Patents

Literature

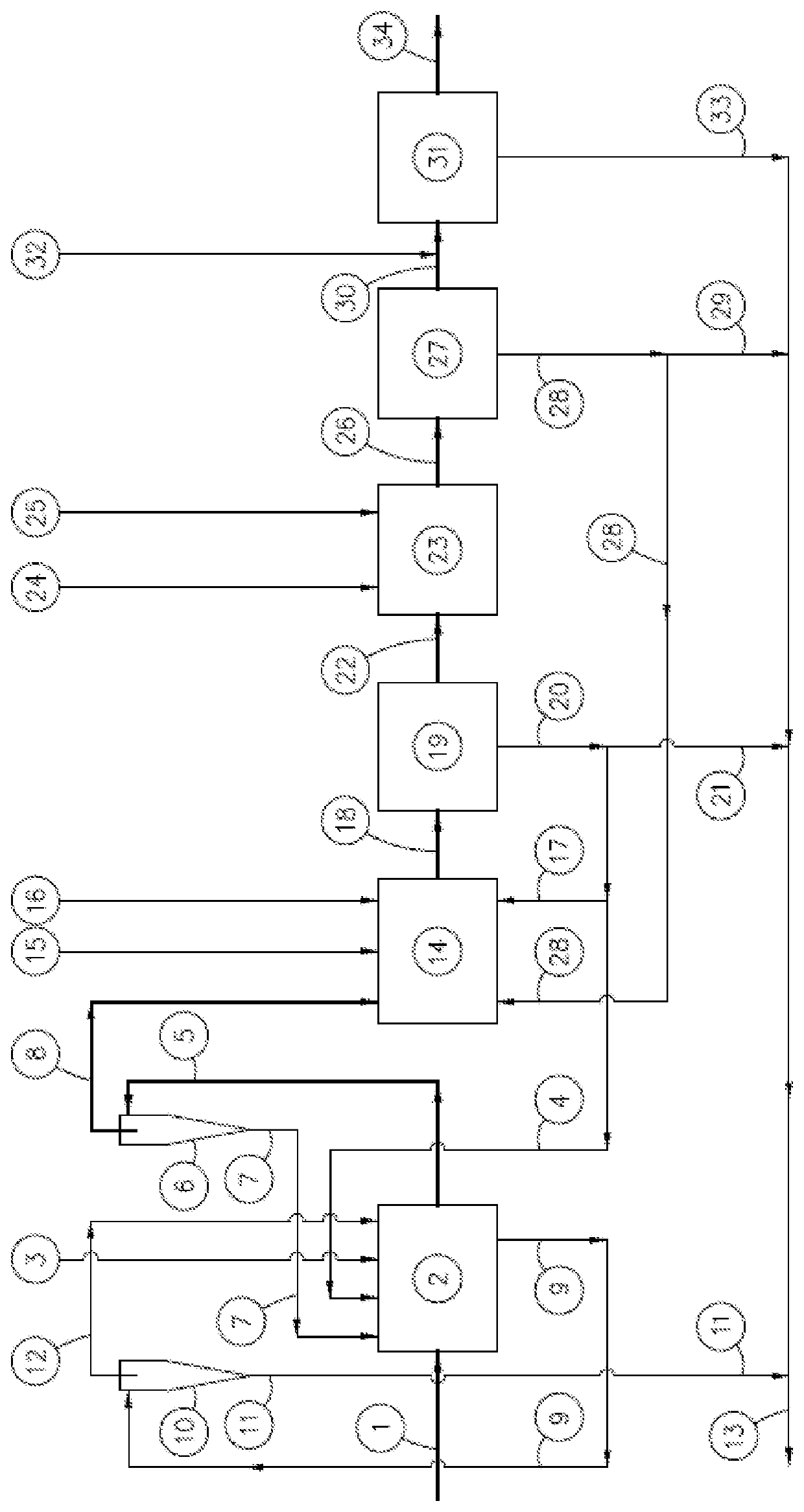

36results about How to "Reduce Leachability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

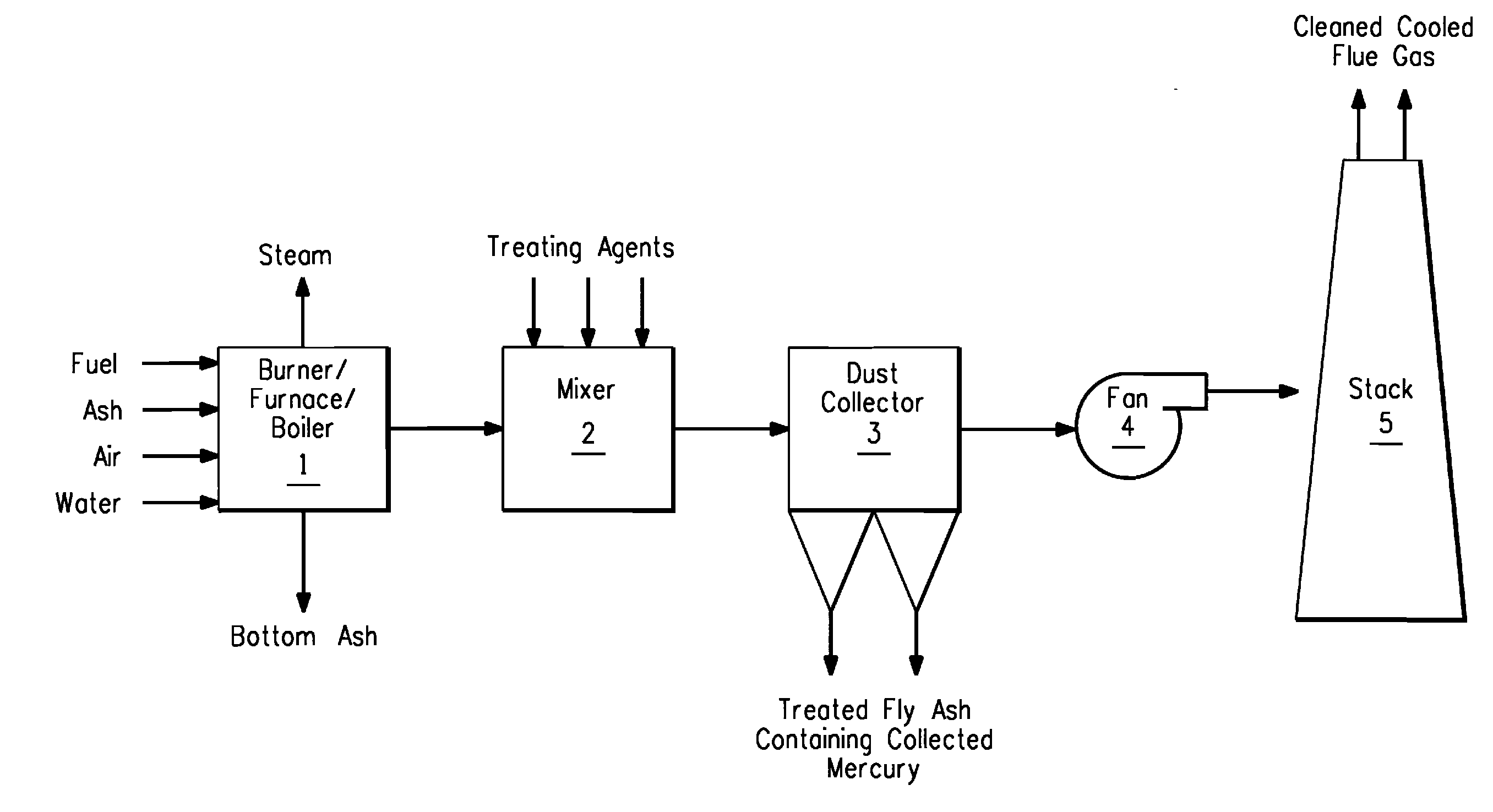

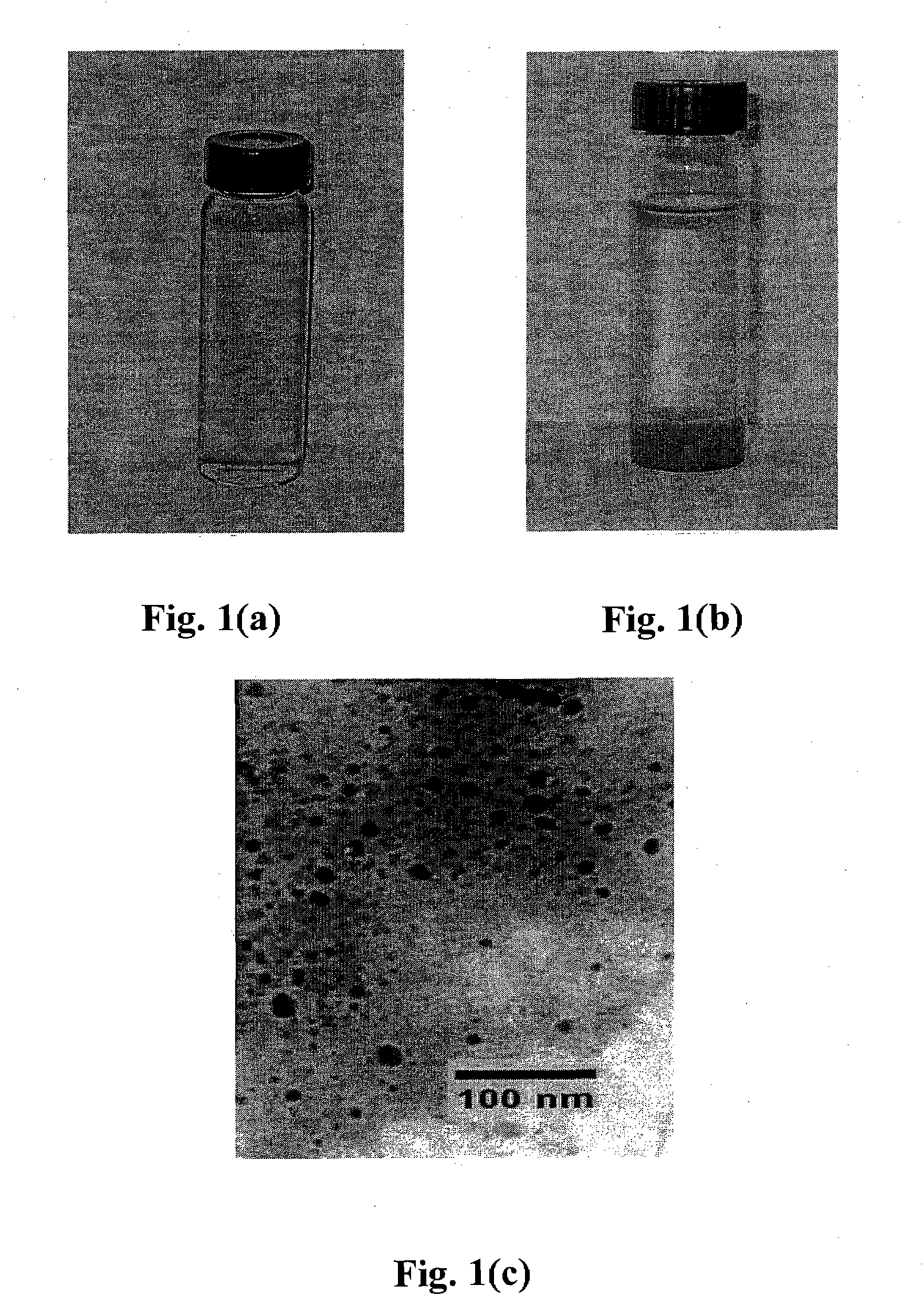

Mercury removal from a gas stream

InactiveUS20090104097A1Reduce LeachabilityReduce carbon contentGas treatmentDispersed particle filtrationOxygenBoric acid

This invention is a novel process for removing volatile mercury from a gas stream to produce a filtered solid. The gas stream is contacted with treating agents which comprise a semivolatile acidic vitrifying compound such as boric acid, water, oxygen-containing gas and a chlorine source. The filtered solids produced in the process have low mercury leachability thereby allowing the solids to be used, for example in flyash-containing concrete.

Owner:EI DU PONT DE NEMOURS & CO

Method for stabilizing heavy metal bearing waste in a waste generation stream

InactiveUS6050929AReduce solubilityReduce LeachabilitySolid waste disposalRadioactive decontaminationWaste treatmentHazardous waste

Heavy metal bearing products during production, processing and / or handling, and / or in landfills, storage or retention areas are stabilized prior to the generation or management as a waste by applying heavy metal stabilizing agents into the product stream thus avoiding complex and costly processing and treatment of waste under hazardous waste regulations.

