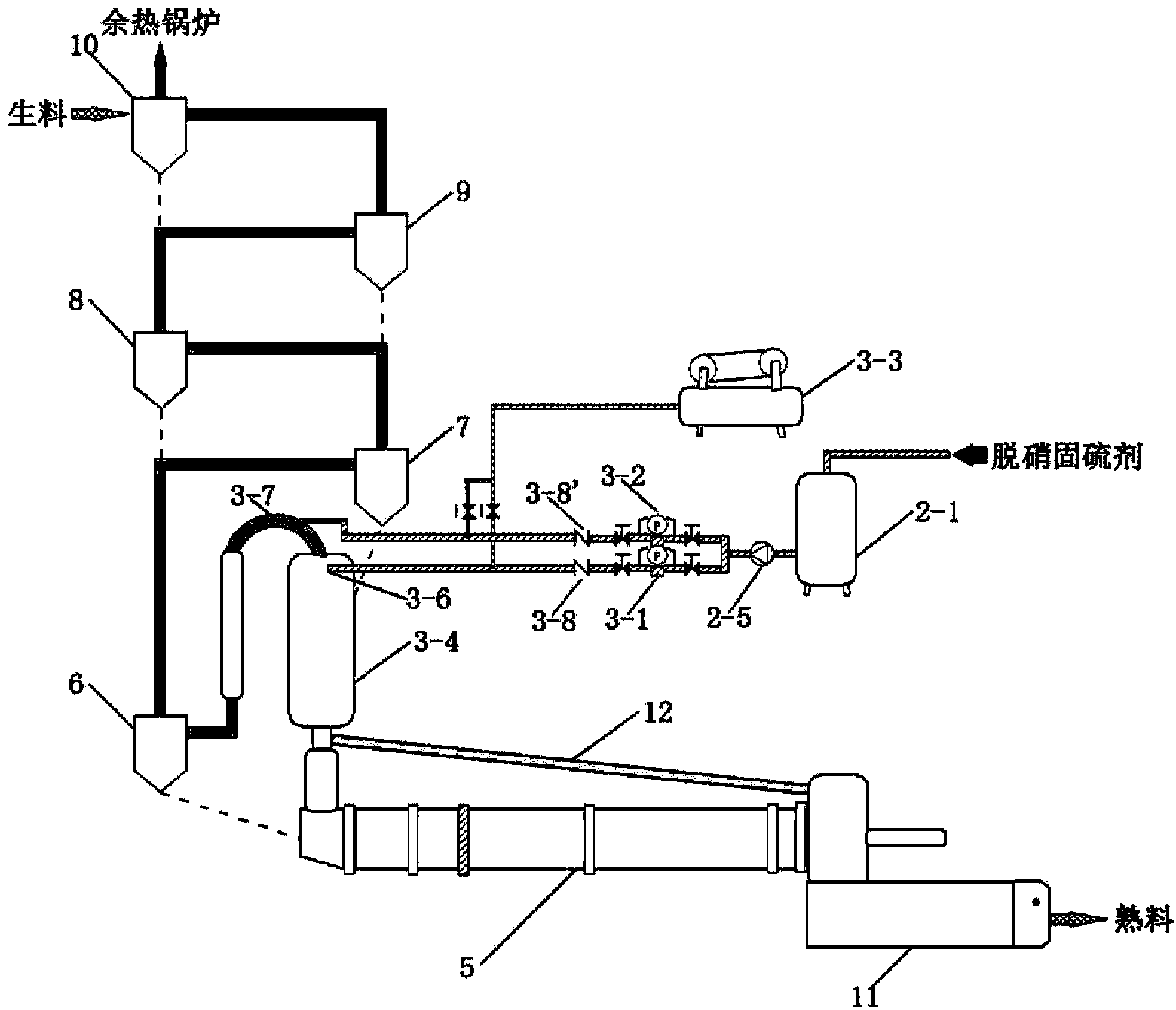

[0035] A process for simultaneous denitrification and desulfurization of flue gas from a cement rotary kiln, such as figure 1 As shown, it includes a cement clinker production system and a denitrification and sulfur-fixing agent injection system. The cement clinker production system consists of a rotary kiln 5, a precalciner 3-4, a fifth-stage preheater 6, and a fourth-stage preheater 7. The third-stage preheater 8 and the second-stage preheater 9 are composed of the first-stage preheater 10, the cooler 11, and the tertiary air pipe 12; The tank 2-1 is sent to the electronic flowmeter 3-1 of the primary denitrification and sulfur-fixing agent and the electronic flowmeter 3-2 of the secondary denitrification and sulfur-fixing agent. Enter the primary denitrification and sulfur-fixing agent spray gun 3-6 with atomizing nozzle and the secondary denitrification and sulfur-fixing agent spray gun 3 with atomizing nozzle respectively through the primary one-way check valve 3-8 and th...

