Solar battery assembly and preparation method thereof

A technology for solar cells and modules, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as potential safety hazards, inability to flexibly obtain voltage and current values, and inability to apply battery modules to inverters, to ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

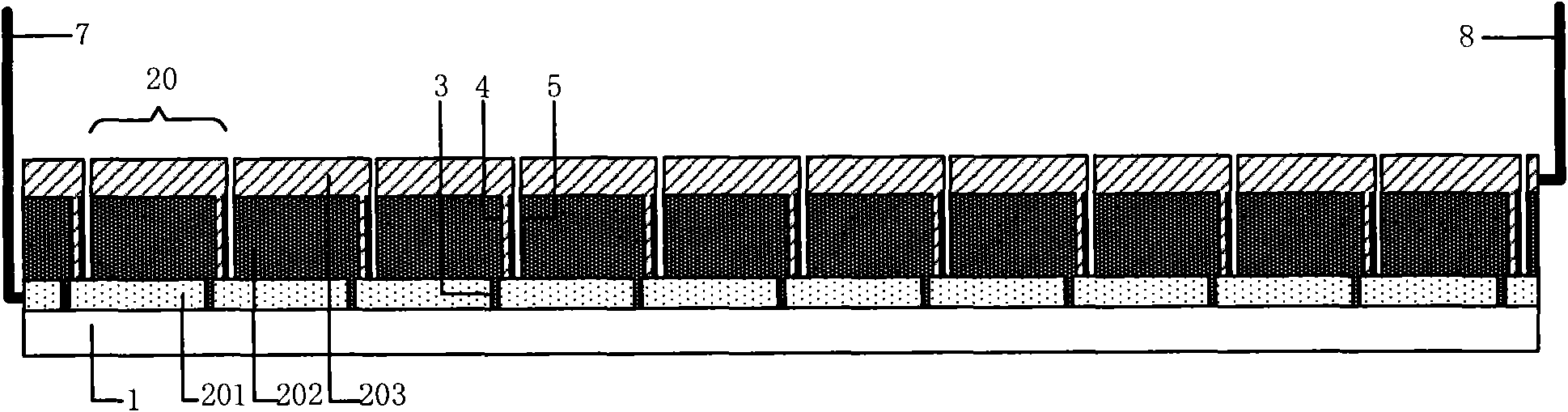

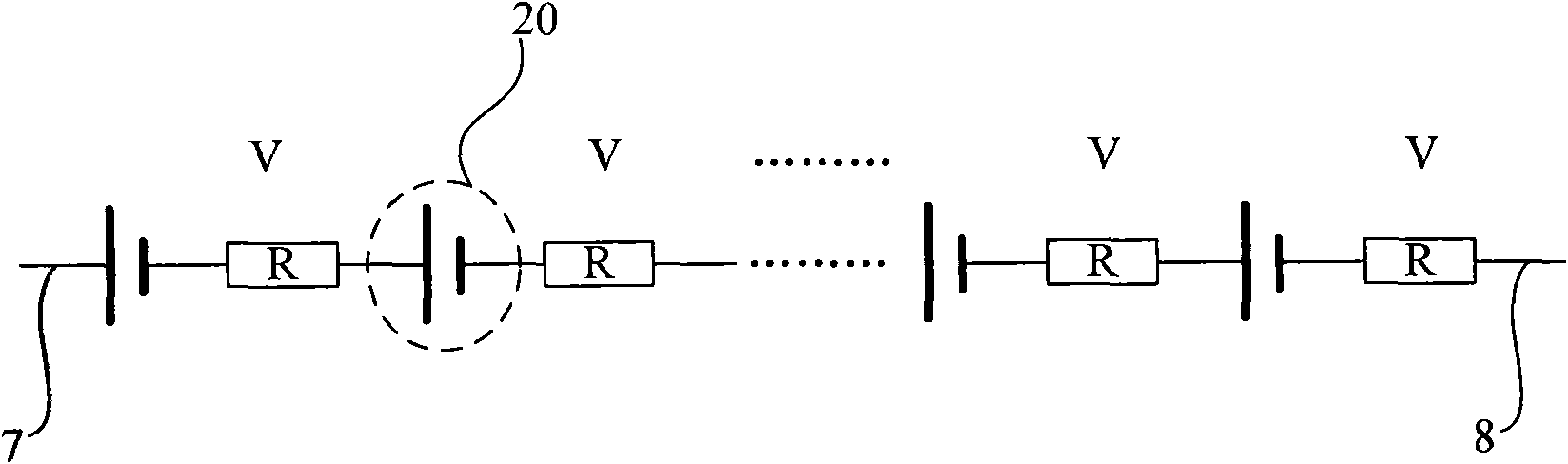

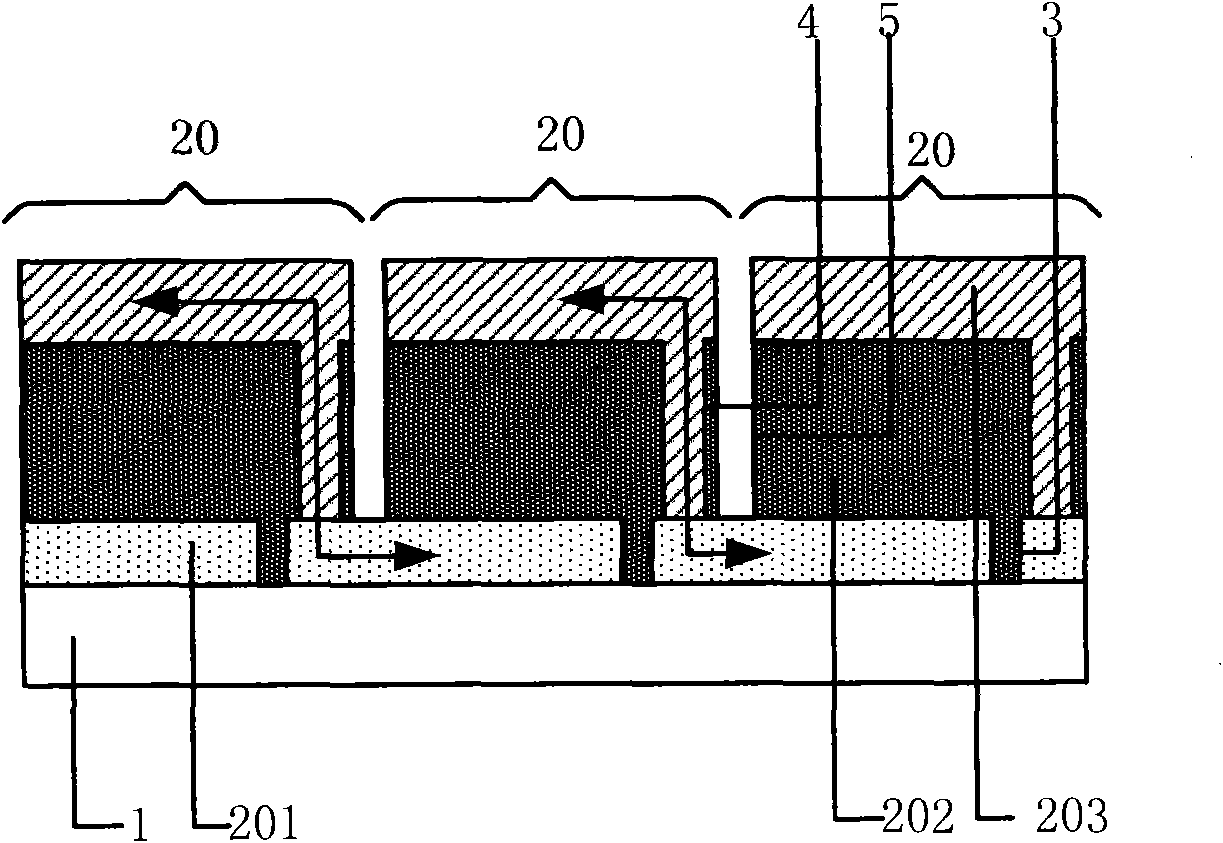

[0031] This embodiment provides a solar cell module, Figure 4 Is a schematic diagram of the structure of the solar cell module provided in the first embodiment of the present invention, Figure 5 for Figure 4 The schematic circuit diagram of the solar cell module shown. From Figure 4 with Figure 5 It can be seen that the solar cell module includes a plurality of solar cells 20 formed on the transparent substrate 1, and each solar cell 20 includes a transparent conductive film 201, a solar cell layer 202, and a metal back electrode 203 stacked in sequence, adjacent to each other. The solar cells 20 are connected in series through the laser scribing process, that is, it can be realized by the first laser scribing 3, the second laser scribing 4, and the third laser scribing 5. Among them, it also includes: at least one fourth laser scribe line 6, which penetrates the metal back electrode 203, the solar cell layer 202 and the transparent conductive film 201, and disconnects adja...

Embodiment 2

[0039] This embodiment provides a method for manufacturing a solar cell module, Figure 7 This is a flow chart of the method for preparing a solar cell module provided in the second embodiment of the present invention. The method for preparing a solar cell module includes sequentially depositing a transparent conductive film material layer, a solar cell material layer and a metal back electrode material layer on a transparent substrate, And forming a plurality of solar cells connected in series through a laser scribing process 10, and further includes the following step 20:

[0040] Perform a fourth laser scribing on the formed solar cell module, cutting through the metal back electrode material layer, solar cell material layer and transparent conductive film material layer, and disconnecting adjacent solar cells to form at least two independent cells Unit, the battery unit is composed of solar cells connected in series.

[0041] The present invention divides the solar cell module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com