Owner:FORRESTER KEITH EDWARD

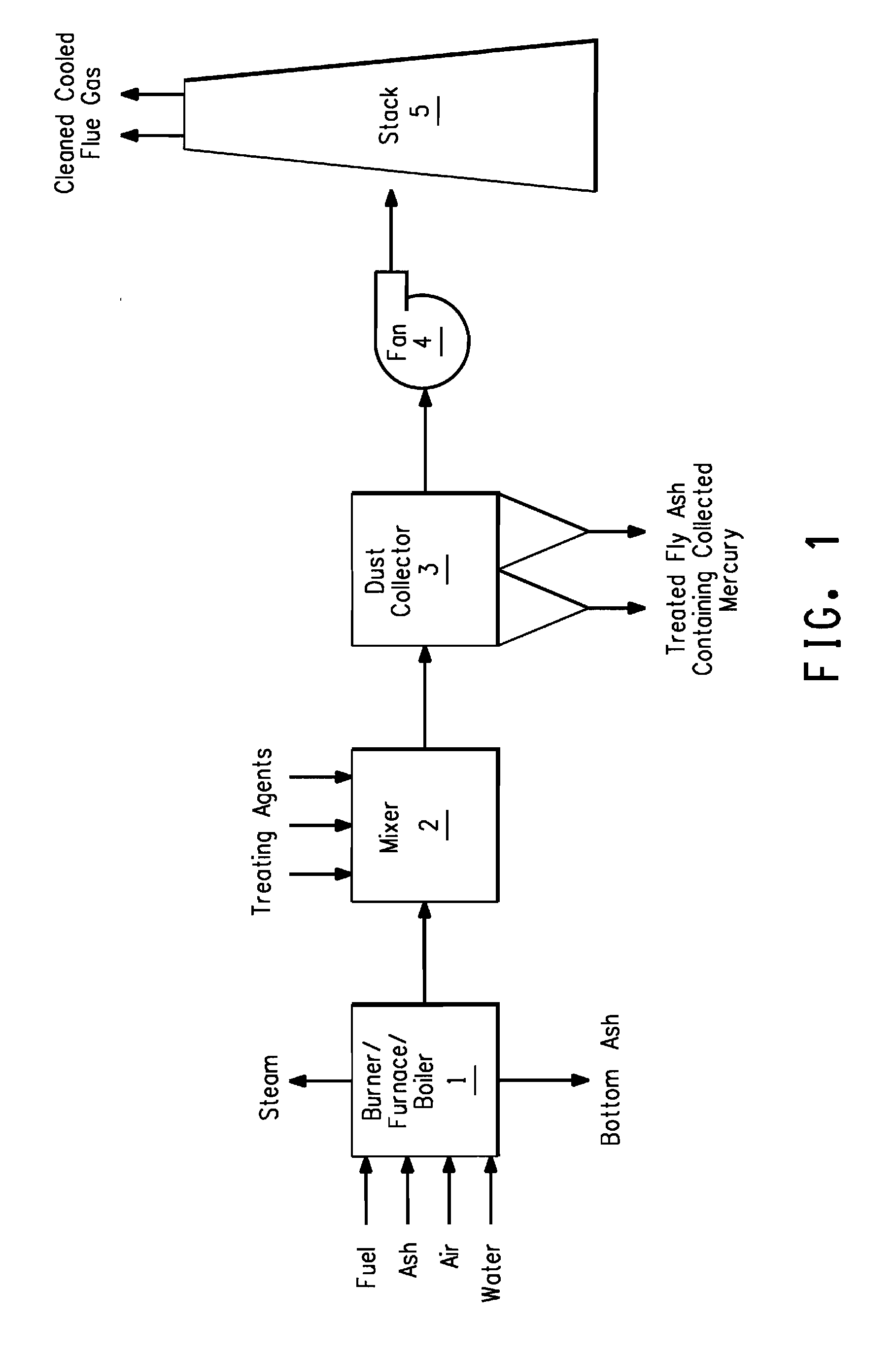

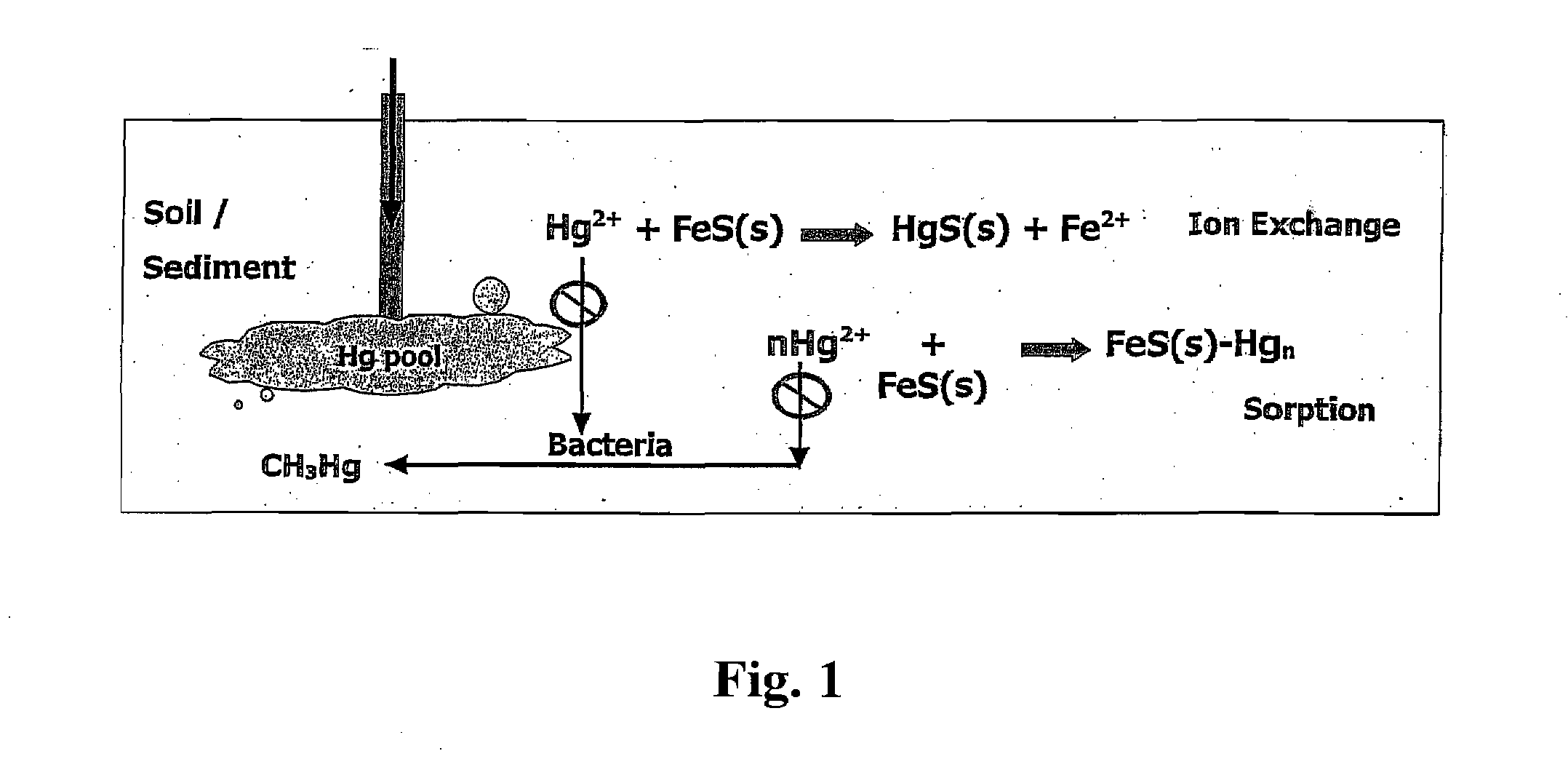

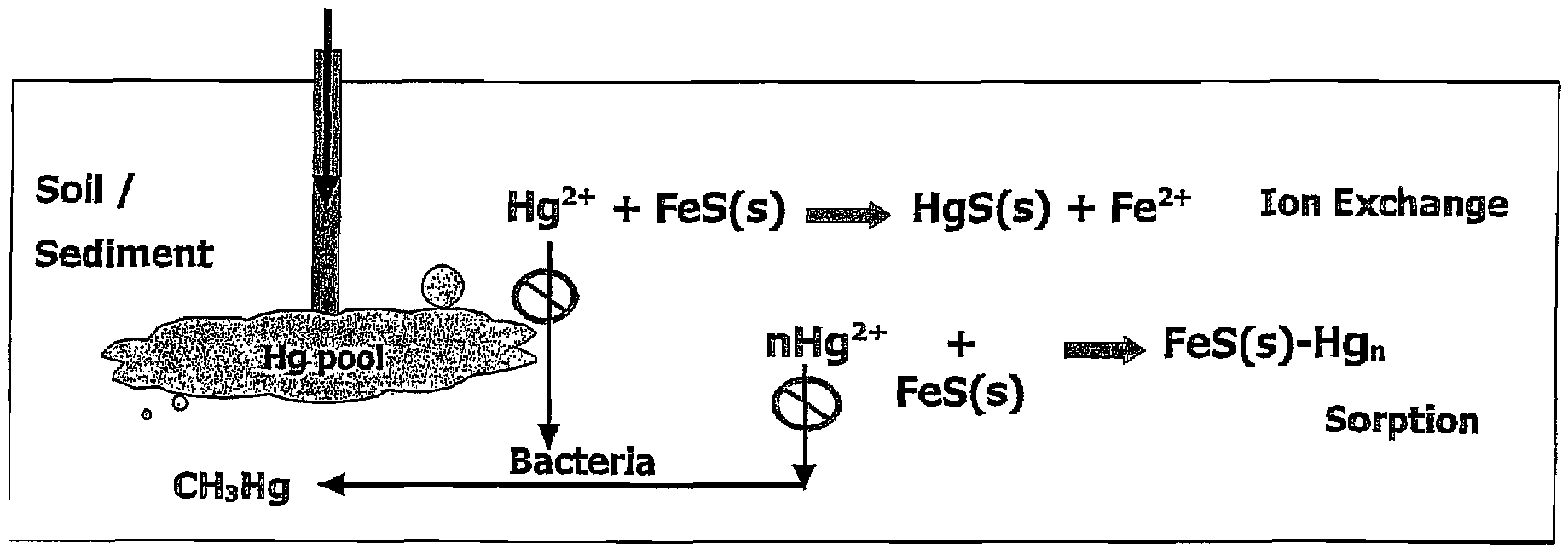

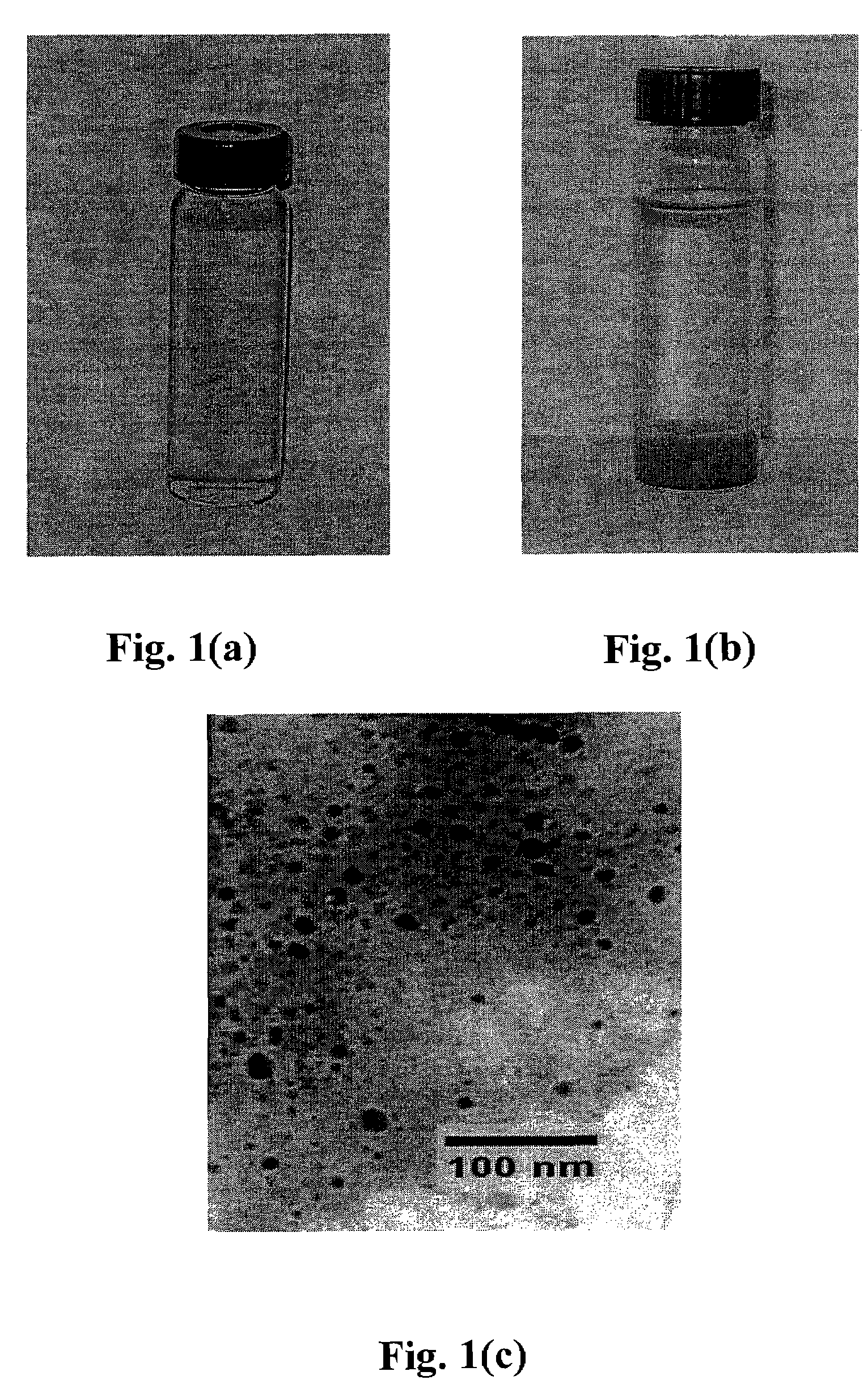

In Situ Immobilization of Metals in Contaminated Sites Using Stabilized Nanoparticles

InactiveUS20070203388A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseNanoparticle

A method for preparing a class of highly stabilized and soil-dispersible nanoparticles and using the nanoparticles as a remediation technology for immobilizing toxic metals at toxic metal contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the nanoparticles in a liquid carrier, and results in suspensions of nanoparticles of desired size and mobility in water, soils or sediments. The stabilizer can facilitate controlling the dispersibility of the nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the nanoparticles can immobilize one or more toxic metals of the contaminated site.

Owner:AUBURN UNIV

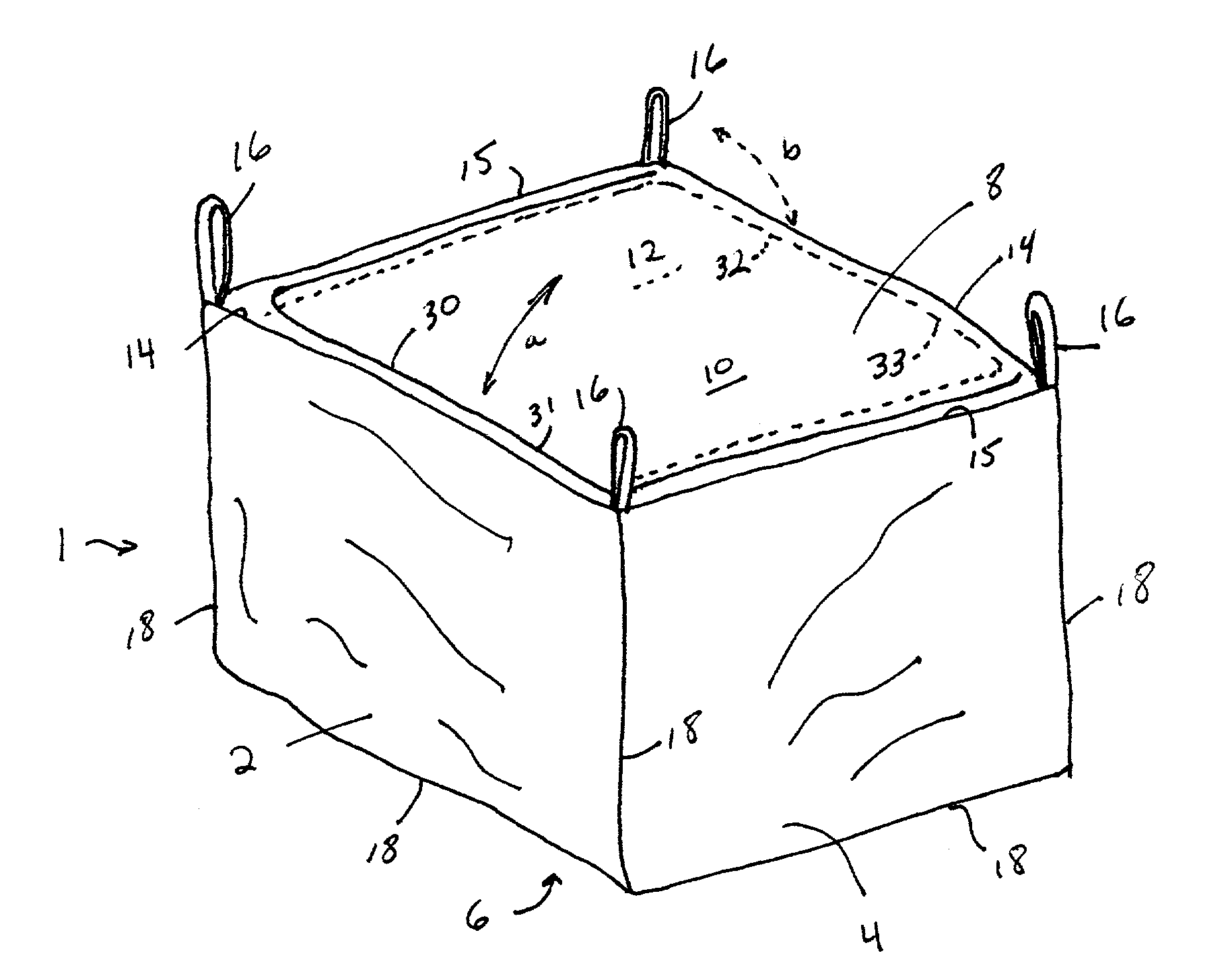

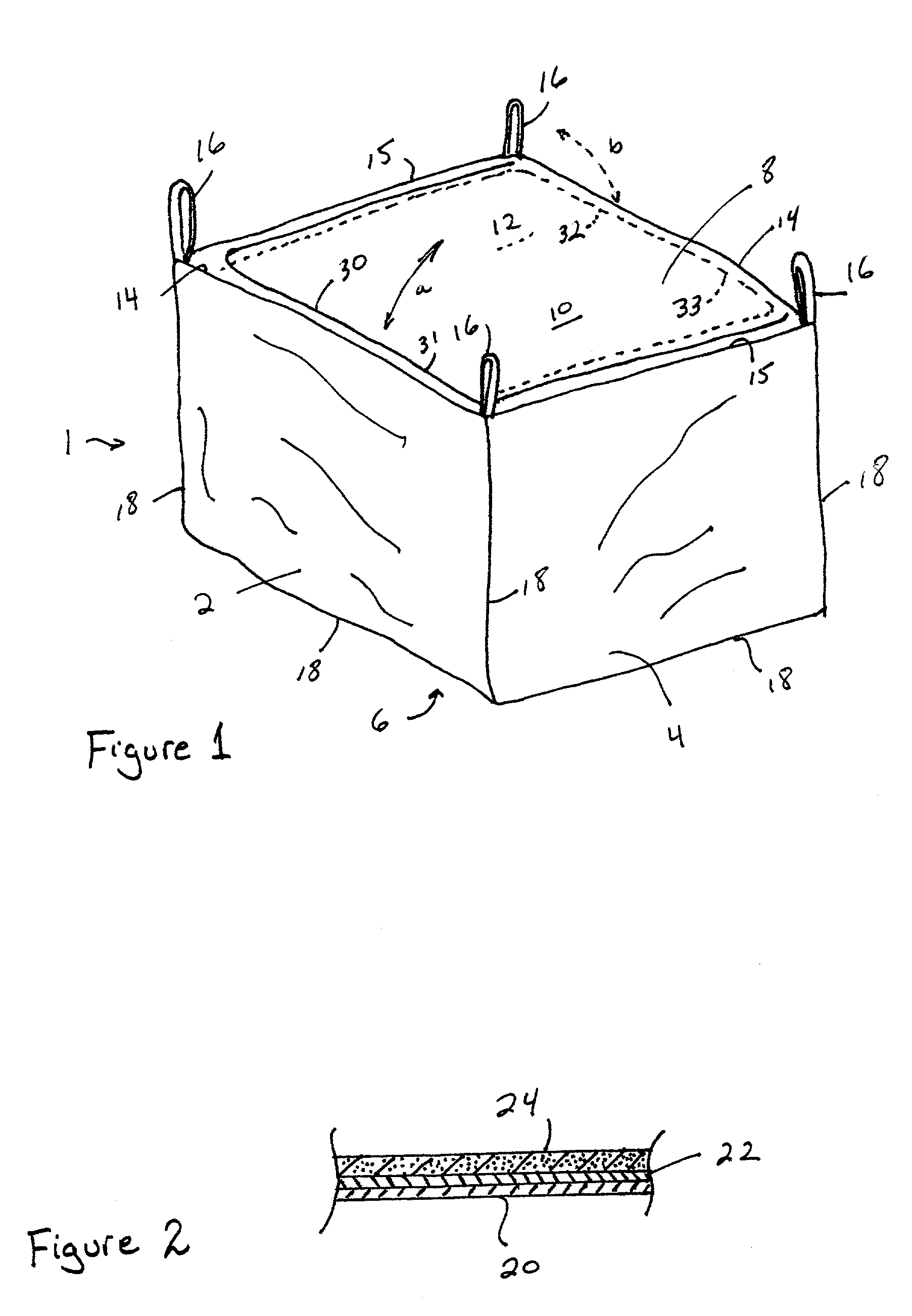

Methods and apparatus for encapsulating hazardous debris

InactiveUS7074174B2Reduce exposureReduce LeachabilitySludge treatmentSolid waste disposalWood splinterLitter

A method of collecting, treating, transporting and disposing of hazardous debris which combines the standards of macroencapsulation and microencapsulation and involves the use of a liner to contain hazardous debris together with reagents that reduce leachability of a constituent of the hazardous debris. The liner is supported in a rolloff box or other transportable container on site where the hazardous debris is collected. Prior to placing hazardous debris into the liner, a layer of reagent(s) is provided in the bottom of the liner. Once hazardous debris is loaded in the liner, addition free flowing reagent(s) is / are added to fill void space in and around the hazardous debris, after which the top of the liner is sealed for disposal in a landfill.

Owner:HESS ENGINEERING INC +1

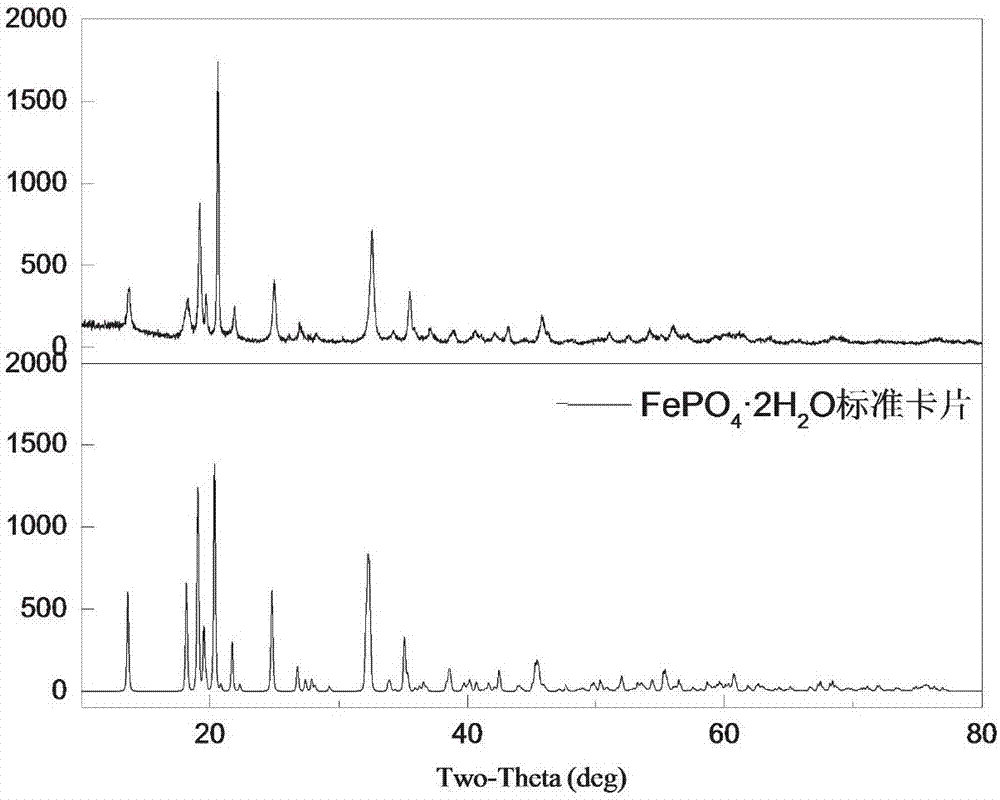

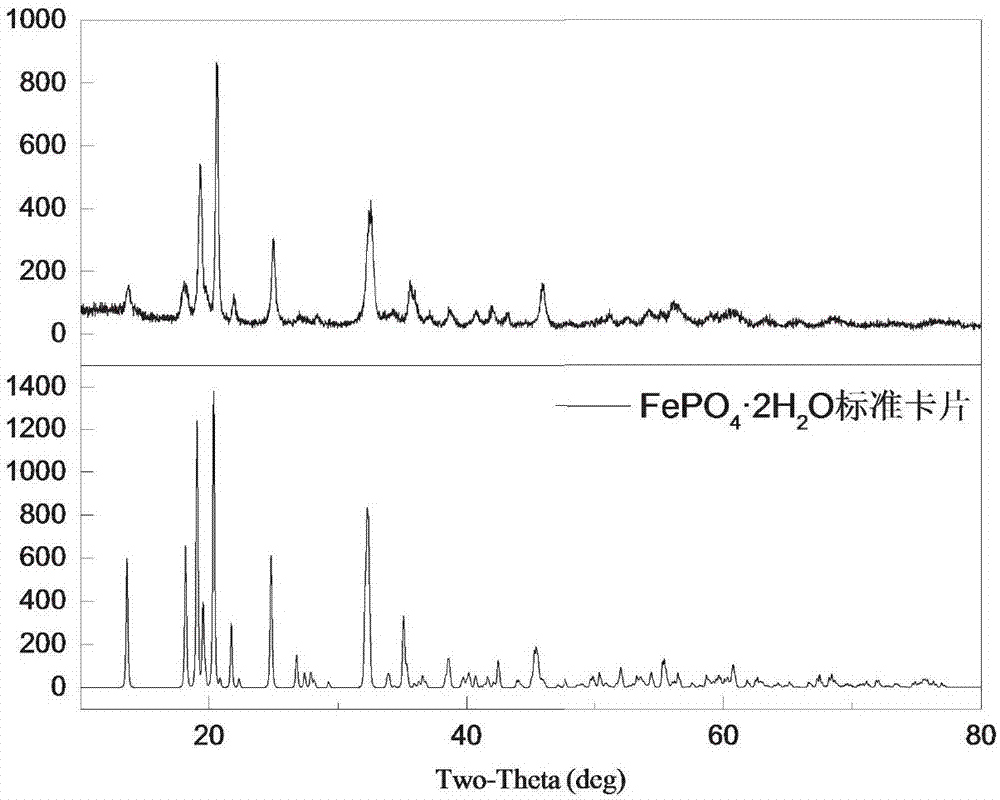

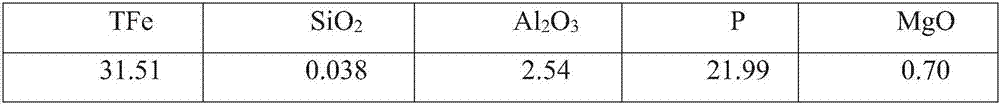

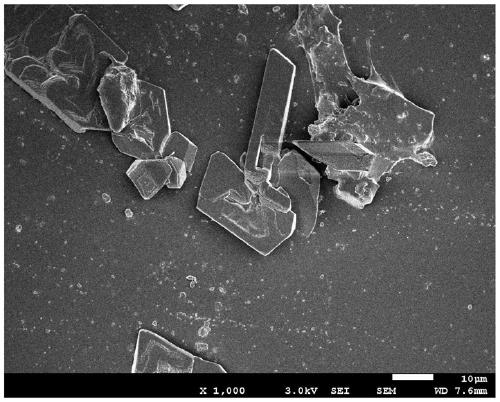

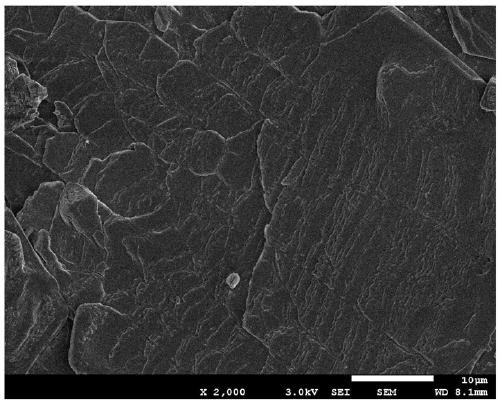

Method for normal-pressure phosphoric-acid leaching of nickel-cobalt and synchronous preparation of iron phosphate

ActiveCN106987728AImprove leaching rateEfficient separationProcess efficiency improvementPhosphorus compoundsPhosphoric acidLaterite

The invention discloses a method for the normal-pressure phosphoric-acid leaching of nickel-cobalt and the synchronous preparation of iron phosphate. The method comprises the following steps: subjecting laterite nickel ore to normal-pressure acid leading treatment, and then carrying out solid-liquid separation to obtain a leaching residue of iron phosphate and a leaching solution of enriched nickel-cobalt, wherein in the leaching process, phosphoric acid with a concentration of 1-3 mol / L is adopted; the adding amount of phosphoric acid is 1-3 times as much as the theoretical molar mass of metal elements in the leached transformed laterite nickel ore; and the laterite nickel ore is subjected to transformation at 300-400 DEG in advance before the acid leading treatment. The method is particularly suitable for the treatment of low-grade limonite-type laterite nickel ore; the nickel-cobalt recovery rate is high; the nickel-iron separation effect is good; and the leaching residue of iron phosphate is not only applicable to the preparation of iron phosphate lithium batteries but also utilized as a raw material for the manufacturing of catalysts and ceramics.

