Pre-processing method in process of producing paper pulp

A production process and pretreatment technology, applied in the field of papermaking, can solve problems such as increased cost, pollution, and reduced market competitiveness of enterprise products, and achieve the effects of low heat energy and production cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

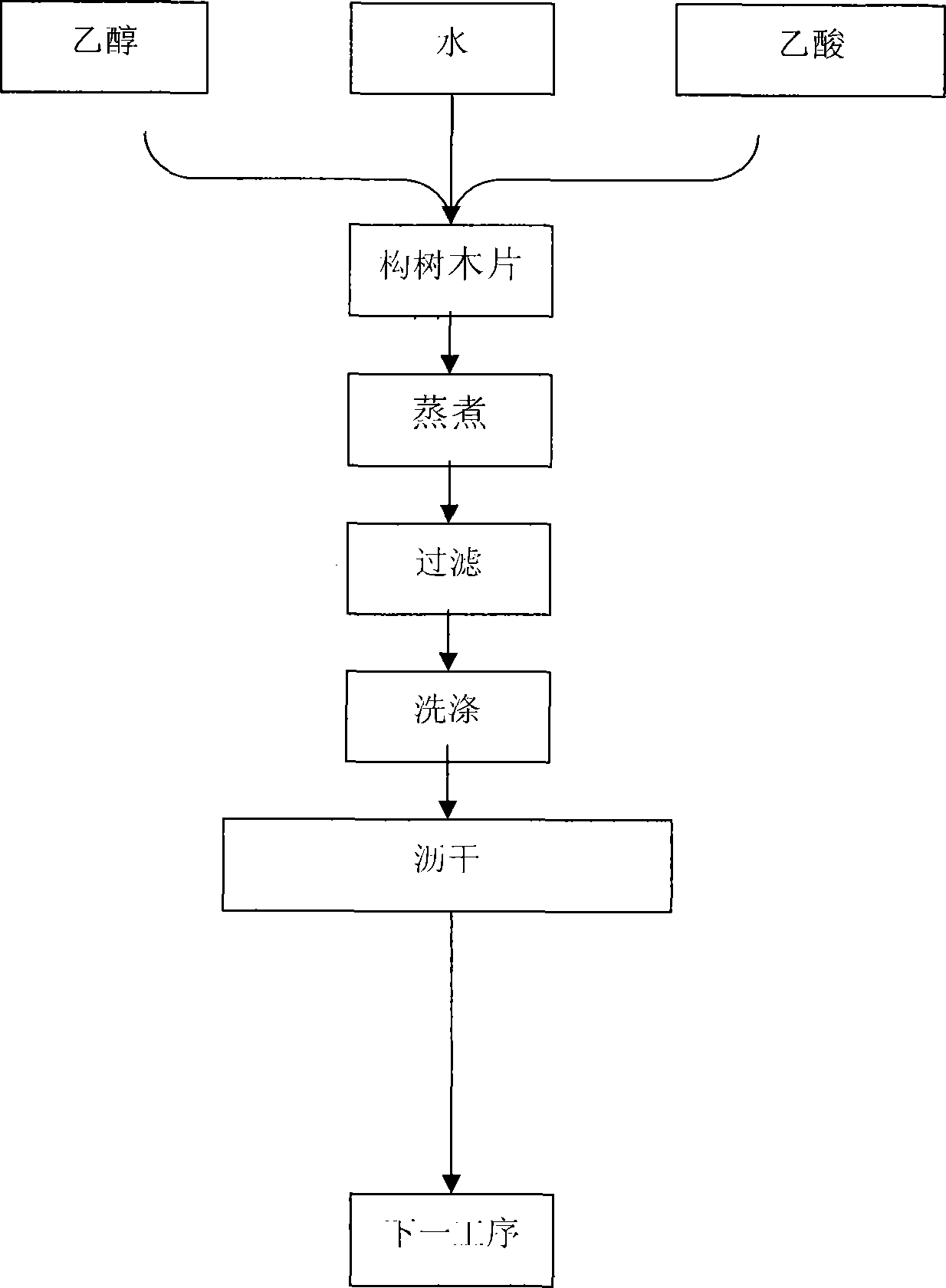

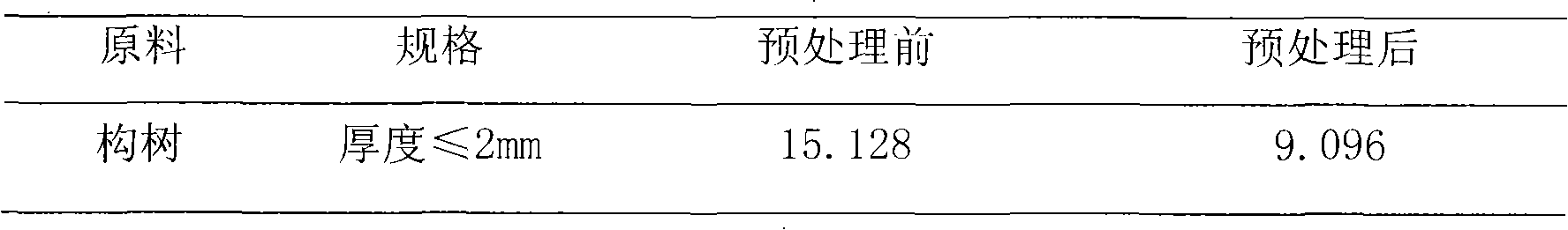

[0023] Mix 10 mL of water, 40 mL of ethanol, and 40 mL of acetic acid, and stir evenly to prepare a pretreatment solution. Take 90 g of the pretreatment solution and 60 g of berry wood chips into a 250 mL reactor. The thickness of the berry wood chips is ≤ 2mm, and the temperature is 100℃. After 25 minutes, stop heating, let stand, cool to room temperature, filter, and wash. After filtering, wood chips are pretreated raw materials and enter the next process.

[0024] 1. The environmental friendliness of waste liquid produced by this technology

[0025] In the process, the filtered filtrate and the washed wastewater are mixed to become process waste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com