Embodiment 2

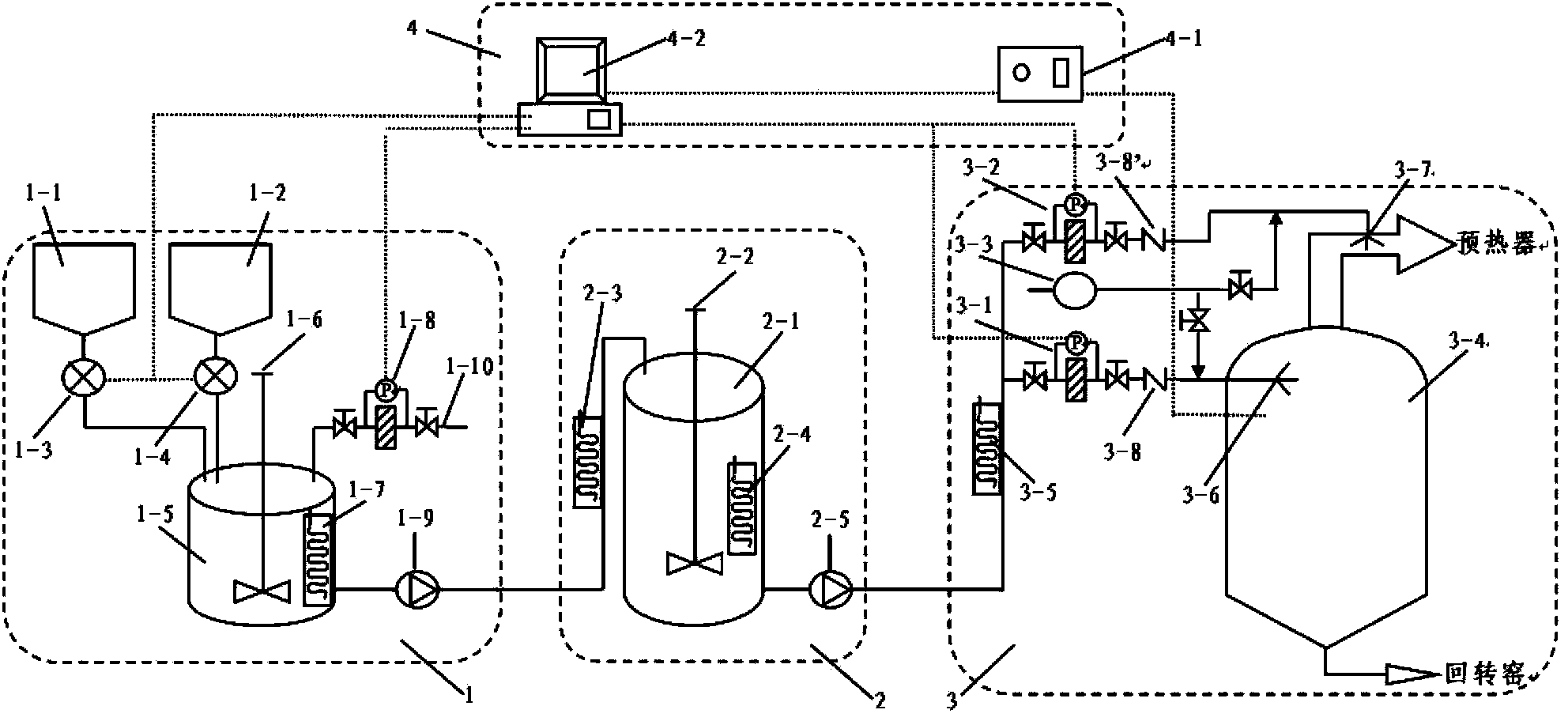

[0037] A device for simultaneous denitrification and desulfurization of flue gas from a cement rotary kiln, such as figure 2 As shown: the device includes denitration and sulfur fixing agent preparation system 1, denitration and sulfur fixing agent storage system 2, denitration and sulfur fixing agent injection system 3 and automatic control system 4, wherein, denitration and sulfur fixing agent preparation system 1, denitration and sulfur fixing agent storage The system 2 is sequentially connected with the denitration and sulfur fixing agent injection system 3; the automatic control system 4 is respectively connected with the denitration and sulfur fixing agent preparation system 1 and the denitration and sulfur fixing agent injection system 3.

[0038] Denitrification and sulfur-fixing agent preparation system 1 includes reducing agent storage tank 1-1, sulfur-fixing agent storage tank 1-2, reducing agent weighing feeder 1-3, sulfur-fixing agent weighing feeder 1-4, mixing a...

Embodiment 3

[0045] See figure 1 , figure 2 , taking the simultaneous denitrification and desulfurization of flue gas from a 2500t / d cement rotary kiln as an example, the total flue gas volume is about 30×10 4 N m 3 / h, NO x The content is 700mg / m 3 , SO 2 The content is 500mg / m 3 , that is, NO emission per hour x 210kg, SO 2 150kg. Take the molar ratio NH 3 : NO x =0.8︰1, sulfur-fixing agent cation M︰SO 2 =1:1 ratio, the demand for reducing agent urea is 109kg / h respectively.

[0046] (1) The automatic control system 4 transfers 125kg of urea from the reductant storage tank 1-1 by controlling the reductant weighing feeder 1-3, and controls the sulfur fixing agent weighing feeder 1-4 to transfer 75.2kg of powdered CaO, 78.3kg powdered Mg(OH) 2 Transport from the sulfur-fixing agent storage tank 1-2 to the mixing and dissolving tank 1-5, simultaneously control the desalinated water electronic flowmeter 1-8, input 221.5kg of desalinated water through the desalinated water pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com