Owner:CENT SOUTH UNIV

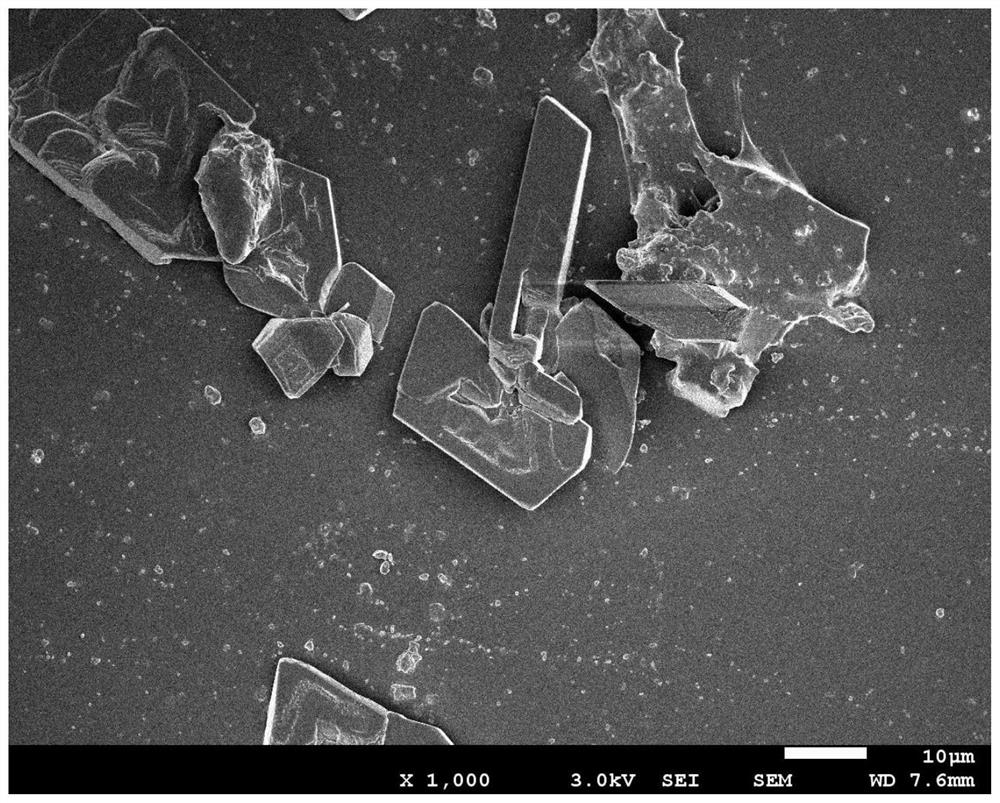

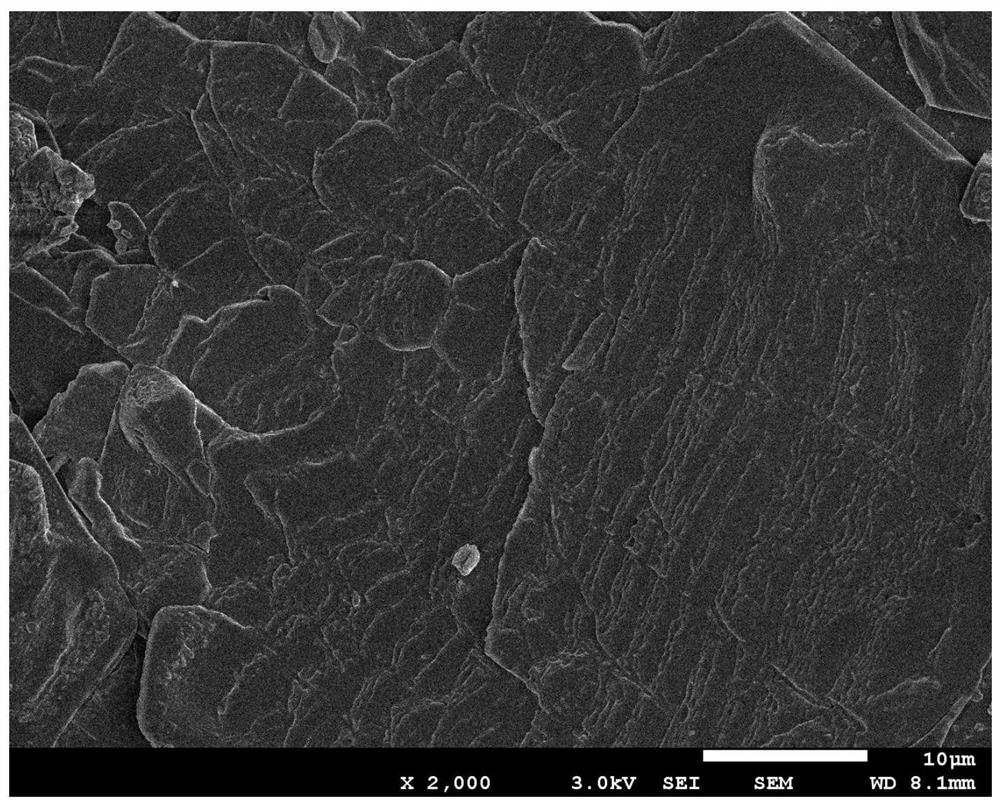

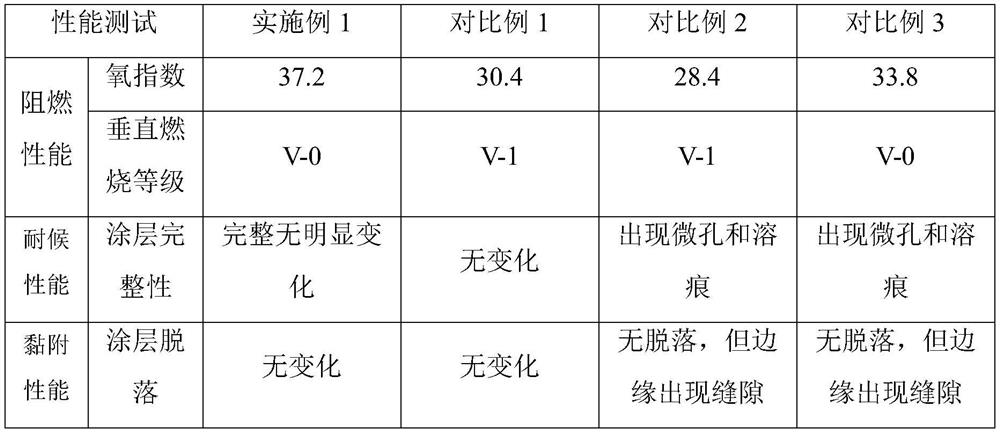

Flame-retardant protective coating for rubber and plastic products and preparation method thereof

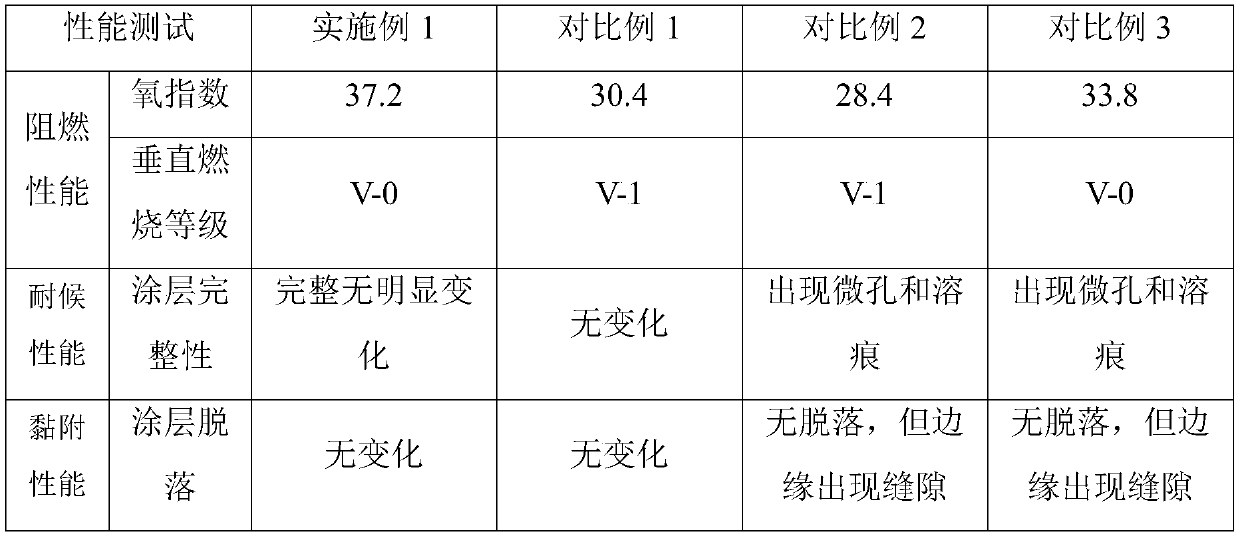

ActiveCN110128918AGood dispersionReduced ability to migrateFireproof paintsPolyurea/polyurethane coatingsThermal insulationPolystyrene

The invention discloses a rubber and plastic product flame-retardant protective coating and a preparation method thereof. The protective coating comprises the following components by mass: 100 parts of a polar polymer, 0.5-20 parts of two-dimensional nano filler, 5-50 parts of flame retardant, 0.01-10 parts of amine compound, 1-50 parts of polyphenol compound and 0.01-10 parts of polyvalent metalsalt. The preparation method comprises the following steps: 1) adding the two-dimensional nano-filler, the flame retardant, the amine compound, the polyphenol compound and the polyvalent metal salt into a solvent A, and performing a reaction under certain conditions to perform coating modification on the two-dimensional nano-filler and the flame retardant to obtain dispersion liquid A; 2) dispersing the polar polymer in a solvent B under certain conditions to obtain a dispersion liquid B, the solvent A and the solvent B being the same or being mutually soluble; and 3) mixing the dispersion liquid A and the dispersion liquid B under certain conditions to obtain the flame-retardant protective coating which can be brushed on the surfaces of expanded polystyrene thermal insulation foam, staticrubber products and the like to form a flame-retardant protective coating.

Owner:QINGDAO UNIV OF SCI & TECH

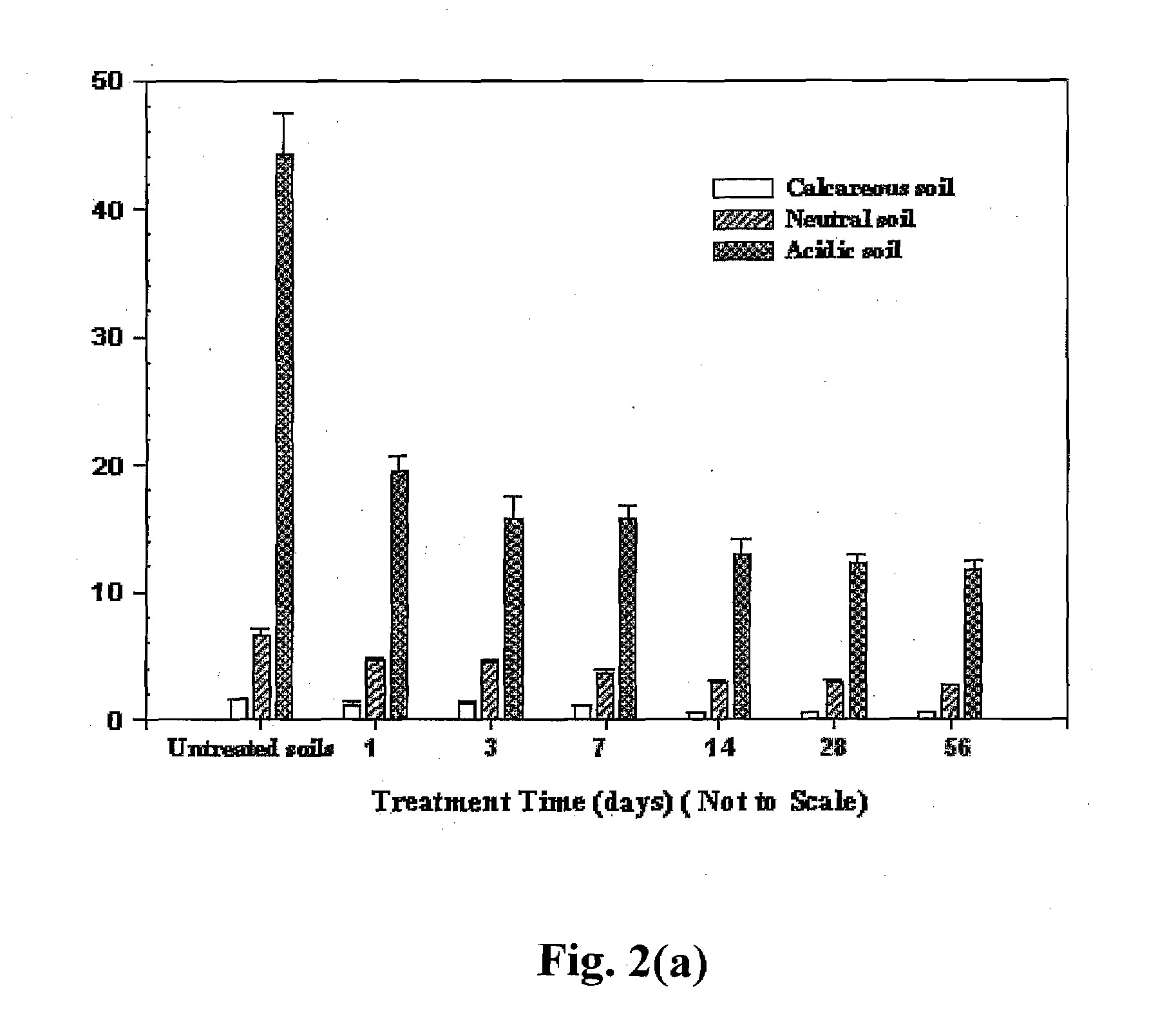

In situ immobilization of metals in contaminated sites using stabilized iron phosphate nanoparticles

InactiveUS7581902B2Easy to controlEasy to fixMaterial nanotechnologyWater treatment compoundsNanoparticleIron phosphate

A method for preparing a class of highly stabilized and soil-dispersible nanoparticles and using the nanoparticles as a remediation technology for immobilizing toxic metals at toxic metal contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the nanoparticles in a liquid carrier, and results in suspensions of nanoparticles of desired size and mobility in water, soils or sediments. The stabilizer can facilitate controlling the dispersibility of the nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the nanoparticles can immobilize one or more toxic metals of the contaminated site.

Owner:AUBURN UNIV

Controlled release pesticide and fertilizer briquettes

InactiveUS6225258B1Simple compositionEasy to useBiocideAgriculture gas emission reductionAdhesiveFosetyl-Al

An attrition and shatter resistant plant nutrient / pesticide briquette composition which slowly releases the nutrients and biologically active materials over long periods of time, comprising slow release plant nutrient particles, pesticide sorption particles, liquid systemic pesticide sorbed on the pesticide sorption particles to reduce pesticide leachability, an adhesive, coating the slow release plant nutrient and pesticide sorption particles, the composition formed into briquettes by pressing into dies at elevated pressures and temperatures to make briquettes resistant to attrition and shattering. A six step method is provided for the preparation of the slow releasing briquettes from slow release fertilizers, such as magnesium ammonium phosphate; pesticide sorption particles, such as activated carbon; liquid systemic pesticides emulsions, such as imidachloprid fosetyl-Al, and metalaxyl; and adhesives, such as a vinylidine chloride, 2-ethylhexyl acrylate, acrylic acid resin emulsion.

Owner:AGRINUTRIENTS TECH GRP INC

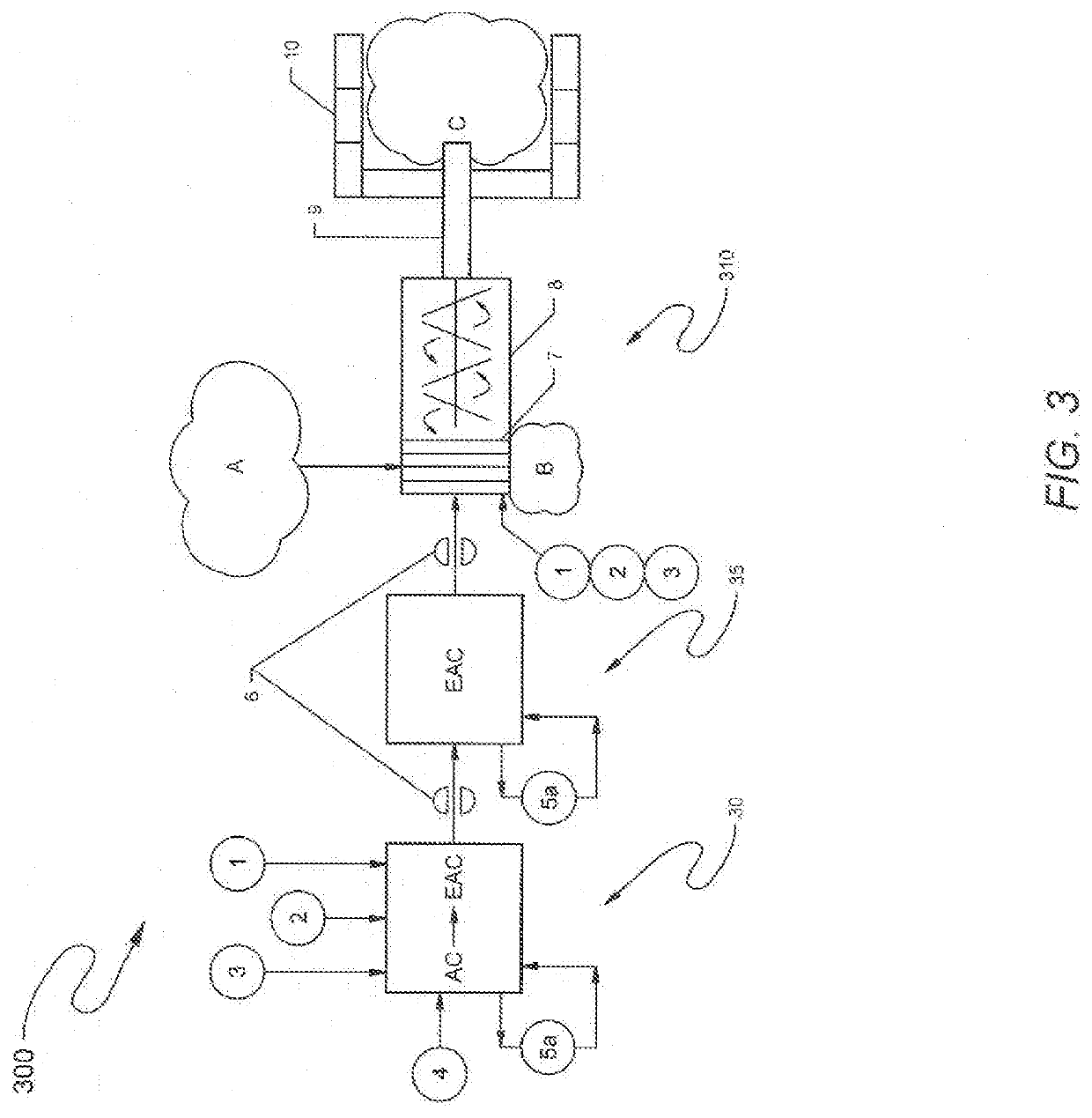

Dry sorbent injection (DSI) recovery system and method thereof

InactiveUS20140205521A1Reduce operating costsLow sodiumProductsGas treatmentSodium bicarbonateSorbent

The invention generally relates to system and method for recovering sodium bicarbonate from a solid waste, and more particularly to a method and system for recovering sodium bicarbonate from fly ash of a coal fired plant collected downstream of an injection process for pollution reduction from the industrial process.

