Method for preparing fibre humidity-controlling board and apparatus

A fiberboard and fiber technology, which is applied in the field of production equipment for manufacturing such desiccants, can solve the problems of lack of matching, limited moisture absorption and desorption, and poor moisture absorption and desorption characteristics, and achieves the effect of good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] 1. Selection of fiber materials:

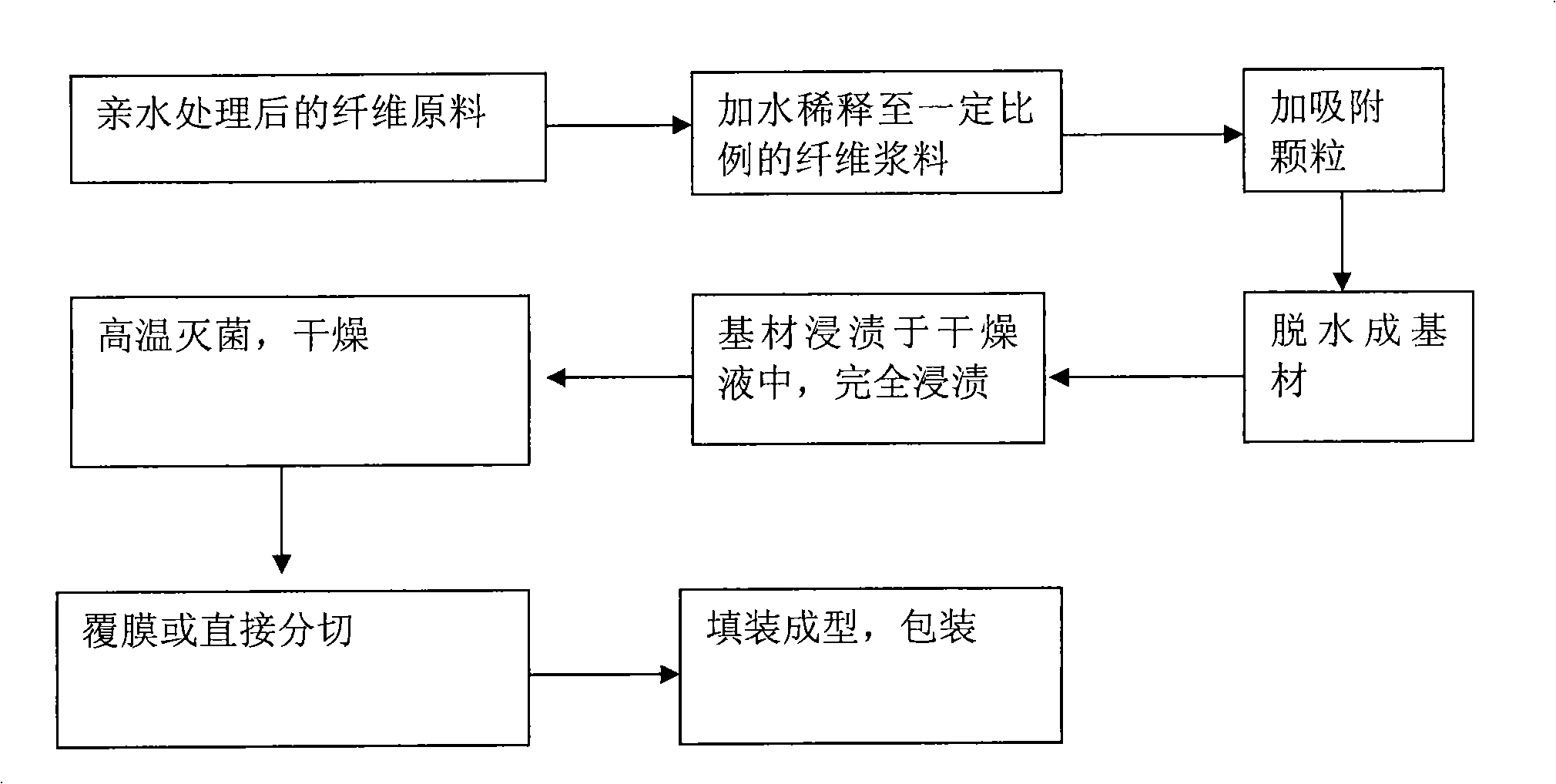

[0081] Such as figure 1 As shown in the forming flow chart of the fiber humidity control board of the present invention, the forming process of the fiber humidity control board is as follows: the processed fiber raw material is diluted with water to a certain ratio to make a slurry, enters the forming pool and adds powdery inorganic adsorption particles , dehydrated into fiber base material, the base material is fully soaked in the drying liquid, sterilized and dried at high temperature into a fiber temperature-regulating plate, and the humidity-regulating plate is treated with an anti-back seepage film, and can also be directly cut to the required specifications, and finally , filled and molded, and packaged to leave the factory after passing the inspection.

