Sintering synergistic agent and use method thereof

A technology of sintering synergist and particle size, which is applied in the field of metallurgical materials and metallurgical chemical additives for steelmaking and sintering, can solve the problems of reduced utilization factor of sintering machine, incomplete sintering of sintered material, and poor gas permeability of material layer, and achieves improved performance. Utilization coefficient, suppression of chalking phenomenon, effect of reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further describe the present invention, the sintering synergist of the present invention will be described in more detail below in conjunction with examples.

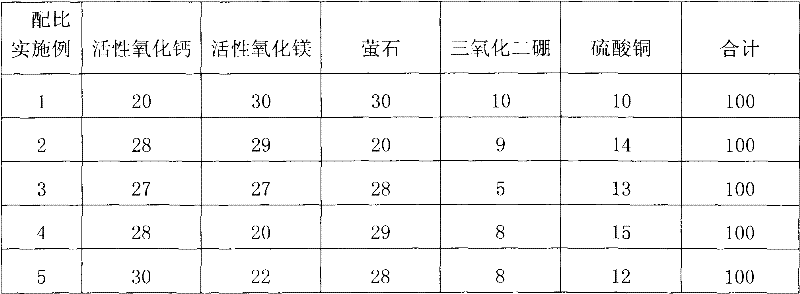

[0033] Table 1 lists the weight percent composition of the sintering synergist of the present invention.

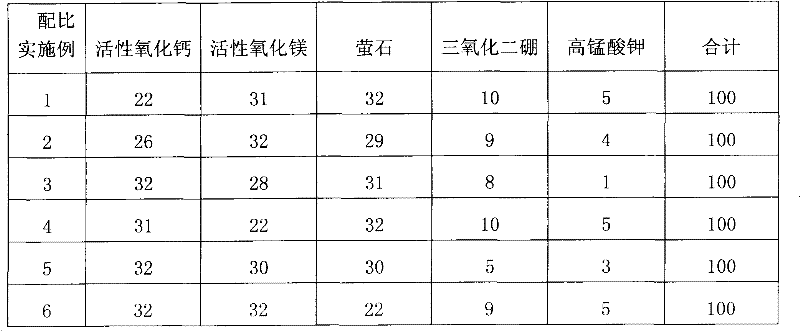

[0034] Table 2 lists the weight percent composition of another formulation of the sintering synergist of the present invention.

[0035] The particle size, activity and purity of each component are the same as above.

[0036] The weight percentage composition (%) of table 1 sintering synergist

[0037]

[0038] The weight percentage composition (%) of another kind of formulation of sintering synergist of table 2

[0039]

[0040] The sintering synergist of the present invention is evenly stirred according to the components and proportions listed in the examples in Table 1 and Table 2, that is, it is formulated into a product. In the process of sintering production, add 0.4‰~0.45‰ of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com