Owner:NEUMANN SYST GROUP

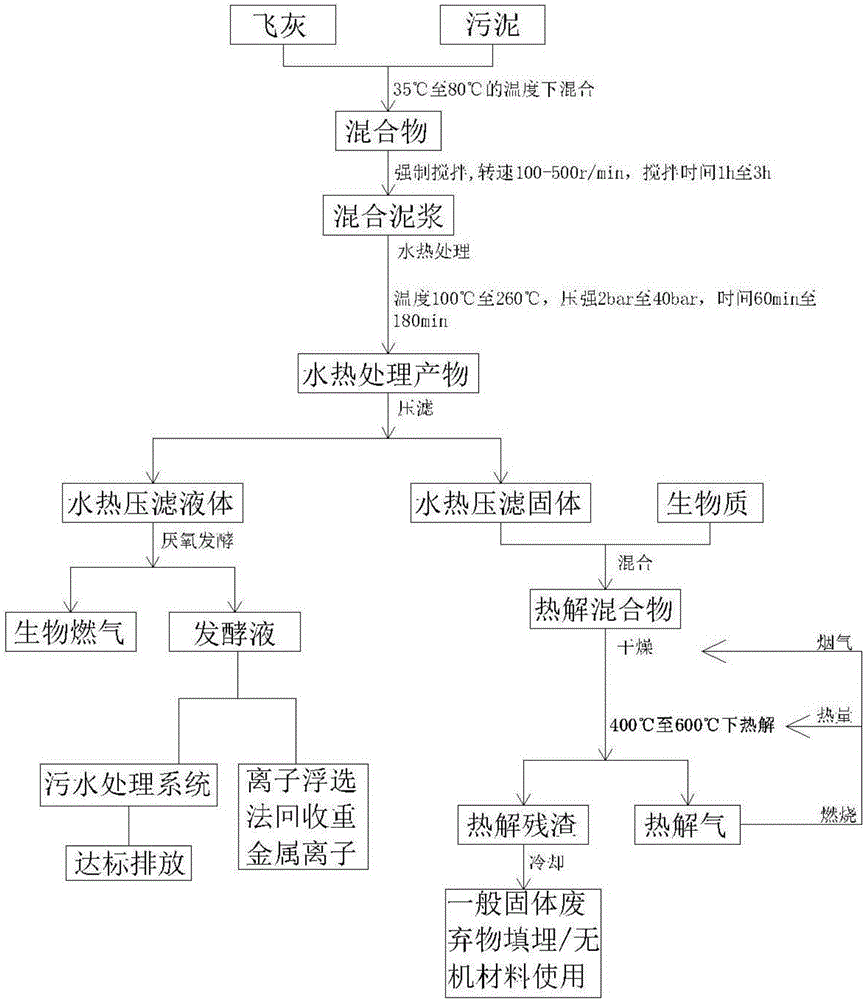

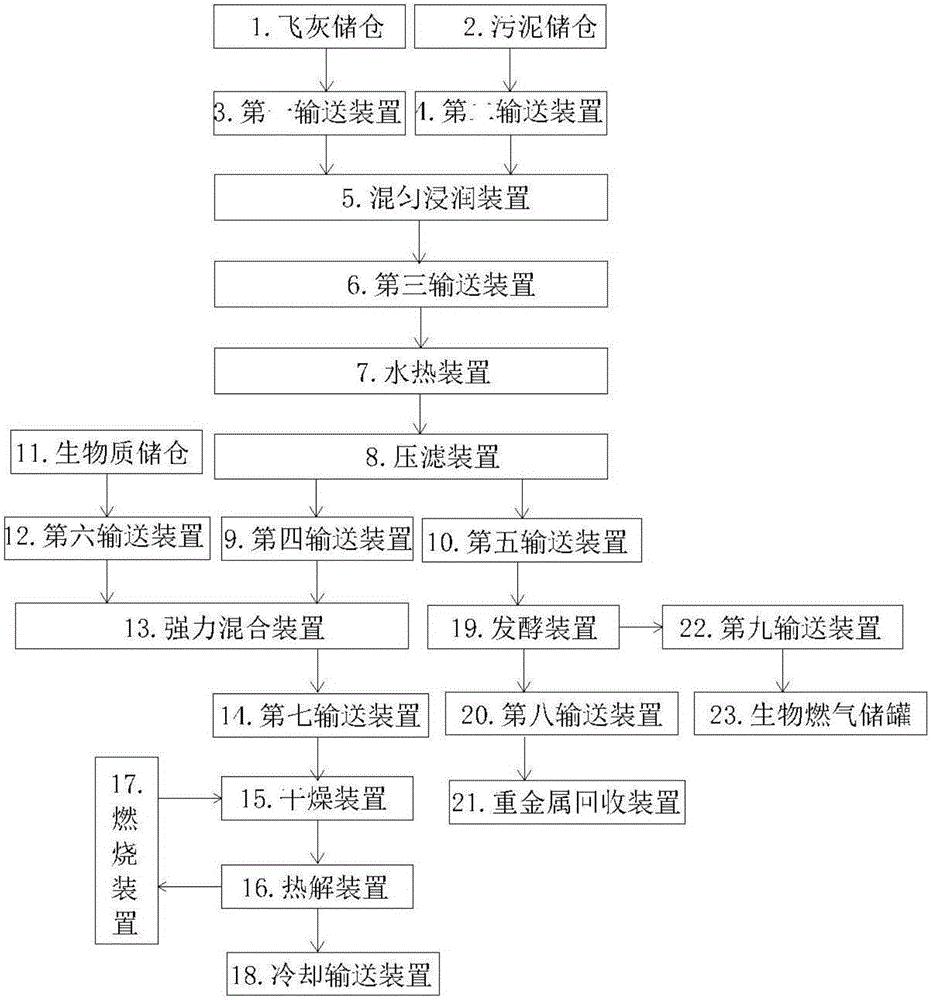

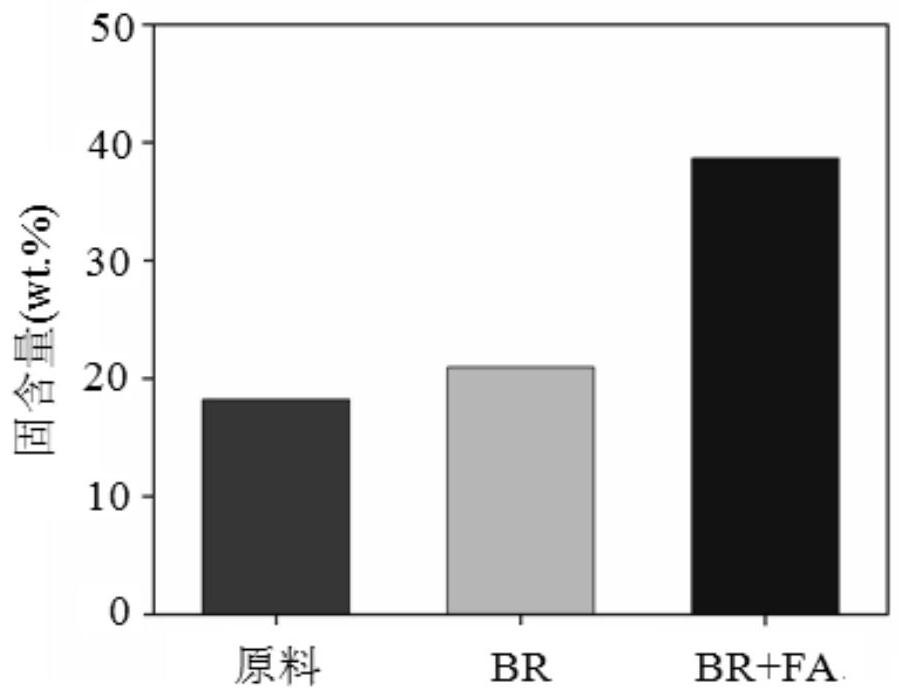

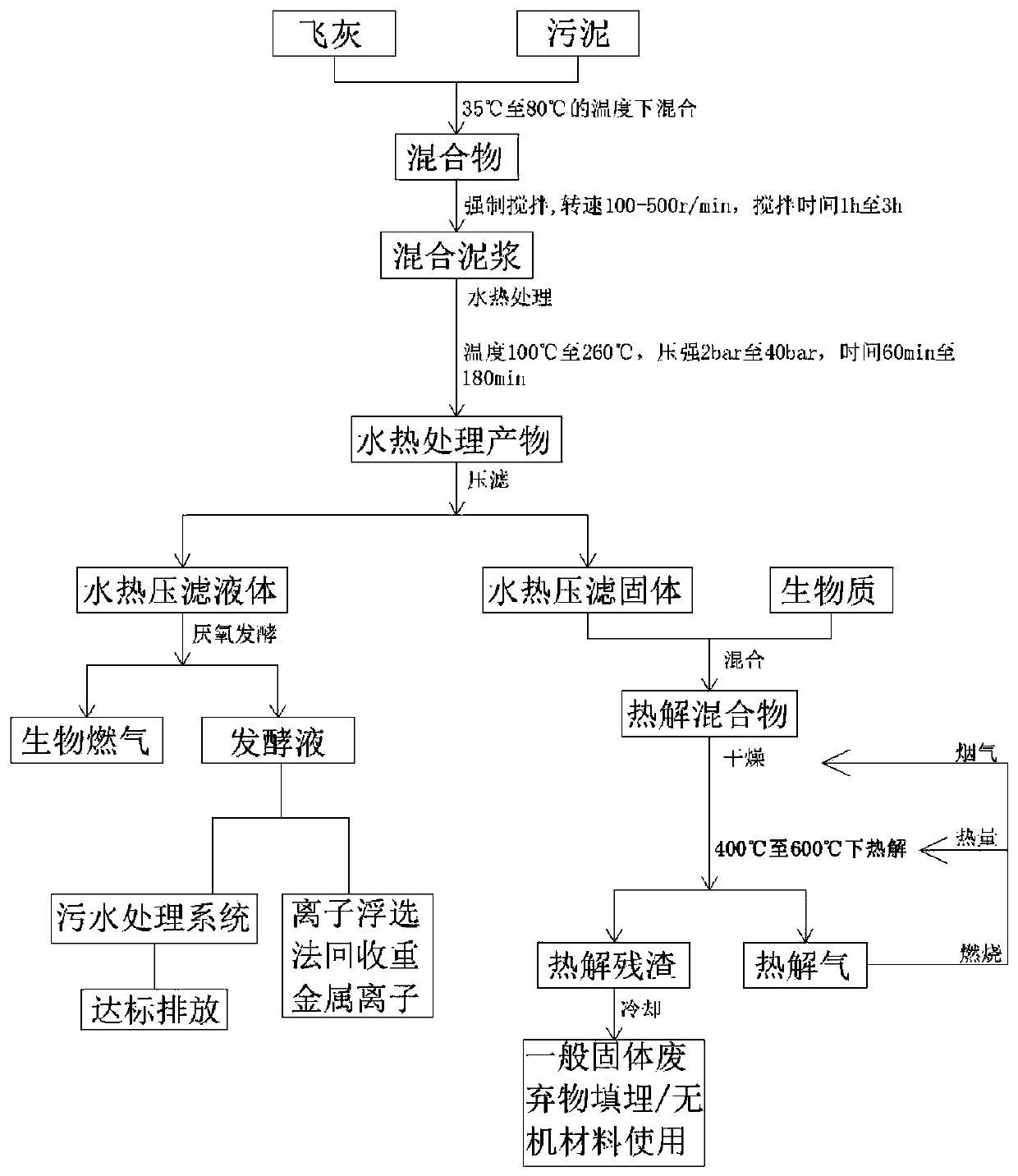

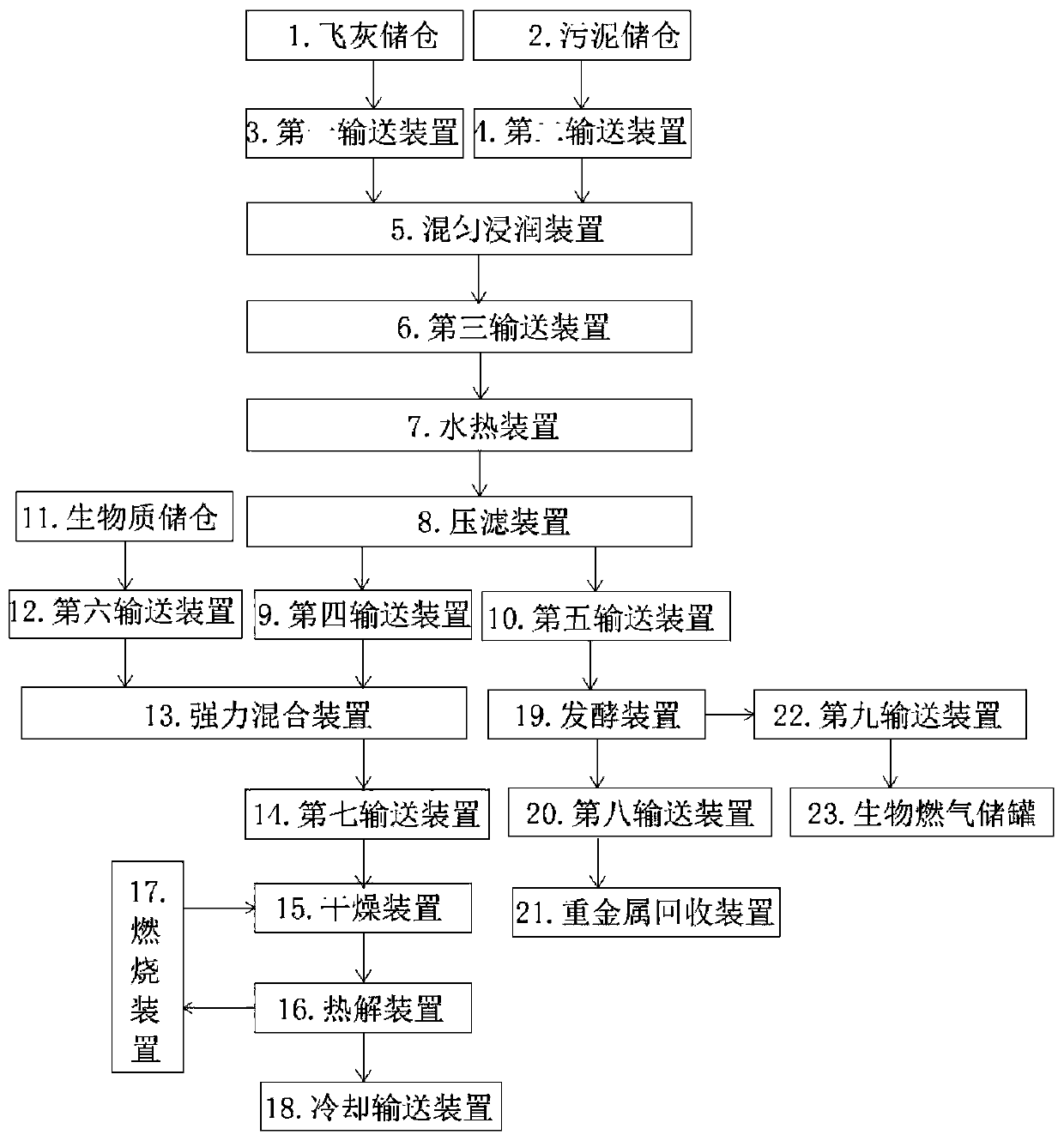

Method for treating fly sh by sludge

ActiveCN106424077AImprove dehydration efficiencyEfficient hydrolysis detoxificationSludge treatment by de-watering/drying/thickeningSolid waste disposalSludgeTreated water

The invention discloses a method and equipment for treating fly sh by sludge. The method comprises the following steps: a mixture of the fly ash and the sludge is forcedly stirred to obtain mixed mud; the mixed mud is hydrothermally treated to obtain a hydrothermal treatment product; the hydrothermal treatment product performs solid-liquid separation through a pressing filter mode to obtain hydrothermal pressing filter liquid and a hydrothermal pressing filter solid; a biomass is added in the hydrothermal pressing filter solid to form a pyrolysis mixture; the pyrolysis mixture is pyrolyzed to obtain pyrolysis residues; the pyrolysis residues serve as general solid wastes for backfilling or serve as inorganic materials for use; the hydrothermal pressing filter liquid performs anaerobic fermentation to generate gas and fermentation liquid; the fermentation liquid generated by fermentation is purified; and the treated water is qualified for emission. The invention further provides equipment for realizing the method. The method uses the sludge for realizing detoxification of the fly ash and stabilization, thoroughly eliminates dioxin substances in the fly ash to prevent secondary pollution, and realizes harmless treatment of the fly ash.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

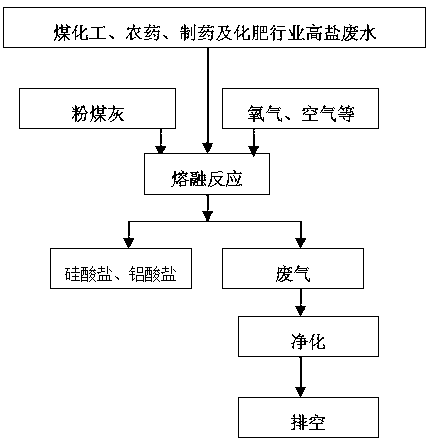

Method for harmlessly treating high-salt wastewater by using fly ash as additive

InactiveCN108571736AEasy complex conversionEasy to burn and gasifyIndirect carbon-dioxide mitigationIncinerator apparatusMelting tankChemical industry

The invention relates to a method for harmlessly treating high-salt wastewater by using fly ash as an additive, and belongs to the field of harmless treatment of dangerous waste and environment protection and the industries of coal chemical industries, fertilizer industries, agricultural chemicals industries and pharmaceutical industries. The invention provides a novel approach of harmlessly treating the high-salt wastewater by using the fly ash as the additive. The high-salt wastewater is placed in an electric stove to heat materials, a certain amount of the fly ash is added to the materialsafter the materials are in a melted state, oxidation gas is added to a melting pool through a jetting gun to perform oxygen enriched combustion of organic pollutants and the like to achieve oriented conversion of sodium salt and potassium salt in harmlessly treated organic pollutants and the like in the high-salt waste water, and purifying processing is conducted on generated fumes enriched with harmful substances such as HCL, NOX, SOX and the like to finally achieve the harmless treatment of the high-salt wastewater of the coal chemical industries, the fertilizer industries, the agriculturalchemicals industries and the pharmaceutical industries. The process of the method is simple to operate and has better industrial application prospect.

Owner:泫龙(北京)环保科技有限公司

Stabilization of at least one heavy metal contained in a sodic fly ash using a water-soluble source of silicate and a material containing calcium and/or magnesium

A treatment method for stabilizing at least a portion of at least one heavy metal contained in a sodic fly ash to reduce leachability, wherein the sodic fly ash is provided by a process whereby a sodium-based sorbent is injected in a combustion flue gas to remove pollutants therefrom. The treatment method comprises contacting the sodic fly ash with at least one water-soluble source of silicate and at least one additive comprising calcium and / or magnesium. The material obtained from the contacting step is preferably dried. The additive may be selected from the group consisting of lime kiln dust, fine limestone, quicklime, hydrated lime, dolomitic lime, dolomite, selectively calcined dolomite, hydrated dolomite, magnesium hydroxide, magnesium carbonate, magnesium oxide, and any mixture thereof. A particularly preferred additive comprises lime kiln dust and / or dolomitic lime. The heavy metal to be stabilized in the sodic fly ash may comprise selenium and / or arsenic.

Owner:SOLVAY SA

Treatment method for coal fly ash

InactiveUS20170113085A1Reduce sodiumReduce LeachabilityGas treatmentSolid waste managementSilicic acidDolomite

A treatment method for coal fly ash, and in particular sodic fly ash, comprises 1) contacting the coal fly ash with anhydrite, and 2) contacting the coal fly ash in the presence of water with at least one additive. The material obtained from the contacting steps (1) and (2) may be dried. The steps (1) and (2) may be carried simultaneously or sequentially. The additive may comprise at least one component selected from the group consisting of strontium-containing compounds, barium-containing compounds, dolomite, a dolomite derivative such as calcined or hydrated dolomite, water-soluble sources of silicate such as sodium or potassium silicate, iron-containing compounds, and any combinations thereof. A particularly preferred additive comprises sodium silicate. The method may be effective in reducing the sodium content in the fly ash (Na2O), reducing the alkalinity of the fly ash, and / or stabilizing at least one heavy metal such as selenium and / or arsenic to reduce their leachability.

