Co-processing method for household garbage incineration fly ash and yellow iron tailings

A domestic waste incineration and co-processing technology, which is applied in the production of bulk chemicals and the removal of solid waste, can solve the problems of inability to neutralize the acidity of the lower ore matrix, pH value reduction, soil re-acidification, etc., and achieve harmless disposal Solve and prevent the effect of continued oxidation and re-acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix the fly ash mixture mixed with 25% pyrite tailings sand and water at a solid-to-liquid ratio of 1:3 to form a slurry with a pH value of 12 and place it in a high-temperature and high-pressure reactor; Thermal reaction, the pressure is 5Mpa, O 3 Reaction 10min, O 3 The flow rate is 30mL / min; the high-temperature and high-pressure reactor continues to heat up to the extraction temperature of 275°C, and the pressure is maintained at 5Mpa to make the water in a subcritical state, and the O 3 Reaction 20min, O 3 The flow rate of the high-temperature and high-pressure reactor is 30mL / min; 3 Reaction 2min, O 3 The flow rate of the reactor is 30mL / min; after the three reaction stages are completed, the slurry in the reactor is subjected to solid-liquid separation to obtain a solid product.

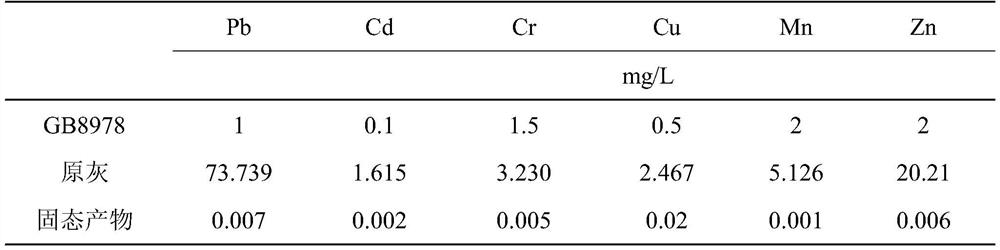

[0036] Solid products are prepared according to the HJ 557 method; the concentration of heavy metals should not exceed the maximum allowable discharge concentration limit specified ...

Embodiment 2

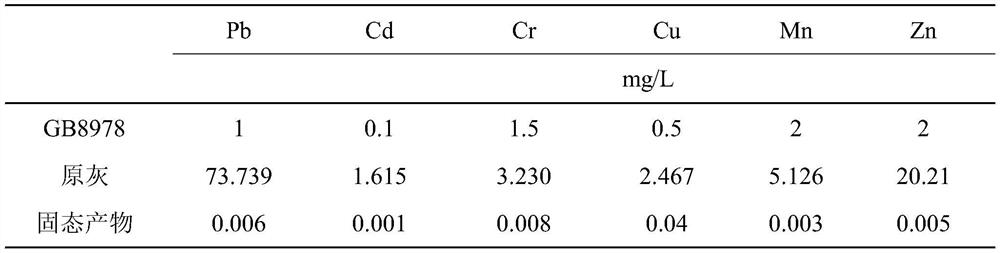

[0043] Mix the fly ash mixture mixed with 35% pyrite tailings sand and water at a solid-to-liquid ratio of 1:5 to form a slurry. The pH value of the slurry is 11.5, and it is placed in a high-temperature and high-pressure reactor; Thermal reaction, the pressure is 5Mpa, O 3 Reaction 10min, O 3 The flow rate is 50mL / min; the high-temperature and high-pressure reactor continues to heat up to the extraction temperature of 300°C, and the pressure is maintained at 5Mpa to make the water in a subcritical state, and the O 3 Reaction 15min, O 3 The flow rate of the high-temperature and high-pressure reactor is 50mL / min; 3 Reaction 3min, O 3 The flow rate of the reactor is 50mL / min; after the three reaction stages are completed, the slurry in the reactor is subjected to solid-liquid separation to obtain a solid product. The solid product is prepared according to the HJ557 method, and the leaching concentration of heavy metals should not exceed the maximum allowable discharge concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com