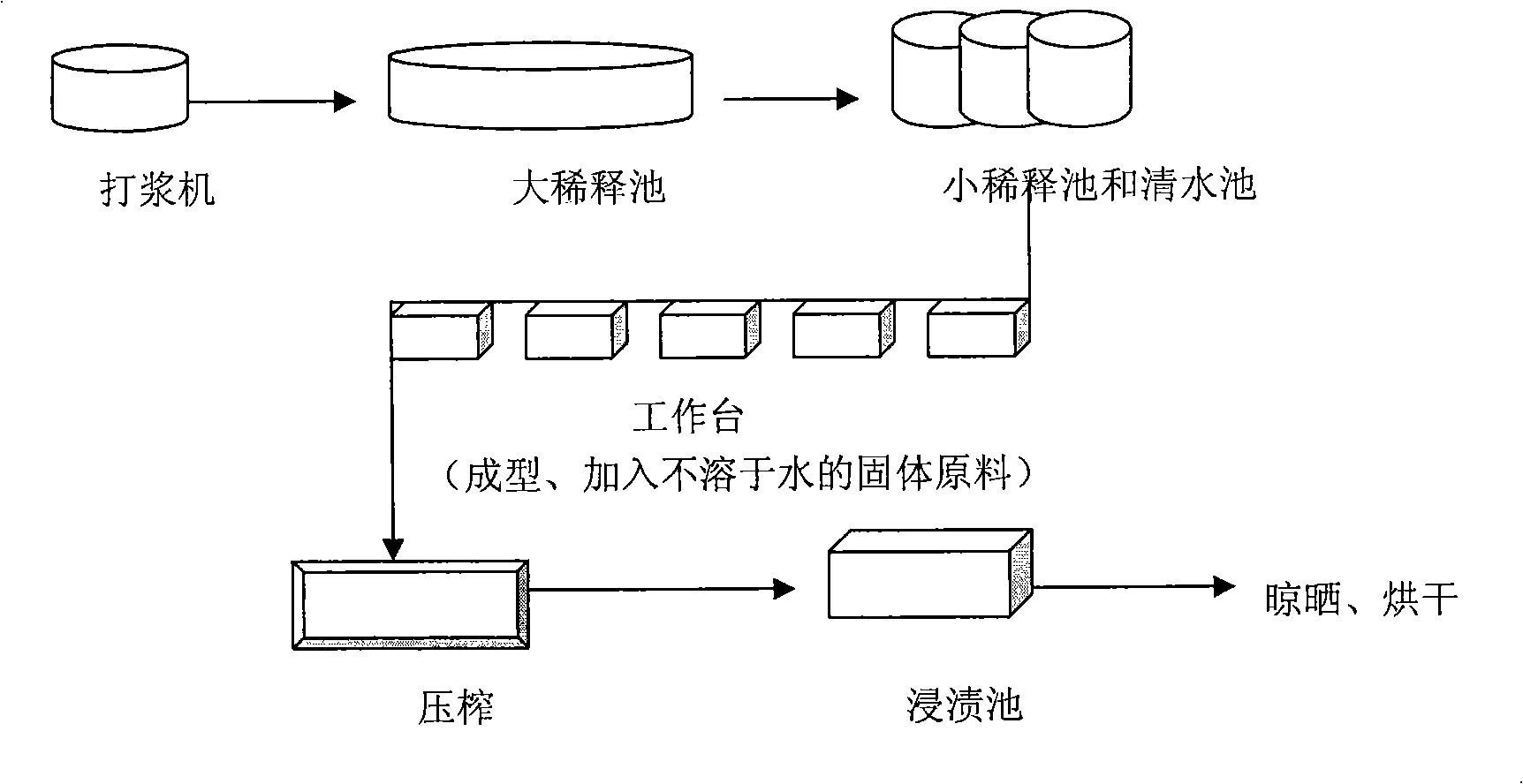

[0082] The specific production process of the fiber humidity control board is carried out according to the following steps: screening the base material, and in the process of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com