Owner:SOLVAY SA

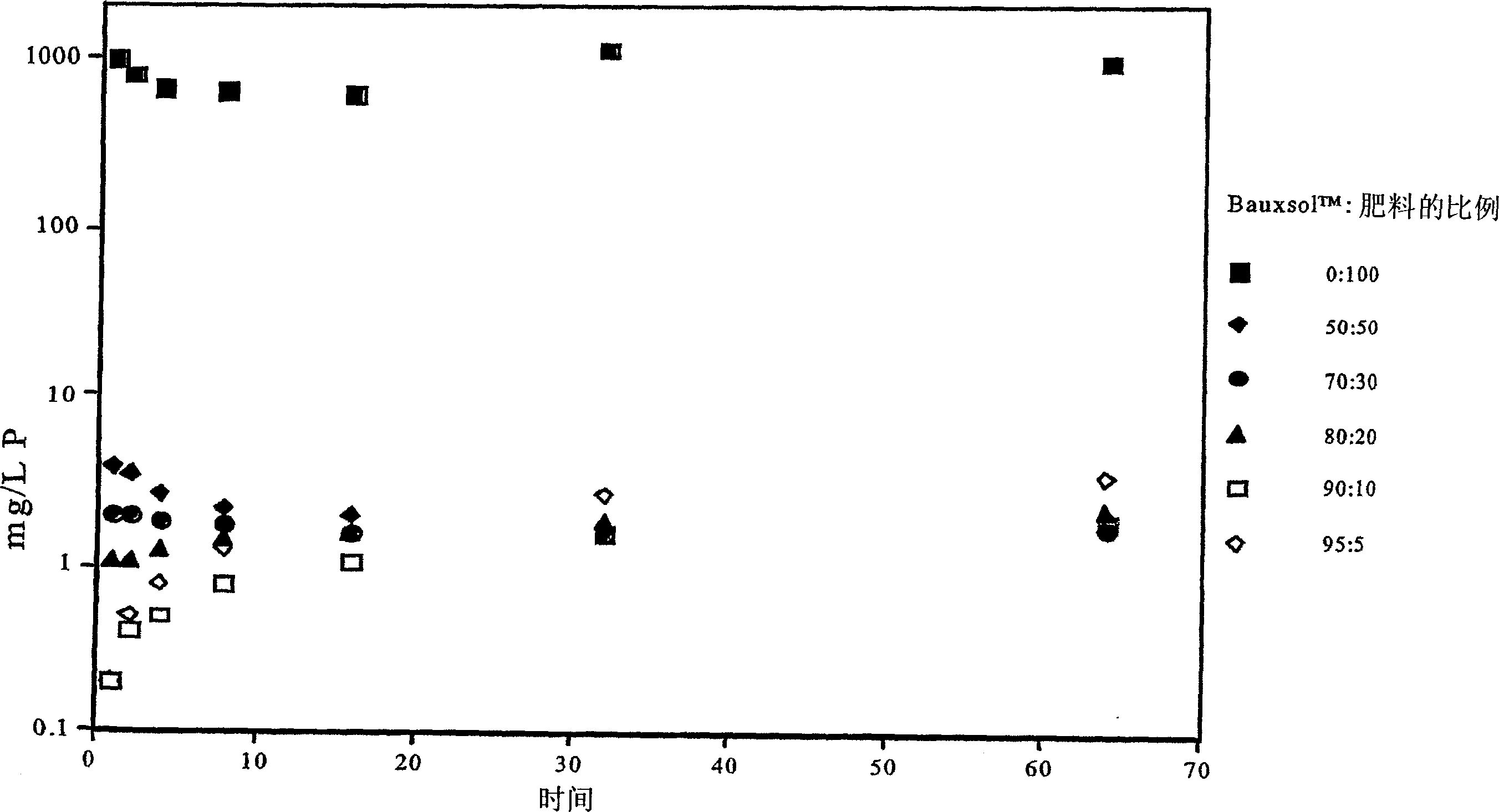

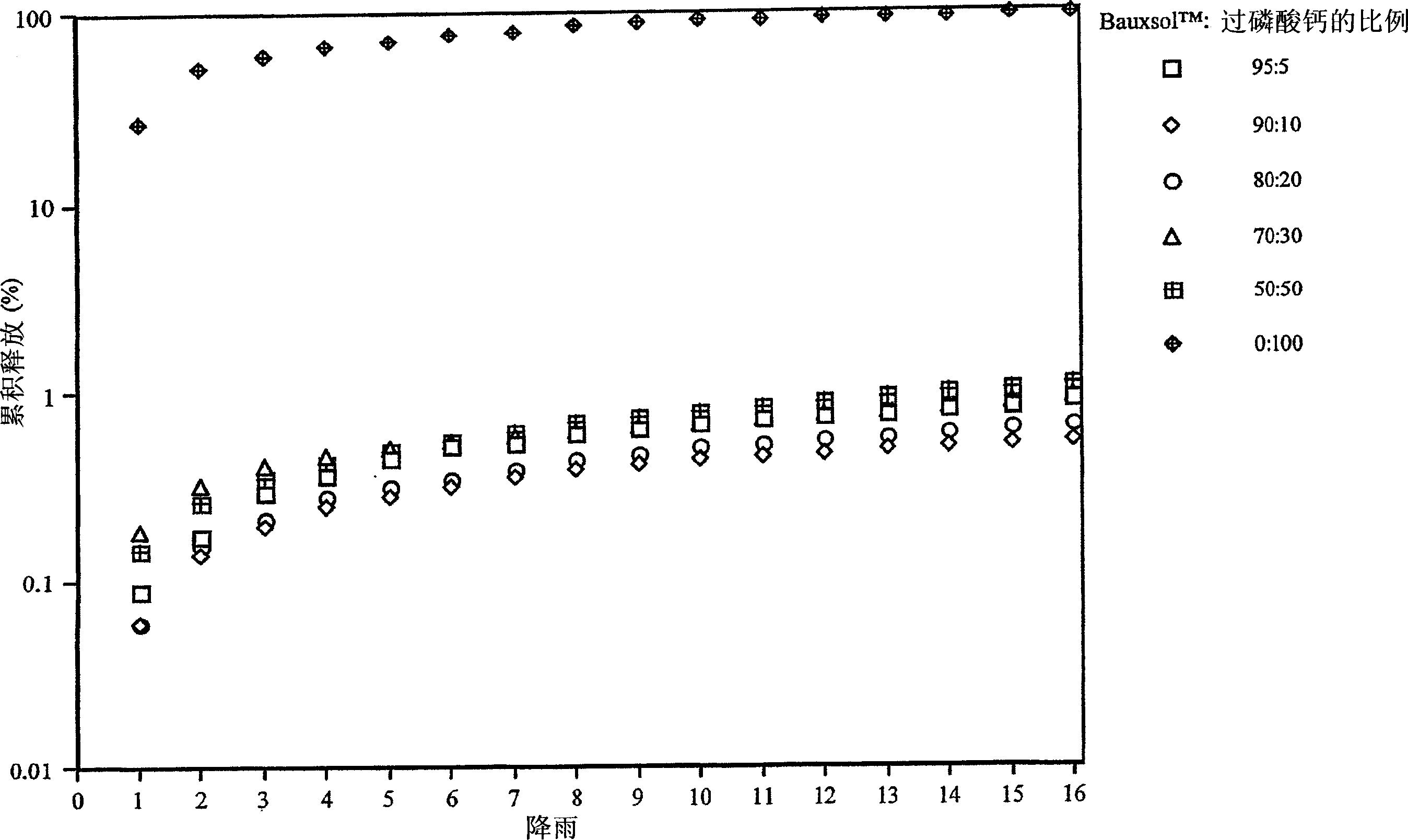

Fertilizer

Owner:MT ASPIRING GEOCHEMISTRY CONSULTANTS PTY LTD

Method for producing brick from oil sludge and coal gangue

InactiveCN101891452ASave clay resourcesEnergy savingCeramic materials productionClaywaresCoal gangueWaste treatment

The invention relates to a method for producing a brick from oil sludge and coal gangue as raw materials. The brick comprises the following components in percentage by weight: 10 to 20 percent of oilfield oil sludge, 10 to 30 percent of coal gangue, 40 to 65 percent of clay, 5 to 20 percent of water and 0.5 to 3 percent of modifying additive. The method comprises the following steps of: stirring the components uniformly in a stirring device to form a semi-finished brick blank, and drying and roasting the brick blank to form a finished product of the brick. By combining an internal combustion process for manufacturing the brick by sintering and making full use of heat values of the oil sludge and the coal gangue, the method reduces external fuels during roasting, saves a large amount of energy, meanwhile solves the treatment problem of the oil sludge and the coal gangue, and protects the environment. The brick manufacturing method is simple, has low cost, realizes reduced, harmless and recycling requirements of solid waste treatment, and has good market prospect and popularization value.

Owner:SHANDONG UNIV OF SCI & TECH

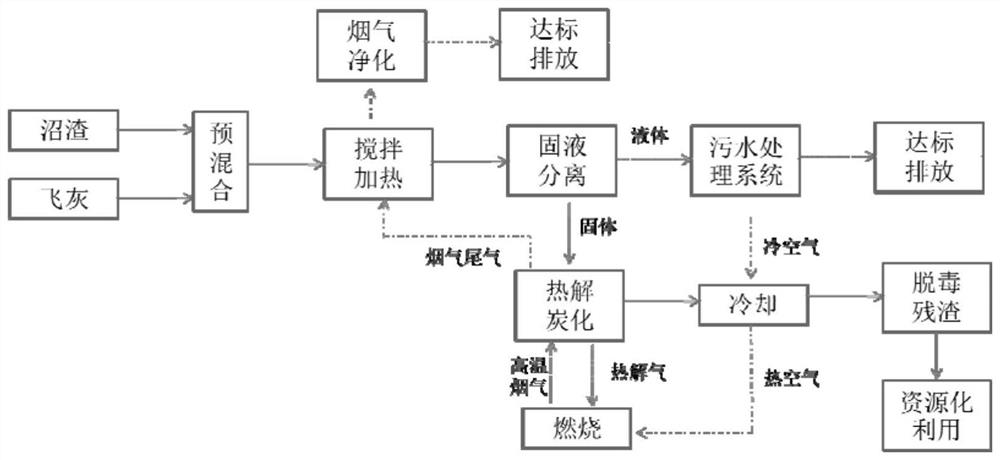

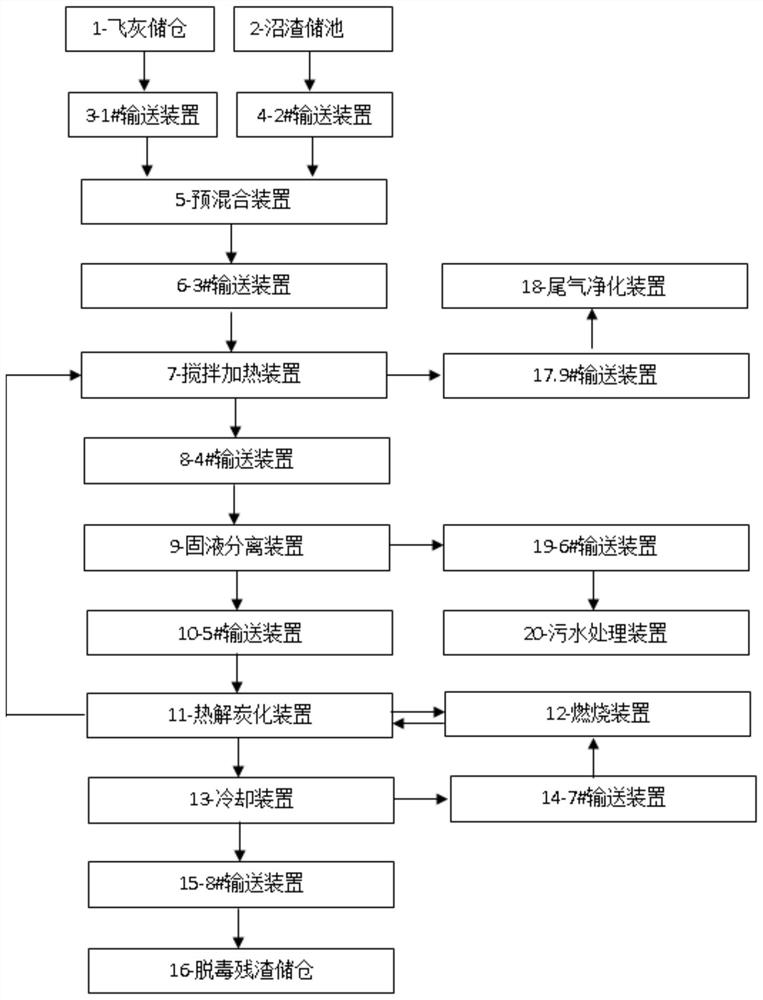

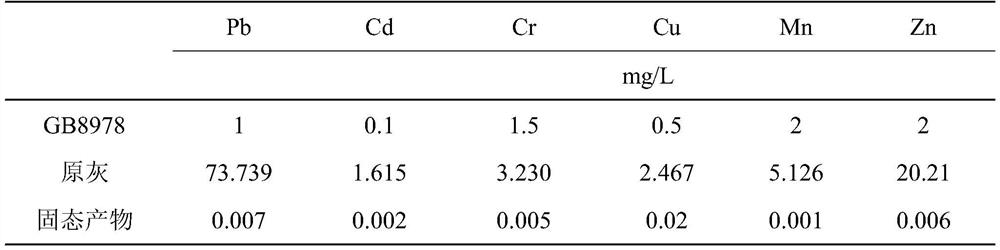

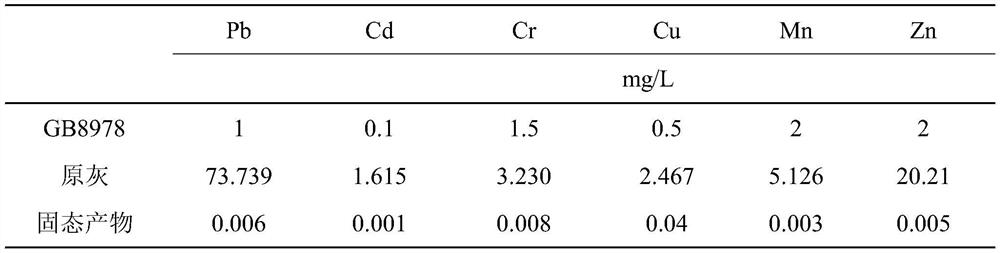

Fly ash detoxification treatment method and equipment

PendingCN112275783AImprove dehydration efficiencyImprove stabilityWaste processingTransportation and packagingBrickSewage

The invention belongs to the technical field of fly ash treatment, and relates to a fly ash detoxification treatment method and equipment. The fly ash detoxification treatment method comprises: uniformly mixing fly ash and biogas residues, forcibly stirring to obtain premixed mortar, heating and stirring the premixed mortar for 0.5-1 hour at 100-180 DEG C under a closed condition to obtain heatedmortar, and performing solid-liquid separation on the heated mortar to obtain a liquid and a solid; treating the liquid with sewage until the liquid reaches the standard, and discharging the treated liquid; and pyrolyzing the solid at 400-600 DEG C to obtain pyrolyzed residues, wherein the pyrolyzed residues are used as solid wastes for landfill or used as inorganic materials for preparing ceramics or sintered bricks. According to the method, detoxification of the fly ash can be implement by using the biogas residues, and stable solidification of heavy metal is implemented, so that dioxin substances in the fly ash are thoroughly eliminated, and secondary pollution is avoided; and efficient dehydration of the biogas residues and synergistic resource utilization of dehydration products can be implemented by using the fly ash, so that the problem of low-cost treatment of the fly ash and the biogas residues is solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

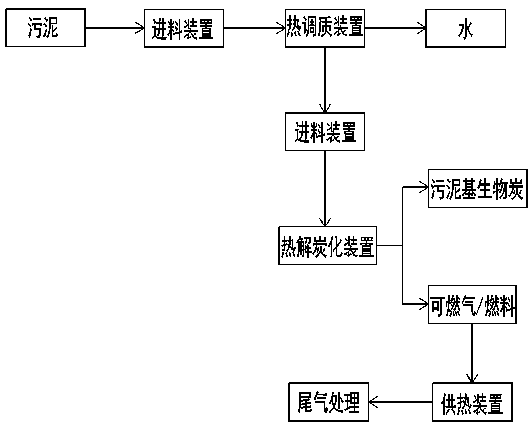

Municipal sludge pyrolysis treatment packaged technology and device thereof

PendingCN108911459AAchieve balanceAvoid secondary pollutionSludge treatment by pyrolysisByproduct vaporizationSludgeResource utilization

The invention discloses a municipal sludge pyrolysis treatment device for whole-course closed negative pressure, solidifying heavy metal in sludge and avoiding secondary pollution so as to overcome the defect that a traditonal treatment method of municipal sludge is easy to cause secondary pollution. Meanwhile, the invention also discloses a municipal sludge pyrolysis treatment packaged technologywith the application of the above device, comprising the following processes: a thermal tempering separation process, a pyrolysis carbonization process and a tail gas treatment process. By the technology and the device, resource utilization of municipal sludge can be realized, cyclic development of ''treating waste by waste'' can be achieved, energy recycling of municipal sludge is realized, andexternal energy is reduced. By the whole technological process, heat balance can be realized, and secondary environmental pollution is avoided.

Owner:SHANDONG YONGJIN ENERGY SAVING TECH CO LTD

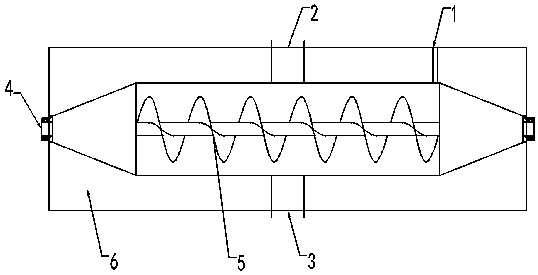

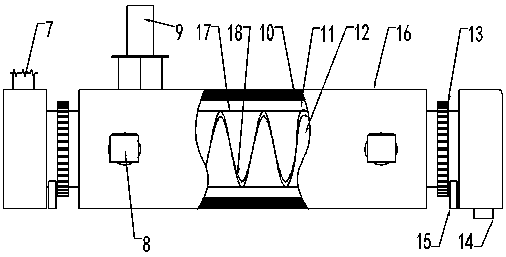

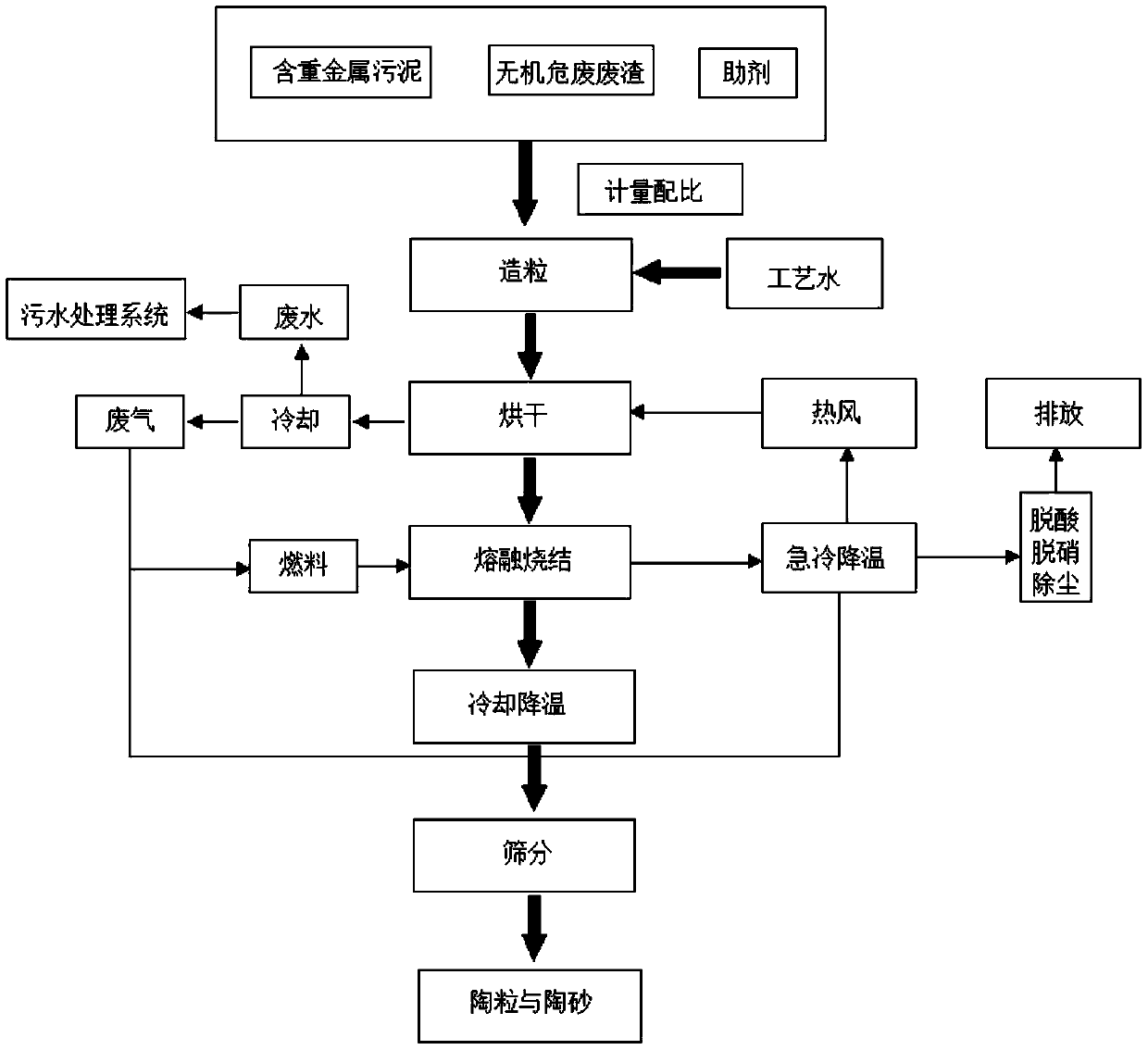

Process for preparing building ceramsite by synergistically melting and sintering various inorganic hazardous wastes

The invention discloses a process for preparing the building ceramsite by synergistically melting and sintering of multiple inorganic hazardous wastes. The process comprises the steps of synergistically mixing the powdery and muddy inorganic hazardous waste, the inorganic residues obtained after hazardous waste treatment, a high-salt content concentrated solution obtained after sewage treatment and as the process water and an inorganic auxiliary agent, and drying after granulation; taking the organic hazardous wastes, such as the waste lubricating oil, the mineral oil and the hazardous waste pyrolysis oil, etc., as fuels, melting and sintering, recycling a carrier gas during a pellet drying process; cooling the sintered product, and screening to obtain the ceramsite and the pottery sand. The ceramsite can be used as a roadbed material, a concrete aggregate, a light brick filling material and a raw material required by a cement for mixture and production. According to the process, the purposes of harmless treatment and final resource utilization of various inorganic hazardous wastes are achieved, the problems that the single inorganic hazardous waste treatment is high in investment,the technological process is long, the residues are difficult to treat and the like are solved, and the secondary pollution emission during the hazardous waste treatment process is greatly reduced.

