A directional vibration jaw crusher

A jaw crusher and fixed jaw technology, applied in cement production, grain processing, etc., can solve the problems of inability to guarantee high-strength ore, low crushing efficiency, low energy utilization rate, etc., and achieve environmental protection and simplified structure , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

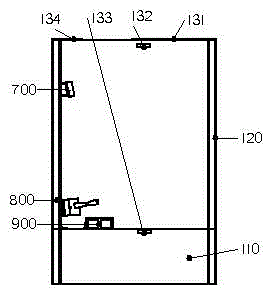

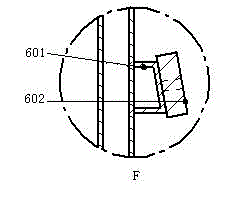

[0036] Combine below Figure 1 to Figure 14 The present invention is described further:

[0037] This embodiment includes a frame 100, a vibration source 200, a vibrating jaw assembly 300, a shock absorber 400, a fixed jaw assembly 500, an upper adjustment mechanism 600, a lower adjustment mechanism 700, and a fixed jaw support 800. The crushing stroke is similar to that of the vibrating jaw. Vertical, the frame 100 adopts a box-shaped structure, the vibrating jaw assembly 300 and the fixed jaw assembly 500 form the ore crushing chamber, the vibration source 200 and the vibrating jaw assembly 300 are the force application mechanisms for crushing the ore, and the ore in the crushing chamber is vibrating Broken under impact force.

[0038] The vibrating jaw assembly 300 includes the vibrating jaw bottom plate 301, the vibrating jaw lower wedge plate 311, the vibrating jaw lower lining plate 321, the vibrating jaw middle wedge plate 331, the vibrating jaw upper lining plate 341,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com