Circular track type cell cutting system for manufacturing flexible OLED (Organic Light Emitting Diode) display panel

A display panel and cutting system technology, applied in the field of display screens, can solve the problems of low box cutting efficiency, inconvenient handling, and large master chip size, and achieve the effects of high automation, high site utilization, and compact space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

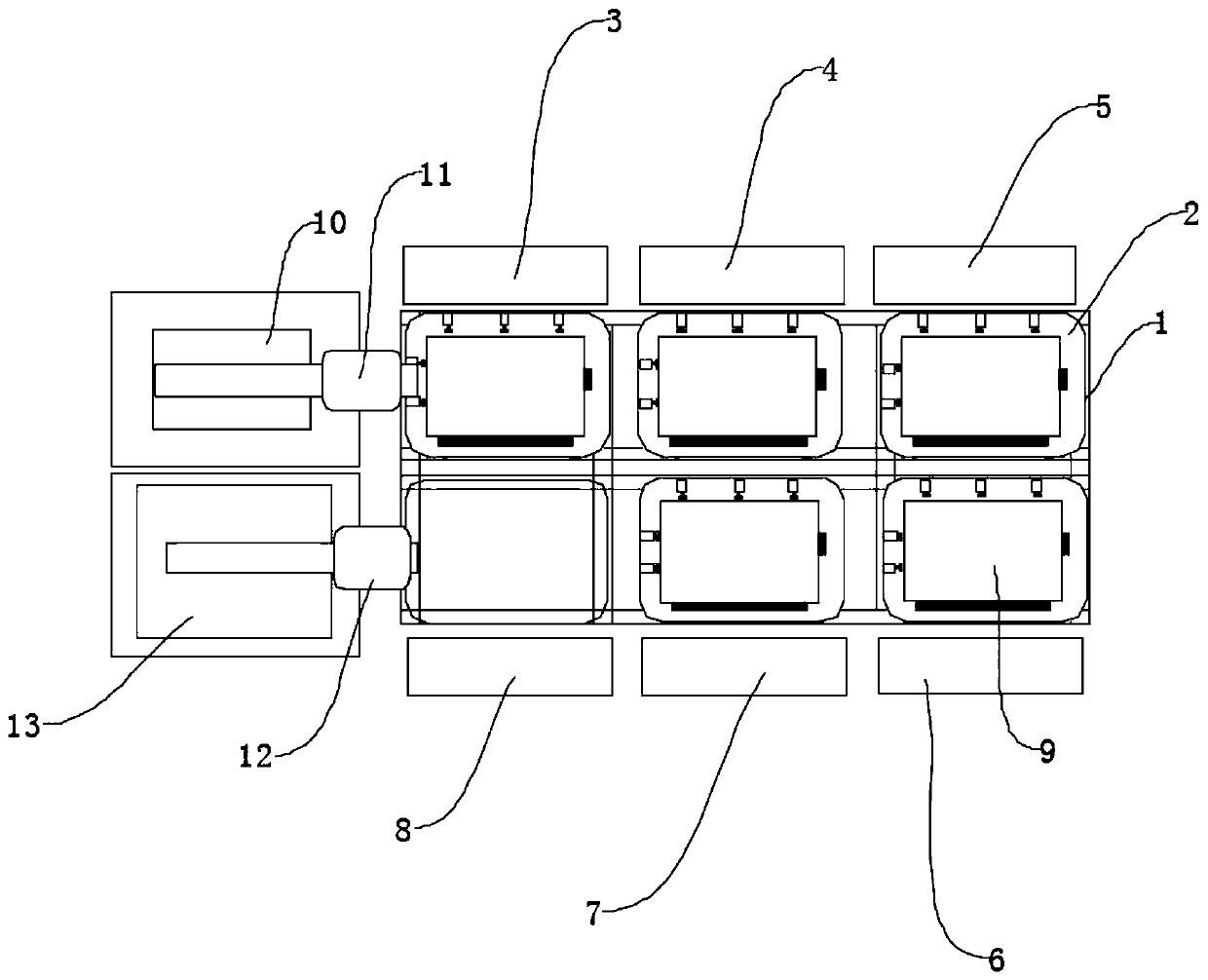

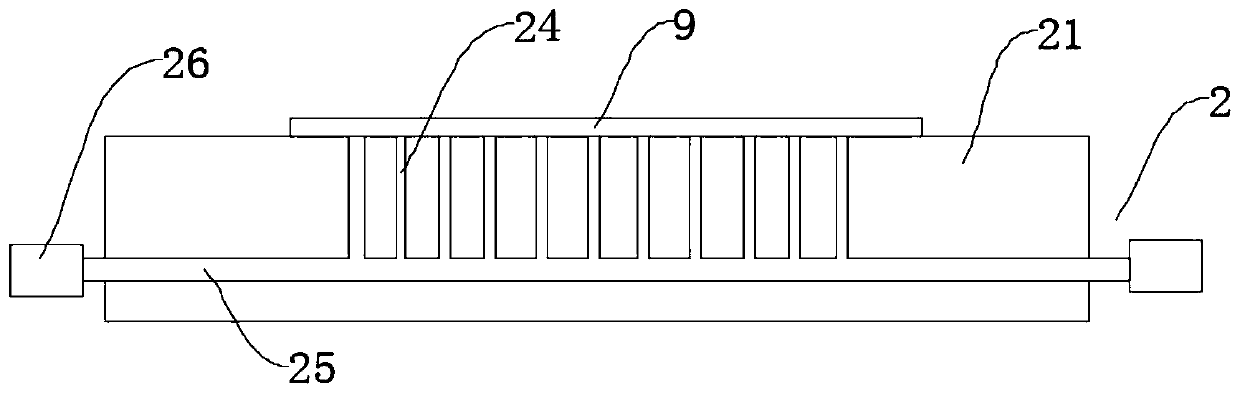

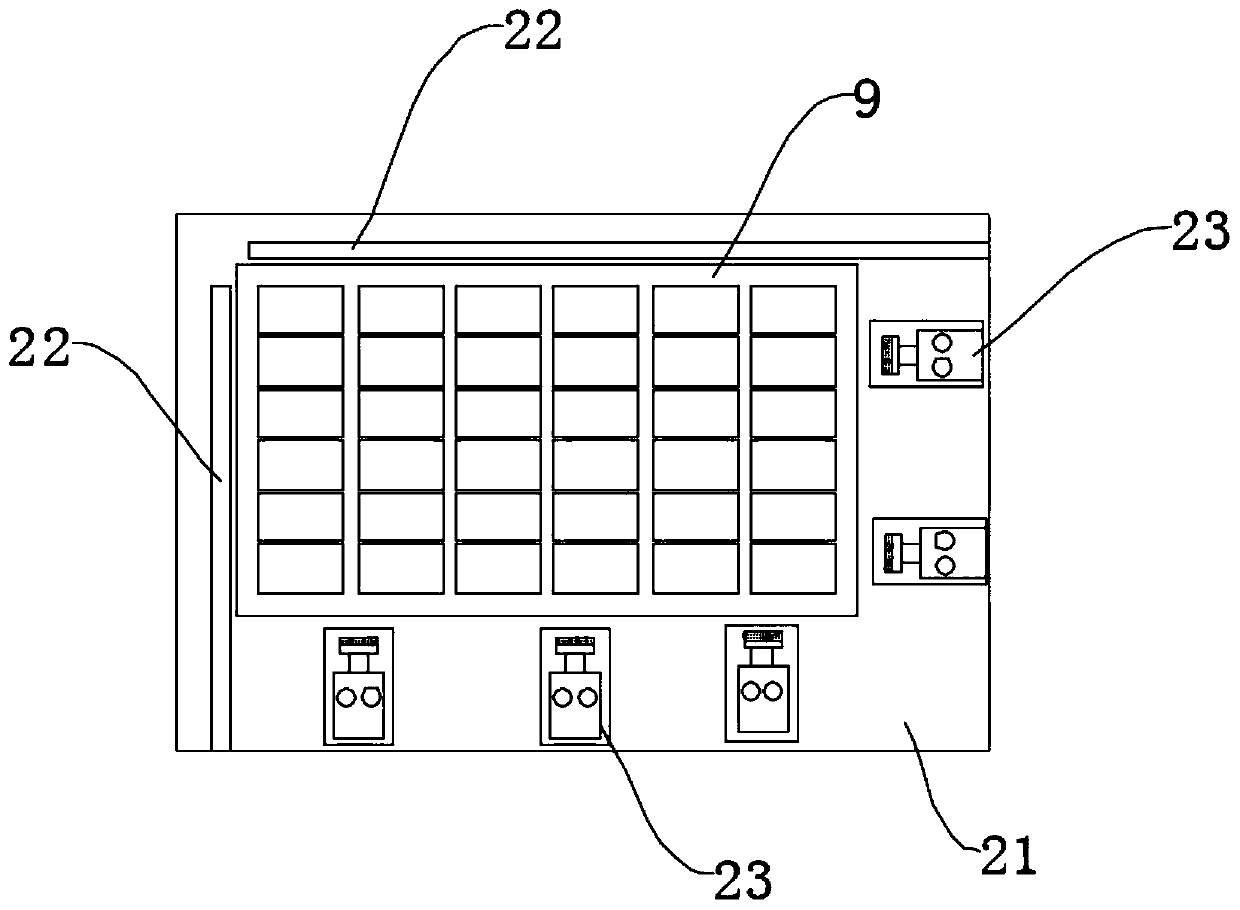

[0055] to combine figure 1 As shown, the present invention proposes a ring-rail type box-forming cutting system for manufacturing flexible OLED display panels, including a ring guide rail 1 and several positioning jigs 2 arranged on the ring guide rail 1, and the ring guide rail 1 The upper end is also set in turn with CO 2 Laser cutting station 3, tearing off protective film station 4, UV laser cutting station 5, IR laser cutting station 6, split station 7 and discharge station 8; the CO 2 A feeding table 10 is arranged beside the laser cutting station 3, and a first linear manipulator 11 is arranged between the feeding table 10 and the annular guide rail 1, and the first linear manipulator 11 is a multi-suction cup manipulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com