Owner:中原环资科技有限公司

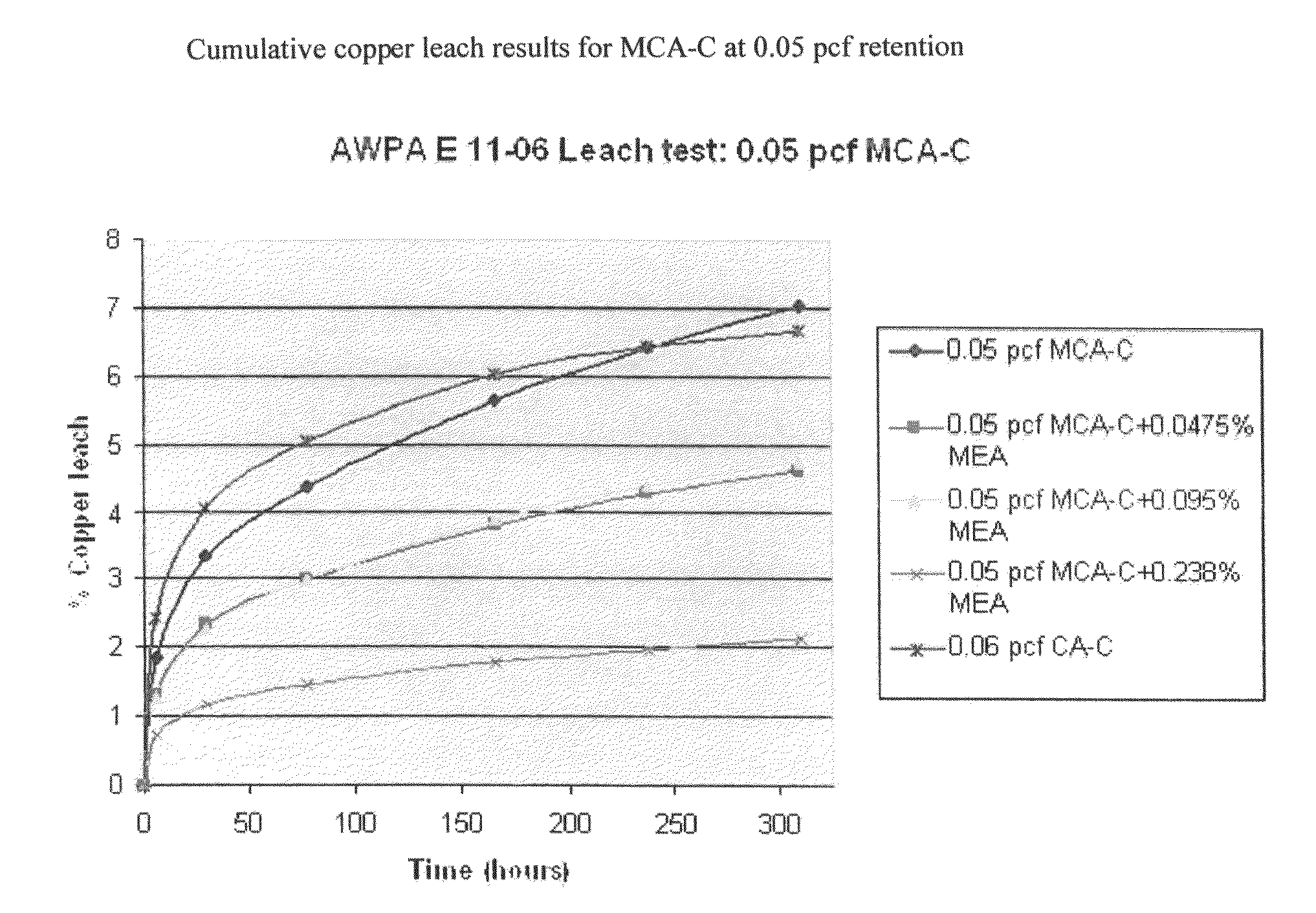

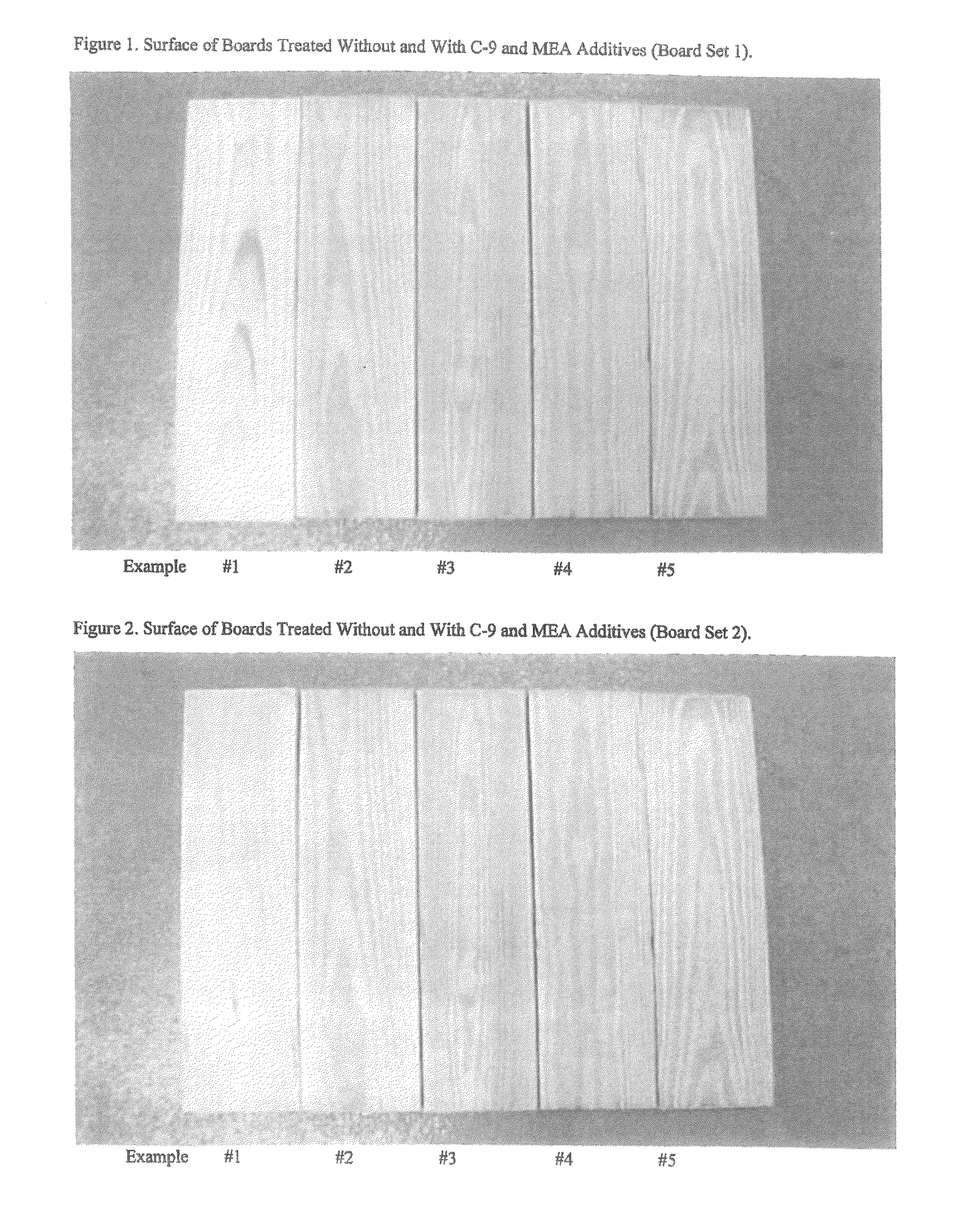

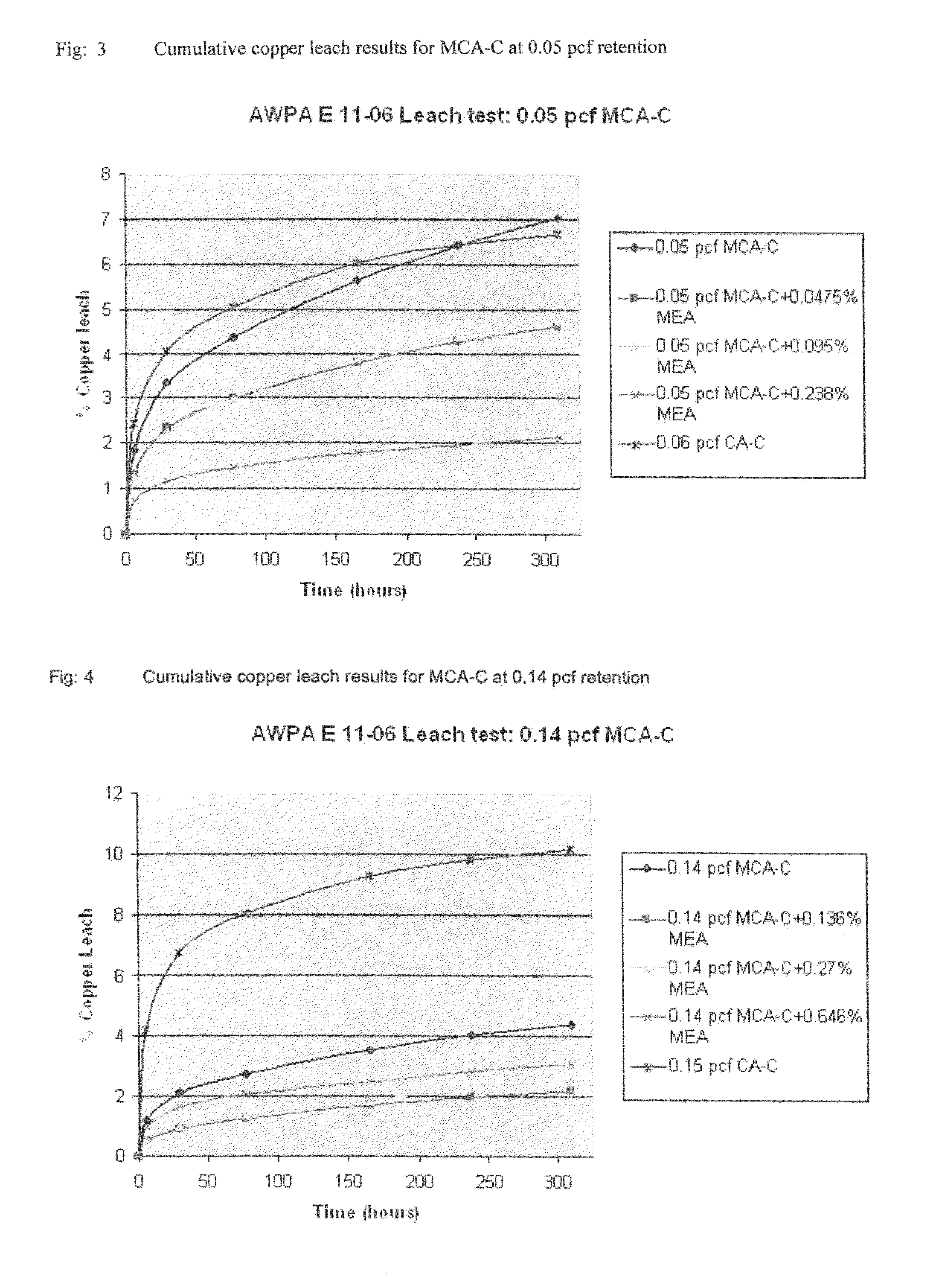

Micronized copper-containing compositions useful to mitigate residues on wood surfaces

ActiveUS8293282B2Reduce LeachabilityImprove efficacyBiocideLiquid surface applicatorsPreservativeSlurry

Owner:ARCH WOOD PROTECTION

Method and reagents for treating materials contaminated with mercury, pfas, or other contaminants

ActiveUS20200338378A1Reduce LeachabilityReduce releaseSolid waste disposalTransportation and packagingDisposal wasteSorbent

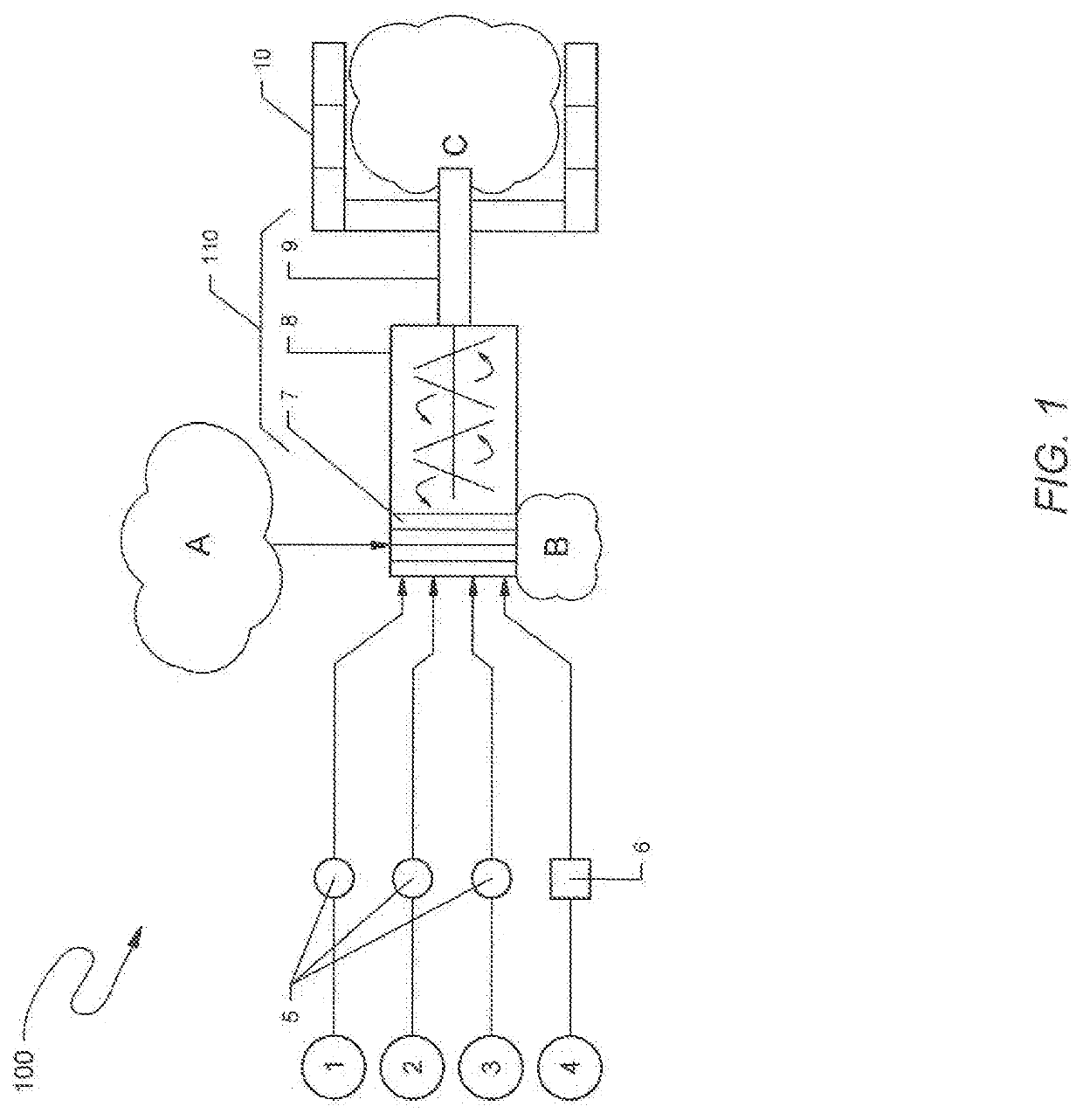

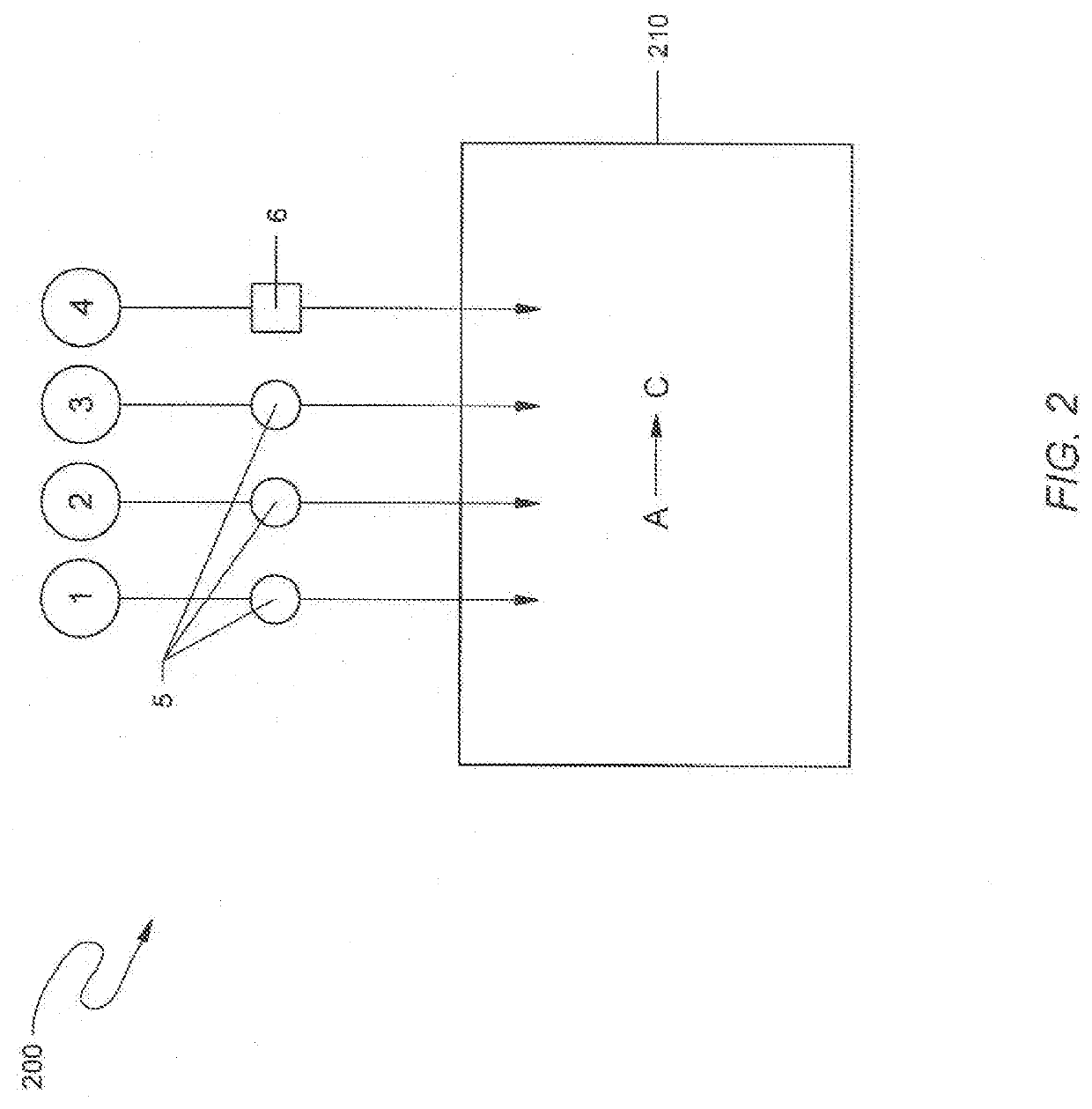

A reagent set includes an oxidant, acid, and adsorbent, which is used in a method for reducing the leachability and release of PFAS, mercury, and other contaminants from soils, sediments, and other solid materials or waste when treated materials are exposed to acid rain, snow melt, runoff, landfill leachate, etc. The reagents are mixed with a quantity of contaminated material and water is added as needed in order to reduce the leachability of the contaminants from the treated host material, where the admixture end-product suitably removes contaminants from fluids that contact and / or otherwise permeate and / or pass through and / or around the treated admixture. The reagent set and method of use offer environmental professionals long-term, economically viable waste management solutions for removing contaminants from contamination source areas, spill and manufacturing release sites, impacted media, and landfills, as well as from the fluids that contact reagent-treated material.

