Novel nano energy-saving film

An energy-saving film and nanotechnology, applied in the direction of film/flake adhesives, adhesives, etc., can solve the problem of unsatisfactory insulation effect of glass film, achieve good protection, prevent skin from darkening, high-strength adhesion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

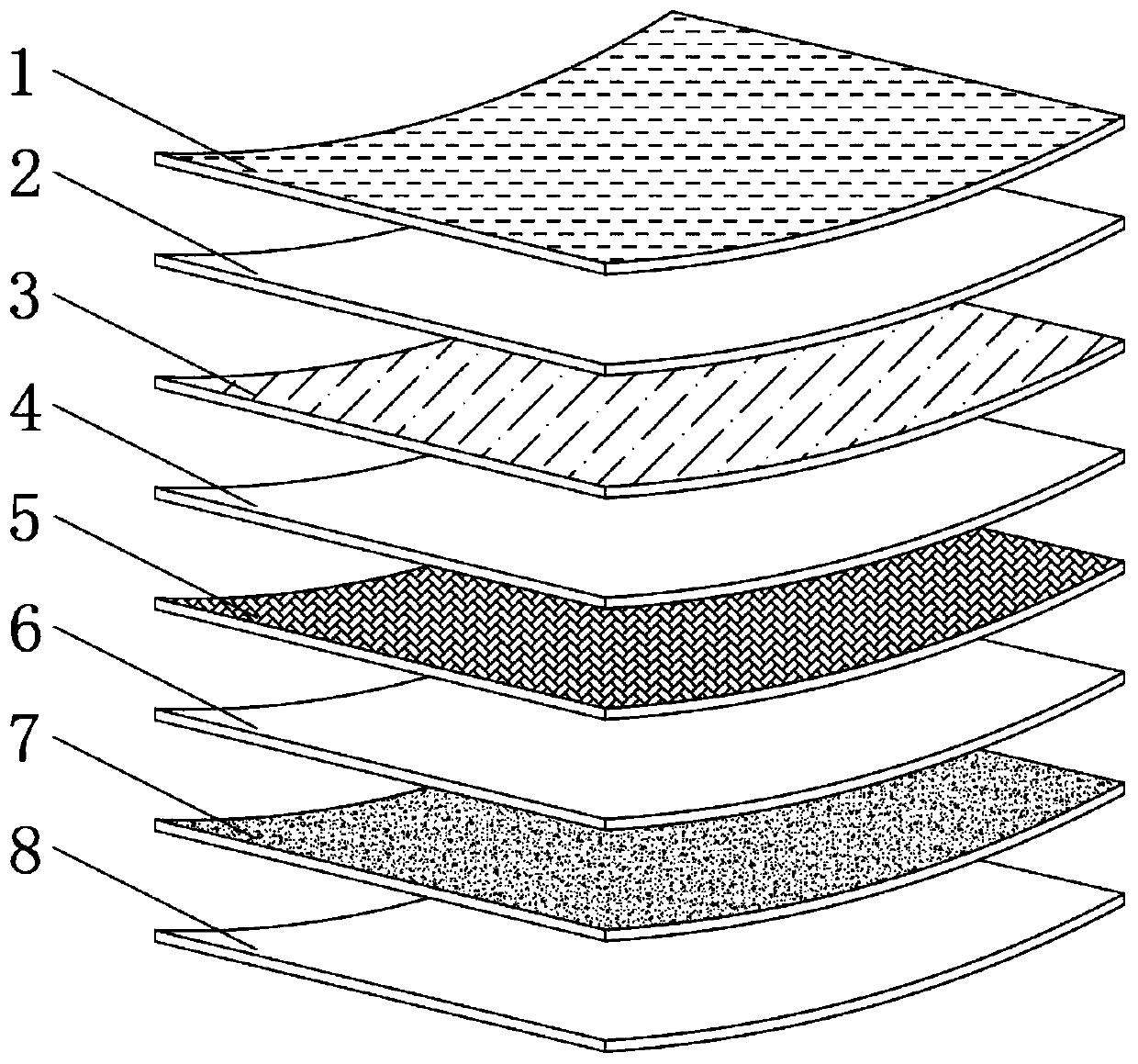

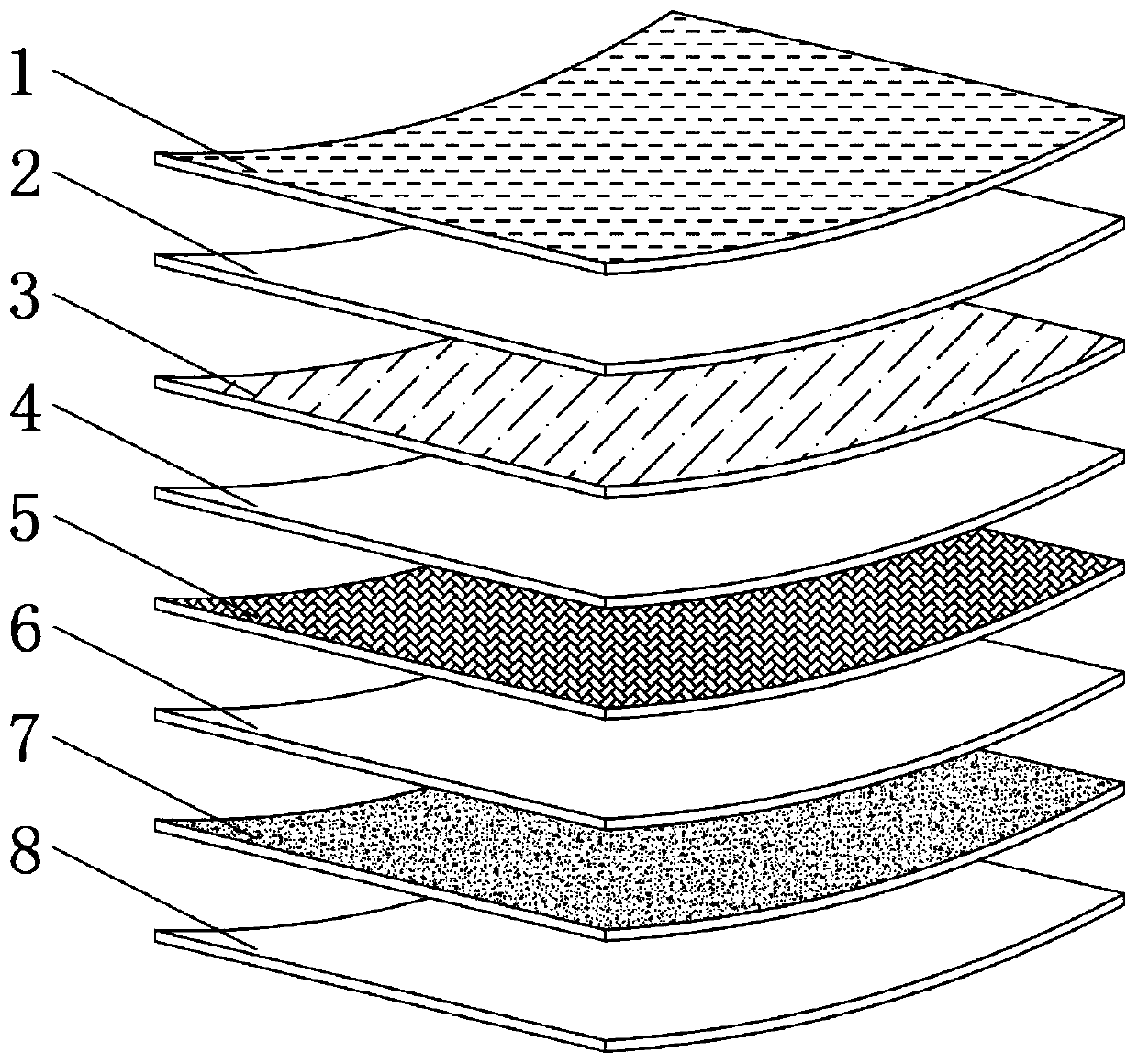

[0023] Example 1: See figure 1 , a novel nano-energy-saving film of the present invention, comprising anion reaction layer 1, HC anti-glare layer 2, glass substrate 3, HC nano-anti-infrared barrier layer 4, nano-UV resistant layer 6, pressure-sensitive adhesive layer 7 and release Type layer 8, HC anti-glare layer 2 covers the top surface of glass substrate 3, the top surface of HC anti-glare layer 2 is fixedly connected with anion reaction layer 1, and the side of glass substrate 3 away from HC anti-glare layer 2 is fixedly connected There is an HC nano anti-infrared barrier layer 4, the bottom of the HC nano anti-infrared barrier layer 4 is fixedly connected with a nano UV resistant layer 6, and the bottom of the nano UV resistant layer 6 is glued and fixed with a release layer 8.

[0024] The pressure-sensitive adhesive layer 7 is a film-like structure made of acrylate, the thickness of the pressure-sensitive adhesive layer 7 is 0.01mm, and the top and bottom of the pressur...

Embodiment 2

