EVA damping element and shoe sole with the same

A technology for shock absorbing components and components, applied in the directions of soles, footwear, applications, etc., can solve the problems of not realizing resources, waste of resources, integrated processing of EVA waste heads, etc., to improve structural stability, reduce production costs, and achieve effective sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

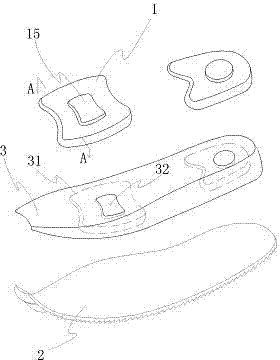

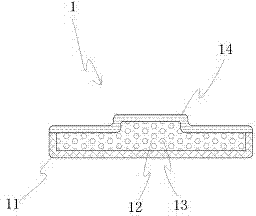

[0016] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that an EVA shock absorbing element 1 includes an EVA element body 11 having a filling groove, the filling groove is filled with a silica gel medium 12, and the silica gel medium 12 is distributed with EVA waste head particles 13; the EVA waste head particles 13 are obtained by chopping the EVA waste head particles, and the maximum radial dimension of the EVA waste head particles 13 is less than the groove depth of the filling groove; the filling groove of the EVA element body 11 The notch is also covered with an EVA sealing sheet 14, and the EVA sealing sheet 14 makes the filling groove form an airtight space. The EVA shock-absorbing element 1 uses silica gel 12 as a medium to gather the dispersed EVA waste head particles 13 into an integrated structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com