Owner:HMR SOLUTIONS INC

Stabilization of sodic fly ash of type f using calcium-based material

A treatment method for stabilizing a sodic fly ash to reduce their leachability which is provided by a combustion process when a sodium-based sorbent comes in contact with a flue gas generated by combustion to remove at least a portion of pollutants contained in the flue gas. The treatment method comprises contacting the sodic fly ash with at least one additive comprising calcium. The material obtained from the contacting step is preferably dried. The material may be selected from the group consisting of lime kiln, dust, fine limestone, quicklime, hydrated lime, dolomitic lime, dolomite, selectively calcined dolomite, hydrated dolomite, and any mixture of two or more thereof. A particularly preferred additive comprises lime kiln dust.

Owner:SOLVAY SA

A method of using sludge to treat fly ash

ActiveCN106424077BImprove dehydration efficiencyEfficient hydrolysis detoxificationSludge treatment by de-watering/drying/thickeningSolid waste disposalSludgeTreated water

The invention discloses a method and equipment for treating fly sh by sludge. The method comprises the following steps: a mixture of the fly ash and the sludge is forcedly stirred to obtain mixed mud; the mixed mud is hydrothermally treated to obtain a hydrothermal treatment product; the hydrothermal treatment product performs solid-liquid separation through a pressing filter mode to obtain hydrothermal pressing filter liquid and a hydrothermal pressing filter solid; a biomass is added in the hydrothermal pressing filter solid to form a pyrolysis mixture; the pyrolysis mixture is pyrolyzed to obtain pyrolysis residues; the pyrolysis residues serve as general solid wastes for backfilling or serve as inorganic materials for use; the hydrothermal pressing filter liquid performs anaerobic fermentation to generate gas and fermentation liquid; the fermentation liquid generated by fermentation is purified; and the treated water is qualified for emission. The invention further provides equipment for realizing the method. The method uses the sludge for realizing detoxification of the fly ash and stabilization, thoroughly eliminates dioxin substances in the fly ash to prevent secondary pollution, and realizes harmless treatment of the fly ash.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

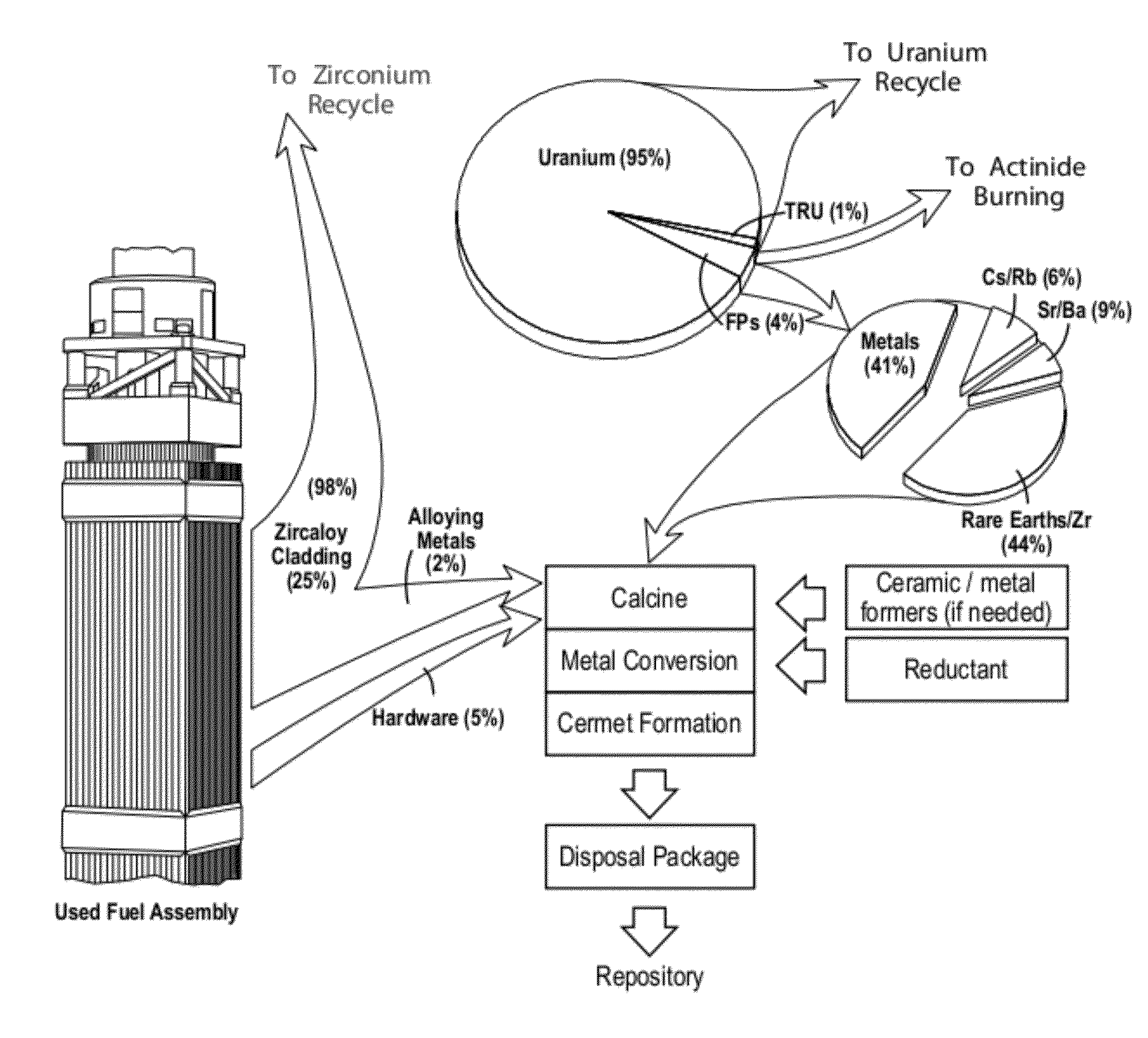

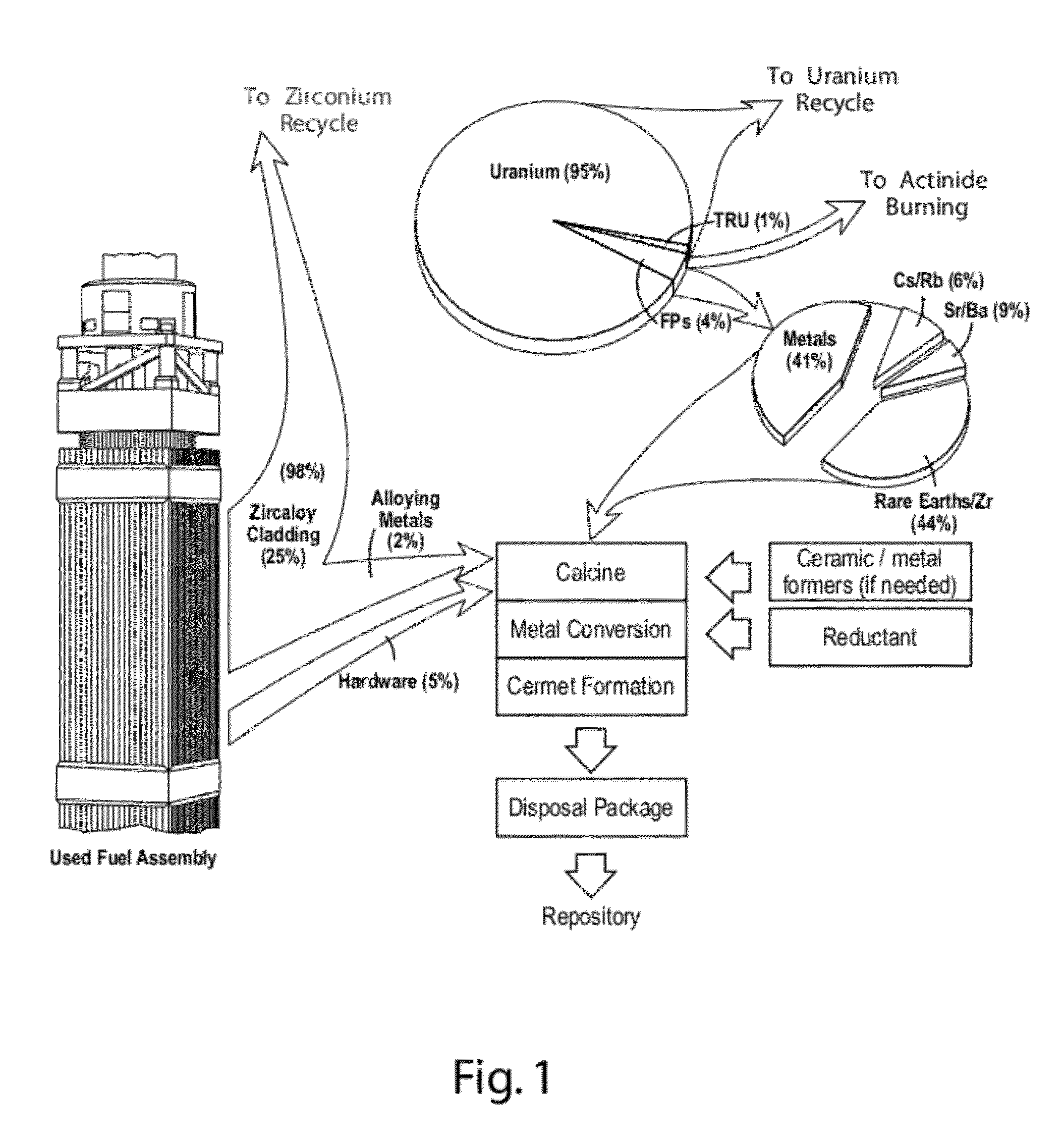

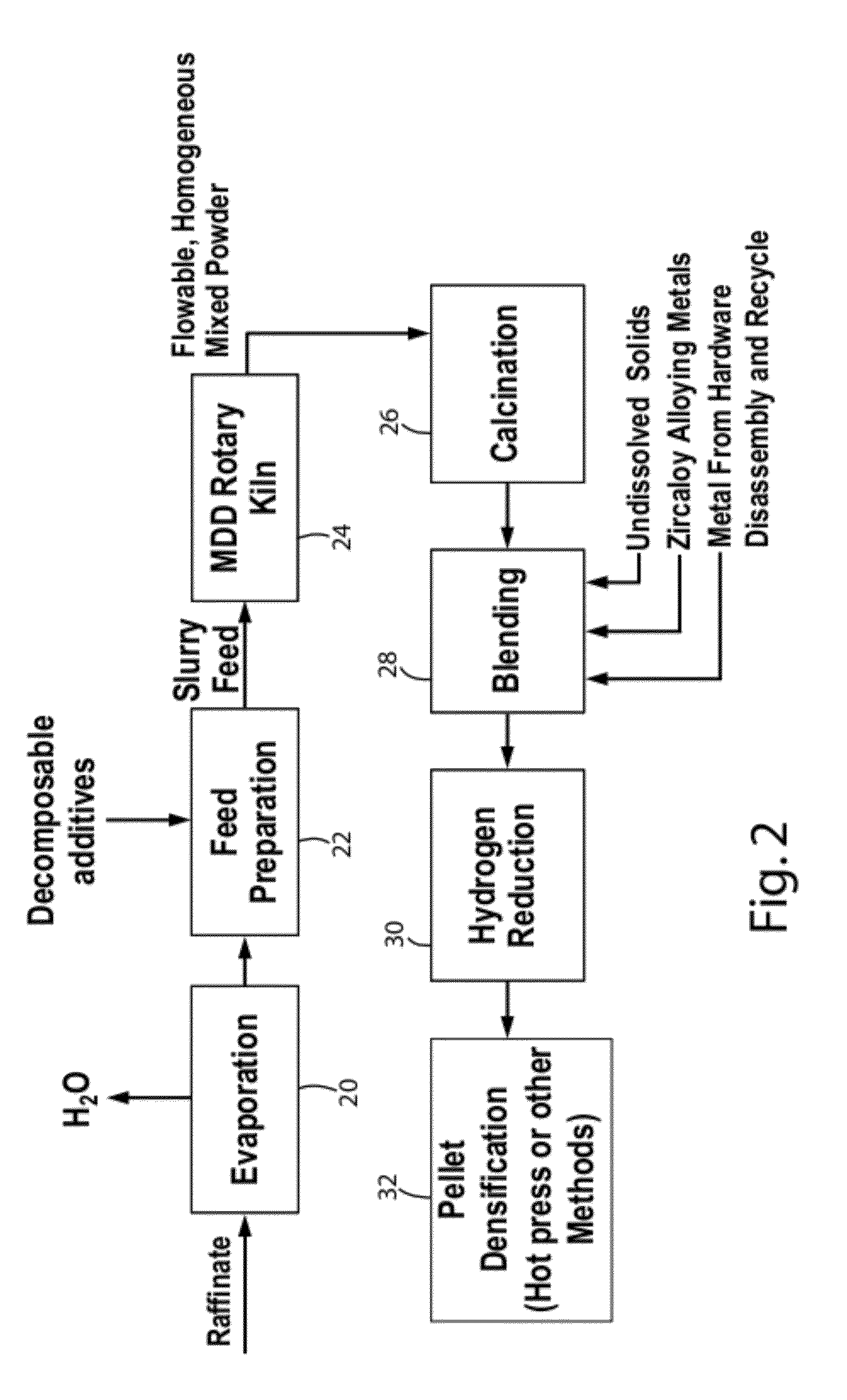

Cermet high level waste forms

A system and method for stabilizing fission products in a cermet for long term storage. The method includes forming a metal oxide precipitate, combining the metal oxide precipitate with an undissolved solid, and densifying the combined metal oxide precipitate and the undissolved solid to provide a cermet having a ceramic dispersed phase and a metallic matrix phase, wherein the metallic matrix phase includes metallic content from the undissolved solid. The undissolved solid can include fission product metals from the reprocessing of irradiated nuclear fuel. The cermet waste loading can be greater than approximately 30 percent, reducing waste volume by 50 percent or more when compared to baseline glassified articles.

Owner:UT BATTELLE LLC

Co-processing method for household garbage incineration fly ash and yellow iron tailings

ActiveCN113458127AAchieve effectivenessPrevents oxidative re-acidificationSolid waste disposalBulk chemical productionCatalytic oxidationMagnetite

The invention discloses a co-processing method for household garbage incineration fly ash and yellow iron tailings. The method comprises the following steps of S1, mixing yellow iron tailing sand with the fly ash to prepare slurry; S2, putting the slurry into a reaction kettle, and sequentially carrying out a hydrothermal reaction stage, a transition stage and a supercritical oxidation reaction stage; S3, carrying out solid-liquid separation on the treated slurry to obtain a solid product and filtrate; and S6, excavating surface tailing sand from a pyrite tailing pond site; covering the pyrite tailing pond site with solid products and compacting the solid products to serve as a tailings covering layer; and using the tailing covering layer to prevent oxygen and rainwater from infiltrating, and neutralizing the yellow iron tailing sand below the tailing covering layer by utilizing the alkalinity of the tailing covering layer. A vegetation planting layer is laid on the tailing covering layer; and the vegetation planting layer is obtained by mixing surface tailing sand, the solid products obtained in S5, a water-retaining agent and an organic fertilizer. According to the method, magnetite can be generated in the hydrothermal reaction process by utilizing ferrous ions of the yellow iron tailing sand; and the magnetite can catalytically oxidize dioxin in the presence of ozone.

Owner:杭州灰弘环保科技有限公司

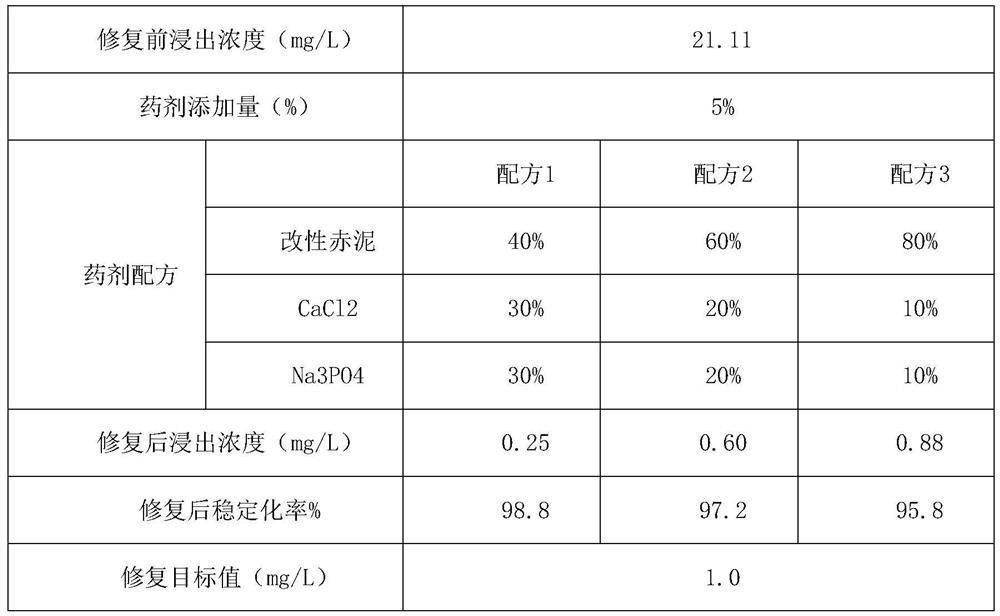

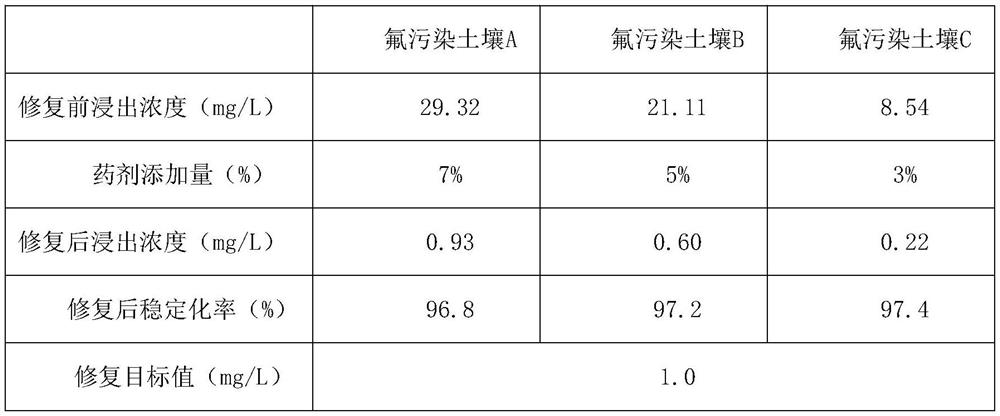

Fluorine-polluted soil remediation agent and laboratory application method

PendingCN113020242ASolve the problem of environmental emissionsLow costContaminated soil reclamationOrganic fertilisersSoil remediationEnvironmental engineering

The invention discloses a fluorine-polluted soil remediation agent and a laboratory application method, wherein the fluorine-polluted soil remediation agent comprises 40-80 wt% of modified red mud, 10-30 wt% of CaCl2 and 10-30 wt% of a phosphorus-based substance; CaCl2 and the phosphorus-based substance are added into the modified red mud, ball milling is performed for 0.5 h in a planetary ball mill, a ball milling product is sieved by a 100-mesh sieve, and undersize is a remediation agent. According to the method, the high-purity and high-stability fluorine-polluted soil remediation agent is prepared through a simple process, so that the use dosage cost of relative fluorine equivalent is reduced, meanwhile, the curing effect on fluorine is better, the utilization rate of raw materials is increased, the production cost is reduced, and the leaching capacity on fluorine is reduced.

Owner:中铝环保生态技术(湖南)有限公司

Stabilization of sodic fly ash of type F using calcium-based material

A treatment method for stabilizing a sodic fly ash to reduce their leachability which is provided by a combustion process when a sodium-based sorbent comes in contact with a flue gas generated by combustion to remove at least a portion of pollutants contained in the flue gas. The treatment method comprises contacting the sodic fly ash with at least one additive comprising calcium. The material obtained from the contacting step is preferably dried. The material may be selected from the group consisting of lime kiln, dust, fine limestone, quicklime, hydrated lime, dolomitic lime, dolomite, selectively calcined dolomite, hydrated dolomite, and any mixture of two or more thereof. A particularly preferred additive comprises lime kiln dust.

