Multi-scale ceramic/metal composite abrasion-resistant material and preparation method thereof

A metal composite, wear-resistant material technology, used in mechanical equipment, heat exchange equipment, belts/chains/gears, etc., can solve the problems of high wear resistance not being fully exerted, restrictions, ceramic broken and falling off, etc. Obvious demonstration and driving effect, achieve sustainable development, avoid large peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

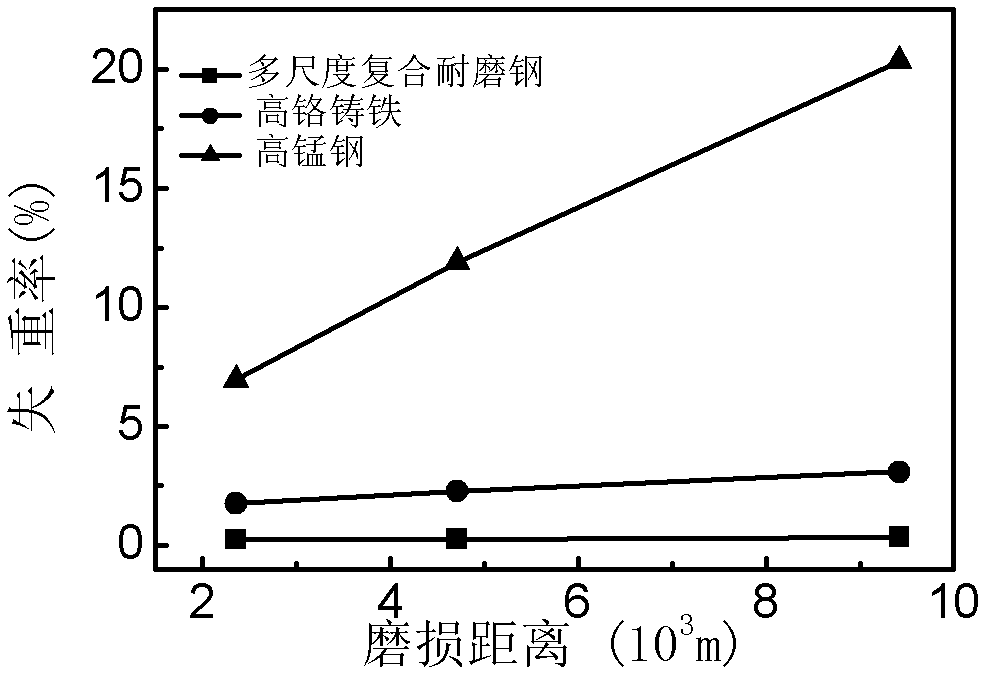

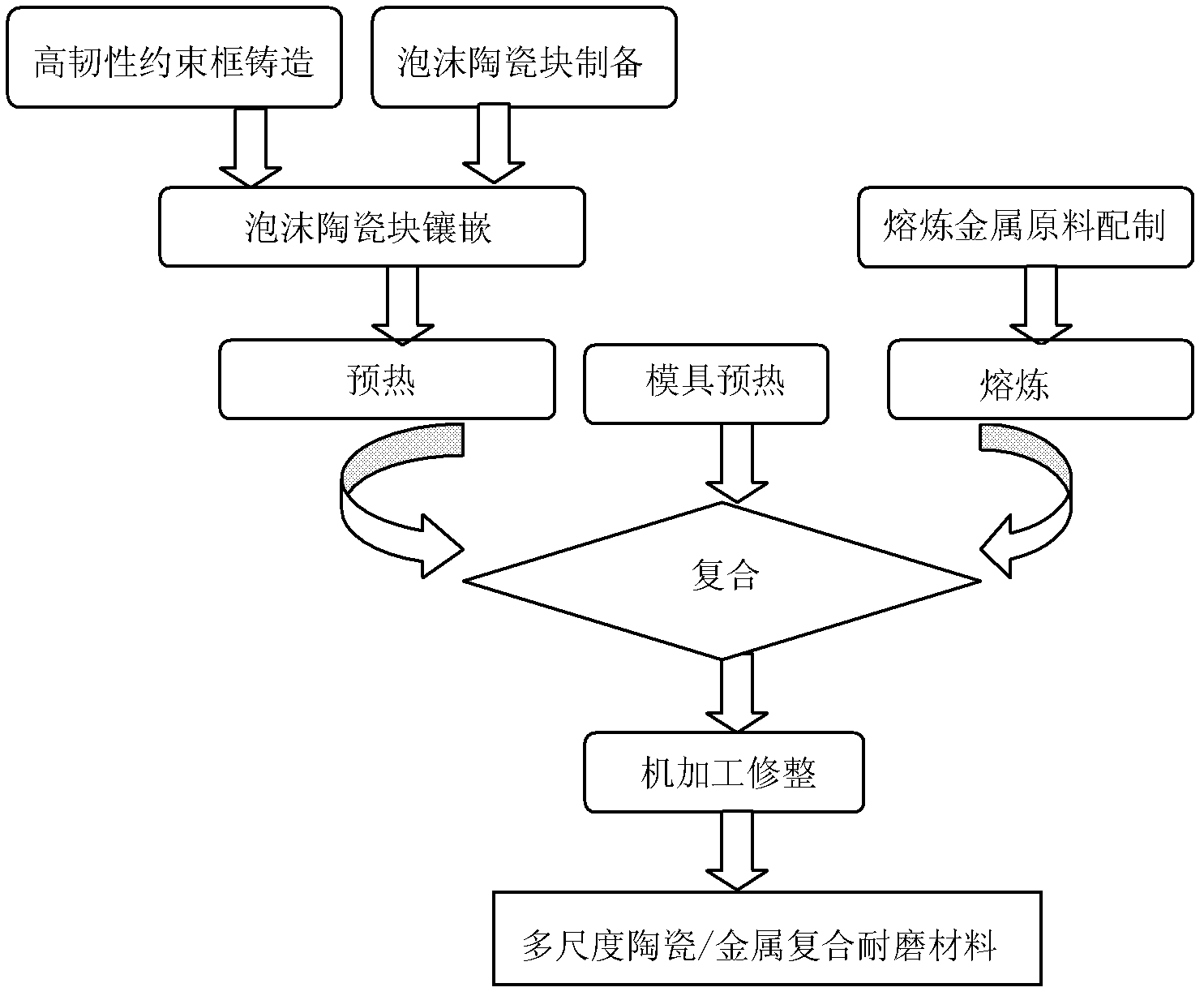

[0051] The performance test results show that the multi-scale composite wear-resistant steel composed of foamed silicon carbide ceramics / cast iron (cast steel) / high toughness steel has a compressive strength of more than 650MPa and an impact toughness of more than 50J / cm 2 , the wear resistance is 7 times that of high chromium cast iron, which shows the advantage of realizing the ideal combination of high wear resistance and high strength and toughness of the material, as shown in Figure 1(a)-(b). The present invention also provides a preparation method for a multi-scale ceramic / metal composite wear-resistant material, the preparation process is as follows figure 2 As shown, it mainly includes: preparation of foam ceramic block, manufacture of high toughness constraining frame, inlay of foam ceramic block, preheating, metal smelting, compounding, machining and finishing, etc., to form a multi-scale ceramic / metal composite wear-resistant material.

[0052] The preparation proce...

Embodiment 1

