Production process of anti-aging agent

An anti-aging agent and production method technology, applied in reductive alkylation preparation, organic chemistry and other directions, can solve the problems of high content of harmful metal particles, unstable product quality, high device pressure, reduce equipment investment, and have a wide range of product applications. , the effect of improving safety

Active Publication Date: 2013-07-17

SHANDONG SUNSINE CHEM

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

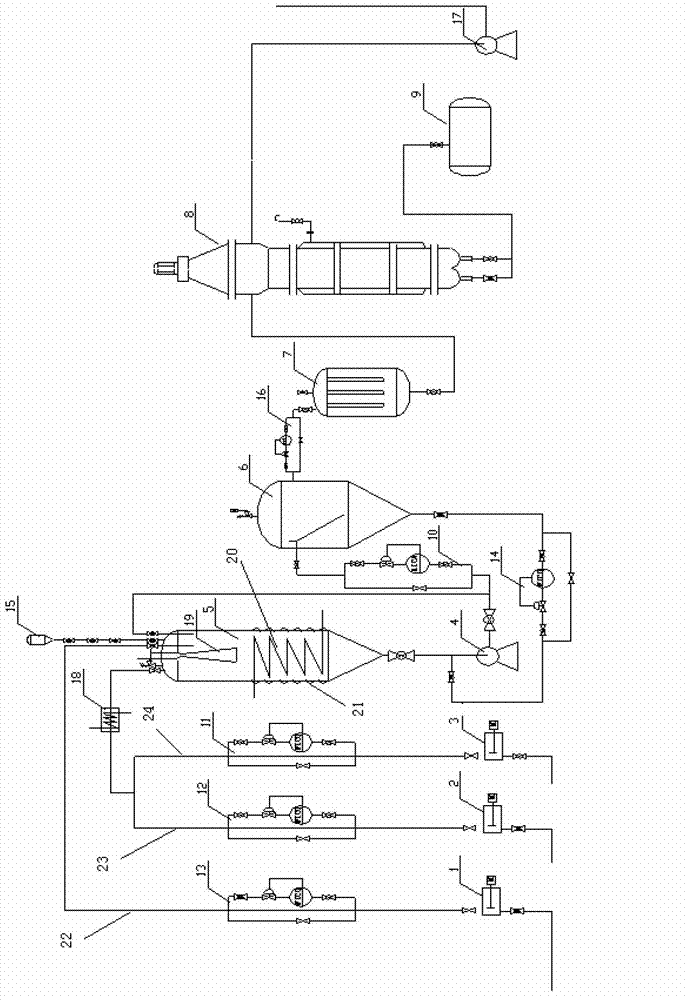

The present invention solves the problem of using a copper-based catalyst to catalyze hydrogenation of 4-aminodiphenylamine and methyl isobutyl ketone under a hydrogen pressure of 5-16 MPa. The device has high pressure, large investment, high energy consumption, and unstable product quality. , the content of harmful metal particles is high, and the application of products is limited to a certain extent. A production process and equipment for the production and preparation of N-(1,3-dimethylbutyl)-Nˊ-phenyl-p-phenylenediamine, an anti-aging agent, are provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a production method of anti-ageing agent N-(1,3-dimehtyl butyl)-N'-phenyl p-phenylenediamine. Ketoamine is adopted for condensing and catalyzing hydrogenation catalyst, so that the amount that the methylisobutyl ketone is converted into alcohol is greatly reducered, and the ketoamine proportion is lowered to 1.05 from 3.5 in the original process, and therefore, the consumption of ketone is lowered, aftertreatment load is lowered and energy consumption is lowered. Besides, a gas-liquid-solid three-phase mixer can be used for greatly improving the mass transfer effect, so that the hydrogenation reaction is easier to implement, and therefore, the device utilization efficiency is improved and the device investment is reduced.

Description

technical field [0001] The invention relates to a p-phenylenediamine rubber antioxidant, specifically a production method and equipment for N-(1,3 dimethylbutyl)-N'-phenyl-p-phenylenediamine. Background technique [0002] Antiaging agent N-(1,3 dimethylbutyl)-Nˊ-phenyl-p-phenylenediamine (antiaging agent 4020 or antiaging agent 6PPD) is an important substance to prolong the service life of rubber products. Its application in rubber products is through Mixed and added, evenly dispersed in the rubber system, and finally migrated to the surface of the product to form a protective film to prevent thermal oxygen and aging, so as to achieve the purpose of prolonging the service life of the product. Anti-aging agent 4020 is currently the largest rubber anti-aging agent used in tires in the world. It has excellent resistance to ozone aging cracks and flex cracks, and has a good protective effect on thermal oxygen and weather aging, and has a passivation effect on variable-valence m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C211/55C07C209/26

Inventor 徐承秋刘经福赵峰苗静沙德昌

Owner SHANDONG SUNSINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com