Owner:SOLVAY SA

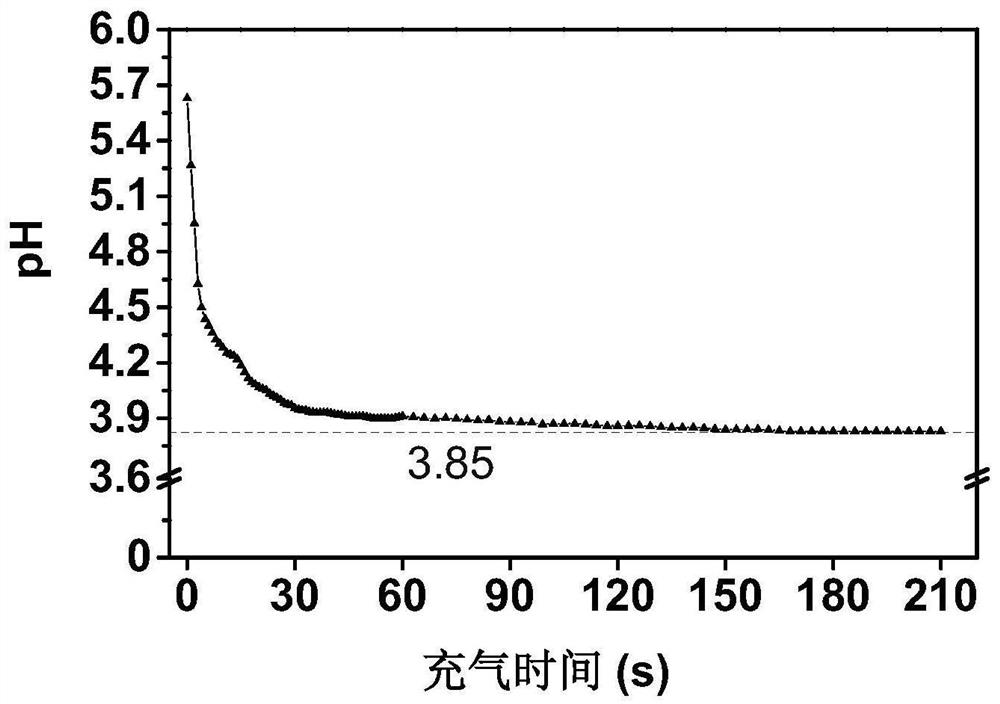

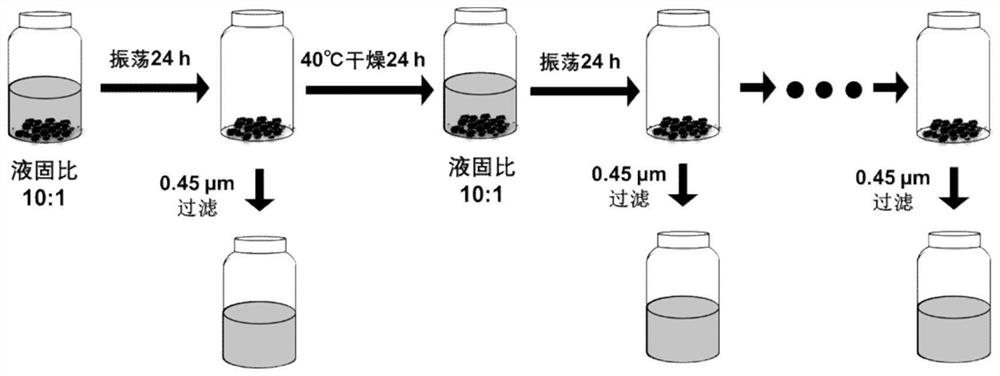

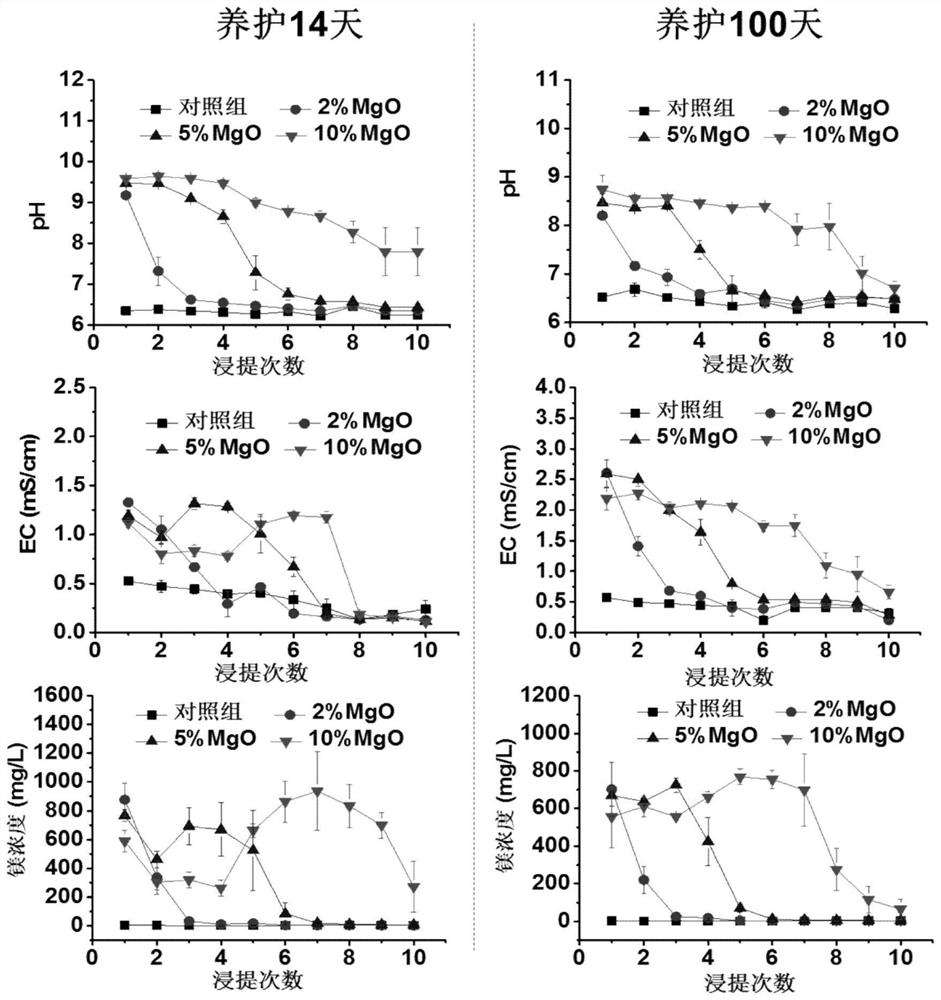

Long-acting evaluation method for active magnesium oxide solidified/stabilized zinc-containing smelting slag based on carbonation accelerated exposure

The invention discloses a long-acting evaluation method for active magnesium oxide solidified / stabilized zinc-containing smelting slag based on carbonation accelerated exposure. The long-acting evaluation method comprises the following steps: adding active magnesium oxide to carry out solidification / stabilization treatment on the zinc-containing smelting slag, and maintaining; the method comprises the following steps: preparing saturated CO2 water, measuring the pH value, carrying out accelerated carbonation continuous extraction on zinc-containing smelting slag after active magnesium oxide treatment and untreated zinc-containing smelting slag, and measuring the pH value, the conductivity, the magnesium ion concentration and the zinc ion concentration of an extract liquid; based on the change rule of pH, conductivity and magnesium ions in the leaching solution, determining the number of times of accelerated carbonation leaching; and based on the corresponding relation between the average concentration of the accumulated leaching liquid zinc and the accumulated carbonic acid exposure, the endurance capacity of the repaired slag body to carbonic acid is evaluated. According to the method, an accelerated carbonation exposure test is designed, key environmental factors influencing the release behavior of zinc in the active magnesium oxide solidified / stabilized zinc-containing smelting slag are considered, and the long-term activation risk of zinc in the smelting slag after solidification / stabilization repair is systematically evaluated.

Owner:NANJING NORMAL UNIVERSITY

Waste incineration power generation fly ash solidification method

ActiveCN113402217AImprove bindingHigh compressive strengthSolid waste managementSolid waste disposalSilane couplingBuilding material

The invention discloses a waste incineration power generation fly ash solidification method which comprises the following steps: S1, mixing fly ash, ground phosphate rock and hydrolysate of a silane coupling agent containing an epoxy group, standing for reaction, and drying to obtain a fly ash premix; s2, mixing the fly ash premix with an aqueous solution of gelatin, heating and stirring for reaction, and drying to obtain a fly ash mixture; and S3, mixing the fly ash mixture with cement, adding a proper amount of water, uniformly stirring, and standing and curing in a mold to form a cured body. According to the solidification method, the compressive strength of the fly ash cement solidification body can be improved, the leaching property of heavy metal impurities in the solidification body is reduced, the obtained solidification body can meet the requirement for being used as a building material under the condition that the fly ash is high in mixing amount, efficient, energy-saving and economical recycling of the waste incineration power generation fly ash is facilitated, and the economic benefit is increased. The actual use requirements are met.

Owner:HEFEI UNIV

Flame-retardant protective coating for rubber and plastic products and preparation method thereof

ActiveCN110128918BGood dispersionReduced ability to migrateFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePolystyrene

The invention discloses a rubber and plastic product flame-retardant protective coating and a preparation method thereof. The protective coating comprises the following components by mass: 100 parts of a polar polymer, 0.5-20 parts of two-dimensional nano filler, 5-50 parts of flame retardant, 0.01-10 parts of amine compound, 1-50 parts of polyphenol compound and 0.01-10 parts of polyvalent metalsalt. The preparation method comprises the following steps: 1) adding the two-dimensional nano-filler, the flame retardant, the amine compound, the polyphenol compound and the polyvalent metal salt into a solvent A, and performing a reaction under certain conditions to perform coating modification on the two-dimensional nano-filler and the flame retardant to obtain dispersion liquid A; 2) dispersing the polar polymer in a solvent B under certain conditions to obtain a dispersion liquid B, the solvent A and the solvent B being the same or being mutually soluble; and 3) mixing the dispersion liquid A and the dispersion liquid B under certain conditions to obtain the flame-retardant protective coating which can be brushed on the surfaces of expanded polystyrene thermal insulation foam, staticrubber products and the like to form a flame-retardant protective coating.

Owner:QINGDAO UNIV OF SCI & TECH

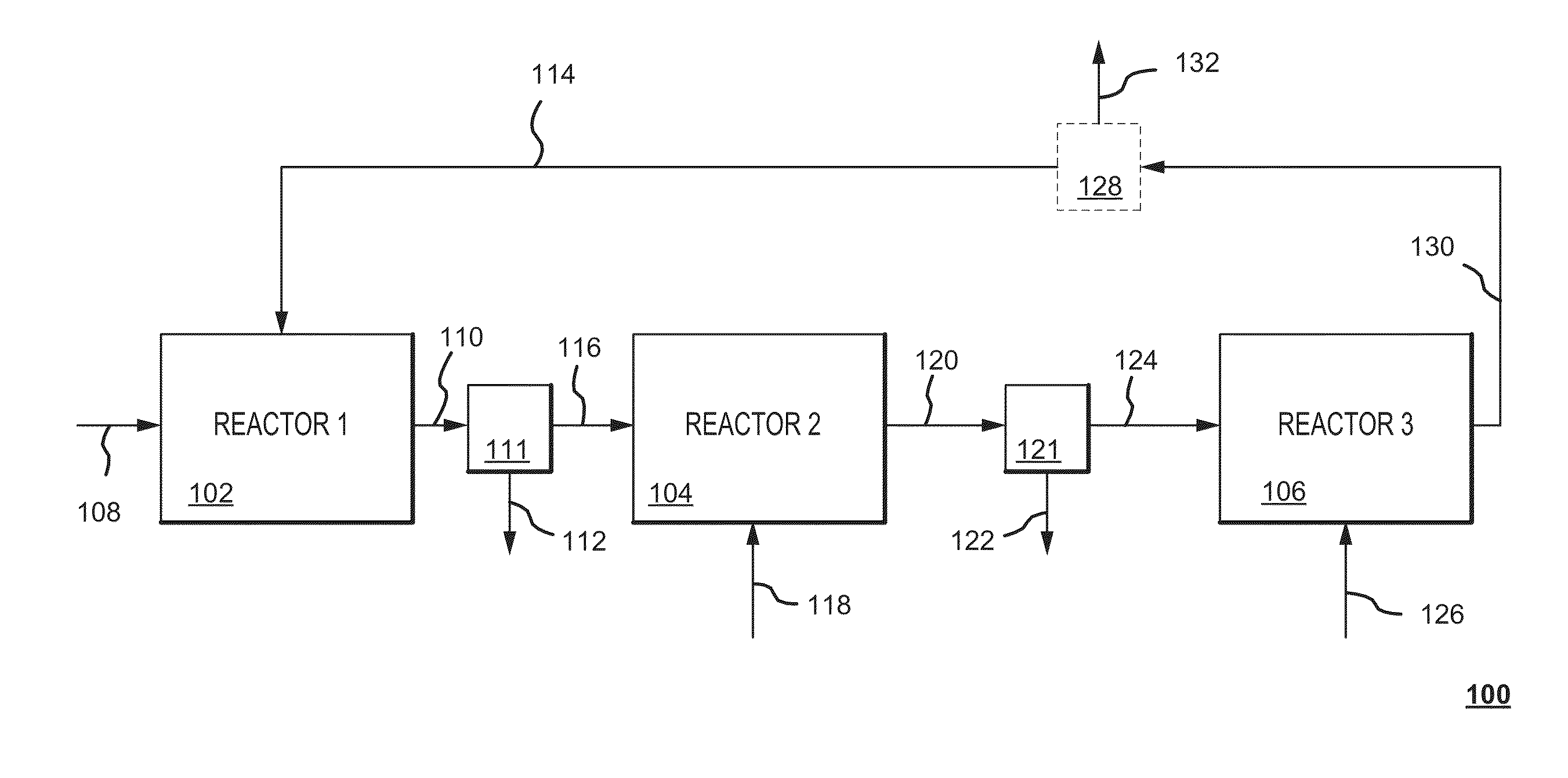

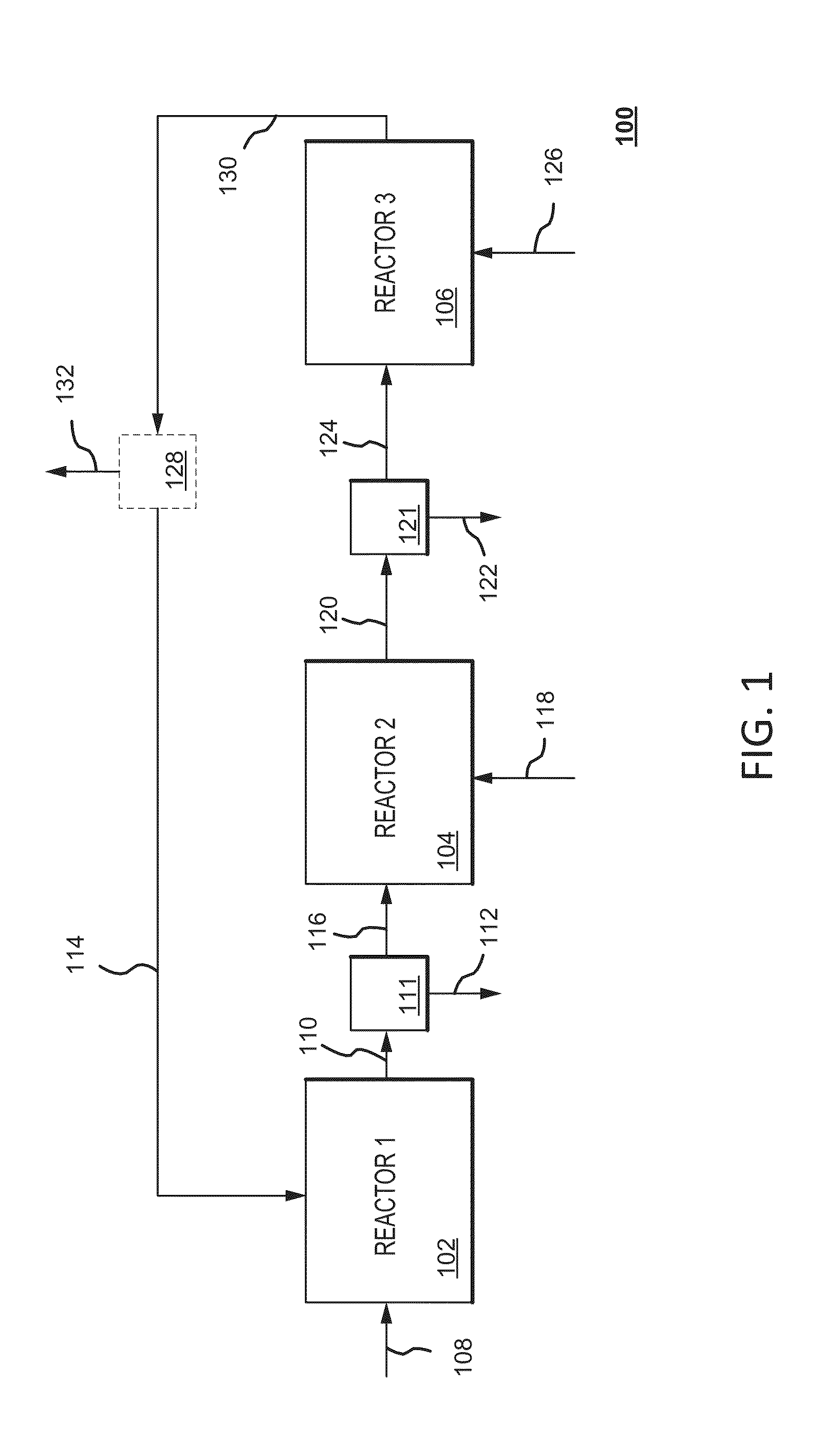

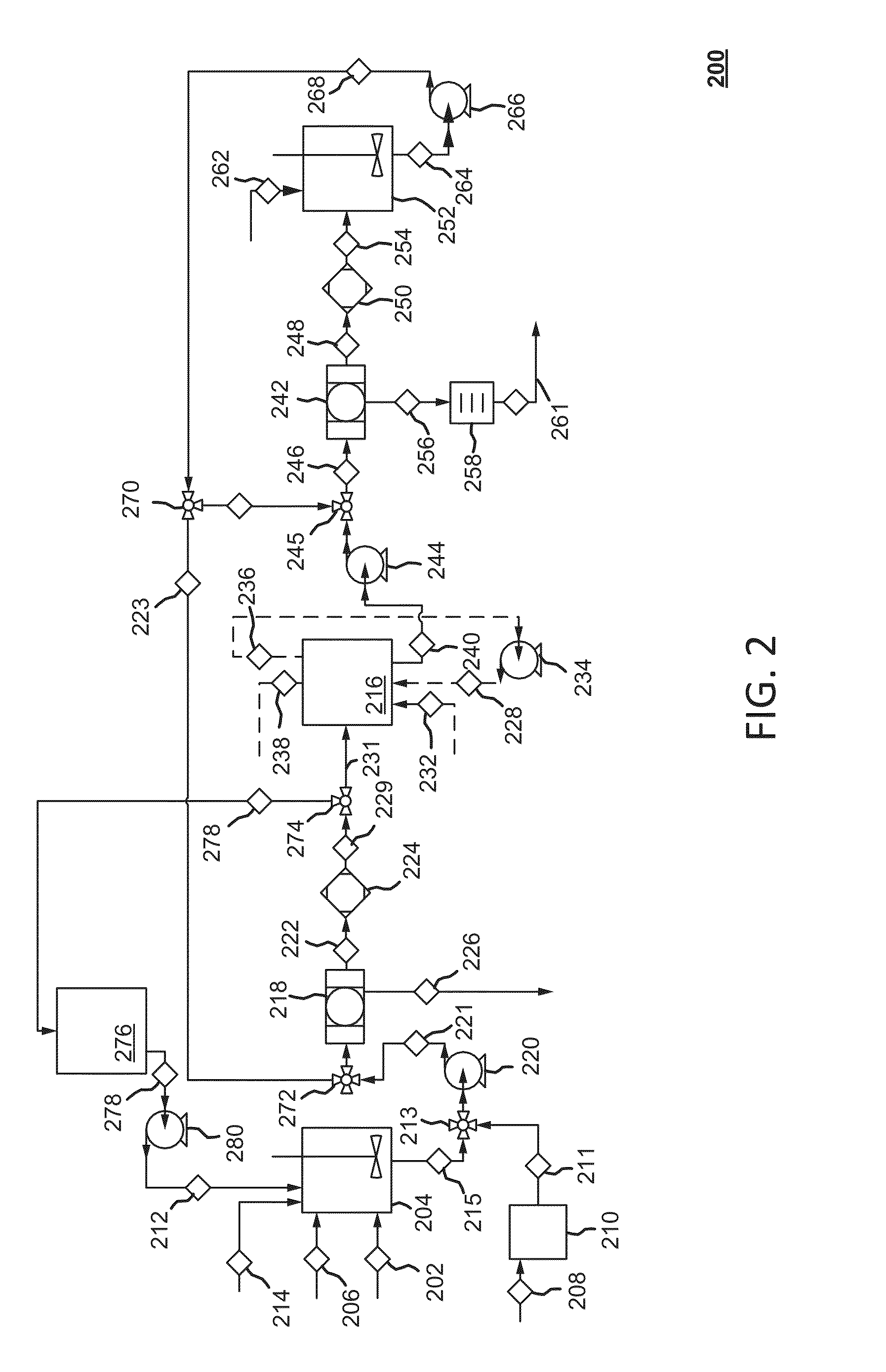

New process for the treatment of high sulphate waters

InactiveUS20200223720A1Low operating cost and ground areaMaximum capabilityWaste water treatment from quariesWater/sewage treatment by centrifugal separationMetal sulfatePhosphate

The present invention relates to an improved process for treating high sulphate waters. In particular, the present invention relates to an improved process making use of aluminium compounds in order to precipitate layered double hydroxide compounds and any one or more of metals, sulphate, aluminate and phosphate. The present invention further relates to the use of one or more particle segregation stages, as well as the return of aluminium containing compounds from the particle segregation stage and aluminium compounds from a further reaction stage to an initial reaction stage.

Owner:SMR TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com