[0098] ① High toughness steel constrained frame casting

[0099] The precision casting method is used to cast a 35# steel constraint frame, and the bottom surface of the constraint frame 1 is opened: the upper dimension is The following dimensions are Inverted taper holes 2, evenly distributed on the surface 21×21×20mm 3 The square hole 3, the width of the middle transverse rib 4 is 3mm, as shown in Figure 3. Then use the sandblasting method to roughen the inner surface of the constraint frame.

[0100] ② Preparation of foamed silicon carbide ceramic block

[0101] According to the patent: A high-strength silicon carbide foam ceramics and its preparation method (ZL00110479.9), a silicon carbide foam ceramic block is prepared. The average size of the mesh is: 1.0mm, the volume fraction is: 60%, and the average grain size is in 5μm, size 21×21×20mm 3 , the ceramic foam blocks are treated at high temperature to remove residual silicon, such as Figure 4 shown.

[0102]...

Embodiment 2

[0116] The difference from Example 1 lies in the preparation of the high-toughness steel confinement frame.

[0117] The precision casting method is used to cast a 16 manganese steel constraint frame. Then use the sandblasting method to roughen the inner surface of the constraint frame.

[0118] In this example, the three phases of foamed silicon carbide ceramic / ductile iron / 16 manganese steel constitute a multi-scale composite wear-resistant steel, which shows the advantage of realizing the ideal combination of high wear resistance and high strength and toughness of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com