Low-load denitration system of circulating fluidized bed boiler

A circulating fluidized bed, low-load technology, applied in chemical instruments and methods, combustion product treatment, combustion methods, etc., can solve problems such as deviation, denitrification efficiency decline, and nitrogen oxide emissions exceeding the standard, so as to reduce emissions, The effect of solving excessive nitrogen oxide emissions and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

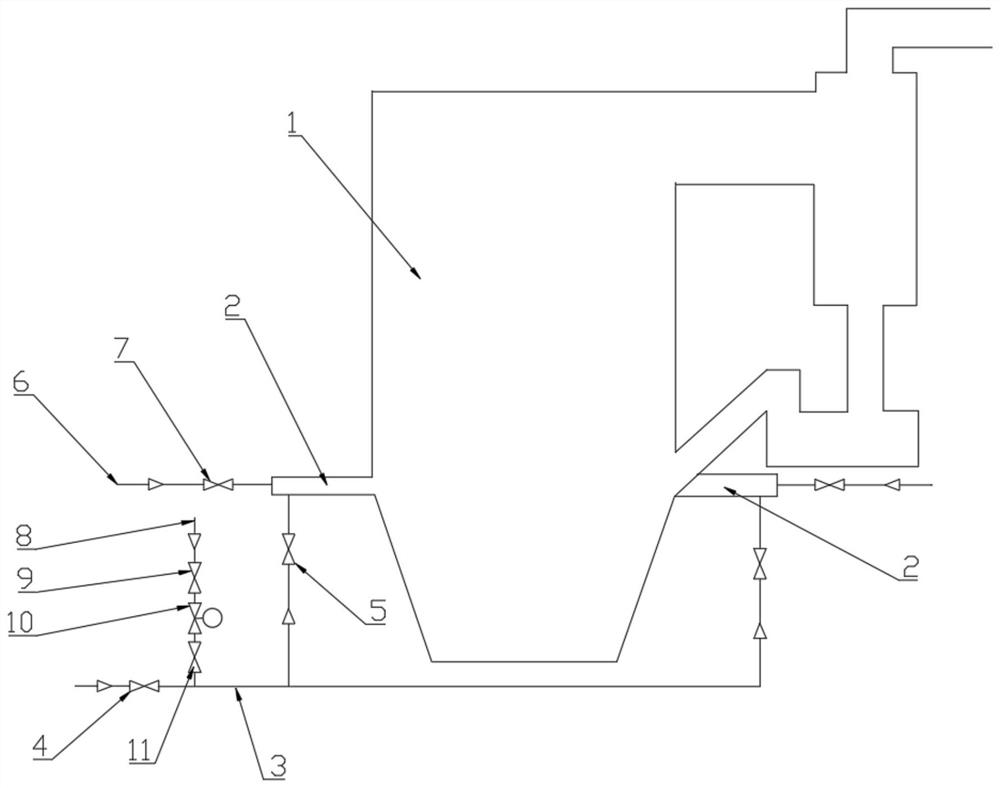

[0010] With reference to the accompanying drawings, a low-load denitrification system for a circulating fluidized bed boiler includes a urea spray gun 2, a urea solution assembly, a compressed air assembly, and a flushing water assembly installed at each secondary air outlet of the boiler furnace 1. The urea solution The assembly includes a urea solution main pipe 3 connected to the urea spray gun 2. The urea solution main pipe 3 is provided with a manual door 4 for the main pipe of the denitrification system in front of the furnace and a manual door 5 for the urea solution to the spray gun. The compressed air main pipe 6 connected to the spray gun 2, the compressed air main pipe 6 is provided with compressed air to the spray gun manual door 7, the flushing water assembly includes a flushing water pipeline 8, and the flushing water pipeline is connected to the urea solution There are 4 manual doors on the main pipe of the denitrification system in front of the furnace on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com