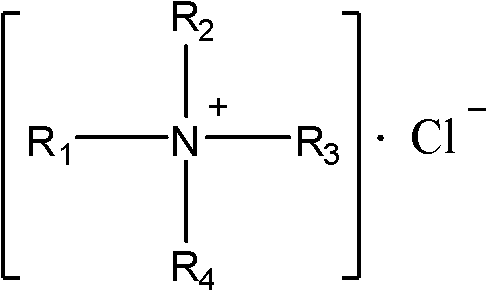

Preparation method of cationic hydroxyethyl cellulose ether

A technology of hydroxyethyl cellulose and hydroxyethylation, which is applied in the field of preparation of fine functional polymer materials, can solve the problems of high salt and monomer residues, high technical requirements for post-processing, and high material consumption, and achieves simplified process and post-processing. Treatment process, to achieve the effect of overall consumption reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pretreatment: At normal temperature and pressure, add hydroxyethyl cellulose (industrial product, hydroxyethyl substitution degree DS is 1.6, 25°C, 1 part of a 2% aqueous solution with a viscosity of 400 mPa·s), and 0.75 part of a 25% sodium hydroxide solution, stirred and reacted at 25°C for 30 minutes to obtain a mixed solution A;

[0032] (2) Cationic reaction: adjust the temperature of solution A to 60°C, add 0.70 parts of 69% CTA aqueous solution, and react at constant temperature for 4 hours to obtain mixed solution B;

[0033] (3) Post-treatment: Liquid B is cooled to room temperature 30°C, adjusted to pH 7 with 10% hydrochloric acid by mass percentage, and filtered, and the filtrate is extracted for 4 hours with ethanol and isopropanol recovery liquid obtained through filtration, After drying, the cationized hydroxyethyl cellulose ether product is obtained.

[0034] (4) Calculation of degree of substitution DS and reaction efficiency Re:

[0035] Determine...

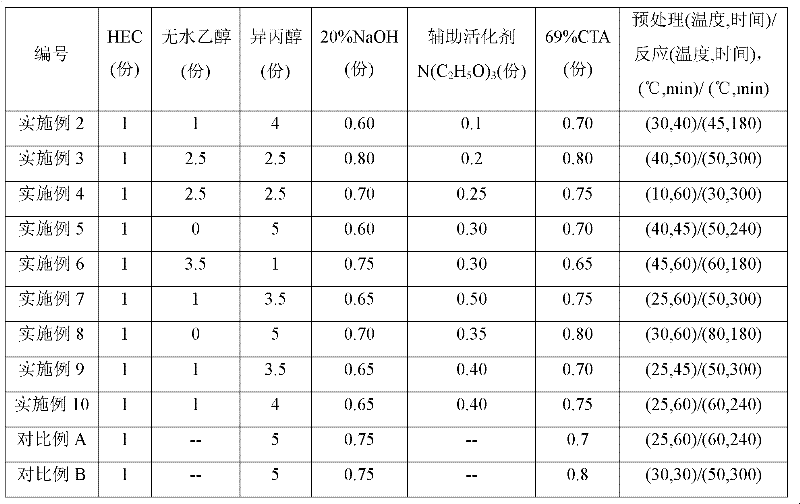

Embodiment 2~10

[0041] The basic operation process of Examples 2-10 is the same as that of Example 1, and the amount of each substance added and the reaction conditions are as shown in Table 1.

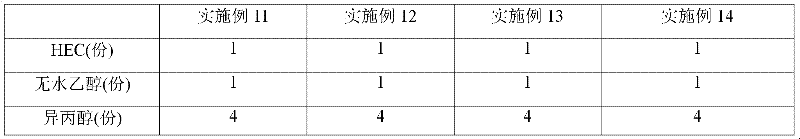

Embodiment 11~14

[0047] The basic operation process of Examples 11-14 is the same as that of Example 1, and the amount of each substance added and the reaction conditions are as shown in Table 2.

[0048] The reaction substance proportioning and condition of table 2 embodiment 11~14

[0049]

[0050]

[0051]According to the calculation method of cationic substitution degree and reaction efficiency given in the present invention, the results of cationic substitution degree and corresponding reaction efficiency of the products obtained in Examples 1-14 and Comparative Example A and Comparative Example B are shown in Table 3.

[0052] Table 3 Embodiment 1~14 and comparative examples A~B, DS and Re calculation result

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com