[0031] Embodiment 2: Different from Embodiment 1, the thickness of the pressure-sensitive adhesive layer 7 is 0.012mm, the thickness of the nano UV resistant layer 6 is 0.007mm, the thickness of the nano anti-aging coating 5 is 0.002mm, and the release layer 8 The thickness of the HC anti-glare layer 2 is 0.006mm, the thickness of the glass substrate 3 is 0.052mm, the thickness of the anion reaction layer 1 is 0.004mm, and the thickness of the HC nano anti-infrared barrier layer 4 is 0.012mm. The light transmittance of the nano UV resistant layer 6 is 35%, and the thickness of the nano UV resistant layer 6 is 0.006mm.

[0032] When the light transmittance of the nano UV-resistant layer 6 is 35%, the infrared blocking rate is 95%, the ultraviolet blocking rate is 99.99%, and the negative ion release is greater than 50 million / cm 3 .

Embodiment 3

[0033] Embodiment 3: Different from Embodiment 1, the thickness of the pressure-sensitive adhesive layer 7 is 0.013mm, the thickness of the nano UV resistant layer 6 is 0.008mm, the thickness of the nano anti-aging coating 5 is 0.003mm, and the release layer 8 The thickness of the HC anti-glare layer 2 is 0.01mm, the thickness of the glass substrate 3 is 0.055mm, the thickness of the anion reaction layer 1 is 0.005mm, and the thickness of the HC nano anti-infrared barrier layer 4 is 0.015mm. The light transmittance of the nano UV resistant layer 6 is 75%, and the thickness of the nano UV resistant layer 6 is 0.007mm.

[0034] When the light transmittance of the nano UV-resistant layer 6 is 75%, the infrared blocking rate is 93%, the ultraviolet blocking rate is 99.99%, and the negative ion release is greater than 50 million / cm 3 .

[0035]Working principle: After the air conditioner is turned on indoors, the HC nano anti-infrared barrier layer 4 can block the external heat fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com